Design method of pressure measuring rake special for deformed flow channel of wing body fusion airplane ventilation model

A technology of wing body fusion and design method, applied in the field of wind tunnel test, can solve the problems of flow asymmetry, can not meet the requirements of high-speed wind tunnel test, and the difference of total pressure distribution at the outlet is large, and achieves the measurement of total pressure distribution and internal resistance. Accurate calculation, meeting the requirements of high-speed wind tunnel test, and good diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

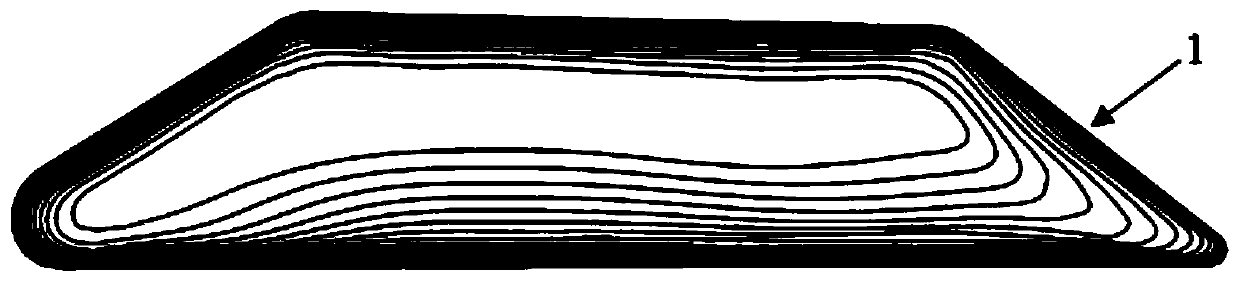

[0047] refer to Figure 1 to Figure 7 As shown, the invention discloses a design method of a special pressure measuring rake for a deformed flow path of a wing-body fusion aircraft ventilation model. The design method of the pressure measurement rake is specifically a design method of providing a special pressure measurement rake for the deformed inner flow path of the aircraft ventilation test model with the wing-body fusion layout.

[0048] The test wind tunnel of this embodiment is a 2.4m×2.4m transonic wind tunnel, and the simulated Mach number is 0.76. The test model is a ventilation model of a wing-body fusion aircraft, and it is required to design a special pressure measuring rake for the deformed inner flow channel of a wing-body fusion aircraft. .

[0049] In a 2.4m×2.4m transonic wind tunnel, the specific operation process of this embodiment includes the following steps:

[0050] a) A section of the deformed inner flow path of the wing-body fusion aircraft is inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com