Aerogel filled structure for bedding and clothing and application of aerogel filled structure

A kind of airgel and gel technology, which is applied in the field of hats and gloves, sleeping bags, ultra-thin clothing containing airgel, and quilts, which can solve the problems of discounted thermal insulation effect, sweat accumulation, and insurmountability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

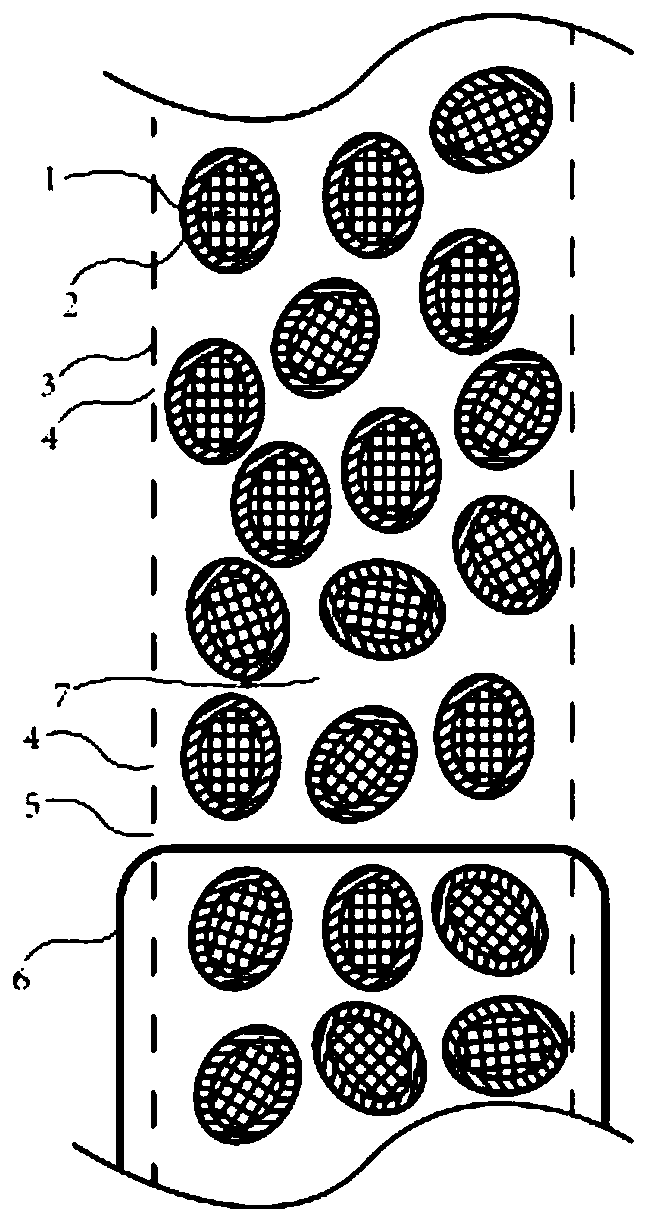

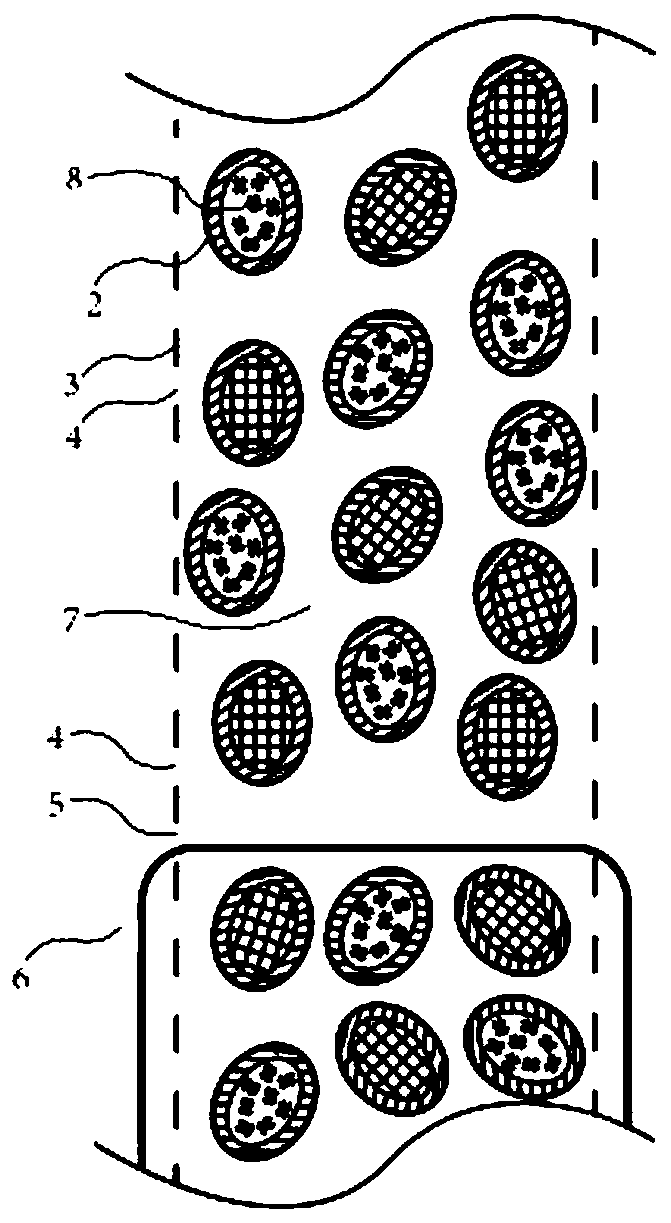

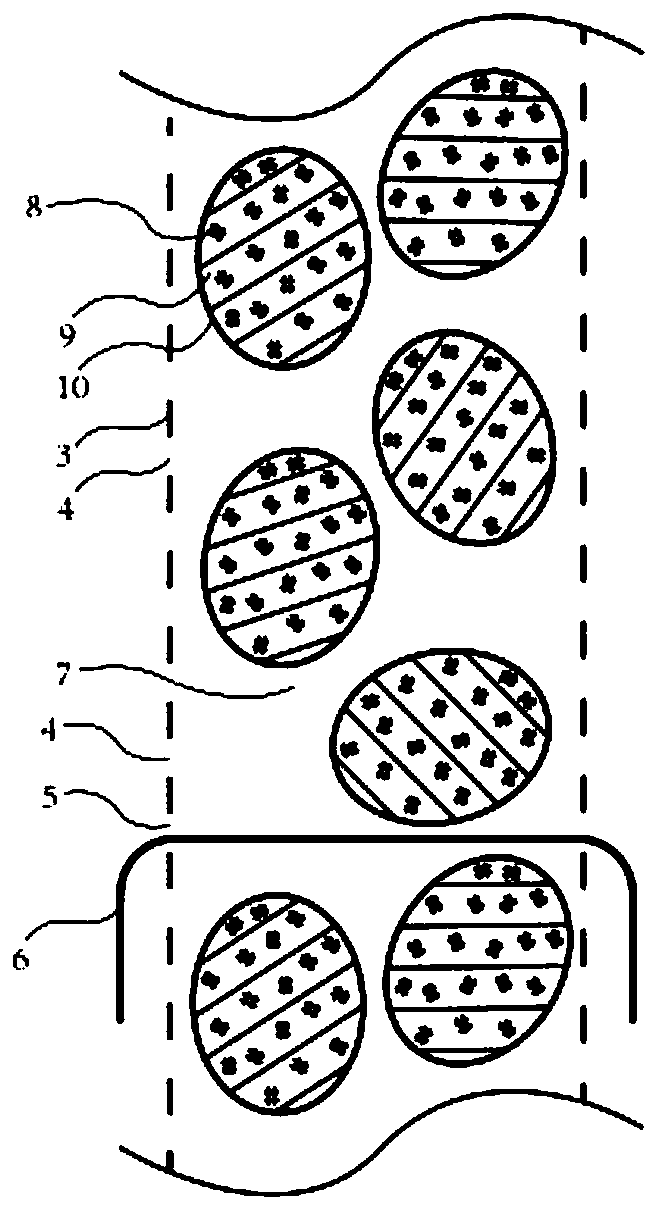

Image

Examples

Embodiment 1

[0074] Weigh 3 kilograms of airgel large-particle monomers with a size of 0.6-1 mm and blow them into a sealed stacking machine, spray polyvinyl acetate fine droplets on the tumbling airgel large-particle monomers to prepare a wrapping layer, and control the wrapping The thickness of the layer is 3-8 μm, after these wrapping layers are dried or solidified, the airgel particles with the wrapping layer that will be made are poured in the cotton scooping machine, make the fiber that the cotton scooping machine outputs and described airgel powder Large particle monomers are mixed evenly. Select 3-5 square meters of cotton or polyester cloth with a gap between the fibers smaller than the above-mentioned airgel large particle monomer, and sew it into a quilt cover. During the sewing process, select an appropriate needle size or thread thickness, and control the needle size as the number System number 6 (that is, metric system number 55, imperial system number 022, and its needle bod...

Embodiment 2

[0076] Water-based adhesive droplets, that is, water-based polyurethane emulsion droplets, are dropped on the hydrophilically modified airgel small particle powder, and such droplets can be generated in large quantities at one time through a drip plate and / or a sprayer. The water-based binder droplets will bind together the small particles of water-based airgel powder they come into contact with. By controlling the size of the droplet (that is, the total amount of the binder in the unit droplet), the size of the aggregate of small airgel particles that can be bonded can be preliminarily controlled. After the aggregates of these small airgel particles are solidified or dried, they are blown violently or blown to a state of violent boiling to collide with each other for many times to peel off the small airgel particles that are not fast enough, and then blow them by wind. And / or the vibrating sieve sieves the airgel small particle aggregate of specified size, the part on the sie...

Embodiment 3

[0082] Weigh the airgel produced by other airgel material suppliers (such as Shenzhen Zhongning Technology Co., Ltd., Suzhou Tongxuan New Material Co., Ltd., Guangdong Allison High-tech Co., Ltd. and other domestic and foreign airgel material manufacturers) Slurry, add curing agent, mix evenly, dry and solidify into blocks. Then use a pulverizer or a mixer to pulverize the dried and solidified block. After being pulverized, it is firstly blown violently or blown to a state of violent boiling to collide with each other extremely many times to peel off the small particles of airgel that are not fast enough, and then sieve the airgel with a specified size through a pneumatic and / or vibrating sieve. Gel small particle aggregates, the part on the sieve is used to make the airgel filling part in the present invention, and the part under the sieve can be returned to the previous slurry mixing process and continue to participate in the airgel mixing together with the newly added slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com