Environment-friendly carbon black and production process thereof

A carbon black and environmental protection technology, which is applied in the direction of fibrous filler, dyed high molecular organic compound treatment, dyed low molecular organic compound treatment, etc., can solve the problems of carbon black easy to fly with the wind, environmental pollution, etc., achieve tight combination, reduce Effects of production cost and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment is an environmentally friendly carbon black, which is granulated after mixing carbon black, water and binder. The mass ratio of carbon black, water and binder is 100:1.0:100. The agent is lignosulfonic acid.

Embodiment 2

[0049] see Figure 1-9 Shown, present embodiment is a kind of production technology of environment-friendly carbon black, comprises the following steps:

[0050] S1: Filter the compressed air, remove impurities, and then preheat to 700°C;

[0051] S2: Send the preheated compressed air, natural gas and potassium carbonate solution with a mass concentration of 1.5% into the reaction furnace, and carry out combustion reaction at 1850°C to generate high-temperature combustion airflow;

[0052] S3: Preheat the ethylene oil to 250°C and atomize it, then mix it with the high-temperature combustion airflow to carry out the cracking reaction to generate carbon black smoke;

[0053] S4: Rapid cooling of the carbon black flue gas to reduce the temperature of the carbon black flue gas to 280°C;

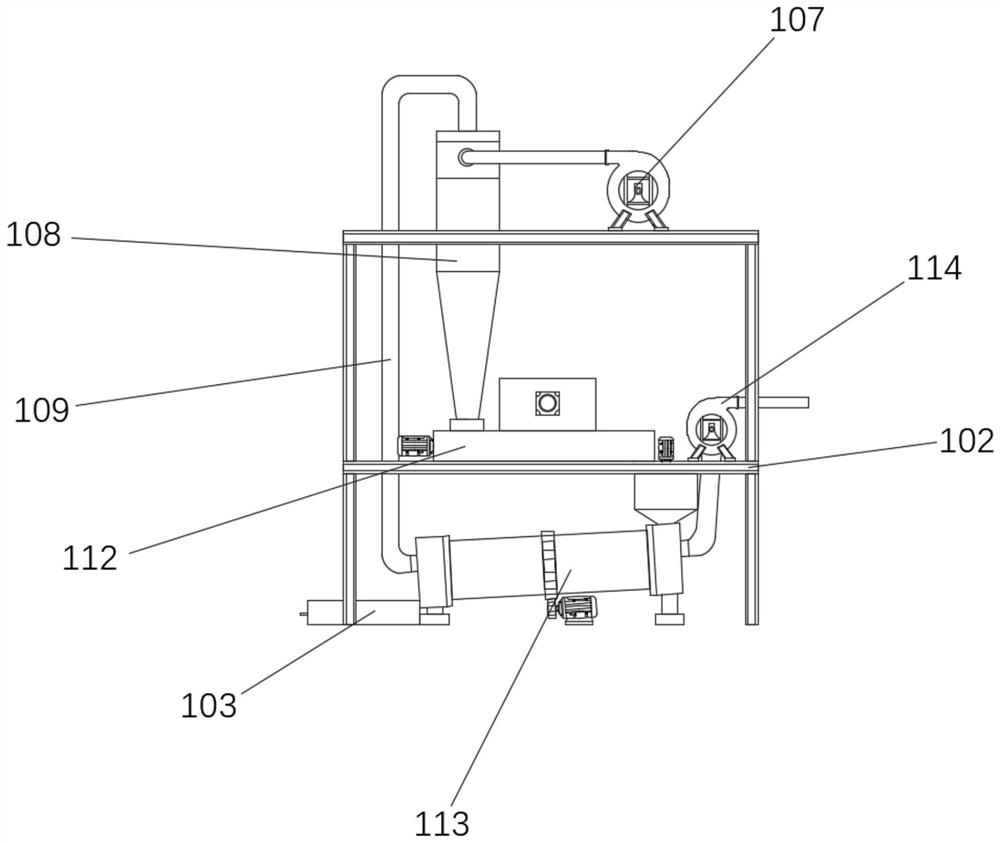

[0054] S5: The carbon black fume after quenching is delivered to the input blower 107 from the input air pipe 111 of the environmental protection carbon black production equipment, and the inpu...

Embodiment 3

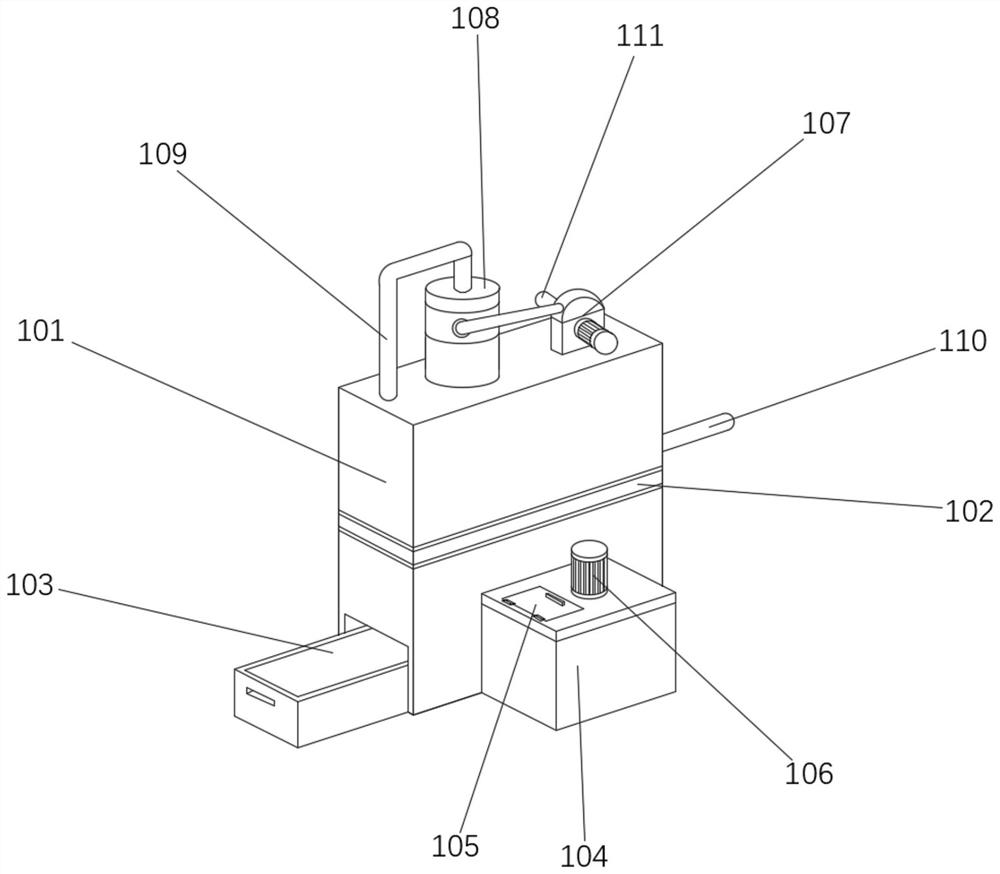

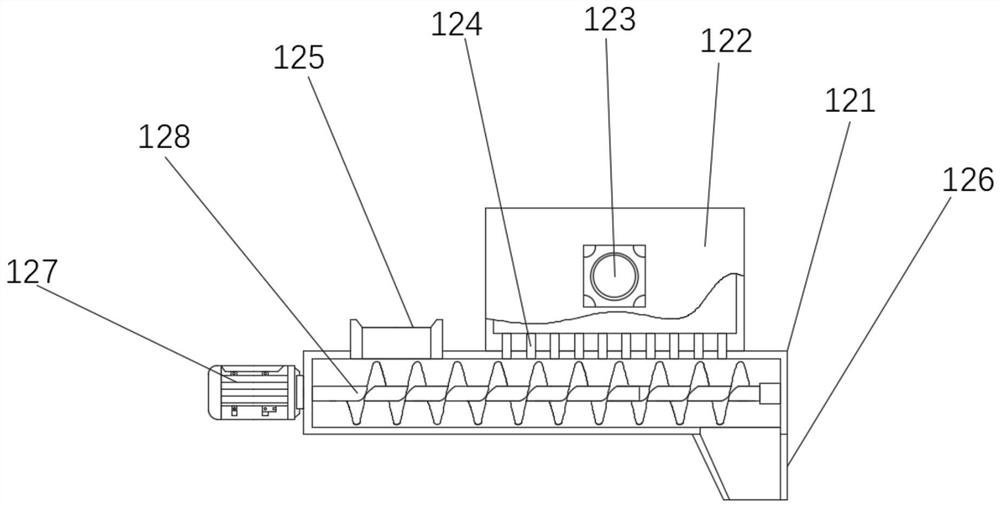

[0062] see Figure 1-9 As shown, the present embodiment is a kind of environment-friendly carbon black production equipment, including production box 101, liquid storage tank 104, input fan 107, cyclone separator 108, mixing mechanism 112, forming mechanism 113 and delivery fan 114, production box 101 A storage box 103 is placed through one end of the bottom of the tank, a liquid storage tank 104 is installed on one side of the bottom of the production box 101, an input fan 107 is installed on one end of the top of the production box 101, and a cyclone separator 108 is installed on the other end of the top of the production box 101. , the input end of the input fan 107 is equipped with an input air pipe 111, and the output end of the input fan 107 is connected to the top side of the cyclone separator 108 in a tangential direction through the pipeline;

[0063] The middle part of the inner cavity of the production box 101 is equipped with a support plate 102, and the top two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com