White mulberry bark fiber cospinning fubric and its production technology

A technology of mulberry fiber and blended fabrics, which is applied in fabrics, textiles, textiles and papermaking, etc., to achieve good vapor permeability, cool hand feeling and good hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Mulberry fiber / long-staple cotton blended pyrge

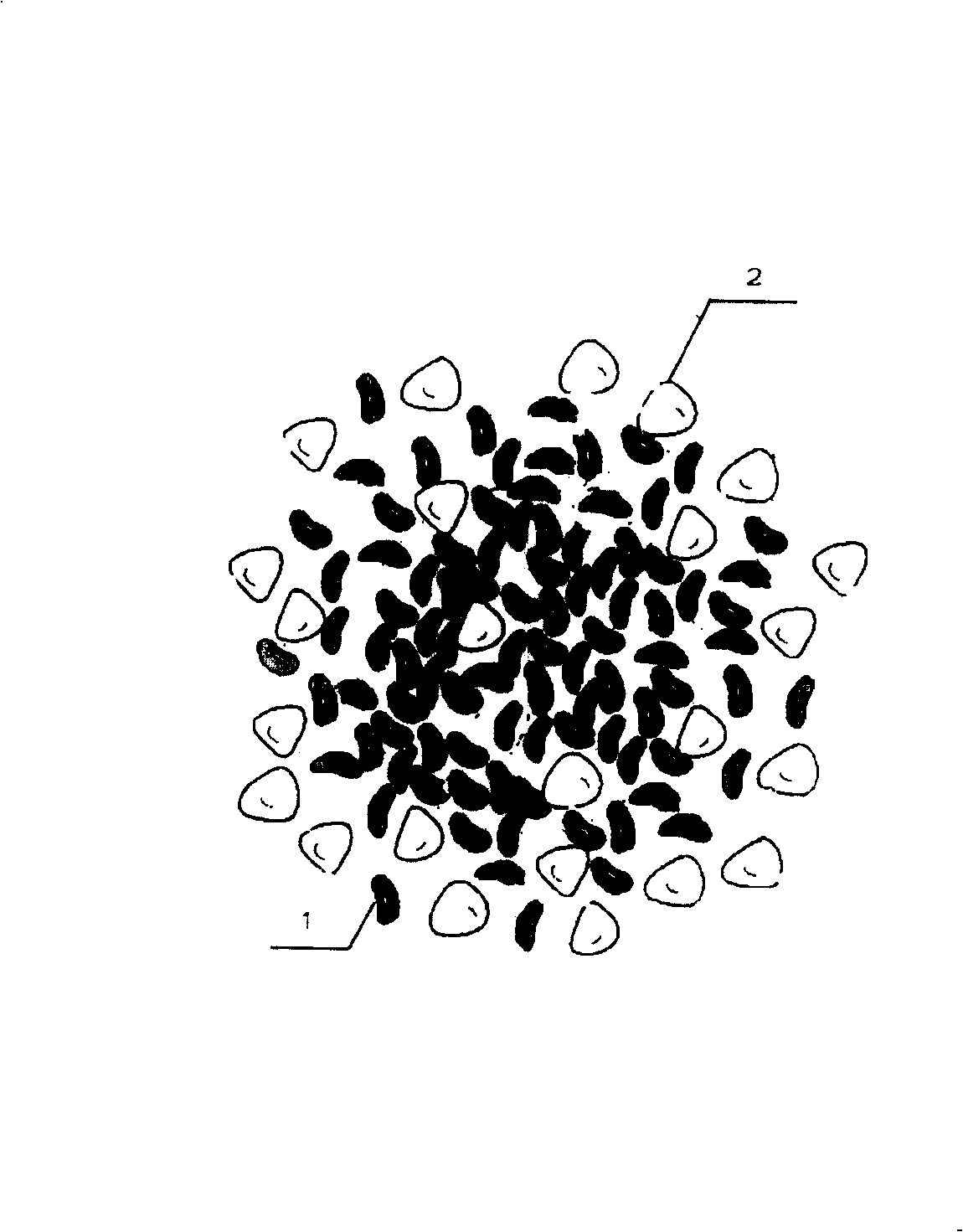

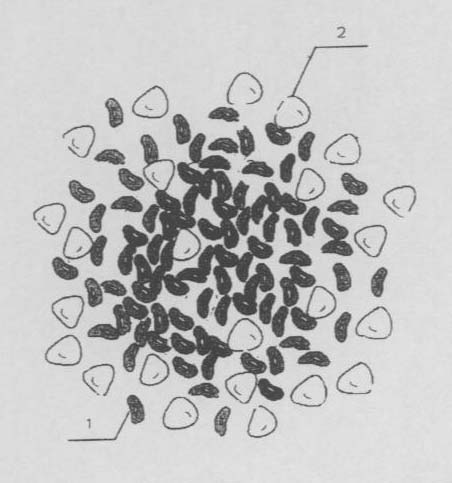

[0022] Present embodiment adopts 10~45mm (the main body length is 18mm) and the long-staple cotton fiber blending that main body length is 35mm with the mulberry fiber of 10~45mm, and the dry weight blending ratio is 20 / 80 (being that dry weight is 20% mulberry fiber, with dry weight Weight is 80% cotton fiber blending); warp yarn and weft yarn are 21Tex, accompanying drawing shows, mulberry fiber 2 is mainly distributed in the outer layer of yarn, and long-staple cotton fiber 1 is mainly distributed in the inner layer of yarn.

[0023] The warp density of the fabric is 366 threads / 10cm, the weft density is 256 threads / 10cm, and the fabric quality is 126.6g / m 2 , width 160cm, fabric weave 2 / 2 Twill.

[0024] This embodiment is a woven fabric, and the technological process of its production process is: the mulberry fiber slivers and cotton slivers are subjected to drawing, roving, and spun yarn processes,...

Embodiment 2

[0029] Embodiment 2: Mulberry fiber / long-staple cotton blended satin fabric

[0030] This embodiment adopts the blending of mulberry fiber with a length of 10-45mm (main body length is 22mm) and long-staple cotton fiber with a main body length of 38mm, and the dry weight blending ratio is 15 / 85; The fibers are mainly distributed in the outer layer of the yarn, and the long-staple cotton fibers are mainly distributed in the inner layer of the yarn. The warp density of the fabric is 456 threads / 10cm, the weft density is 324 threads / 10cm, and the fabric quality is 144.8g / m 2 , a width of 210cm, the fabric weave is a satin weave formed by five pieces of warp satin and five pieces of weft satin.

[0031] The technical process of the production process of this embodiment is basically the same as that of Embodiment 1, the difference is: when weaving, it is woven into cloth on a dobby loom, the number of healds is 12, and the number of reeds is 4.

[0032] 3. Mulberry fiber / long-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com