Manufacturing method for IGBT chip with composite grid

A fabrication method and compound gate technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as the inability to improve the current density and withstand voltage capability of the chip, and achieve optimized current density distribution and thermal balance, and optimized electric field distribution. , Improve the effect of reverse bias resistance and high temperature capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In order to solve the above-mentioned technical problems existing in the prior art, an embodiment of the present invention provides a method for manufacturing an IGBT chip with a composite gate.

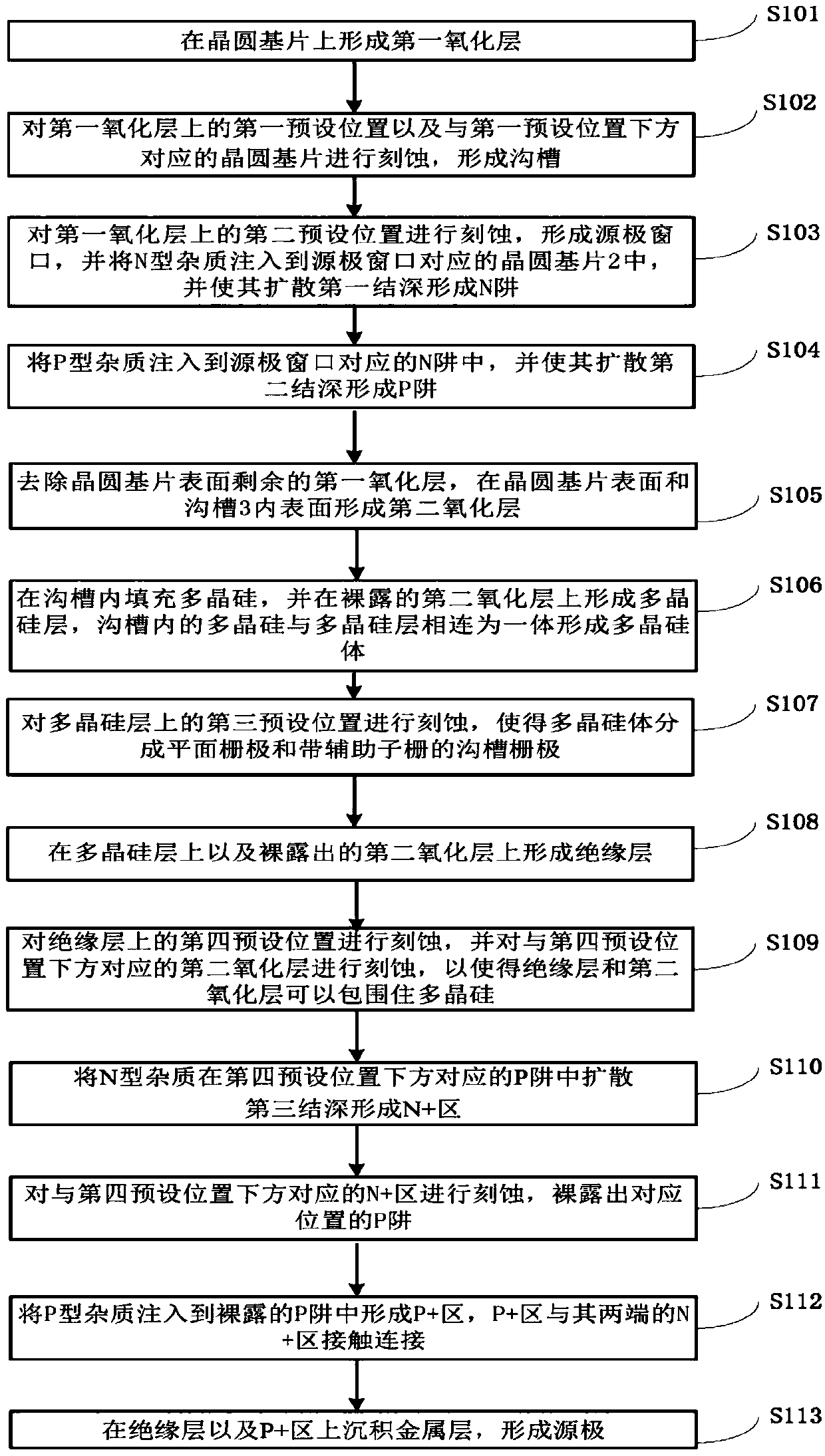

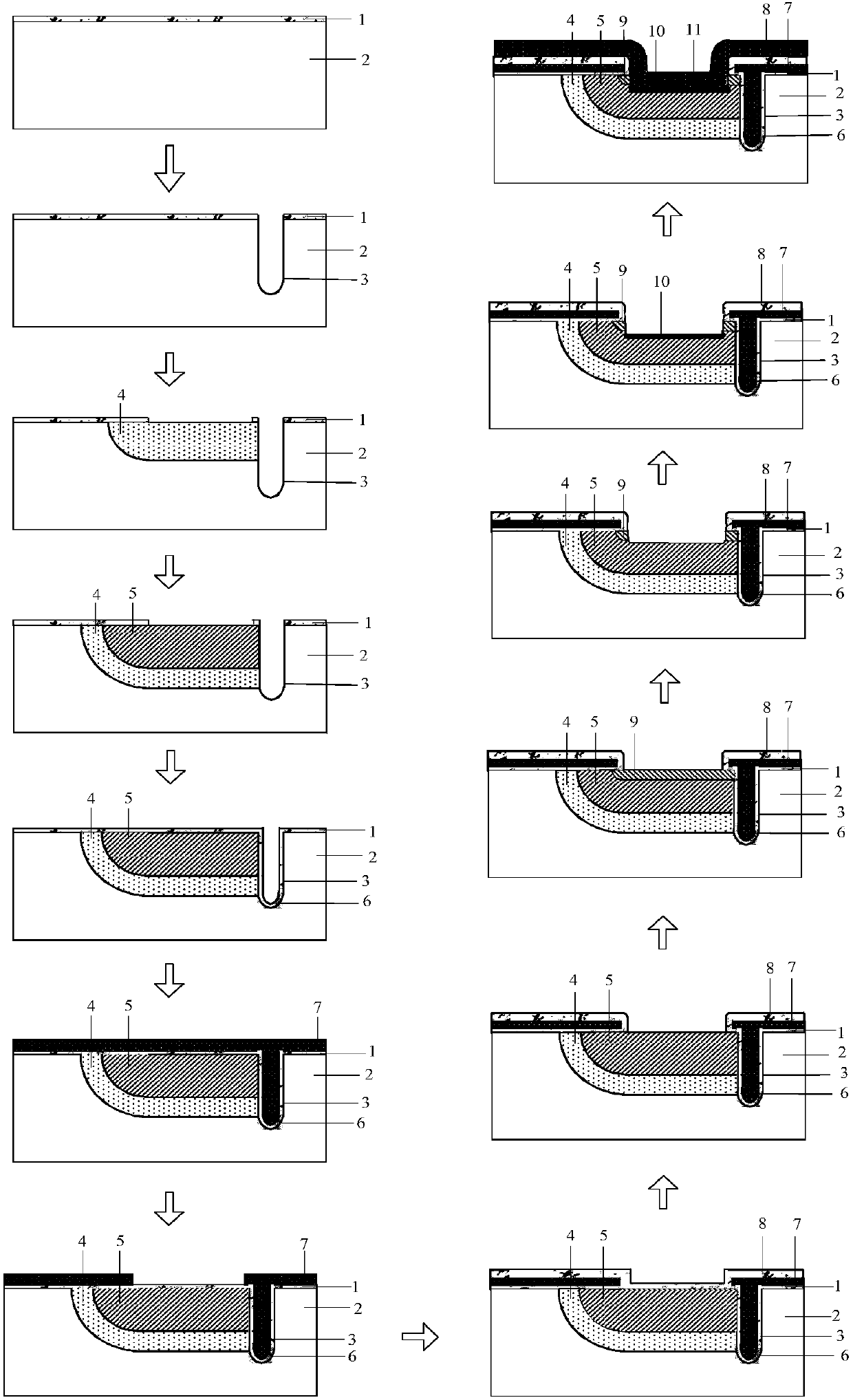

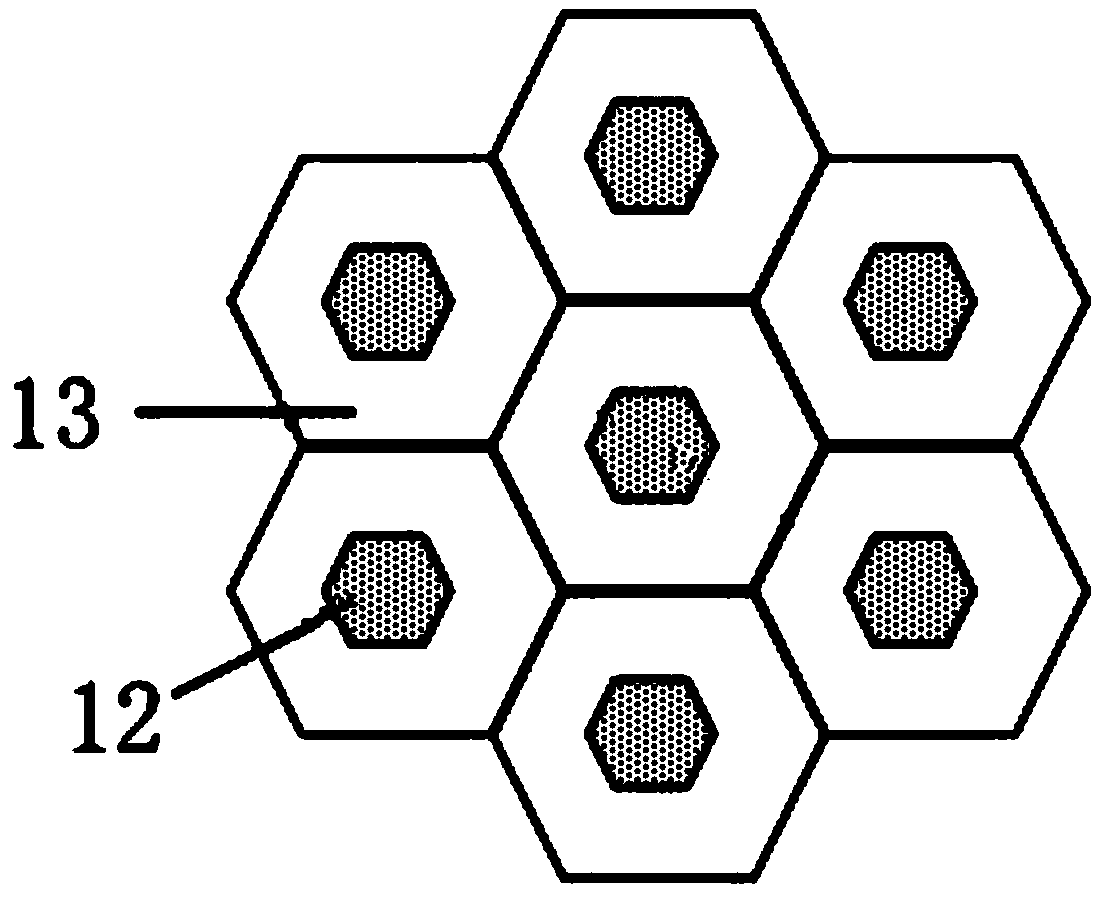

[0043] figure 1 It shows the flow chart of the method for fabricating an IGBT chip with a composite gate in Embodiment 1 of the present invention; figure 2 A schematic structural diagram showing the process of the method for manufacturing an IGBT chip with a composite gate in Embodiment 1 of the present invention.

[0044] refer to figure 1 and figure 2 , the method for fabricating an IGBT chip with a composite gate in this embodiment includes the following steps.

[0045] Step S101 , forming a first oxide layer 1 on the wafer substrate 2 .

[0046] Specifically, a uniform first oxide layer 1 is formed on the upper surface of the wafer substrate 2 by a certain method. Furthermore, the wafer substrate 2 can be a zone-melted silicon wafer, and the oxide layer can be silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com