Valve body wax mold of tri-eccentric butt-clamped metal sealing butterfly valve

A technology of metal sealing and butterfly valves, which is applied in the field of wax molds for triple eccentric wafer metal sealing butterfly valves, can solve problems affecting product quality, rough casting surfaces, and large machining volumes, so as to reduce the amount of follow-up processing and reduce Production cost, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

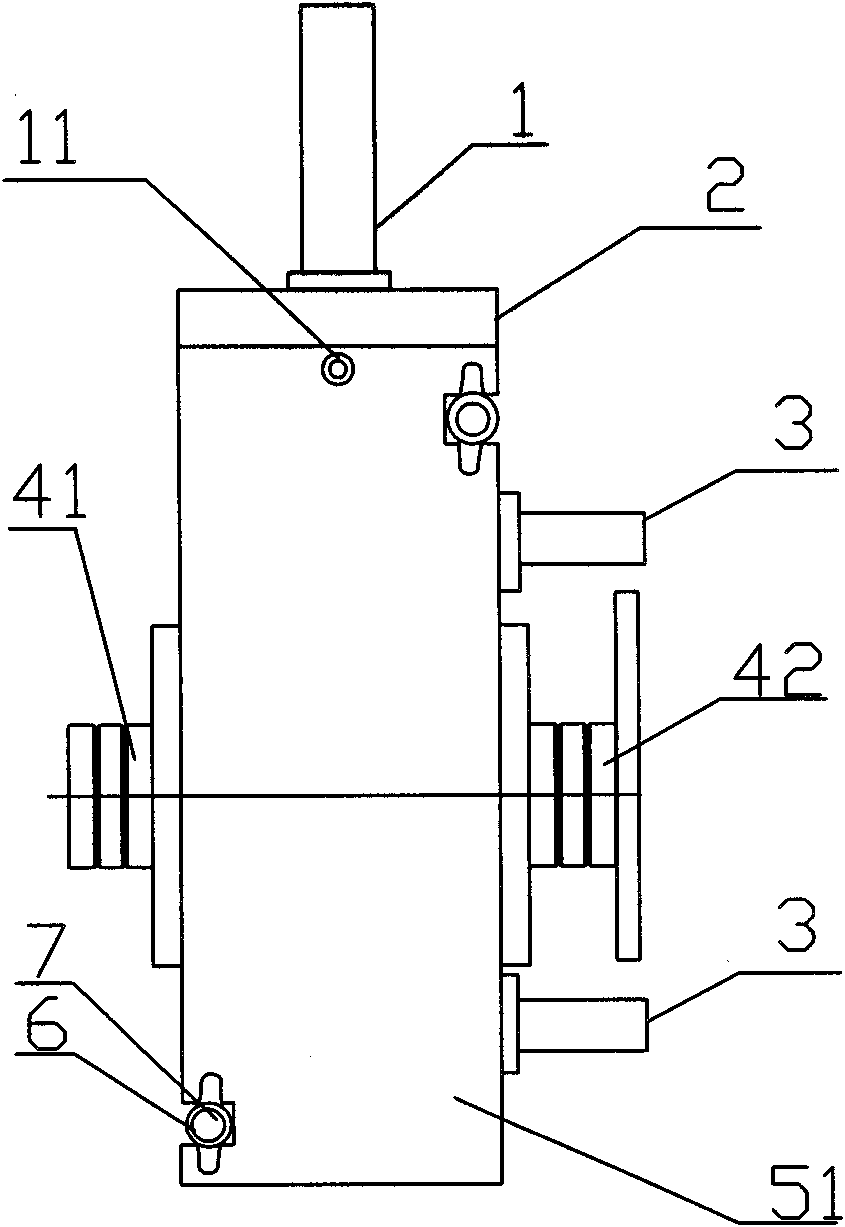

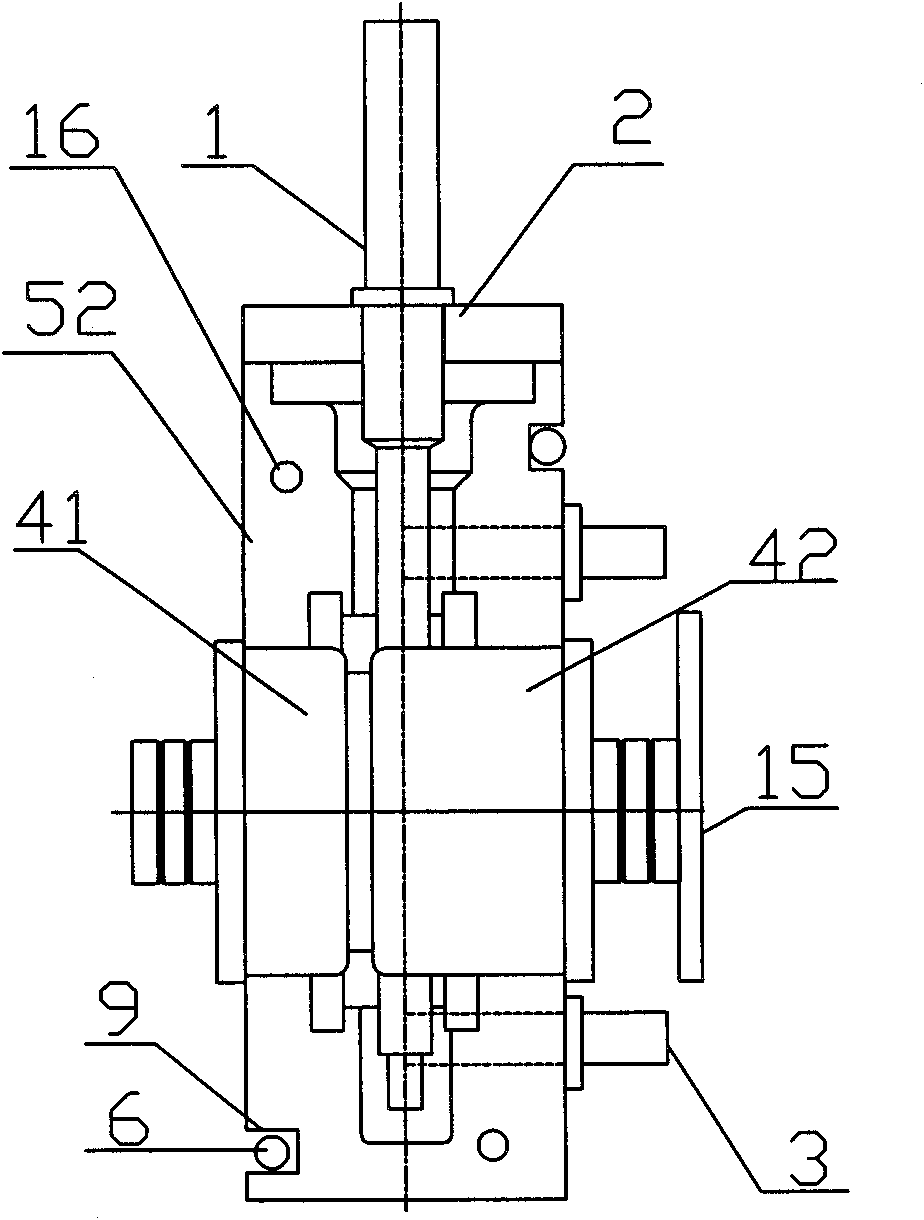

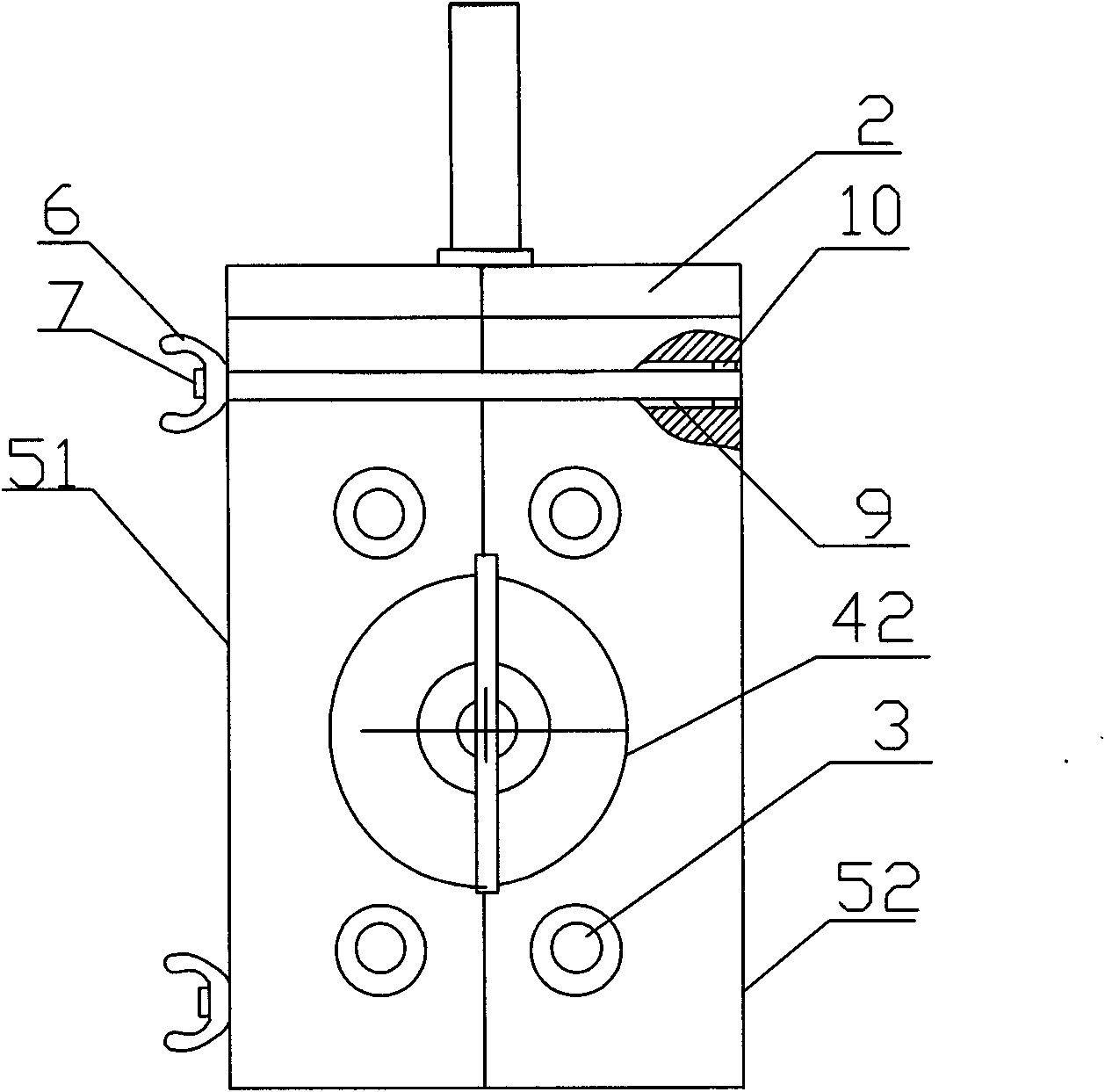

[0018] Figure 1 to Figure 5 Shown is a wax pattern mold for a three-eccentric pair of metal-sealed butterfly valves, which is characterized in that it consists of a front mold shell 51, a rear mold shell 52, a left valve body diameter core 41, and a right valve body diameter core 42. , Shaft hole core 1, multiple mounting hole cores 3, baffle plate 2 and fasteners. The above-mentioned fasteners are at least two screw rods 7 and their fastening nuts 6 that are installed in the horizontal rod grooves 9 that run through the front formwork 51 and the rear formwork 52. Here the fastening nuts adopt wing nuts that are easy to operate. One end of the screw rod 7 is hinged on the rear formwork 52, and the other end is fastened on the front formwork 51 by the fastening nut 6. Of course, one end of the screw rod 7 can also be hinged on the front formwork, and the other end is fastened by the fastening nut 6. Fixed on the rear formwork. In this example, two screw rods are used and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com