Machining process for reducing side wall shrinkage of shell cast parts

A processing technology and casting technology, which is applied in the field of processing technology to reduce the shrinkage cavity of the side wall of the shell casting, can solve the problems of easy occurrence of shrinkage cavity and affect the performance of the shell casting, so as to reduce the weight, avoid the shrinkage cavity defect, and improve the resistance. The effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Further detailed explanation through specific implementation mode below:

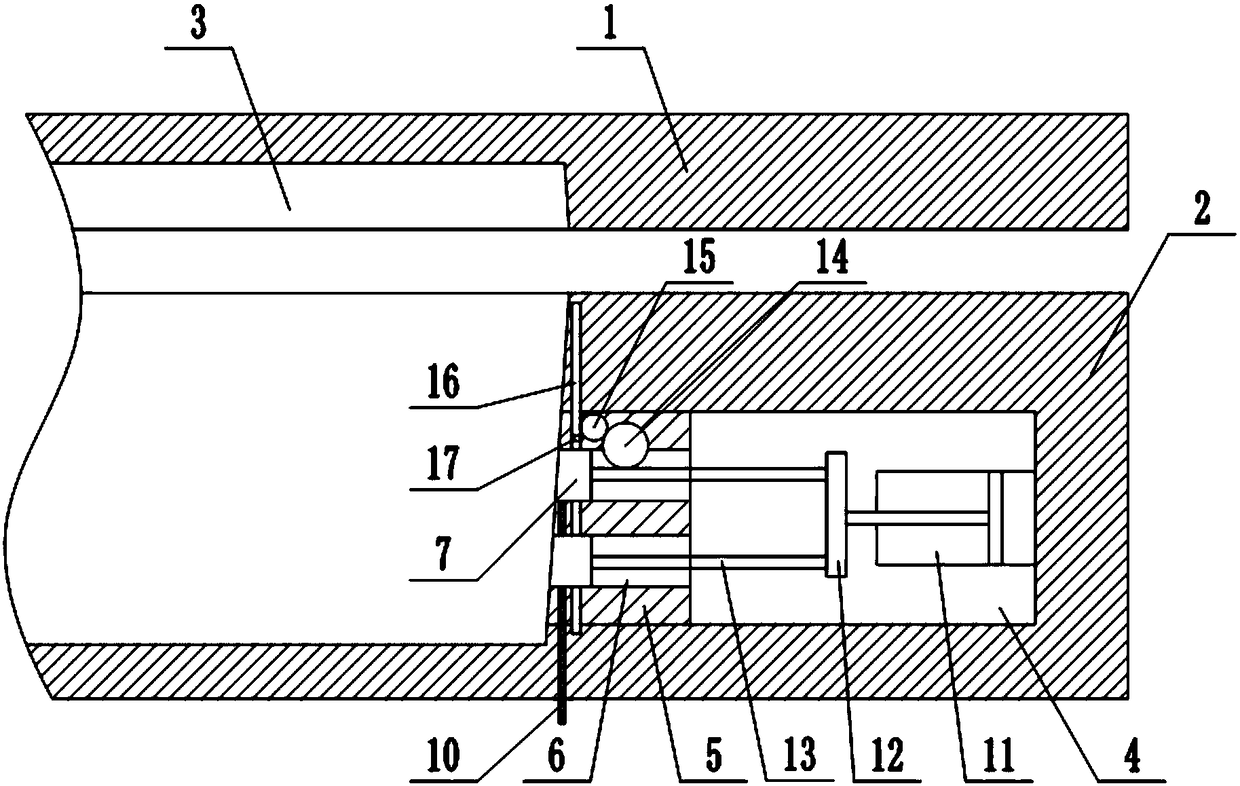

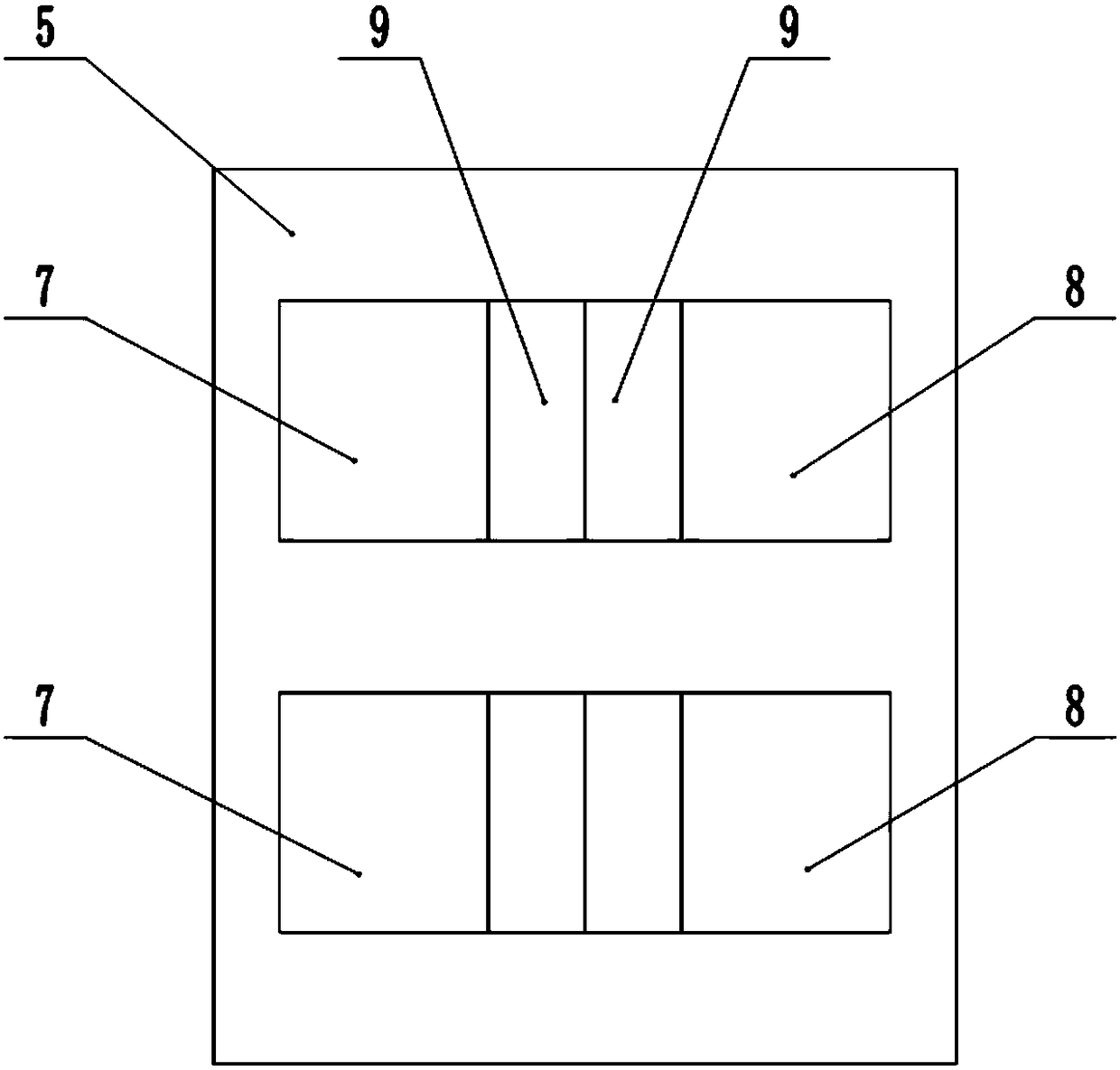

[0033] The reference signs in the drawings of the description include: movable mold 1, fixed mold 2, mold cavity 3, inner cavity 4, baffle plate 5, through groove 6, first slider 7, second slider 8, door body 9, Latches 10, hydraulic cylinders 11, push plates 12, push rods 13, first gears 14, second gears 15, racks 16, cutters 17.

[0034] This embodiment provides a processing technology for reducing the shrinkage cavity on the side wall of the casing casting, which includes the following steps:

[0035] Step 1. Prepare the mold: In this step, the existing mold needs to be improved, and the improved mold is as follows figure 1 , figure 2 As shown, the mold includes a movable mold 1 and a fixed mold 2, and the mold cavity 3 is formed when the movable mold 1 and the fixed mold 2 are closed; The left end of the inner chamber 4 is fixedly connected with a baffle plate 5, and two transverse throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com