Production method of bearing device

The technology of a bearing device and manufacturing method, which is applied in the field of bearing device manufacturing, can solve the problems of difficulty in forming an oil storage tank, narrow and small hollow part of the bearing, and reduction, and achieve the effect of reducing the amount of subsequent processing and high degree of shape freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

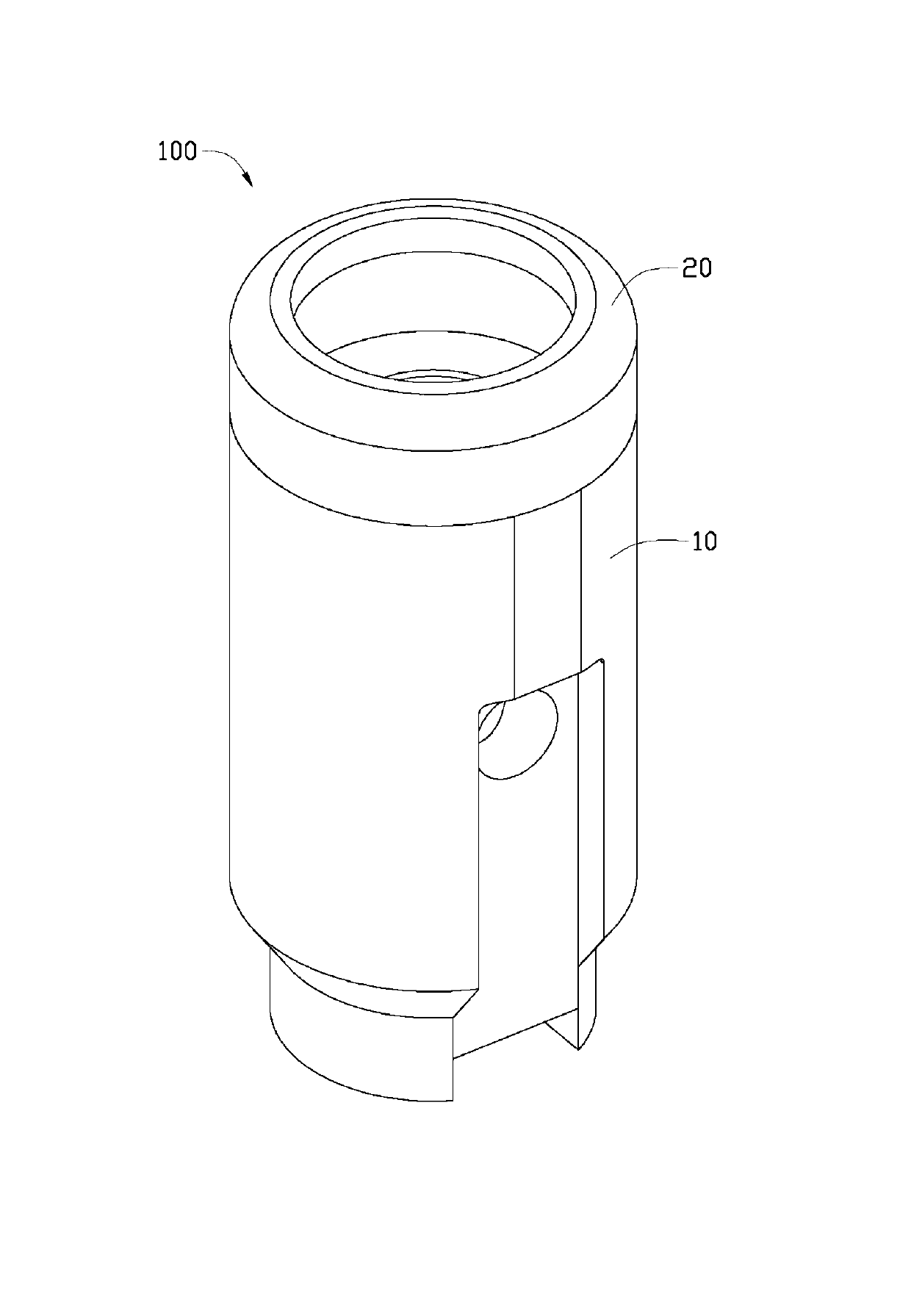

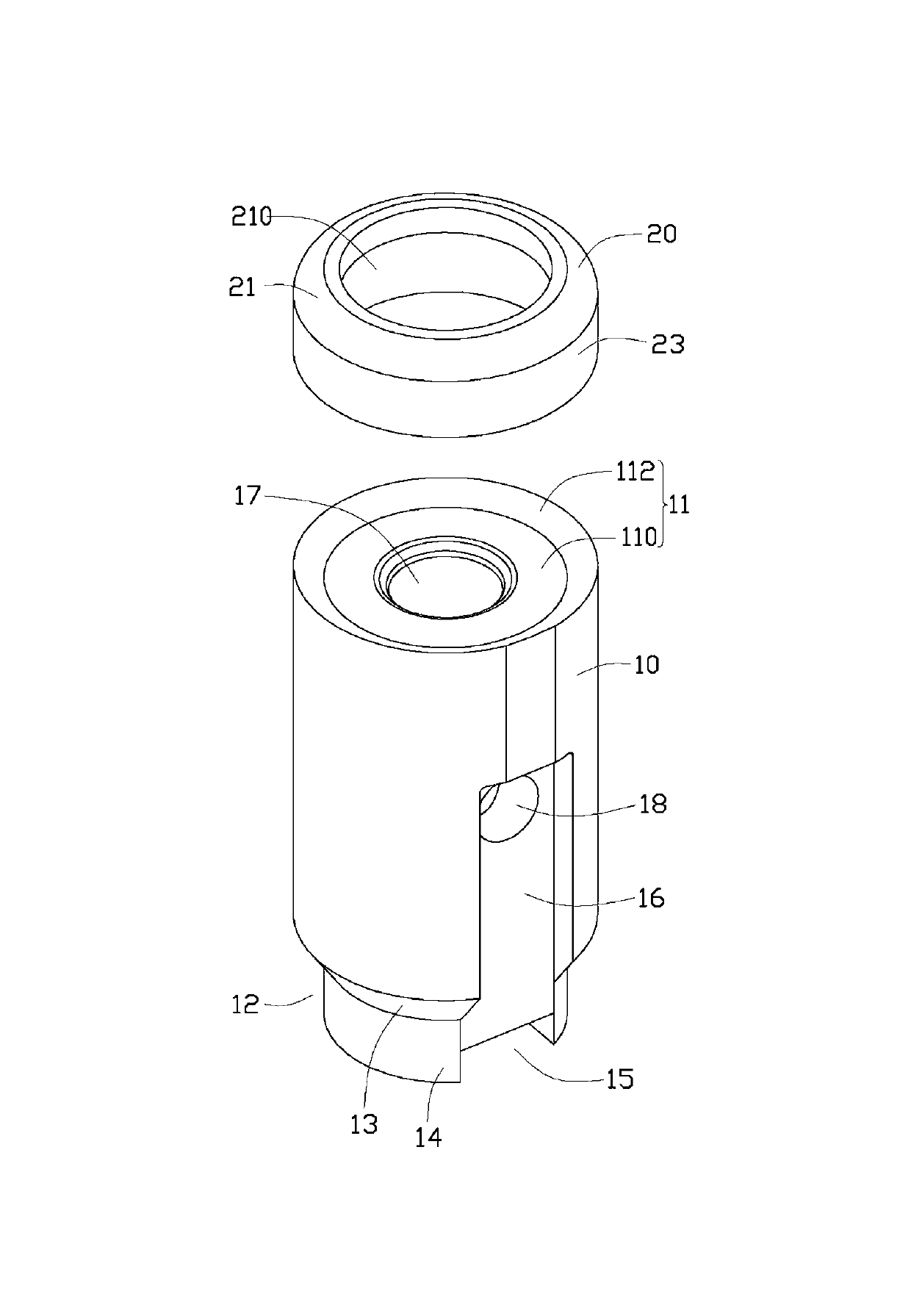

[0018] Such as figure 1 and figure 2 As shown, the bearing device 100 includes a bearing body 10 and an upper cover 20 disposed on the bearing body 10 .

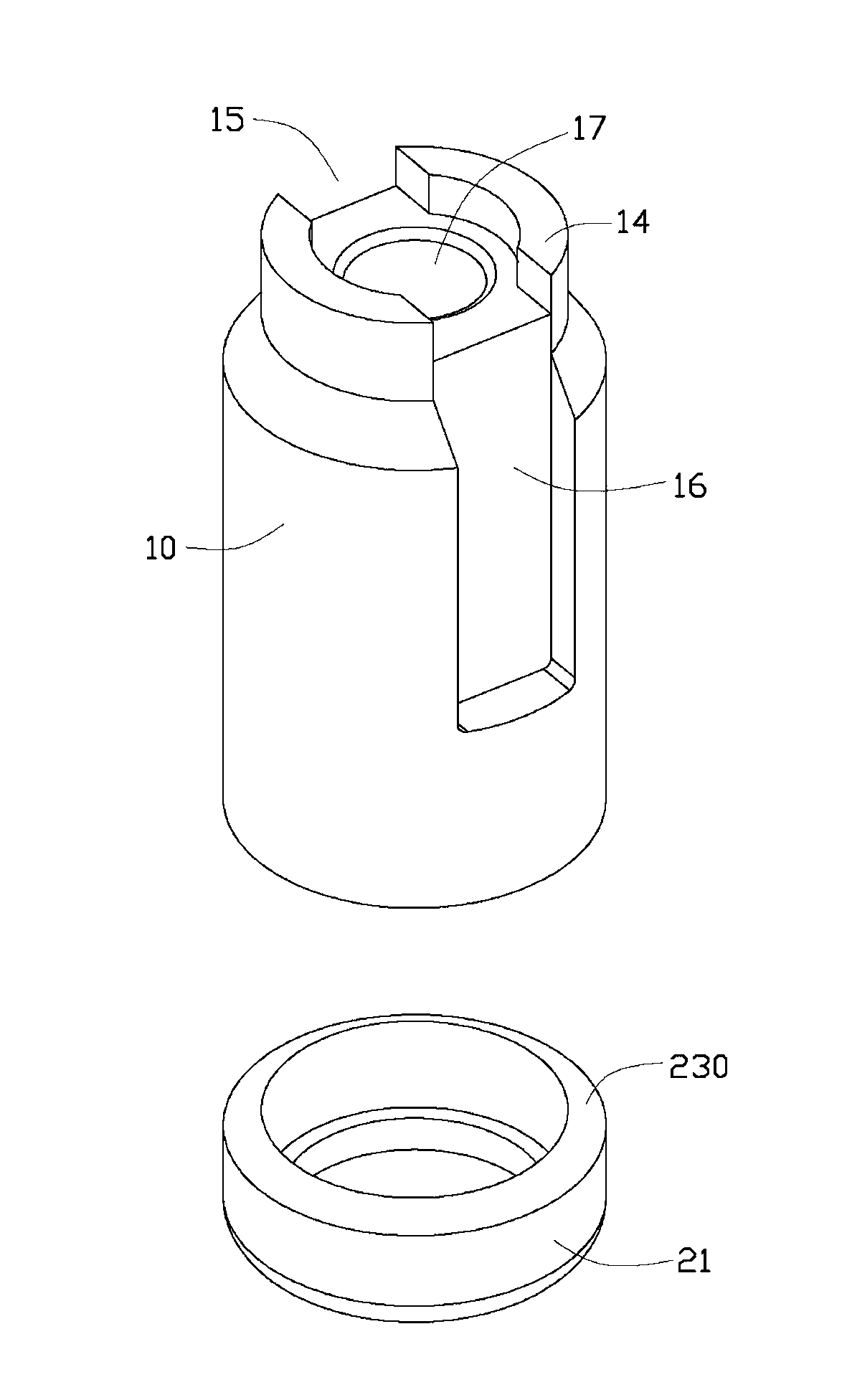

[0019] The bearing body 10 is cylindrical, and a shaft hole 17 is formed therein from the top surface to the bottom surface. A top surface of the bearing body 10 is recessed to form a groove 11 . The groove 11 includes a plane 110 and a slope 112 extending upward from a periphery of the plane 110 . The plane 110 is circular. The slope 112 is annular and formed by extending upwardly from the outer edge of the plane 110 . The bottom of the bearing body 10 defines an annular groove 12 surrounding the bottom of the bearing body 10 . The bearing body 10 forms a guiding surface 13 at the top of the ring groove 12 . The guide surface 13 extends in a tapered shape from top to bottom. Please also see image 3 The opposite sides of the bottom periphery of the bearing body 10 respectively extend downward to form a blocking wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com