A method for forming large-scale thin-walled ring parts with complex curved sections

A ring-shaped, large-size technology, applied in the field of precision sheet metal processing, can solve problems such as high cost, high equipment requirements, and difficult control of shape accuracy, and achieve the effects of improving efficiency, ensuring product quality, and ensuring batch processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following describes the present invention in detail, and the features and advantages of the present invention will become more clear and definite along with these descriptions.

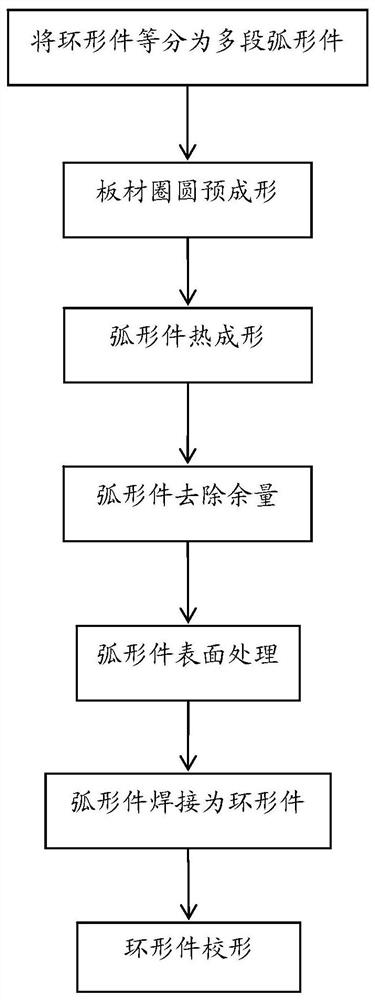

[0036] The invention provides a method for forming a large-scale thin-walled ring with a complex curved section, such as figure 1 shown, including the following steps:

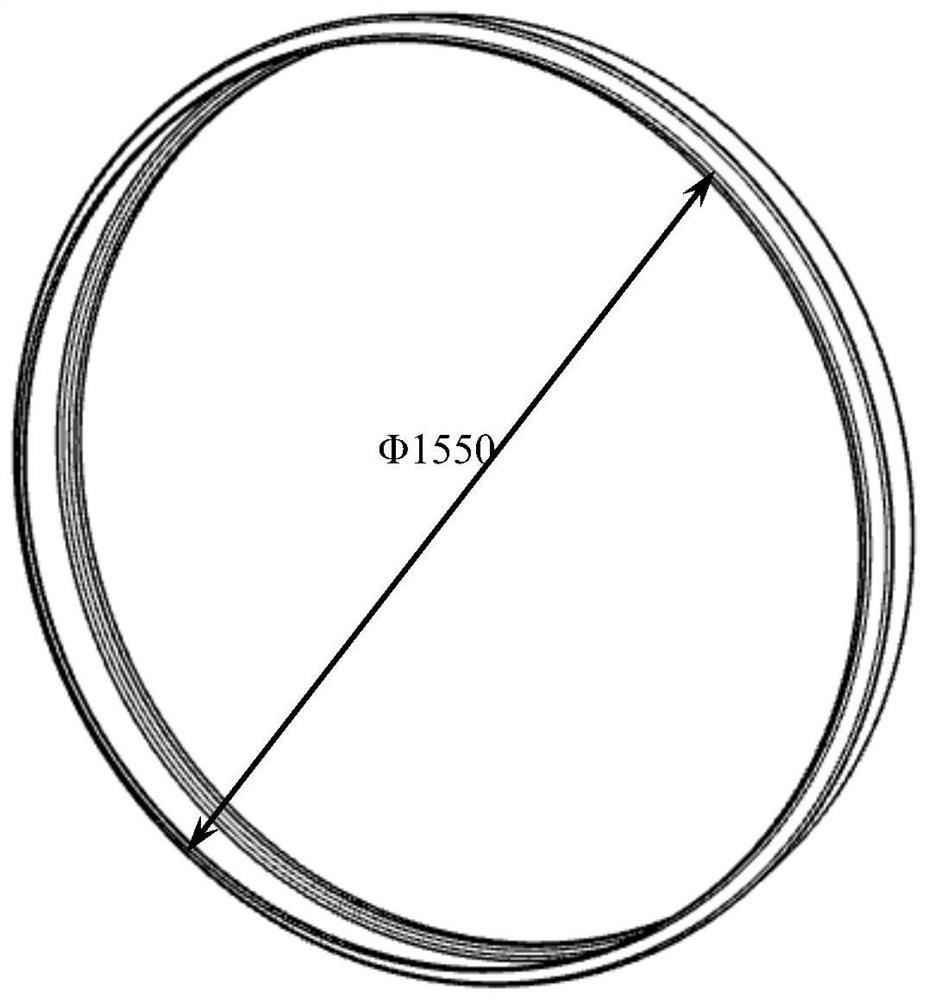

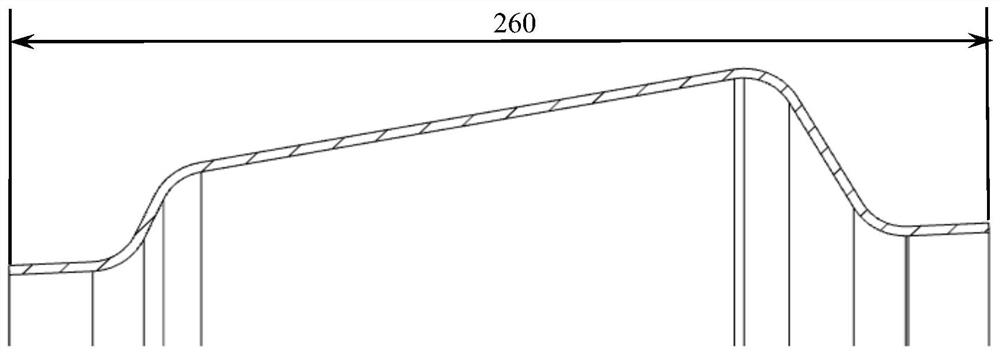

[0037] Step 1, according to the model size of the ring, divide the ring model into N arc models along the circumference; the model of a ring is as follows figure 2 As shown, the cross-sectional curve is as image 3 As shown, the arc model is as Figure 4 shown;

[0038] Step 2, design the thermoforming process part according to the arc part model ( Figure 5 ), and design thermoforming mold ( Figure 6 );

[0039] Step 3, determine the size of the blank required by the external dimensions of the thermoforming process piece and blank it, and preform the circle circle preform of the plate blank obtained by blanking, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com