Additive hot-pressing inflatable composite forming method for topological structure wallboard

A technology of topological structure and hot press forming, which is applied in the field of precision sheet metal processing, can solve the problems of difficult control of shape precision, poor integrity of parts, high cost, etc., and achieve the effect of easy control of shape precision, improvement of processing efficiency, and improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

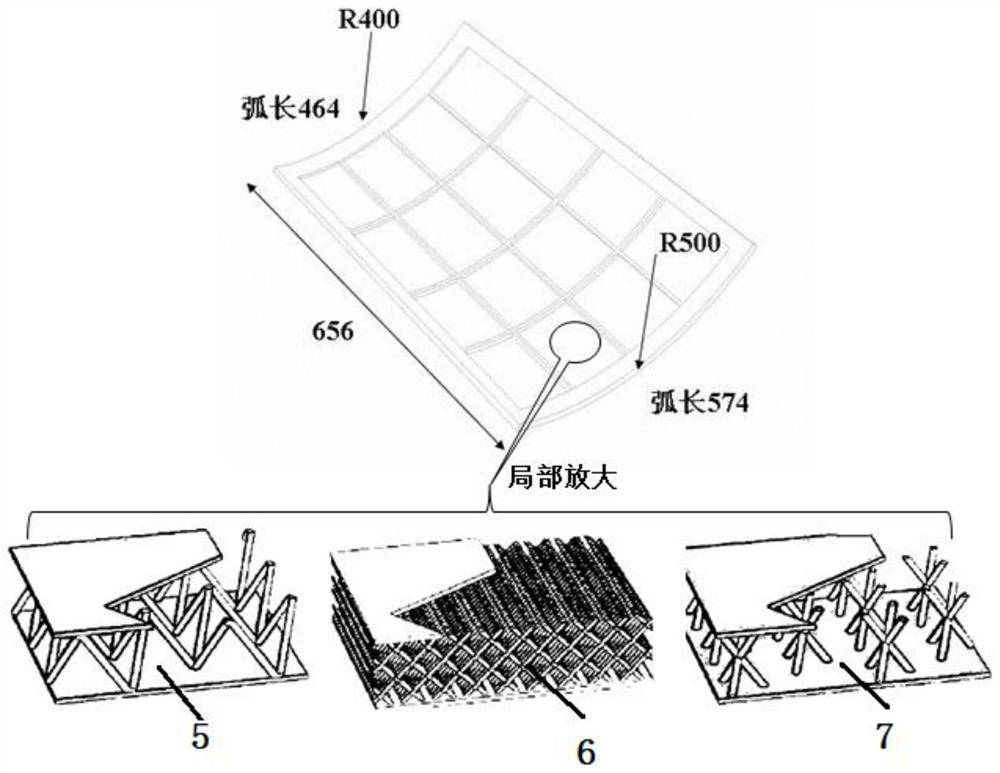

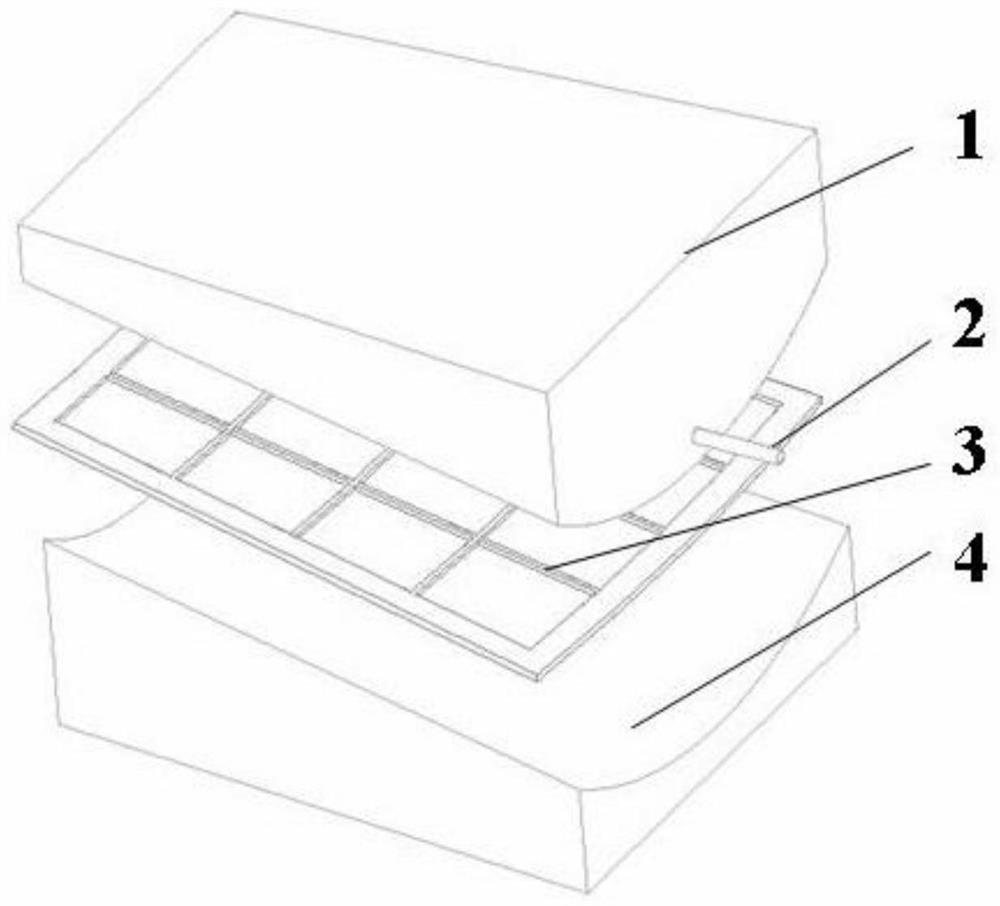

[0051] The topological structure wall panel to be formed in this embodiment, such as figure 1 As shown, it includes curved wall panels and stiffeners on the inner surface of the curved wall panels. The stiffeners alternate vertically and horizontally and are evenly distributed. The formed rib lattice is a topological structure (the stiffener part is solid, and there is no topological structure under the stiffener) The curved wall panel includes an inner surface, a topological part and an outer surface. The inner surface is provided with openings (the topological structure part in each rib is provided with an opening), so that the space where the topological part is located can be formed with the upper mold Closed cavity. The outer surface of the curved wall panel is a smooth curved surface. The exterior surface is a tapered surface, the small end arc radius is R400mm, the small end arc length is 464mm, the big end arc radius is R500mm, the big end arc length is 574mm, and the l...

Embodiment 2

[0059] The topological structure wall panel to be formed in this embodiment has the same structure as the first embodiment, and the material of the topological structure wall panel is TA15 titanium alloy.

[0060] The specific forming method includes the following steps:

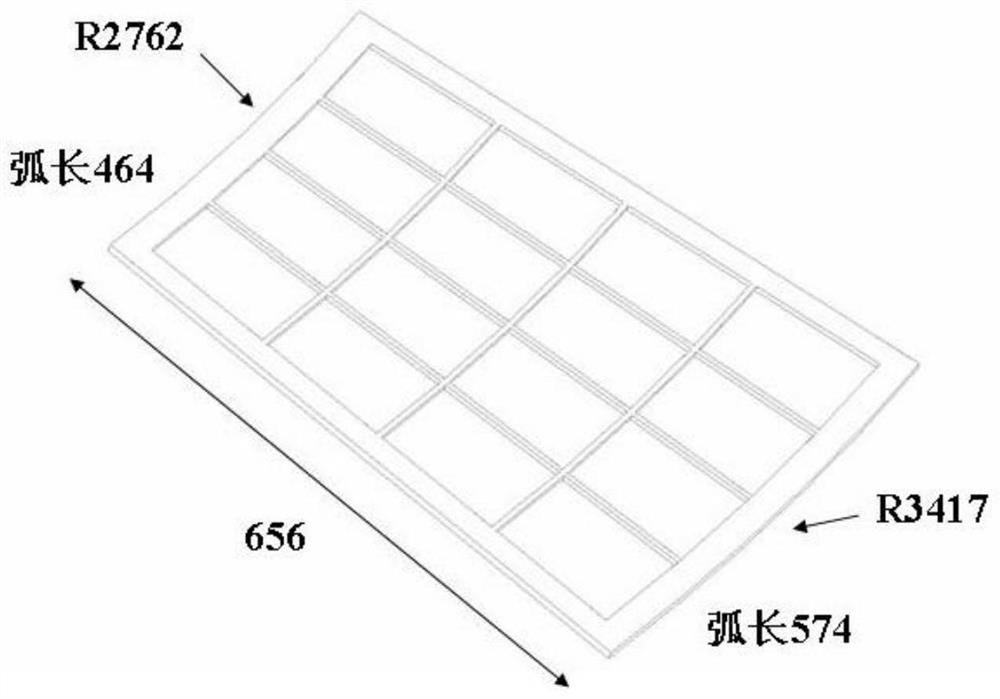

[0061] Step 1. Perform plane expansion: Determine the topological structure wall panel blank required for hot press forming according to the shape of the topological structure wall panel and the relative position of the reinforcing ribs: the topological structure wall at this time The arc radius of the small end of the slab is R2762mm and the arc length is 464mm; the arc radius of the big end is R3417mm and the arc length is 574mm; the length of the topological structure wall slab (that is, the vertical distance between the small end arc end and the large end arc end) ) Is 656mm. Determine the position of the reinforcing ribs in the unfolded plan view according to the relative position of the reinforcing ribs on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com