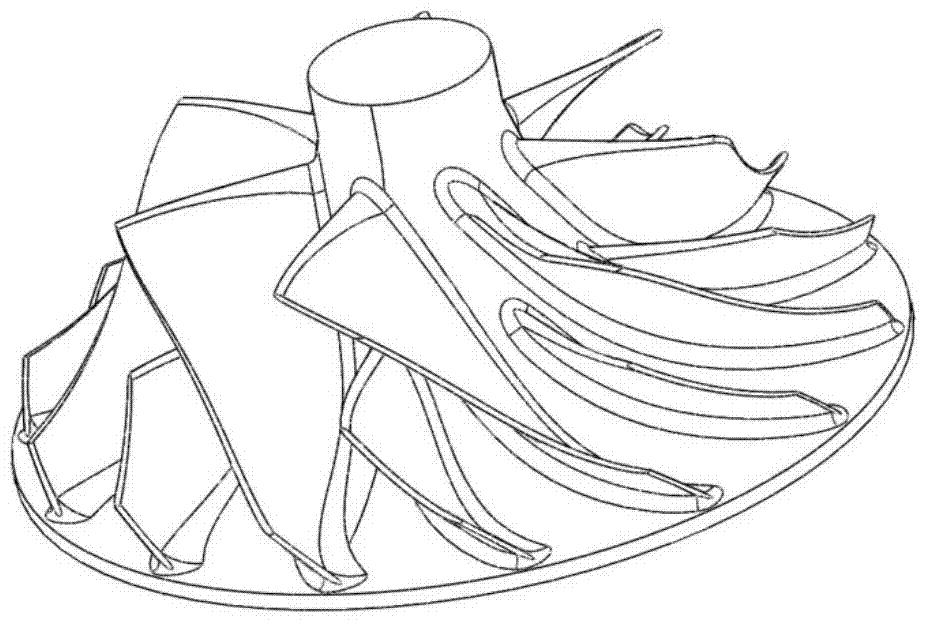

Casting method of a pressure impeller

A technology for pressing impellers and casting molds, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve problems such as high mold production costs, low production efficiency, and difficult mold disassembly, so as to increase disassembly speed and reduce production. cost, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

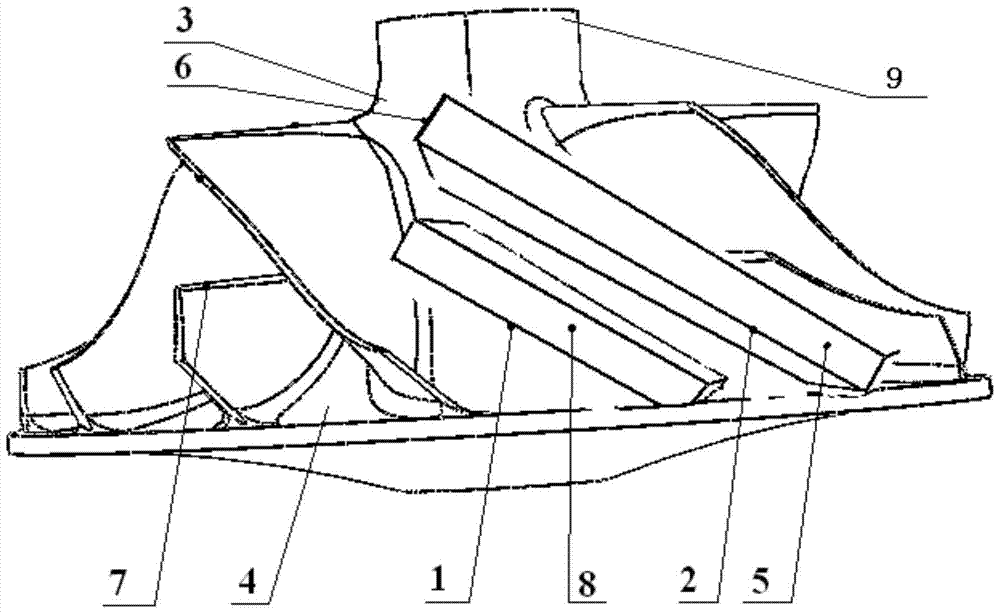

[0027] The angle between the upper edge plane 6 of the primary primary blade and the central axis 9 of the impeller is equal to 90 degrees; the angle between the upper edge plane 7 of the initial secondary blade and the central axis 9 of the impeller is equal to 90 degrees.

[0028] The upper and lower surfaces of the initial primary blade 2 and the initial secondary blade 1 of the impeller casting mold are parallel to each other, and the distance between the initial primary blade and the initial secondary blade is 5mm. The mold can be ejected synchronously in the same direction to realize automatic mold opening and closing.

Embodiment 2

[0030] The angle between the outer edge plane 5 of the primary primary blade and the central axis 9 of the impeller is equal to 95 degrees; the angle between the outer edge plane 8 of the initial secondary blade and the central axis 9 of the impeller is equal to 95 degrees.

[0031] The upper and lower surfaces of the initial primary blade 2 and the initial secondary blade 1 of the impeller casting mold are parallel to each other, and the distance between the initial primary blade and the initial secondary blade is 5mm. The mold can be ejected synchronously in the same direction to realize automatic mold opening and closing.

Embodiment 3

[0033] The angle between the upper edge plane 6 of the primary primary blade and the central axis 9 of the impeller is equal to 100 degrees; the angle between the upper edge plane 7 of the initial secondary blade and the central axis 9 of the impeller is equal to 100 degrees.

[0034] The distance between the initial primary blade and the initial secondary blade is constant from the inlet of the impeller to the outlet of the impeller. The radial distance between the lower surface of the initial primary blade 2 and the upper surface of the adjacent primary secondary blade 1 along the central axis 9 of the impeller becomes larger, and the angle between the two planes is 7 degrees.

[0035] The radial distance between the upper surface of the initial primary blade of the impeller casting mold and the upper surface of the adjacent initial secondary blade along the central axis 9 of the impeller becomes larger, and the angle between the two planes is 9 degrees.

[0036] The linear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com