Metal micro-coating forming system and method thereof

A micro-coating and metal technology, which is applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problems of difficult control, error, and affecting the accuracy of cladding and forming parts, so as to reduce the impact, reduce the processing volume, The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

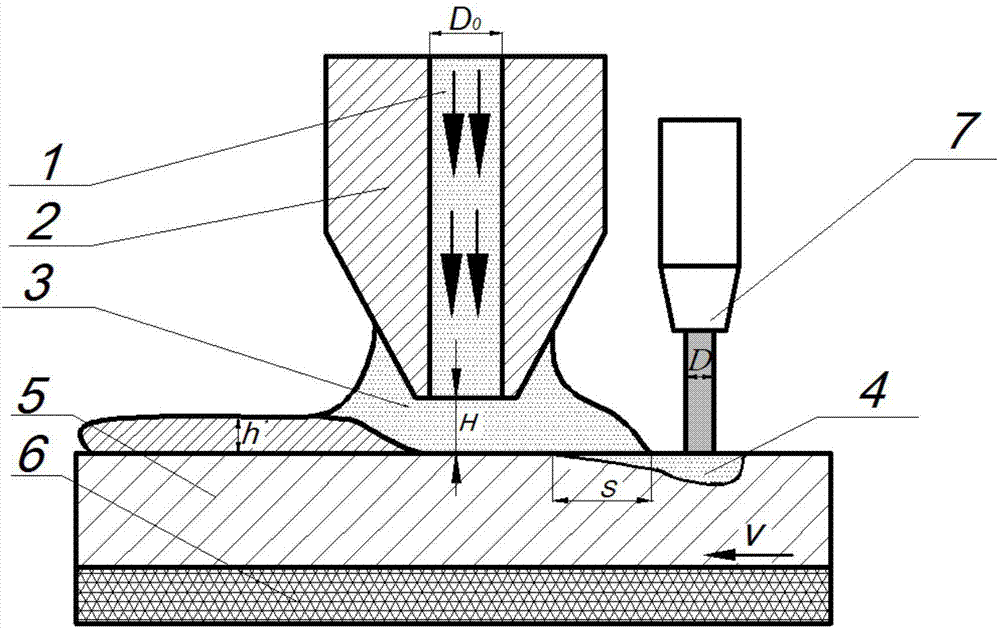

[0020] refer to figure 1 , the metal micro-coating forming system of the present invention includes a substrate 5, a heating device 6, and a fixed feeder 2, the substrate 5 is fixed on the heating device 6, and the fixed feeder 2 is located directly above the substrate 5, Moreover, there is a gap between the fixed feeder 2 and the substrate 5 , and the fixed feeder 2 is provided with a channel 1 for molten metal in the up and down direction.

[0021] In addition, the present invention also includes a laser 7 , and the laser 7 is located right above the substrate 5 .

[0022] Metal micro-coating forming method of the present invention comprises the following steps:

[0023] 1) Adjust the distance between the fixed feeder 2 and the substrate 5 according to the layer thickness H of the required parts, and adjust the heating temperature of the heating device 6;

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com