Full-automatic injection molding machine

An injection molding machine, fully automatic technology, applied in the field of industrial machinery, can solve the problems of plastic molds with single color, unknown, bad product equipment humidity, etc., to achieve the effect of reducing production rate, avoiding loss, and reducing the amount of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0014] The invention will be described in detail below with reference to the accompanying drawings and examples.

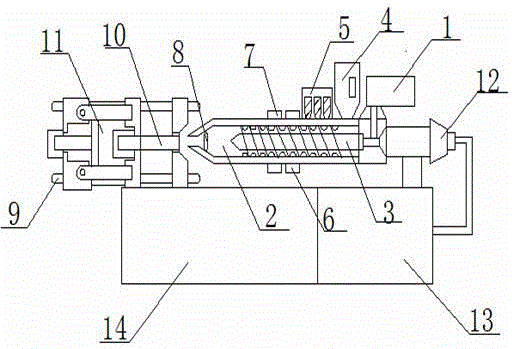

[0015] A fully automatic injection molding machine A fully automatic injection molding machine consists of a driving screw motor 1, a barrel 2, a screw 3, a hopper 4, a paint hopper 5, a heater 6, a humidity measuring device 7, a filter membrane 8, a tie rod 9, and a gate Road 10, mold clamping device 11, injection cylinder 12, oil cylinder 13 and hydraulic motor 14 are composed, the driving screw motor 1 is connected with the screw rod 3, the screw rod 3 is in the machine barrel 2, the front end of the machine barrel 2 has an opening, the hopper 4 and the paint hopper 5 It communicates with the barrel 2, the heater 6 and the humidity measuring device 7 are all on the barrel 2, the filter membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com