Patents

Literature

67results about How to "Solve production inefficiencies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feed for artificially raising Dastarcus helophoroides in large scale and matched breeding technology thereof

The invention provides a feed for artificially raising Dastarcus helophoroides in a large scale and a matched breeding technology of the feed. The invention discloses the feed for artificially raising the Dastarcus helophoroides in the large scale. The feed is prepared by taking yellow mealworm larva dry powder, barley pest larva dry powder and sterile water as raw materials and matching with various amino acids, linoleic acid and glucose; and the preparation manner is simple, raw materials are cheap and are easily available, and the feed has high economic value. Meanwhile, the invention further discloses the matched breeding technology of the feed for artificially raising the Dastarcus helophoroides in the large scale; the feed is matched with a preservation box and de-greased cotton to carry out hatching operation of the Dastarcus helophoroides; an artificial weather box is matched to obtain a shorter breeding period when being compared with the prior art; and meanwhile, high mature larva survival rate can be obtained.

Owner:NANJING FORESTRY UNIV +2

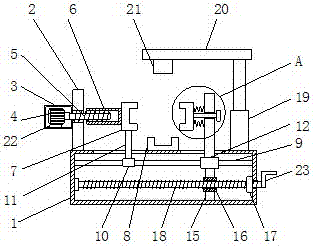

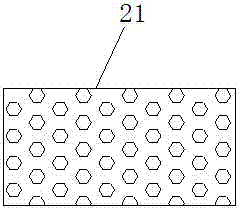

Technical brush production and processing device

PendingCN107334262ASolve production inefficienciesImprove stabilityBrush bodiesScrew threadThreaded rod

The invention discloses a technical brush production and processing device. The technical brush production and processing device comprises a fixing base, the left side on the top of the fixing base is fixedly connected with a first fixing plate, the left side of the first fixing plate is fixedly connected with a motor box, a motor is arranged in the motor box, the output shaft of the motor is fixedly connected with a first threaded rod, and the right end of the first threaded rod penetrates through the motor box and the first fixing plate in sequence, extends to the right side of the first fixing plate and is connected with a threaded sleeve in a sleeved mode. In the technical brush production and processing device, due to the arrangement of the motor, the first threaded rod can be driven to rotate, and a first clamping block is driven to move in the cooperation of the first threaded rod and the threaded sleeve; due to the arrangement of a handle and a second threaded rod, a moving plate and a second fixing plate can be driven by a thread sleeve to move; due to the arrangement of springs, a second clamping block can be adjusted, a brush handle is fixed, and meanwhile, the problems that the brush handle cannot be fixed, and the production time is increased so that the production efficiency is low are solved.

Owner:湖州贝明克斯刷业有限公司

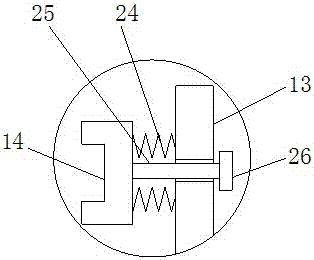

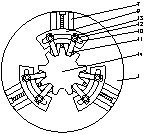

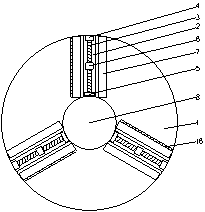

Clamping device used for finish machining of cold extrusion gear

InactiveCN108044206AAdjustable spacingAvoid damageGear-cutting machinesGear teethCouplingEngineering

The invention discloses a clamping device used for finish machining of a cold extrusion gear. The clamping device used for the finish machining of the cold extrusion gear comprises a chuck body; grooves are formed in the chuck body and screw rods are arranged in the grooves; one end of each screw rod is fixedly connected with an output shaft of a speed reducing motor by a coupling and the other end of the corresponding screw rod is rotationally connected with a bearing seat; both the speed reducing motors and the bearing seats are fixedly arranged in the grooves; nut seats are arranged on thescrew rods in a sleeving manner and fixedly connected with the middle parts of the side surfaces of clamping jaws; the two ends of the side surfaces of the clamping jaws are connected with guiding rails arranged at the two sides of the grooves in a sliding manner; kidney shape holes are formed in the clamping jaws and clamping strips are arranged at the lateral sides of the clamping jaws; one endsof the clamping strips are fixedly connected with the clamping jaws by bolts and nuts. According to the device, the screw rods, the kidney shape holes, the clamping strips, a rotary shaft and dividing rulers are arranged, so that the problems can be solved that a gear fixture is inconvenient to adjust and unadapted to the gears with different tooth pitches during the finish machining of the coldextrusion gear.

Owner:TAIZHOU WEIYE MACHINERY MFG CO LTD

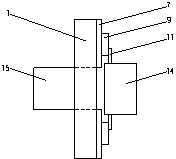

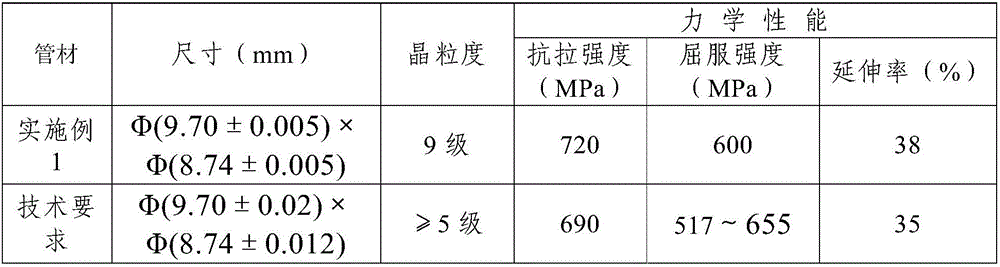

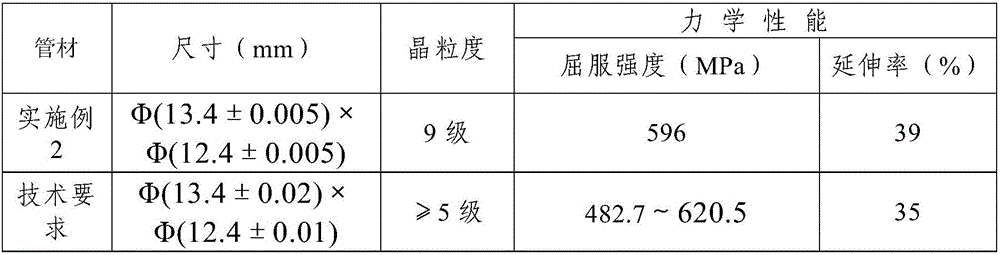

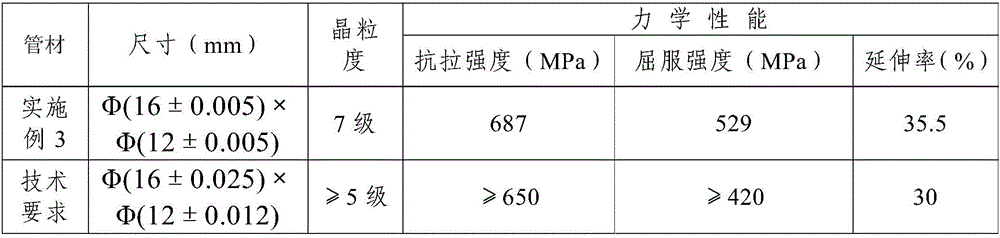

Processing method for improving quality of inner surface of austenite stainless steel tube

InactiveCN106755770AIncrease productivityStable and reliable dimensional accuracyFurnace typesHeat treatment furnacesSteel tubeThin walled

The invention provides a processing method for improving quality of an inner surface of an austenite stainless steel tube. The method comprises the following step: successively carrying out solution treatment, straightening, pulling of a fixed mandrel and aftertreatment on a rolled austenite stainless steel insertion tube to obtain the austenite stainless steel tube with the high-quality inner surface. The processing method is simple in process, easy to implement, high in production efficiency and low in energy consumption; and the austenite stainless steel tube processed by the method is good in quality of the inner surface and the outer surface, even in structure and excellent in mechanical property; the yield of one-time detection in nondestructive test reaches 90% or above; and therefore, the processing method can be widely applied to the processing industry of stainless steel thin-walled slender tubes.

Owner:西安诺博尔稀贵金属材料股份有限公司

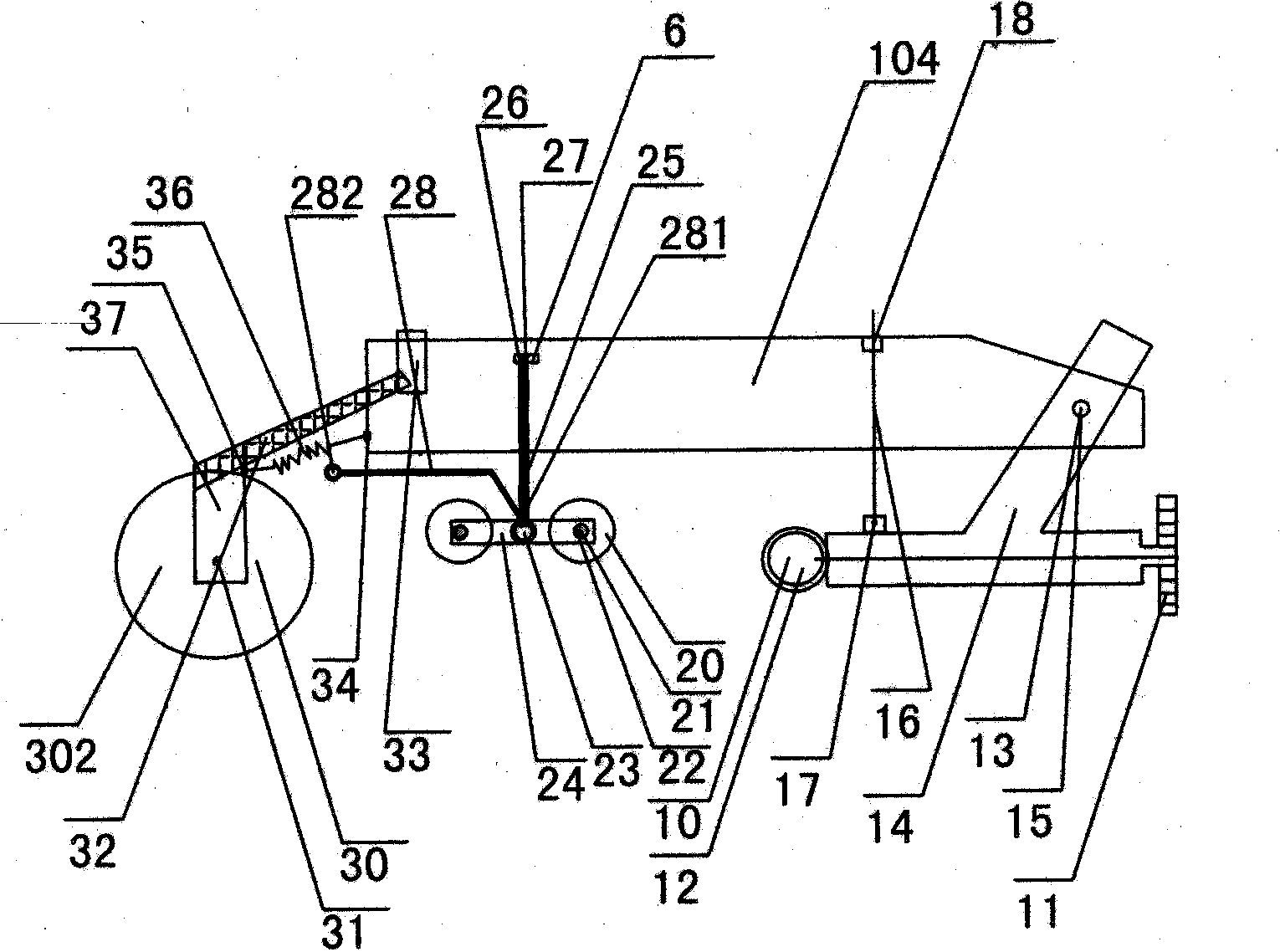

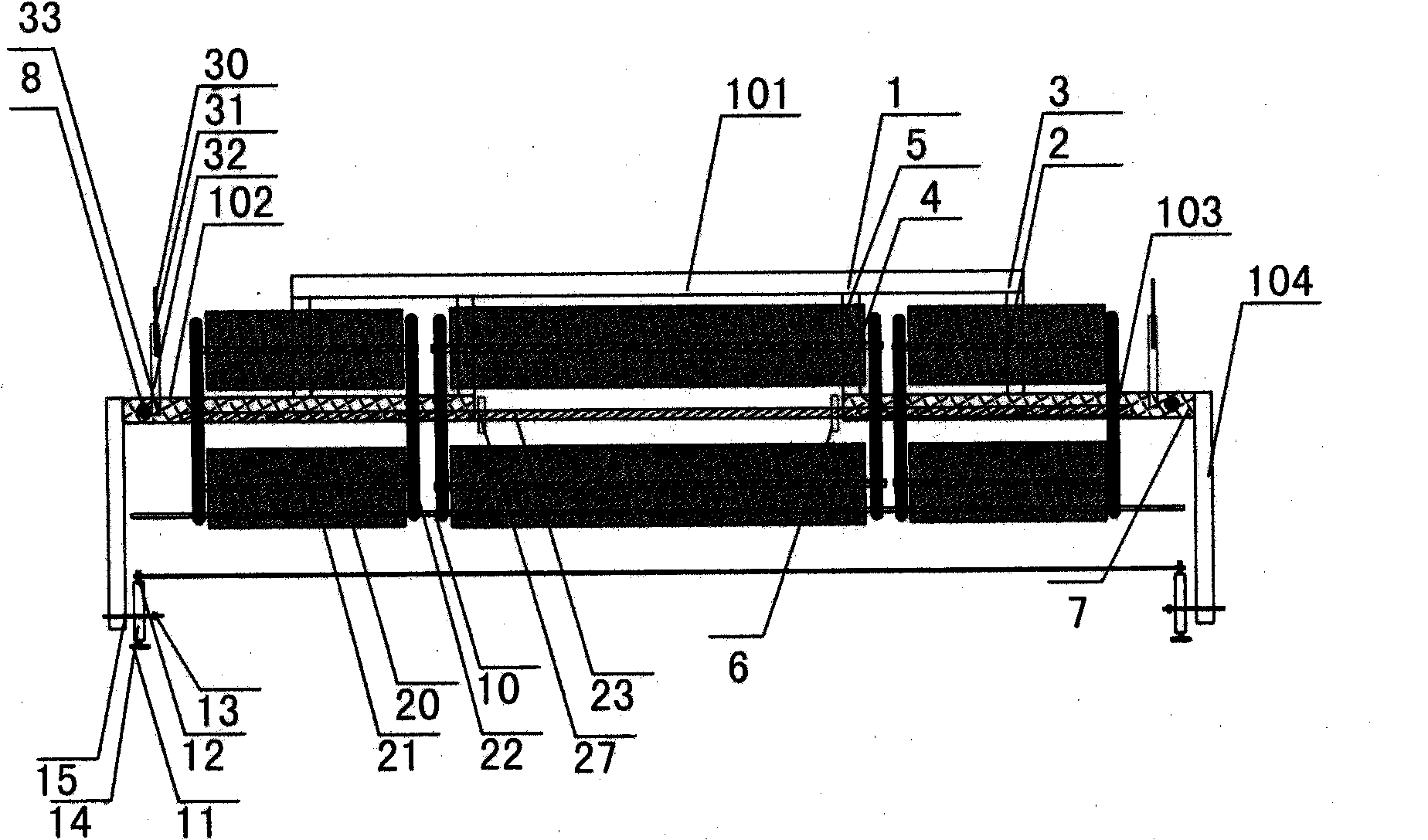

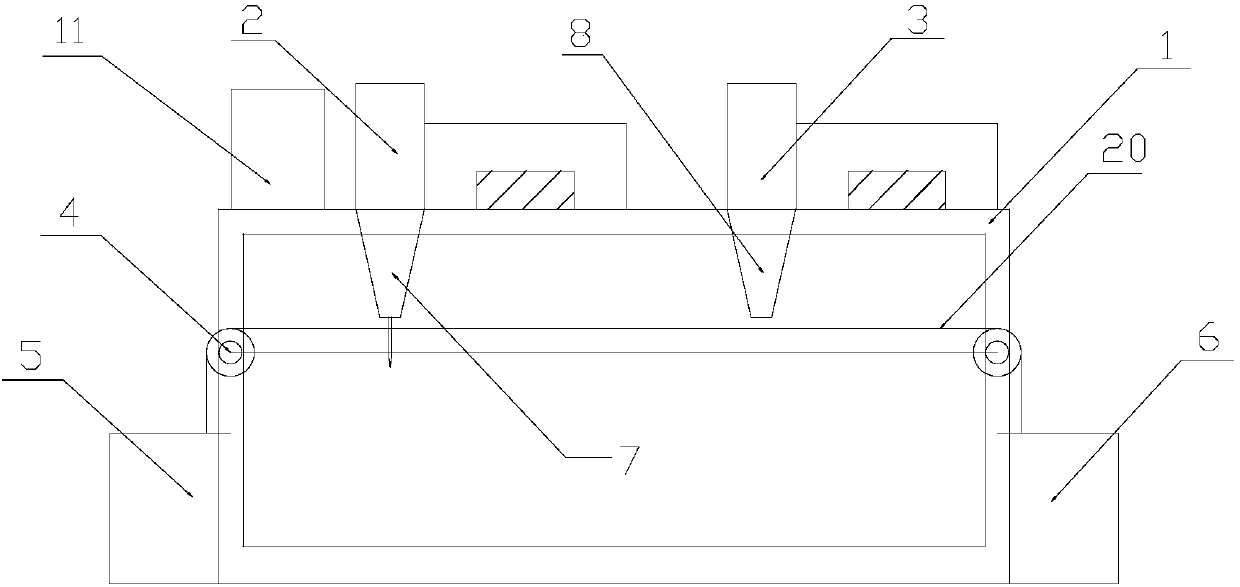

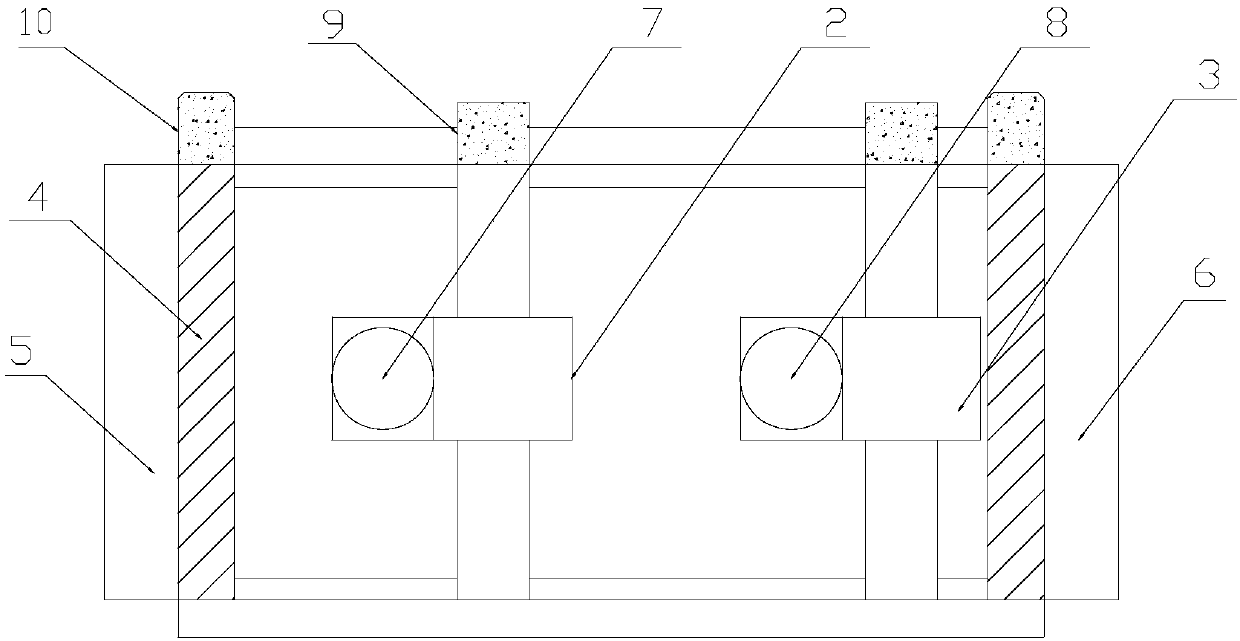

All-in-one film mulching and rice transplanting machine with film cutting knife assembly

InactiveCN104067743ASolve production inefficienciesTransplantingPlant protective coveringsAgricultural engineeringFilm-coated tablet

An all-in-one film mulching and rice transplanting machine with a film cutting knife assembly is used in the planting step of agricultural production; after a mulching film is paved on a field, a rice transplanting claw cannot realize direct rice planting on the film effectively, so that the mulching film is needed to be cut with small openings by a film cutting knife before rice transplanting to enable the rice transplanting claw to transplant seedlings to the field coated with the film; in the organic paddy rice production process, as phytocide, pesticide and artificial fertilizer cannot be adopted, weeding becomes one of the most difficult problems during the production of organic paddy rice, while the paddy rice film coating technology can completely solve the problem; the conventional paddy rice film coating technology can only be realized by firstly performing manual or mechanical film coating and then carrying out manual rice transplanting, and while the manner is troublesome, strenuous and low in efficiency, the condition greatly influences the industrialized planting of organic paddy rice; by the adoption of the all-in-one film mulching and rice transplanting machine with the film cutting knife assembly, the problem that the production efficiency is low in the prior art is solved.

Owner:王威

Method for preparing pectin by high static pressure technology

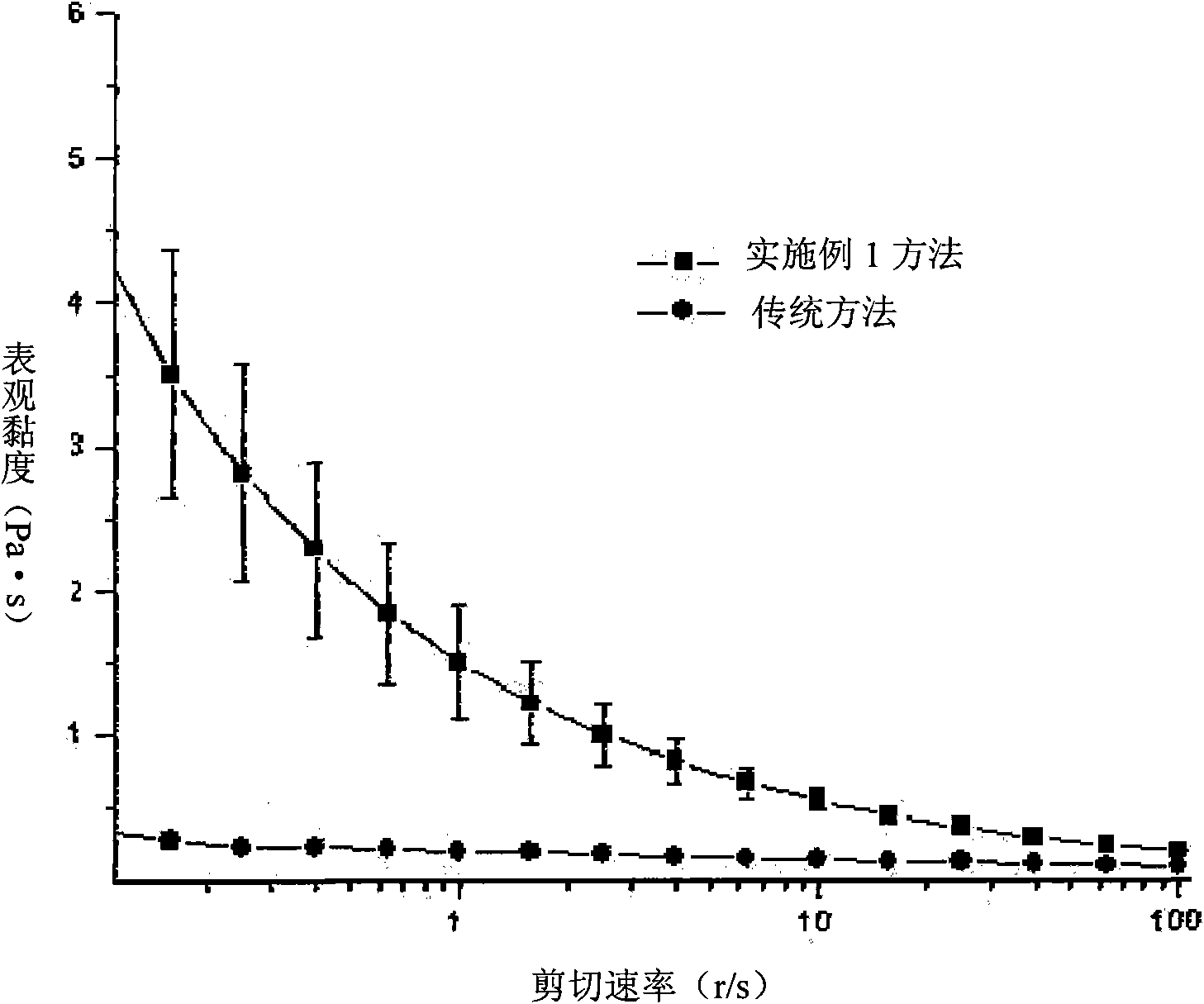

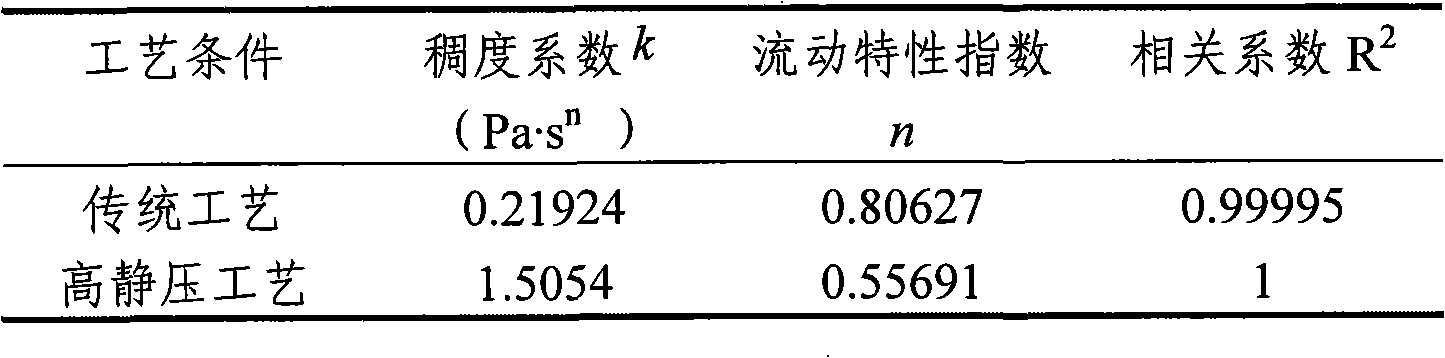

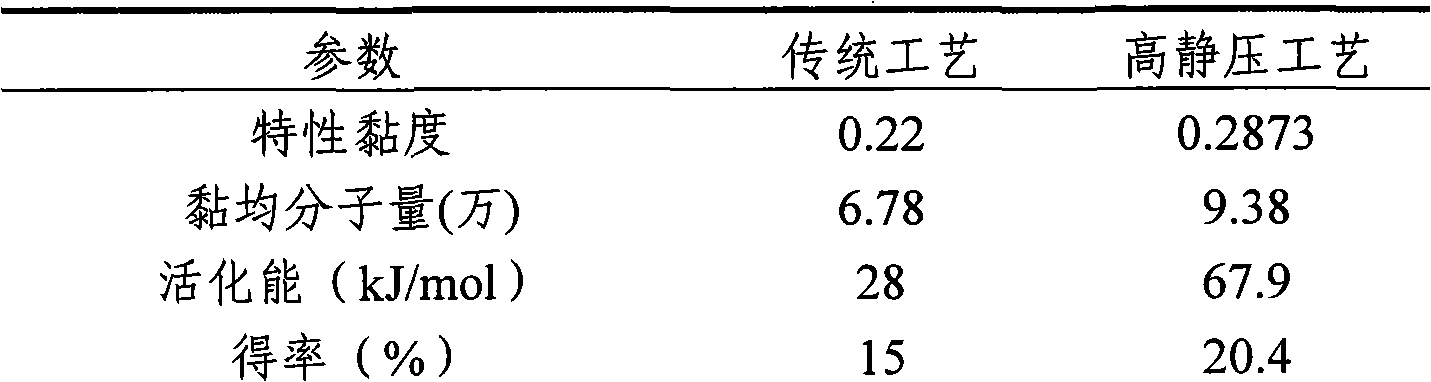

InactiveCN101935361ADoes not destroy the molecular chain structureReduce extraction timeVacuum packAqueous solution

The invention provides a method for preparing pectin by high static pressure technology. The method comprises the following steps of: 1) performing enzyme inactivation, drying and grinding on a pectin-rich raw material, mixing the treated raw material and acid aqueous solution with the pH of 1.5 and performing vacuum packaging on the mixture; and 2) putting a mixture vacuum-packed in the step 1) into high static pressure equipment, performing high static pressure treatment under the treatment pressure of between 300 and 600 MPa at the treatment temperature of between 20 and 55 DEG C for 5 to 15 minutes and separating and purifying to obtain the pectin. In the preparation method, the high static pressure technology is applied to the extraction of macromolecular pectin and a preferred parameter range is determined, so that the molecular chain of the pectin can be protected better and the yield and quality of the pectin are ensured. Moreover, the method of the invention has the advantages of shortening extraction time, lowering extraction temperature, increasing production yield and reducing production energy consumption, along with simple operation and contribution to the market competitiveness of a product.

Owner:CHINA AGRI UNIV

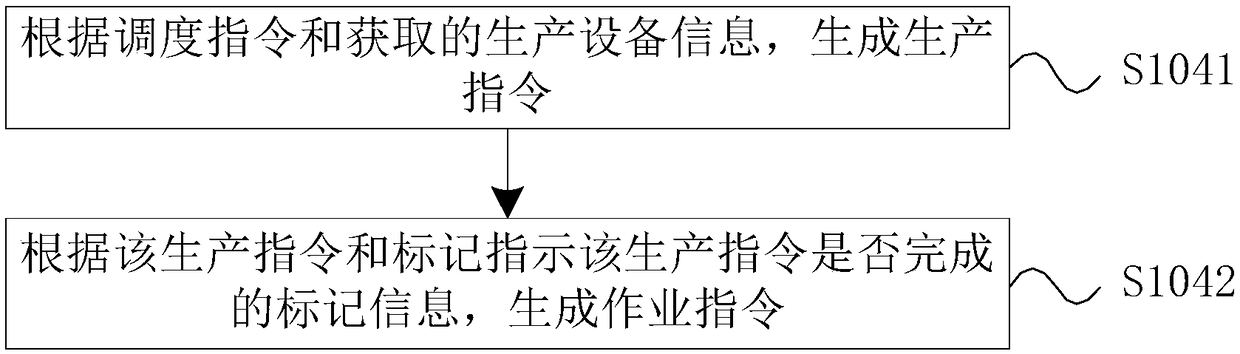

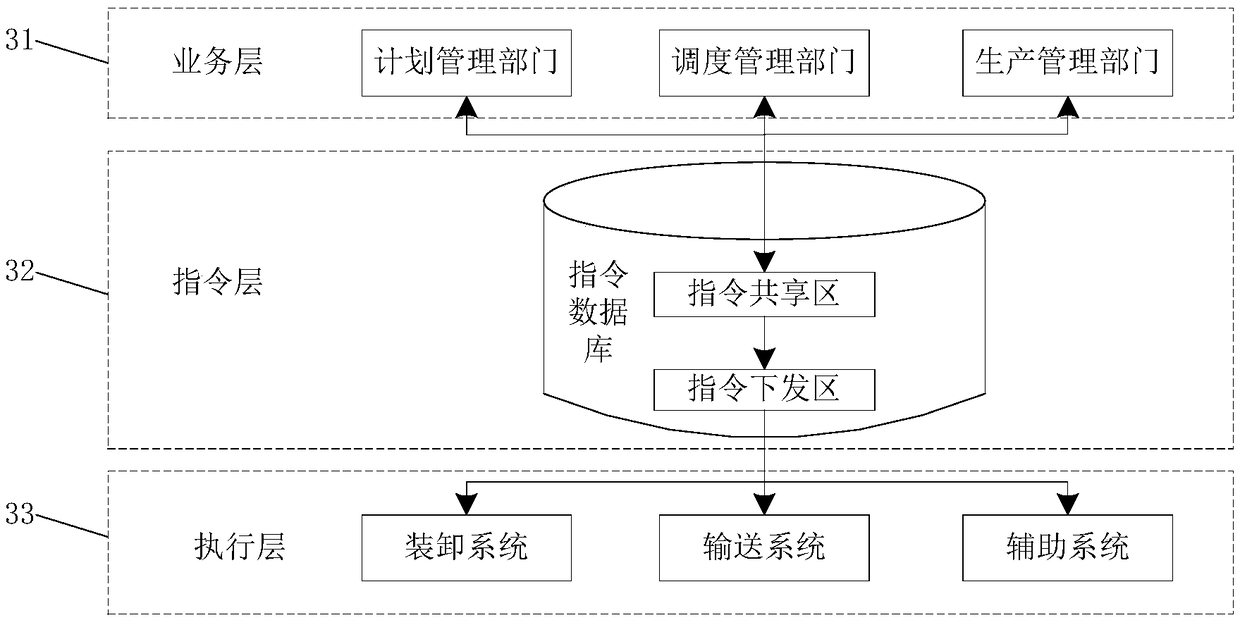

Method and device for generating job instruction, a system, an electronic device and a storage medium

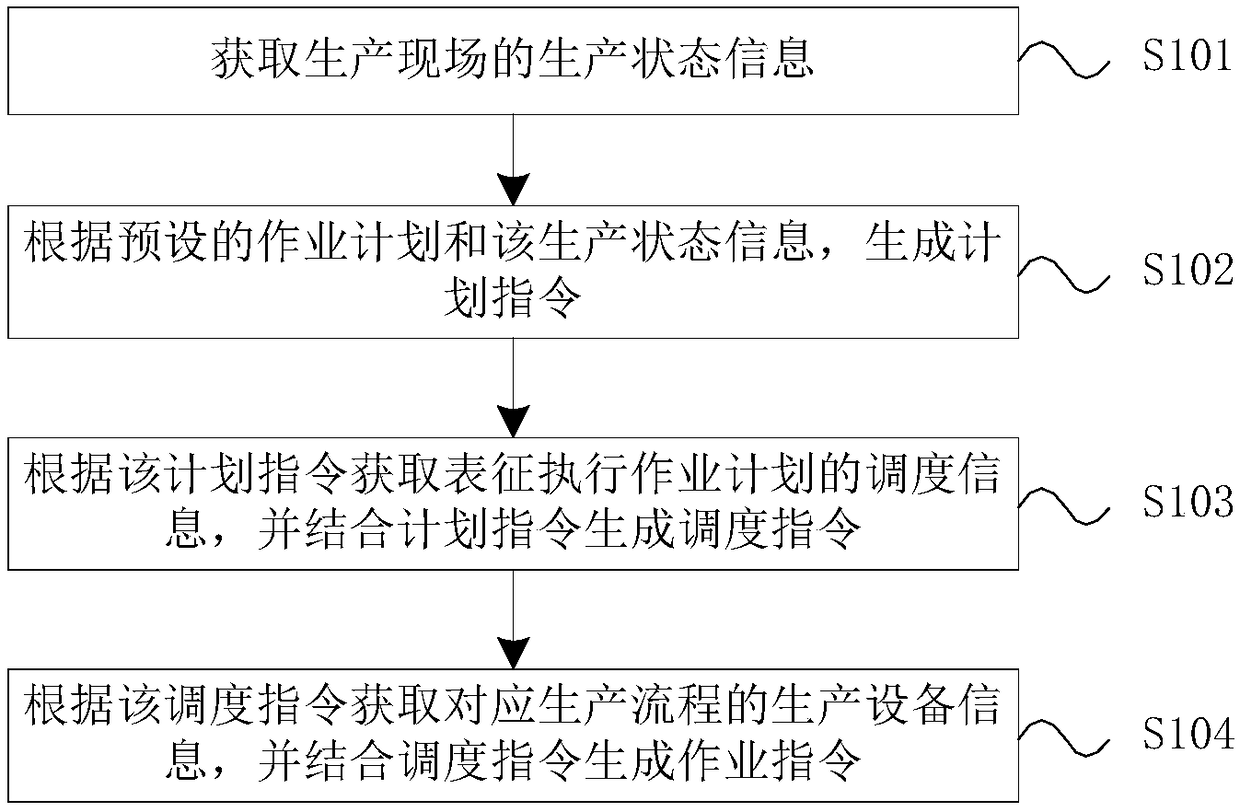

InactiveCN109242269ASolve production inefficienciesResourcesGeneration processScheduling instructions

A method and device for generating job instruction, a system, an electronic device and a storage medium are provided. A method for generating job instructions includes production status information ofa production site is obtained, According to the preset job plan and production status information, a plan instruction is generated, the scheduling information representing the execution job plan is obtained according to the plan instruction, the scheduling instruction is generated according to the plan instruction, the production equipment information corresponding to the production flow is obtained according to the scheduling instruction, and the job instruction is generated according to the scheduling instruction. In accordance with that present invention, the Scheduling instruction in theproduction process is generated according to the plan instruction, the job instruction is generated according to the scheduling instruction, and the final generated job instruction is sent to each execution system, and the generation process of the job instruction is continuous, thus solving the problem that the generation process of the job instruction in the prior art is tedious, and each execution system requires the operator to issue the job instruction separately, resulting in low production efficiency.

Owner:HUADIAN HEAVY IND CO LTD

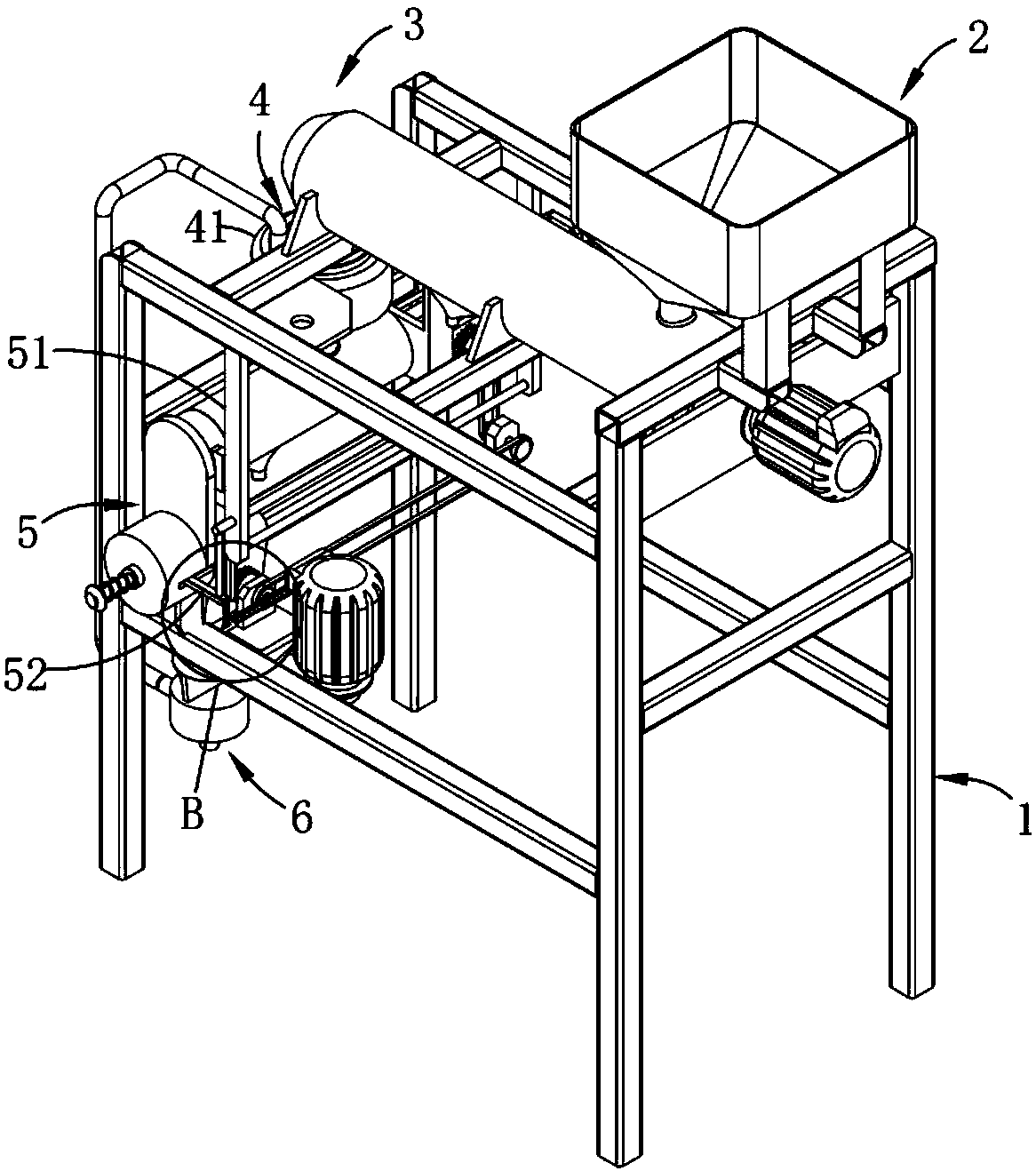

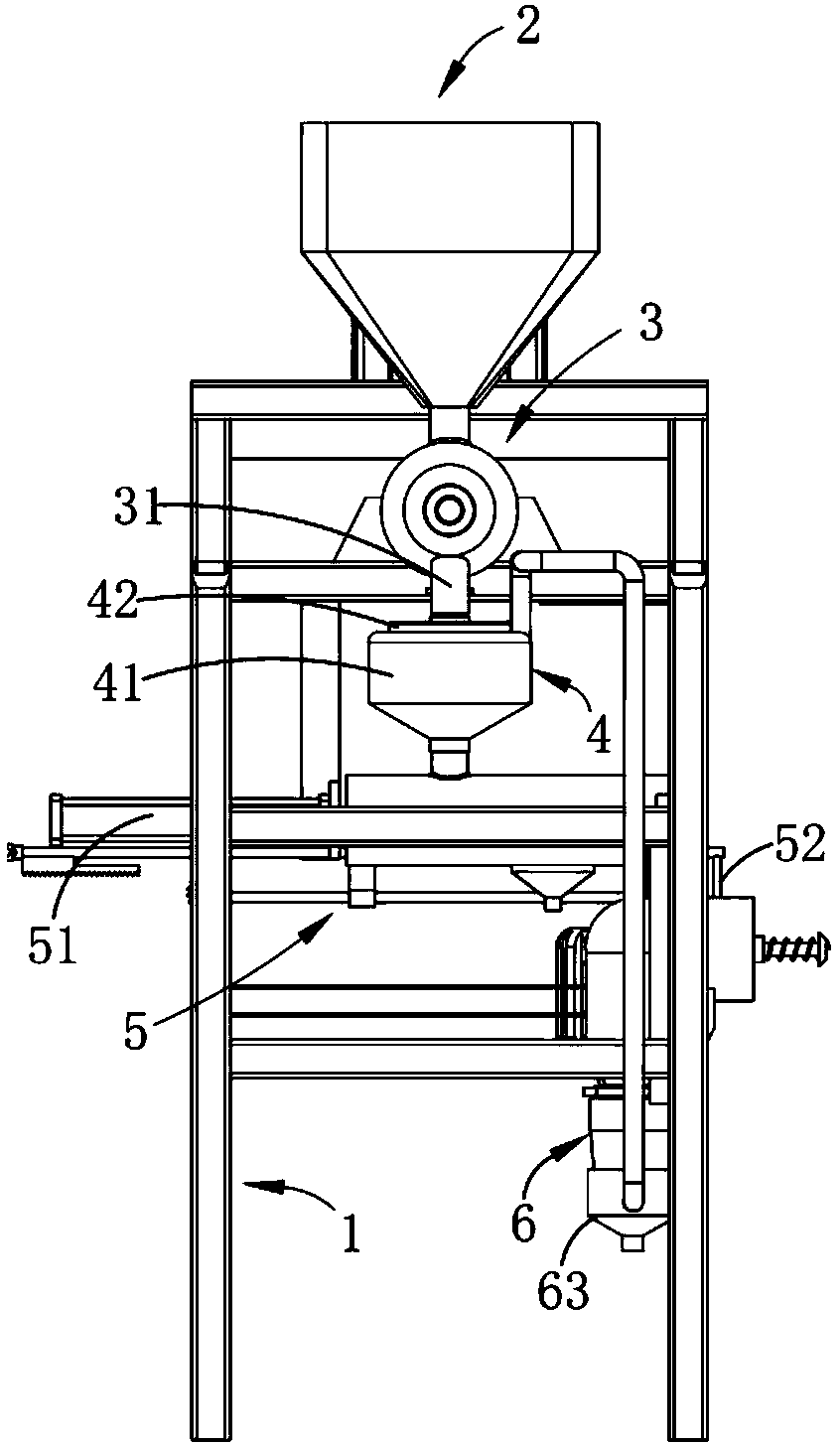

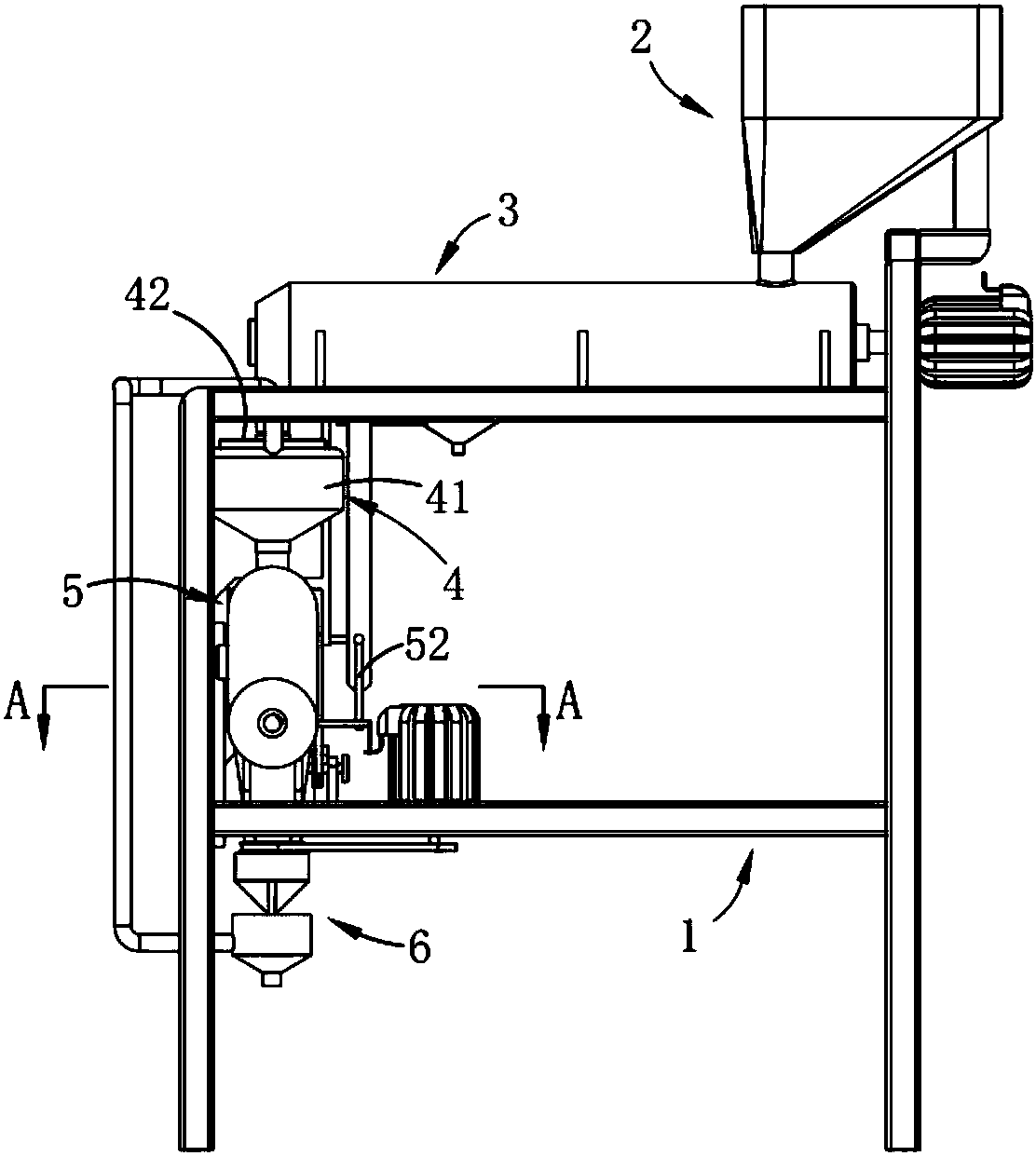

Environmentally-friendly and energy-saving type automatic oil pressing equipment

InactiveCN108381968AImprove energy efficiencySolve production inefficienciesFatty-oils/fats productionGrain treatmentsScrapEnvironmentally friendly

The invention relates to the technical field of oil pressing production equipment, in particular to environmentally-friendly and energy-saving type automatic oil pressing equipment. The equipment comprises a machine frame, a feeding bin, a first-stage oil pressing mechanism, a baking mechanism, a second-stage oil pressing mechanism and a waste treatment mechanism; oil materials are subjected to oil pressing by the first-stage oil pressing mechanism so as to form oil cakes, and the oil cakes are baked by the baking mechanism and then enter the second-stage oil pressing mechanism, and the secondoil pressing assembly comprises an oil pressing assembly and a transferring assembly, wherein the oil pressing assembly performs oil pressing in a reciprocating squeezing mode, and the transferring assembly is arranged at the end part of the oil pressing assembly, communicates with the oil pressing assembly in an intermittent mode and transfers waste subjected to oil pressing; and the waste treatment mechanism communicates with the transferring assembly and comprises a crushing assembly, a subdivision assembly and a dehumidification assembly, wherein the dehumidification assembly communicateswith the baking bin. The equipment has the advantages that through the displacement of the oil pressing assembly during the oil pressing work of the oil pressing assembly, the waste can be transferred, waste drying treatment can be carried out by utilizing hot waste gas, and the technical problems that in the prior art, the production efficiency is low, and the energy recycling rate is low can besolved.

Owner:安徽省皖凯机械有限公司

Mechanical horizontal type broaching machine

InactiveCN103949723AIncrease productivitySimple processingFeeding apparatusBroaching machinesBall screwEngineering

The invention discloses a mechanical horizontal type broaching machine which comprises a horizontally arranged machine body and at least two linear guide tracks which are positioned on the machine body and extend in the horizontal direction at an interval, wherein ball screw rod pairs which extended in the same direction with the linear guide tracks are arranged between the linear guide tracks; a driving device for driving the ball screw rod pairs to move is further arranged on the machine body; a main sliding plate is connected to the ball screw rod pairs and the upper parts of the linear guide tracks; the main sliding plate moves along the linear guide tracks under the driving of the ball screw rod pairs; a clamp for clamping a workpiece is fixed on the main sliding plate; a broaching cutter is fixed on the machine body and is positioned above the clamped workpiece and / or on at least one of the left and right sides of the clamped workpiece. The mechanical horizontal type broaching machine disclosed by the invention is used for broaching in a mode that the broaching cutter is fixed and the workpiece moves, and the broaching cutter adopts a combination mode and can be adjusted according to workpieces to be machined, so that a servodrive is stable, the positioning is accurate, and the consumption of hydraulic oil is greatly reduced; moreover, precise broaching machining on a plurality of surfaces can be completed at one time, and the production efficiency is extremely high.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

Preparation method of water-soluble polyvinyl alcohol fiber wet non-woven fabrics

ActiveCN103276621ASolve messy arrangementSolve blending with virtually unlimited limitsSynthetic cellulose/non-cellulose material pulp/paperPaper-making machinesPolyvinyl alcoholEngineering

The invention discloses a preparation method of water-soluble polyvinyl alcohol fiber wet non-woven fabrics. The method comprises a step of water-soluble polyvinyl alcohol fiber suspension pulp preparation, a step of ratio blending, a step of wet slope screen shaping, a step of drying, and a step of rolling. The method allows the product fluffiness and the fiber web uniformity to be good, and the transverse and longitudinal tension of products to satisfy user requirements, and has a simple production technology.

Owner:YONGAN BAOHUALIN IND DEV

Continuous material distributing device

PendingCN111453428AHigh degree of automationIncrease productivityCharge manipulationNon-linear opticsPaper recyclingProcess engineering

The invention provides a continuous material distributing device. The continuous material distributing device comprises a rack, a controller, a grabbing mechanism, a paper recycling area, a separationarea and a discharging area, wherein the grabbing mechanism, the paper recycling area, the separation area and the discharging area are arranged on the rack; the separation area is used for containing glass to be separated and partition paper; the grabbing mechanism is driven by the controller to grab the glass or the partition paper and moves among the paper recycling area, the separation area and the discharging area; the paper recycling area is used for containing the separated partition paper; and a conveying belt is arranged in the discharging area and used for containing the separated glass. According to the continuous material distributing device, the glass and the partition paper can be separated, the glass is placed on the conveying belt to flow to the next procedure, and therefore continuous material distributing can be achieved without manual participation; and the automation degree is high, the production efficiency is high, and manpower and material resources are saved.

Owner:JIANGMEN YEEBO SEMICON

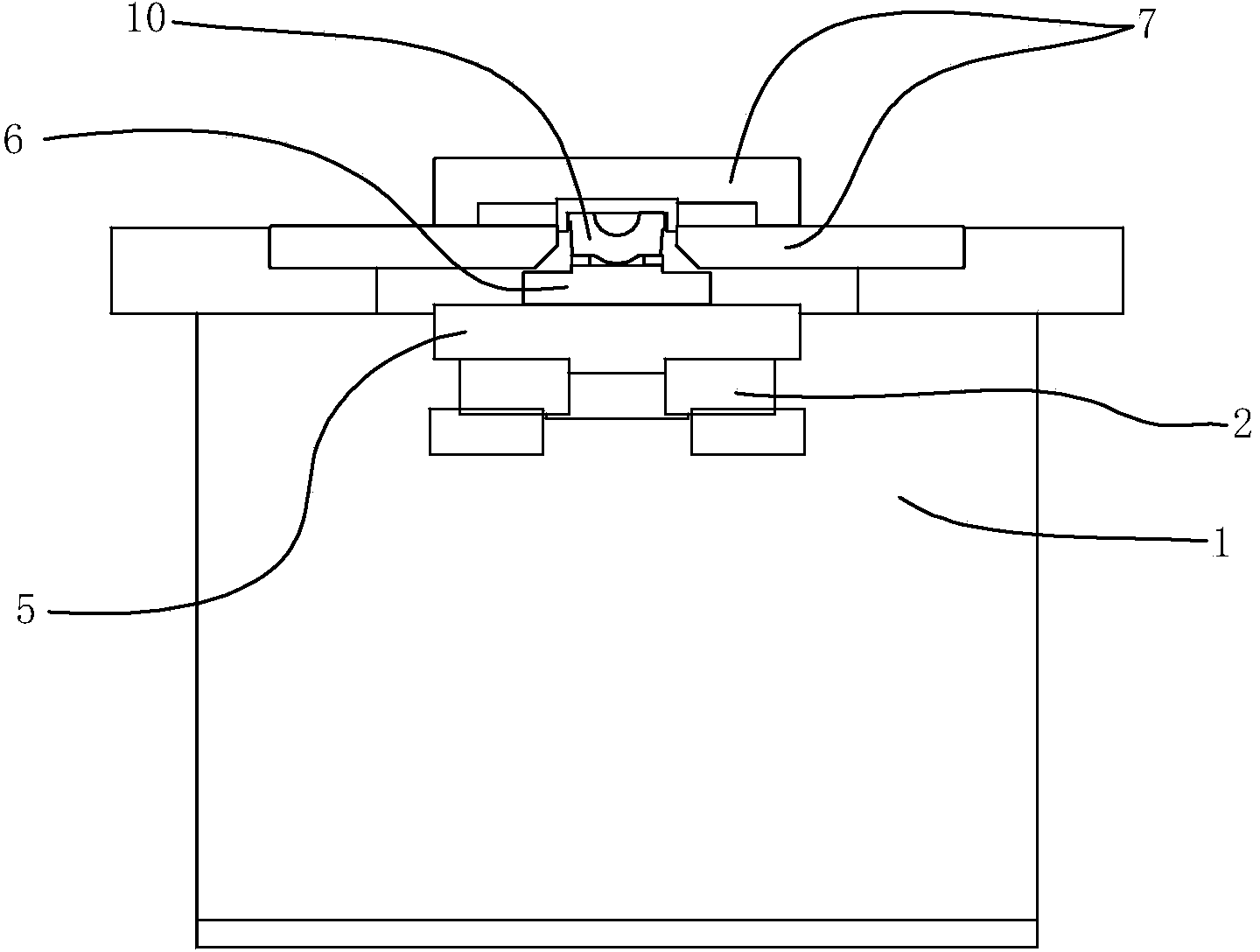

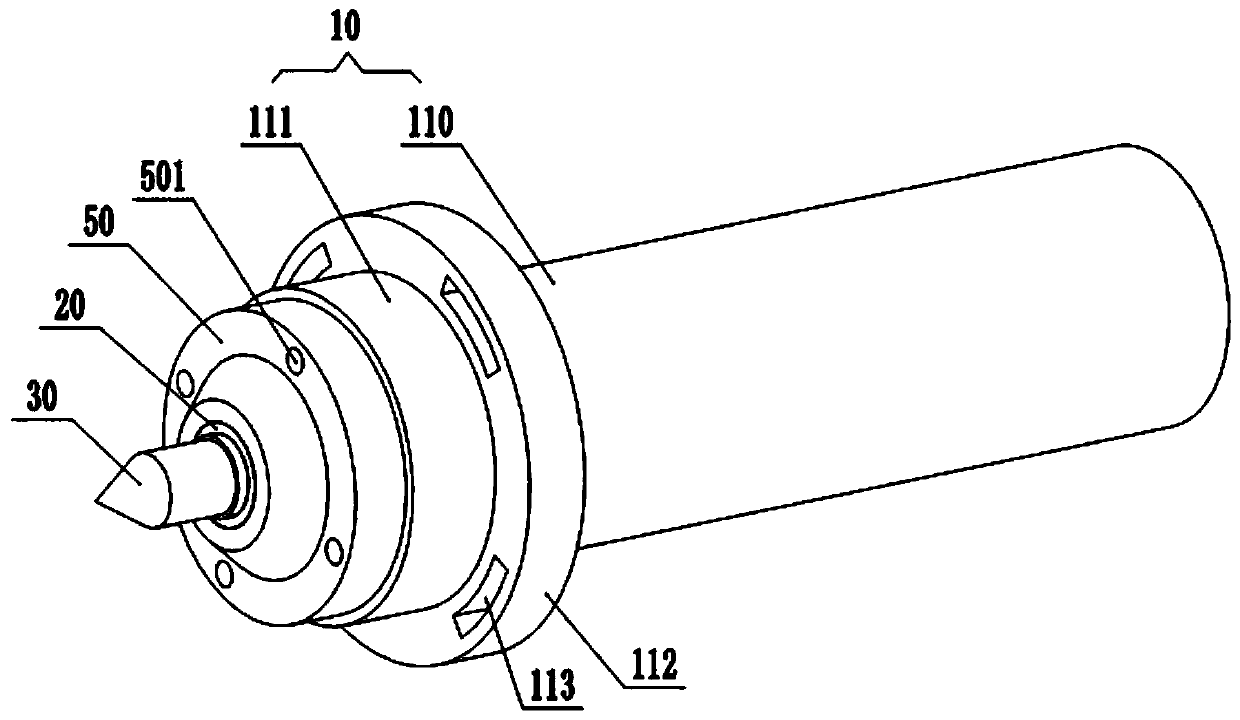

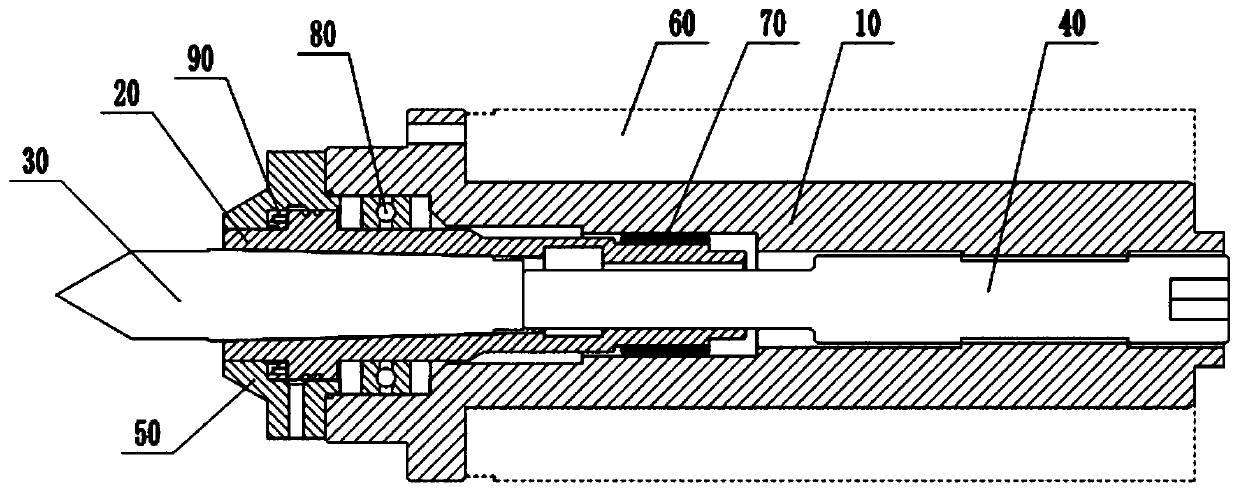

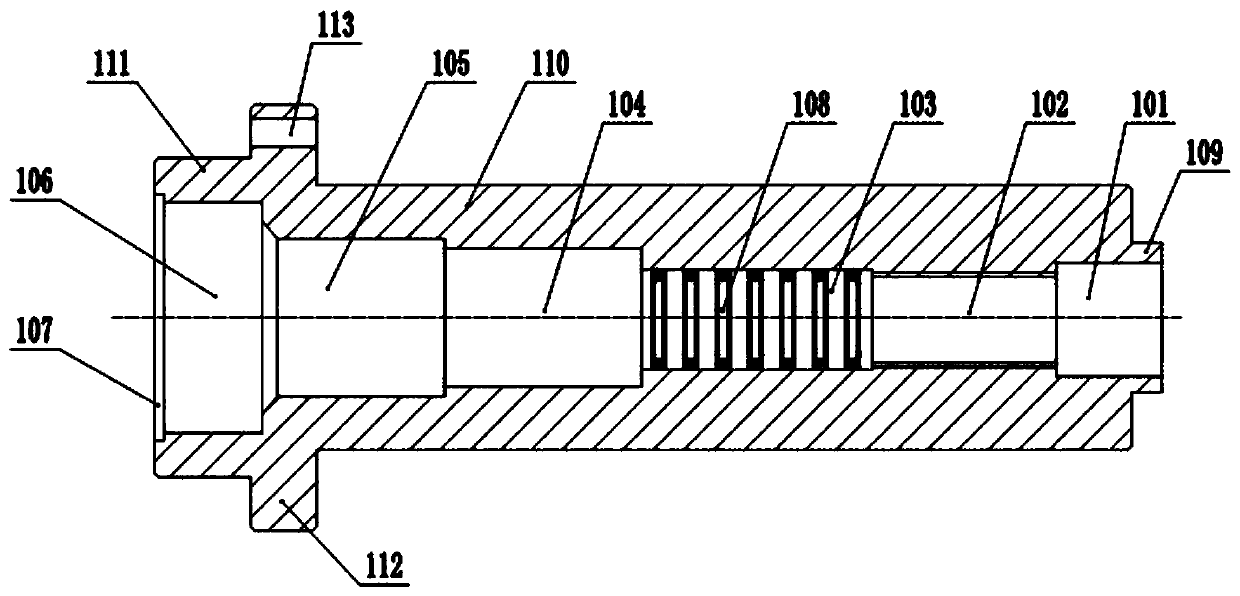

Rapid adjustable tip

The invention relates to the technical field of machine tool components, and particularly discloses a rapid adjustable tip. A sleeve, a core shaft, an ejector pin and an ejector rod are included. A threaded hole, a bearing installing hole and a positioning hole are sequentially in communication in the sleeve in the axial direction of the sleeve. The threaded hole is eccentric relative to the middle axis of the sleeve. The bearing installing hole, the positioning hole and the sleeve are coaxially arranged. The core shaft is rotationally connected in the bearing installing hole and the positioning hole. A conical hole, a middle hole and a supporting hole are sequentially in communication in the core shaft. The conical hole, the supporting hole and the core shaft are coaxially arranged. The middle hole is eccentrically arranged. The ejector pin is matched with the conical hole in taper. The ejector rod is in threaded connection with the threaded hole, and one end of the ejector rod tightly abuts against the tail of the ejector pin. By adoption of the technical scheme, the problems that in the prior art, the tip adjusting consumed time is long, and consequently the production efficiency is low are solved.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

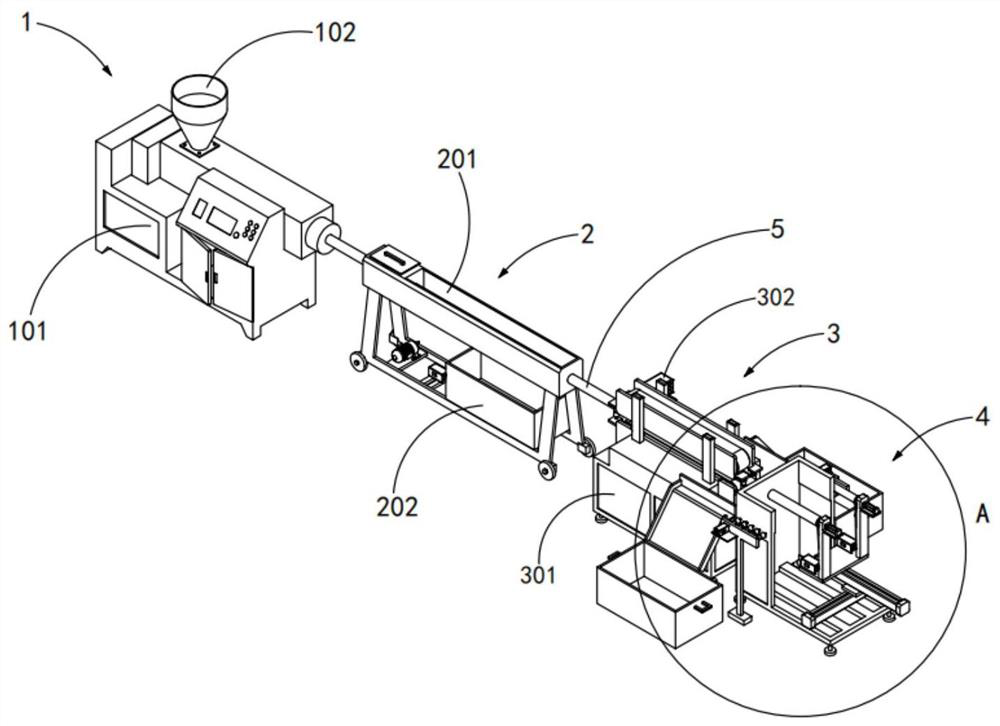

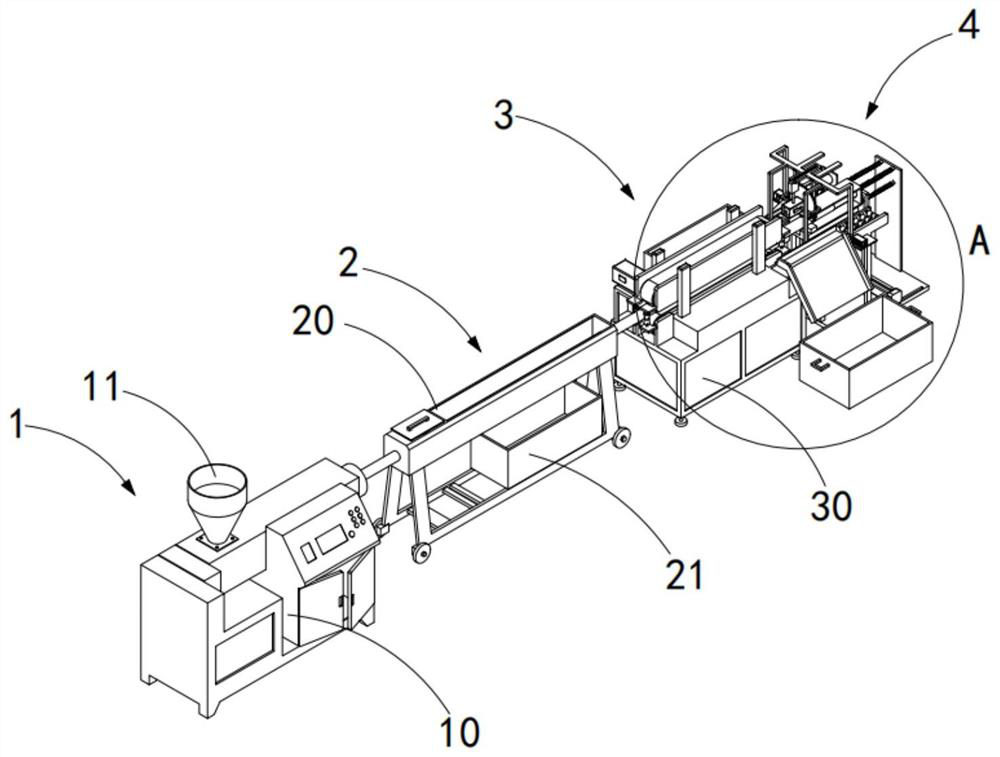

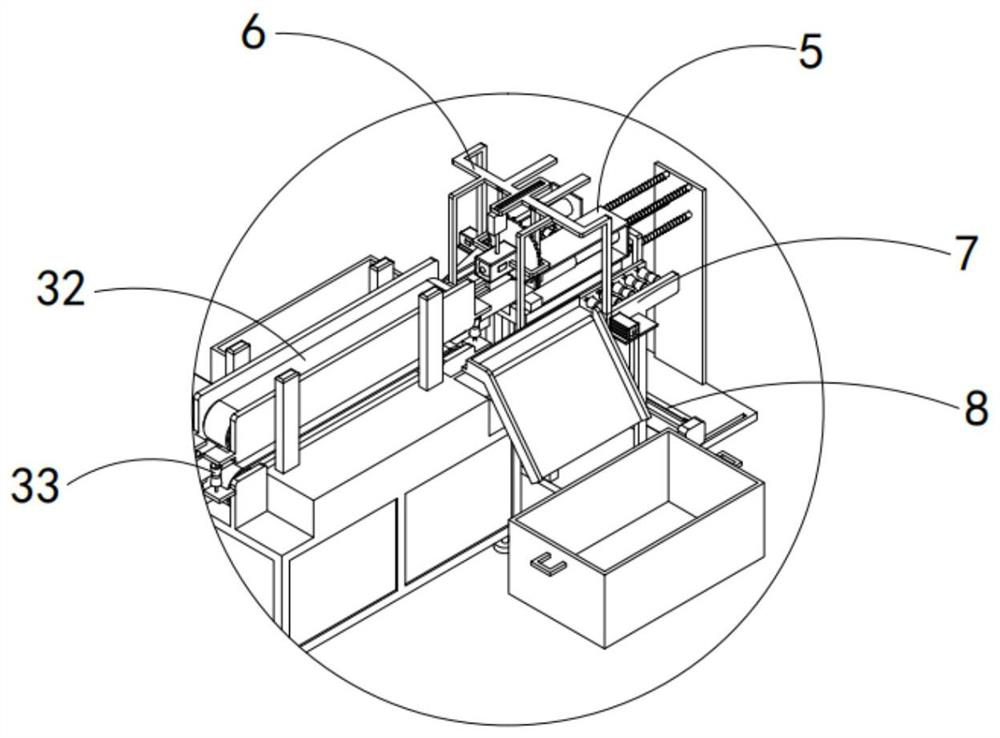

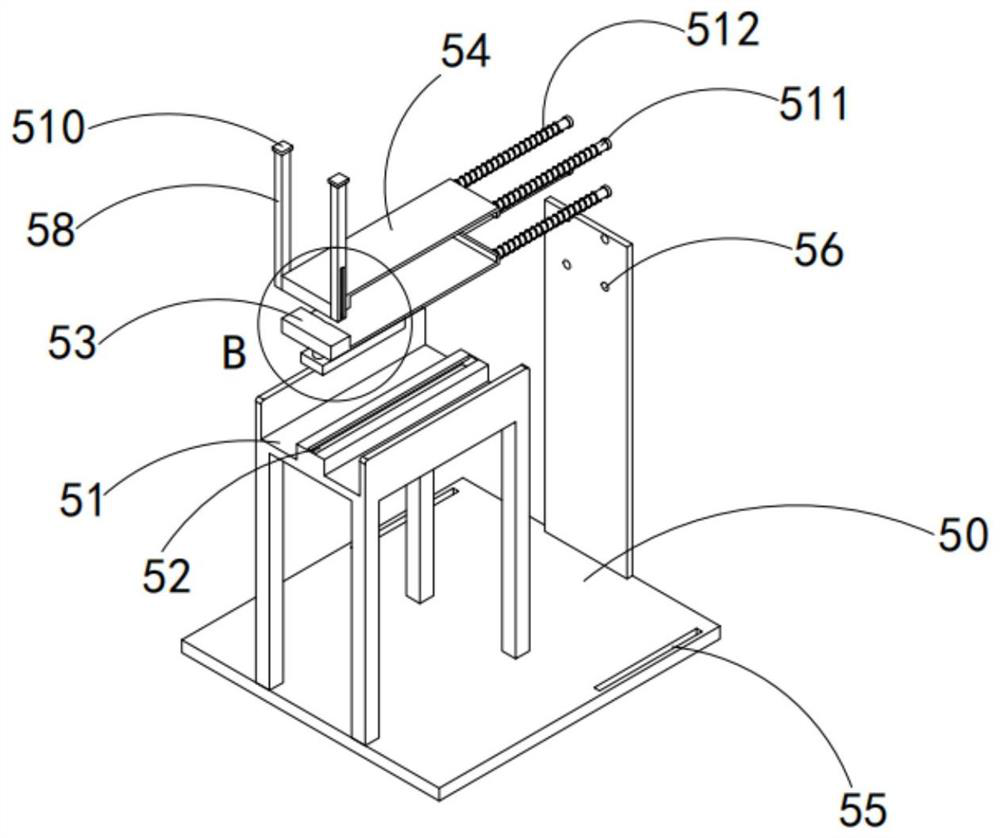

PVC pipe production line

PendingCN113246429ASolve production inefficienciesAvoid blockageMetal working apparatusEngineeringManufacturing line

The invention relates to a PVC pipe production line, which comprises an extrusion device, a shaping device arranged at the tail end of the extrusion device and a traction device arranged at the tail end of the shaping device; a slitting device is arranged at the tail end of the traction device; the slitting device comprises a pushing mechanism, a cutting mechanism a and the cutting mechanism b arranged above the pushing mechanism, and material stroking mechanisms arranged on the two sides of the pushing mechanism; each of the cutting mechanism a and the cutting mechanism b comprises a rotating assembly and a cutter assembly arranged in the rotating assembly; the pushing mechanism achieves switching of stations of the cutting mechanism a and the cutting mechanism b in a translation mode; the rotating assembly is used for driving the cutter assembly to rotate; the cutter assembly is used for cutting PVC pipes conveyed on the traction device from inside to outside; and the material stroking mechanisms are used for stroking down the cut PVC pipes from the cutting mechanism a and the cutting mechanism b. The problems that in the prior art, flatness of a machined notch cannot be guaranteed, the production efficiency is low, and continuity is poor are solved.

Owner:浙江都达新材料科技有限公司

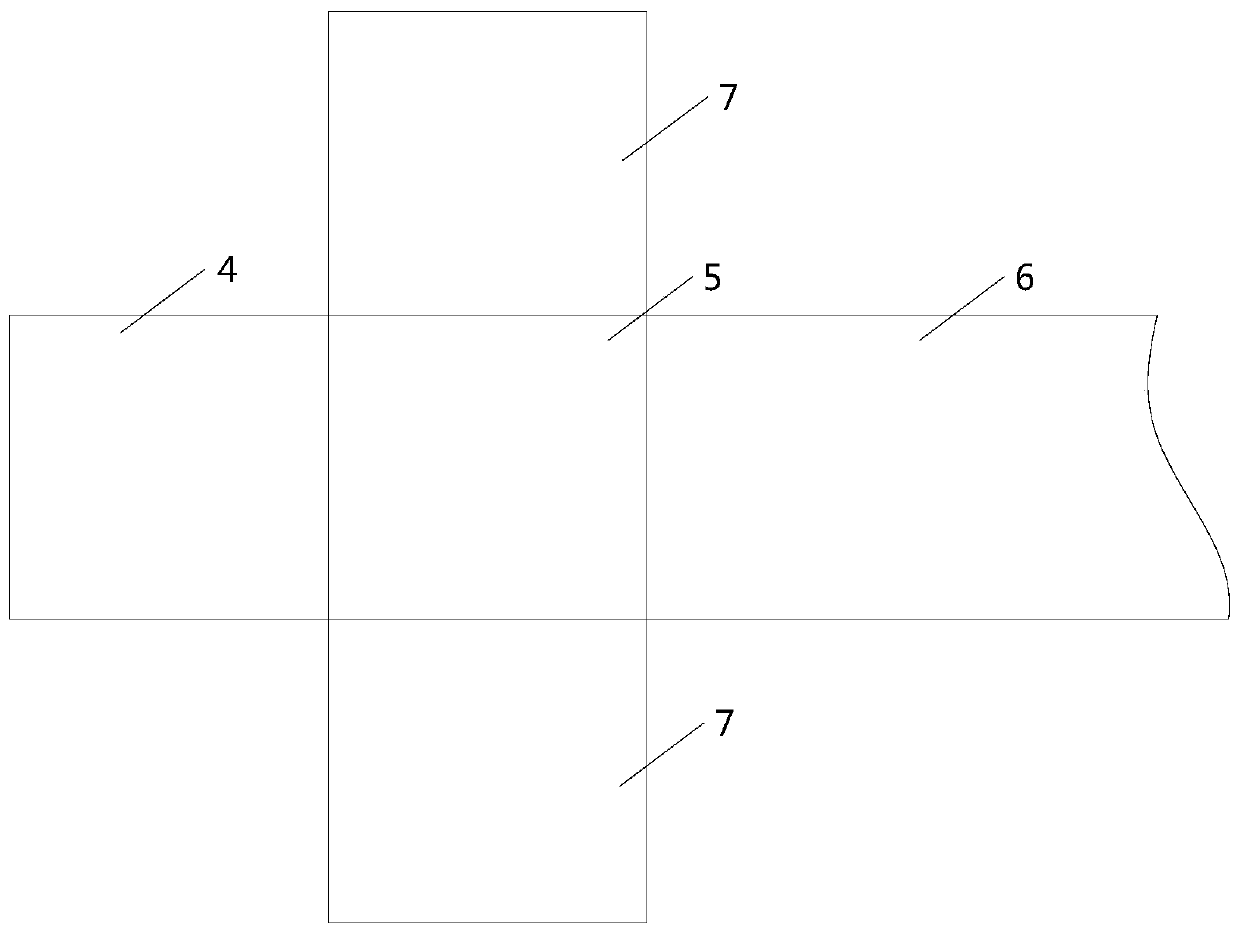

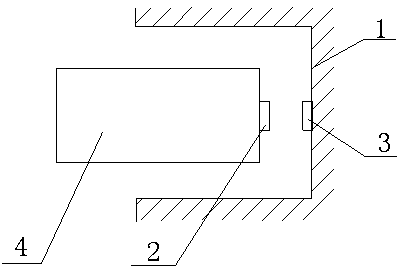

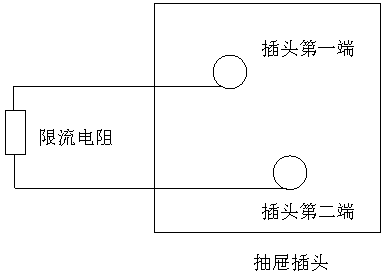

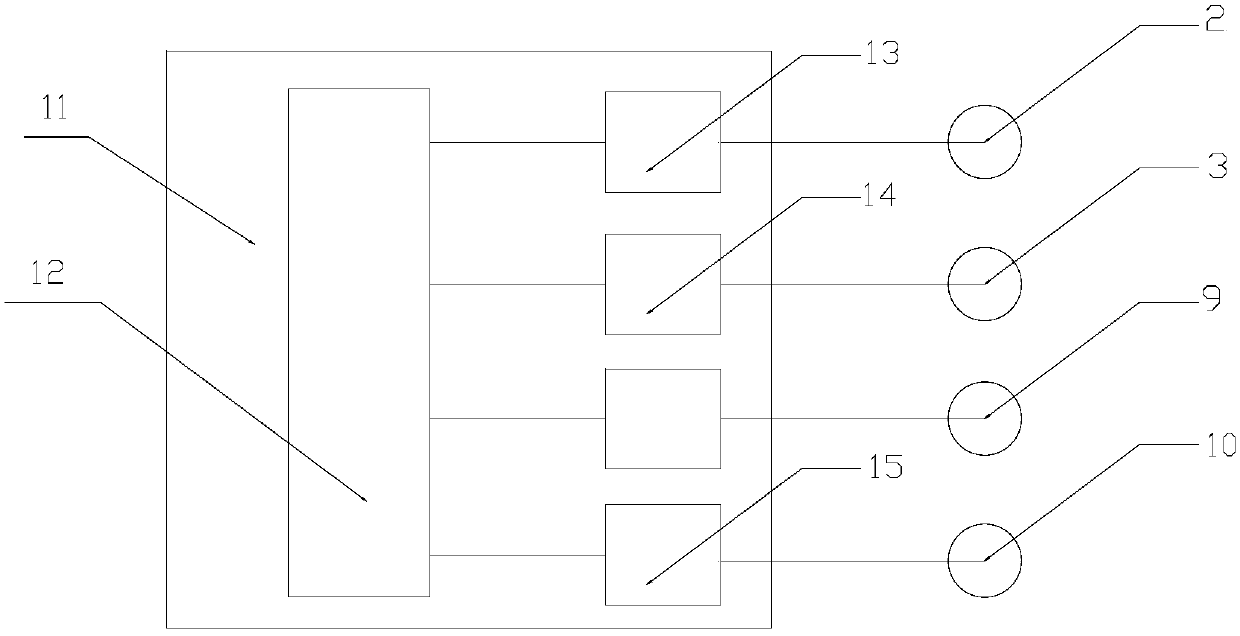

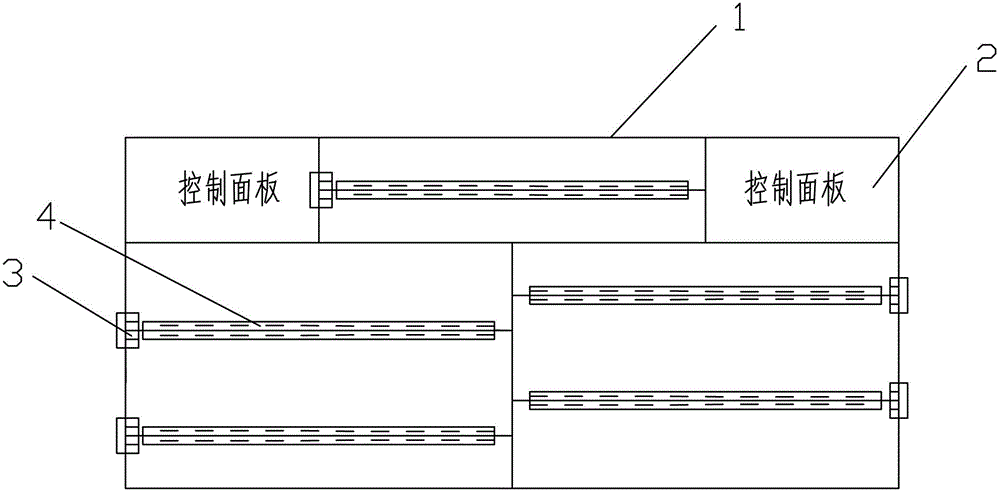

Circuit for controlling braider to work through opening and closing of drawer

InactiveCN103779738AAvoid opening drawers againSolve production inefficienciesCoupling device detailsPackagingStopped workElectrical resistance and conductance

The invention discloses a circuit for controlling a braider to work through opening and closing of a drawer. The circuit comprises the drawer (4), a socket (2) and a drawer plug (3), wherein the drawer plug (3) is arranged on a back baffle (1), the socket (2) is arranged on the corresponding surfaces of the drawer (4) and the back baffle (1), the drawer plug (3) comprises a plug first end and a plug second end which are connected with a current limit resistor serially, and a plug hole corresponding to the drawer plug (3) is formed in the socket (2). When the circuit enables the drawer to be opened, the braider stops working automatically, when the circuit enables the drawer to be closed, the braider continues to work, and workers do not need to stop the braider and open the drawer manually. Therefore, production efficiency is increased, and the circuit is convenient to use. Furthermore, the current limit resistor is arranged, so that the circuit is good in stability and safe and reliable.

Owner:CHENGDU ADVANCED POWER SEMICON +1

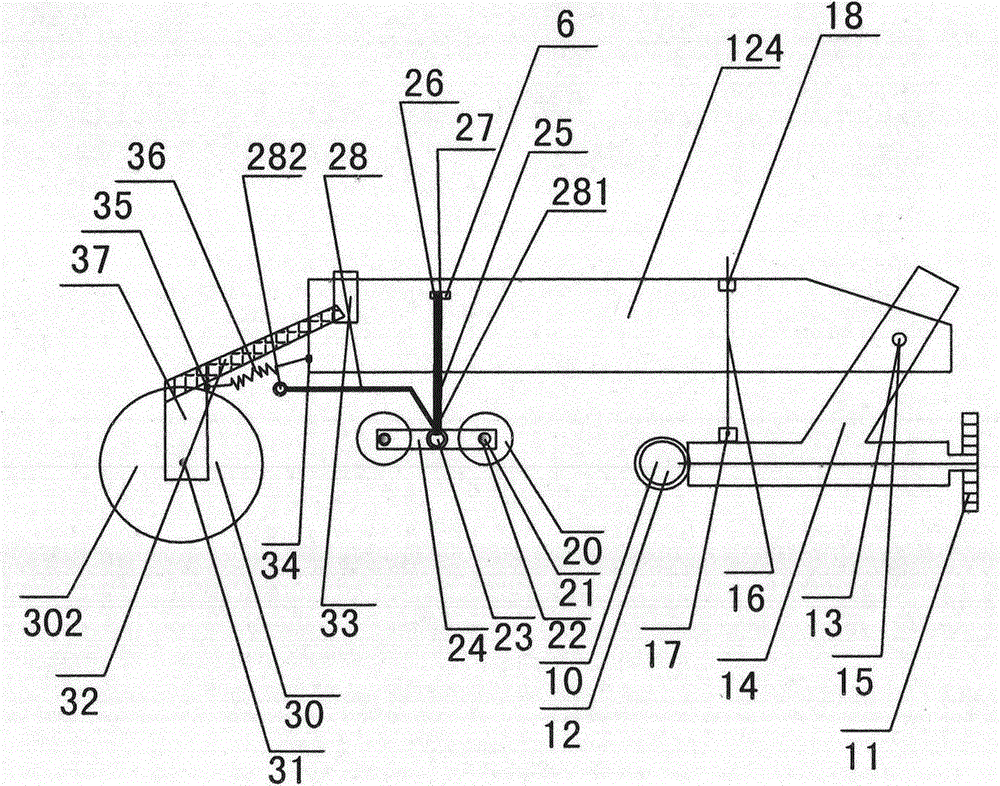

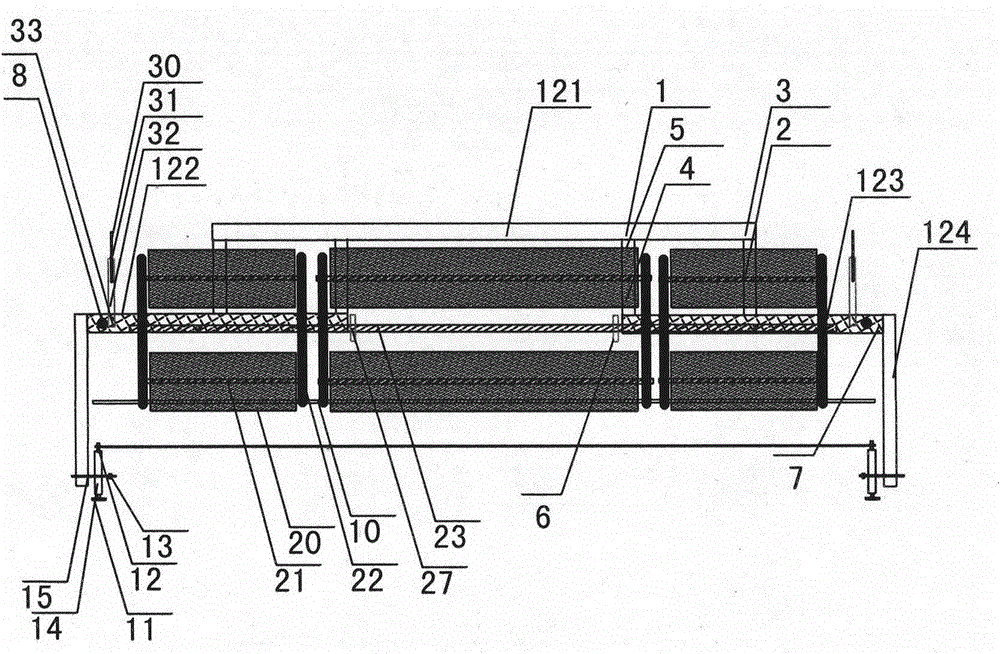

Paddy field film laminating machine with side pressing wheel

A paddy field film laminating machine with a side pressing wheel is used for cultivation of agricultural production. The paddy field film laminating machine with the side pressing wheel can quickly complete film laminating of paddy fields. A film laminating and transplanting integrated machine can be also produced in accordance with the technology to complete film laminating and transplanting at one time. The paddy field film laminating machine with the side pressing wheel is a major breakthrough in the field of farming. The rice film laminating technology completely solves one of the major problems of weeding in organic rice production due to the fact that herbicides, pesticides and chemical fertilizers can not be used in an organic rice production process. The existing rice film laminating technology can be only in the mode of manual or mechanical film laminating followed by manual transplanting, needs great efforts, is low in efficiency and seriously affects the industrialization cultivation of organic rice. The paddy field film laminating machine with the side pressing wheel is a film laminating and transplanting integrated machine provided with a film cutting knife assembly and solves the problem of low production efficiency of the prior art.

Owner:王威

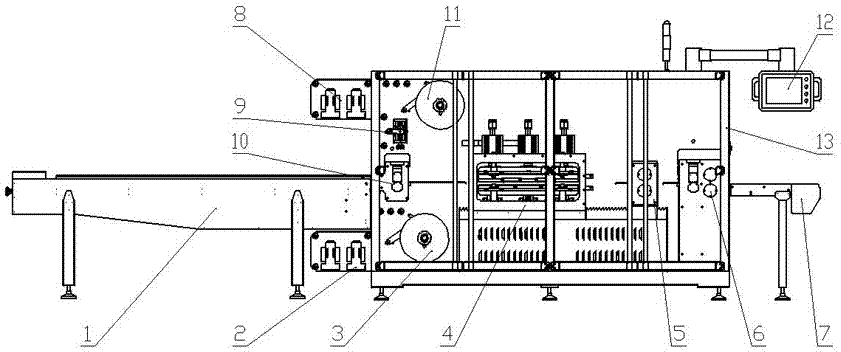

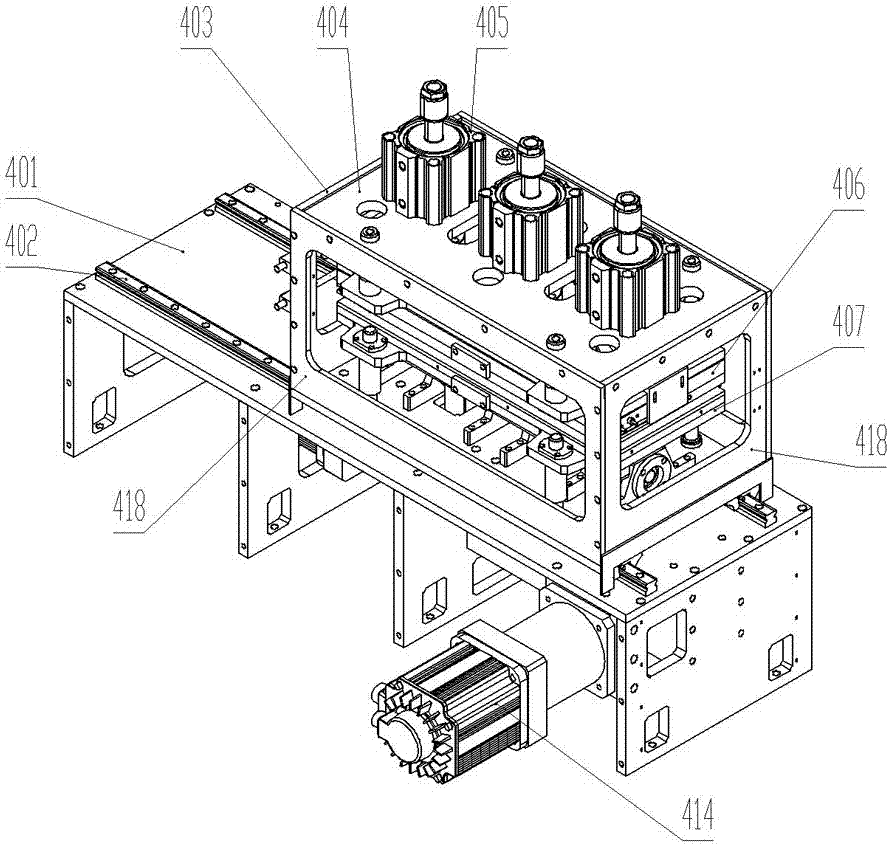

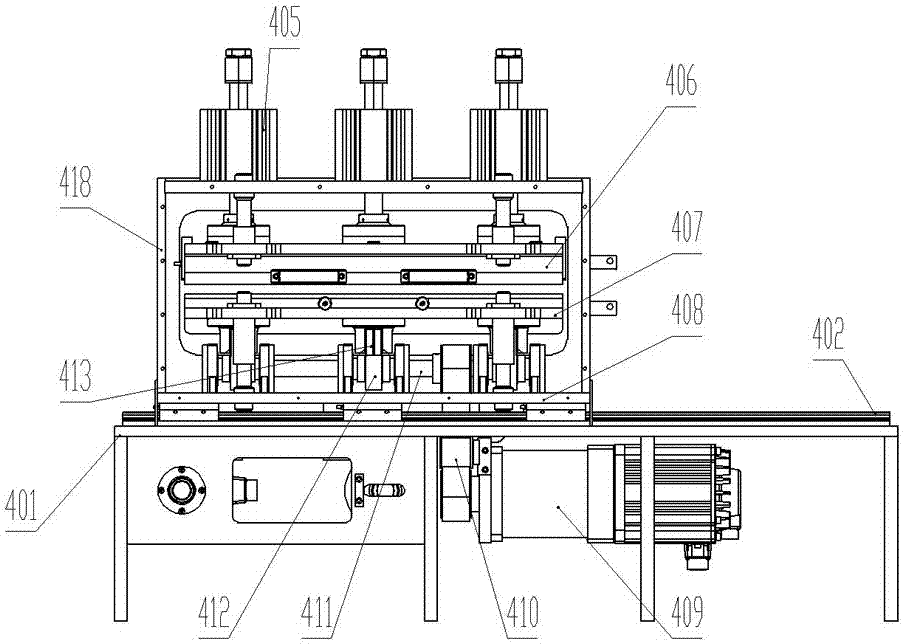

Full-automatic continuous four-side sealing packaging machine

InactiveCN106945886AGuaranteed heat sealing performanceExpanded range of specificationsWrapper twisting/gatheringMotor driveElectric machinery

The invention discloses a full-automatic continuous four-side sealing packaging machine. The full-automatic continuous four-side sealing packaging machine is characterized in that a heat sealing mechanism comprises a heat sealing frame and a heat sealing assembly; a second servo motor, a synchronous pulley I and a synchronous pulley II are arranged on the heat sealing frame; a synchronous belt II is wound on the synchronous pulley I and the synchronous pulley II; the second servo motor and the synchronous pulley I are linked; linear rails are further arranged on the heat sealing frame; the heat sealing assembly is provided with a top plate and a bottom plate; an upper module and a lower module are arranged between the top plate and the bottom plate; the bottom plate is mounted on sliding blocks of the linear rails; the synchronous belt II is linked with the bottom plate; a first servo motor is further fixedly mounted on the bottom surface of the bottom plate; a spindle is arranged on the top surface of the bottom plate; a plurality of eccentric wheels are arranged on the spindle at equal intervals; the first servo motor drives the spindle through a synchronous belt I; the upper module is connected with cylinders arranged on the top plate; and rollers which correspond to the eccentric wheels and are in contact with the eccentric wheels are arranged on the bottom surface of the lower module. According to the full-automatic continuous four-side sealing packaging machine, structure is simple, arrangement is convenient, the heat sealing effect is good, and continuous operation of the entire machine is achieved.

Owner:瑞安市华源包装机械厂

Cutting equipment for producing PVC pipes

PendingCN113400384ASolve production inefficienciesStable deliveryMetal working apparatusEngineeringTransfer mechanism

The invention relates to cutting equipment for producing PVC pipes. The cutting equipment comprises an extrusion device, a shaping device and a dragging device, wherein a cutting device is arranged at the tail end of the dragging device and comprises a bearing mechanism, a cutting mechanism arranged at the front end of the bearing mechanism, a transferring mechanism arranged at the tail end of the bearing mechanism and blanking mechanisms arranged on two sides of the bearing mechanism; the bearing mechanisms are used for bearing the PVC pipes conveyed on the dragging device; the cutting mechanism comprises a guide rail and a saw blade; the transferring mechanism comprises a baffle a and a baffle b; the PVC pipes abuts against the baffle a and the baffle b in the conveying process to drive the bearing mechanisms to move backwards, and meanwhile, the bearing mechanisms drive the saw blade to move backwards along the guide rail to cut the PVC pipes; the transferring mechanism is used for transferring the cut PVC pipes to the blanking mechanism in a translation manner; and the blanking mechanism is used for stroking the cut PVC pipes down from the transferring mechanism. Through the cutting equipment for producing the PVC pipes, the problems that machined notches are uneven, the cutting efficiency is low and the labor cost is high are solved.

Owner:浙江都达新材料科技有限公司

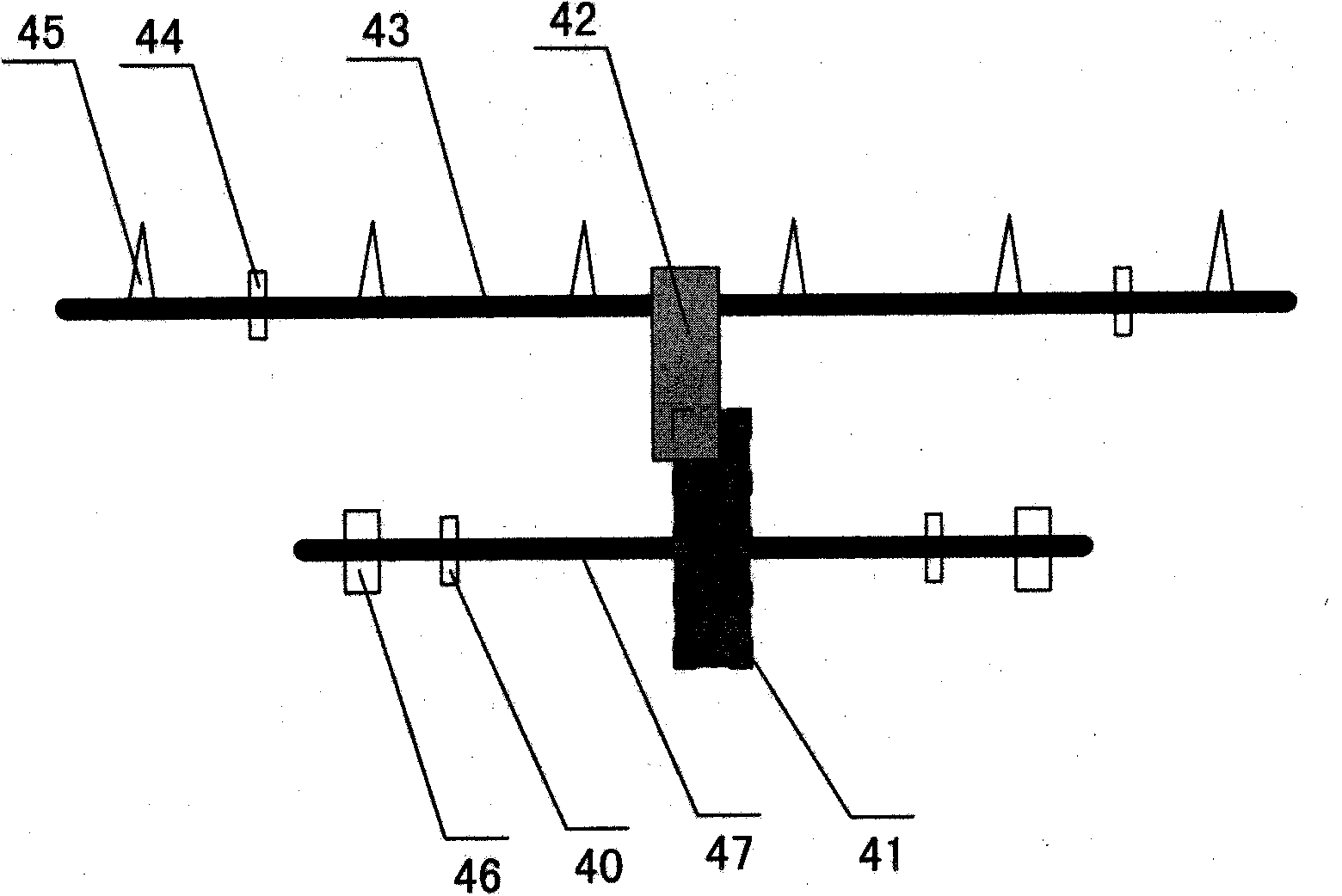

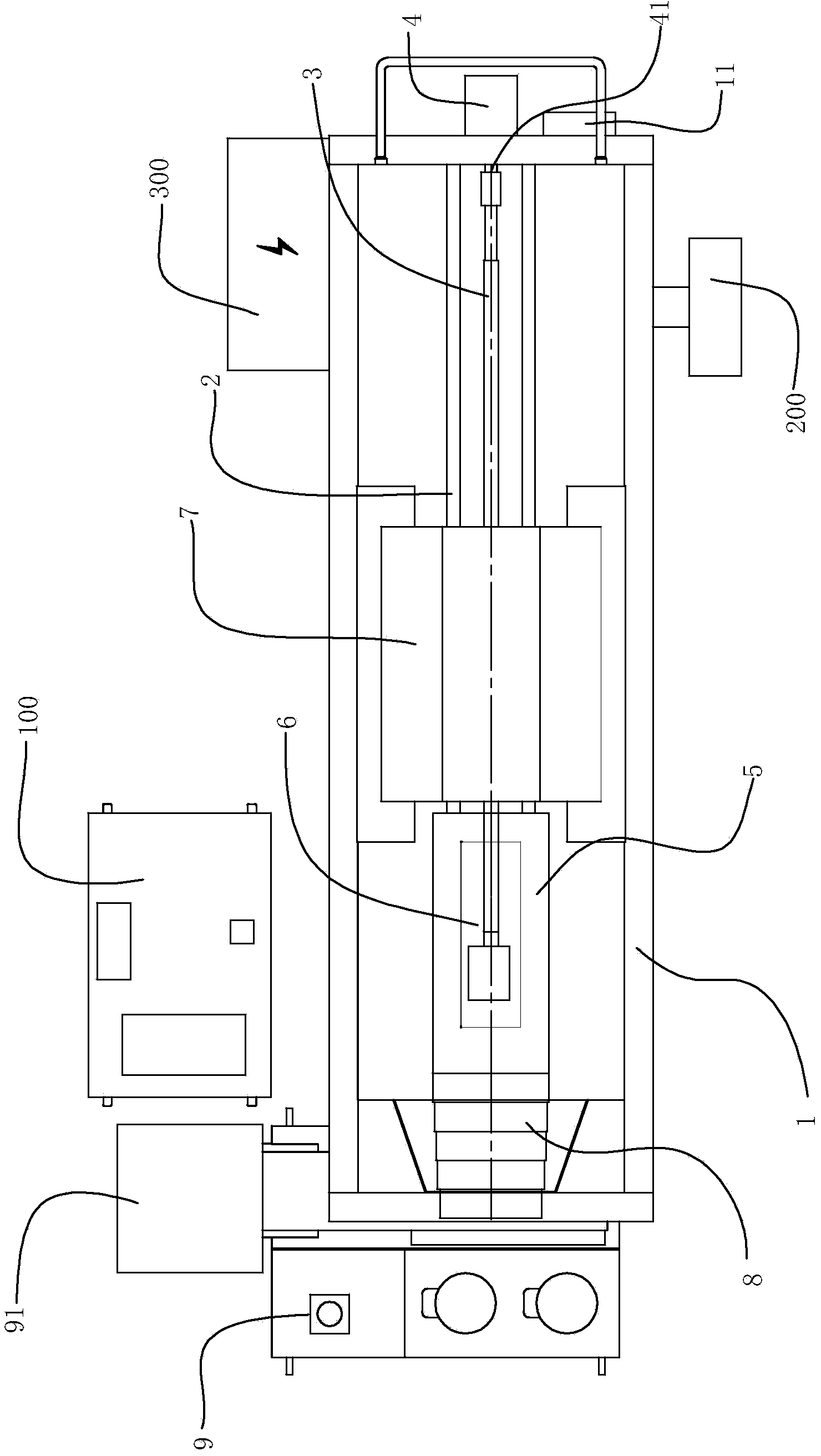

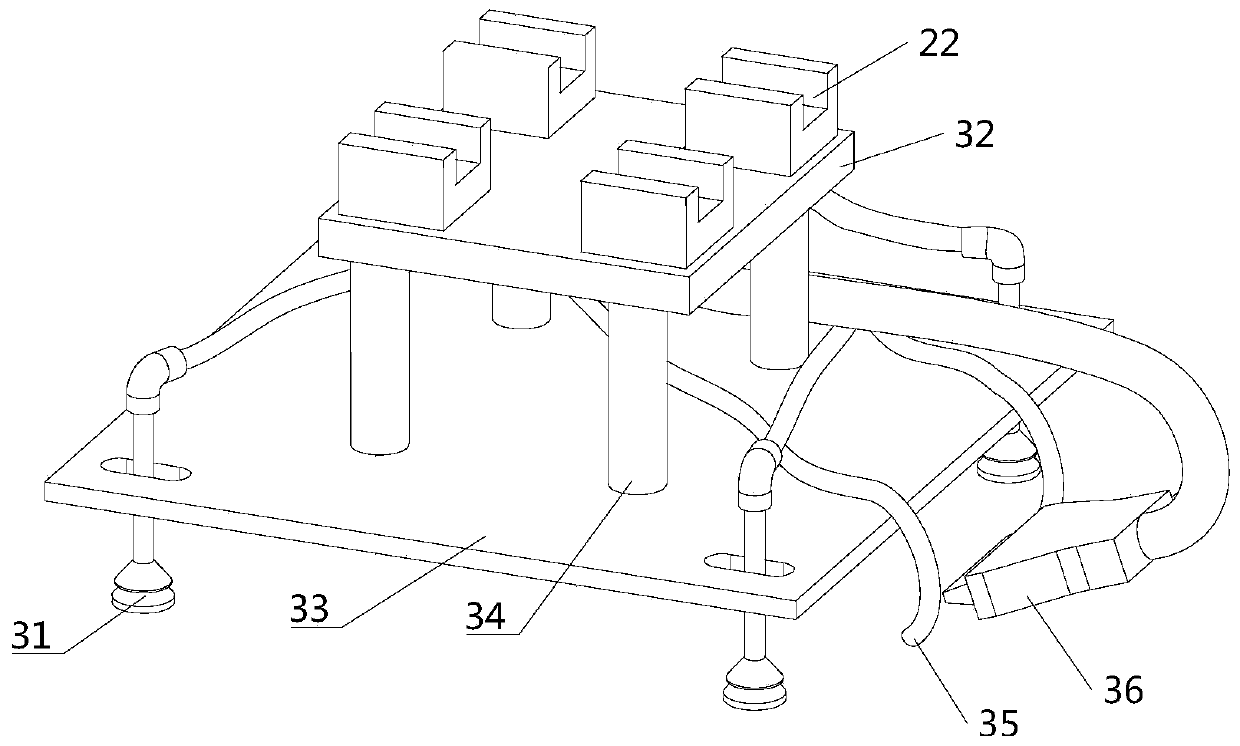

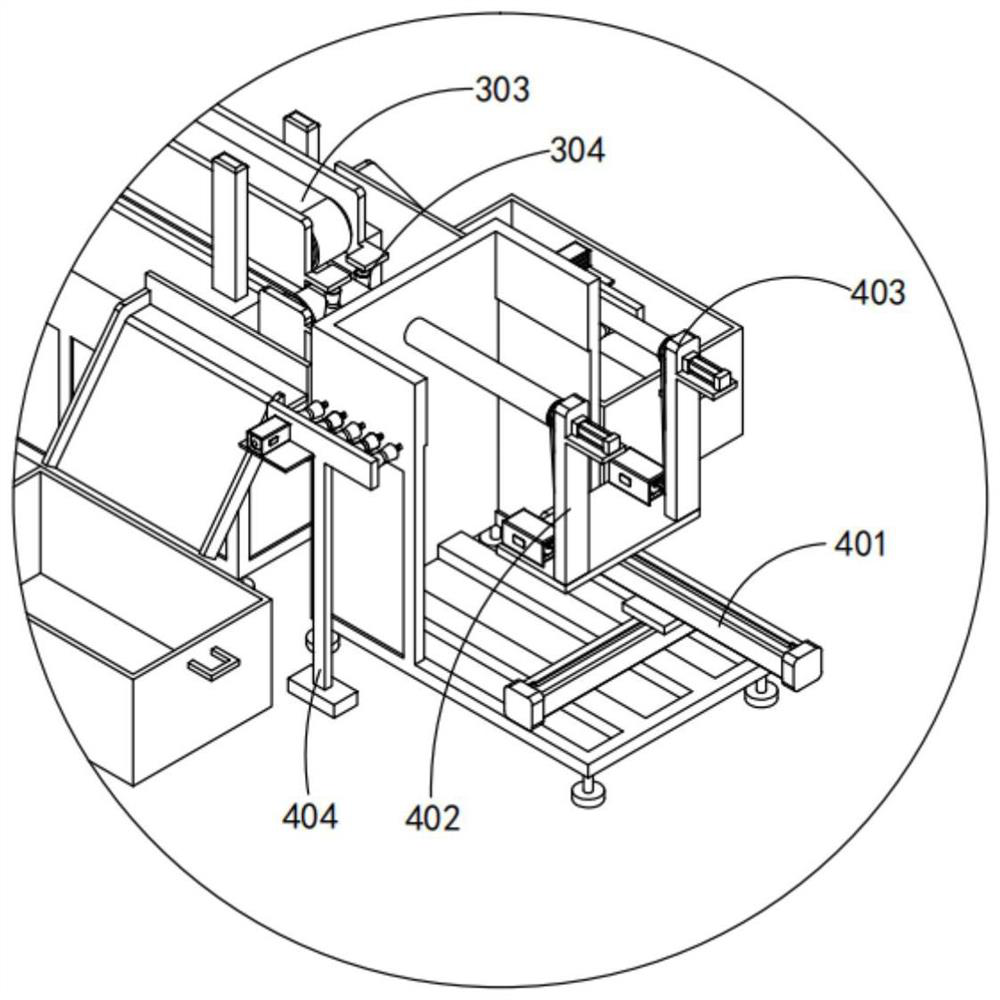

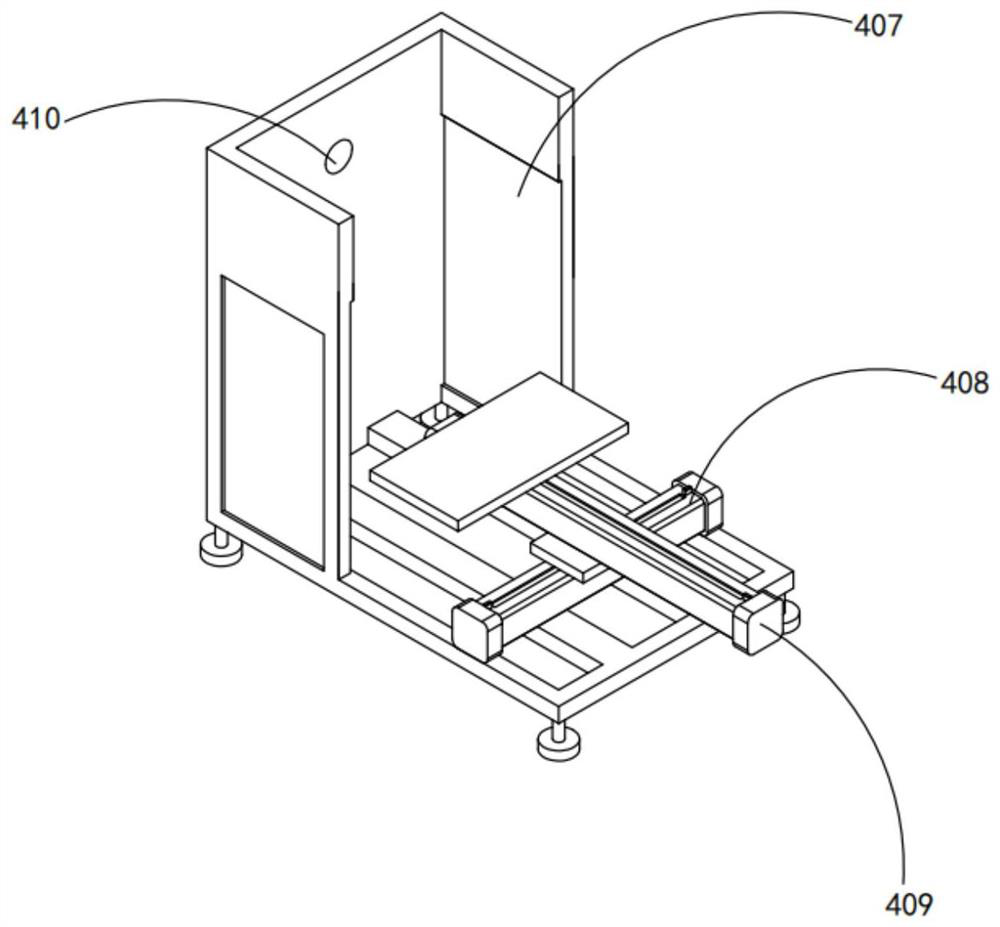

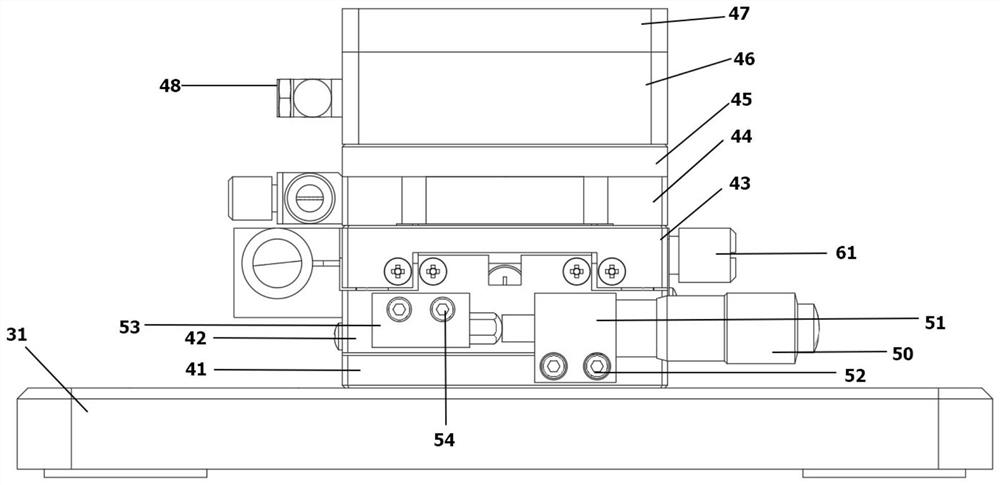

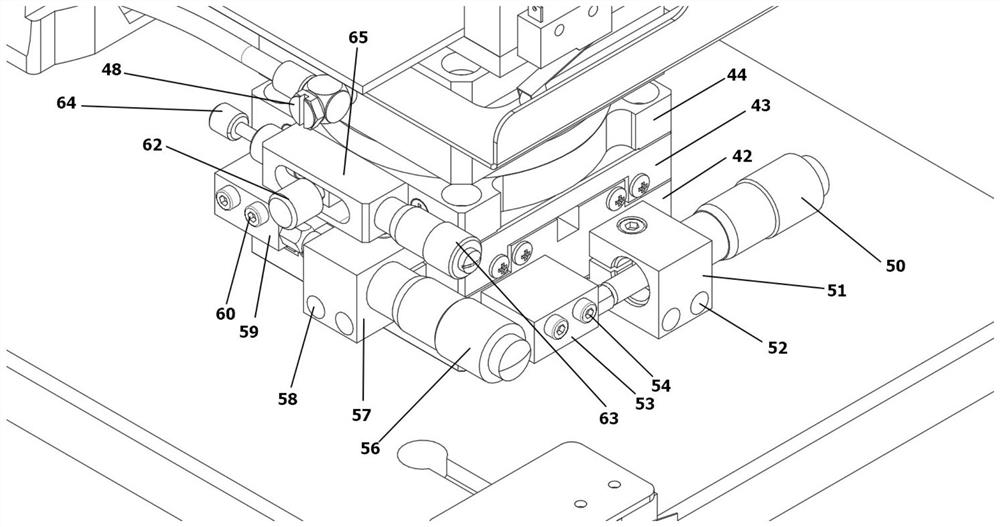

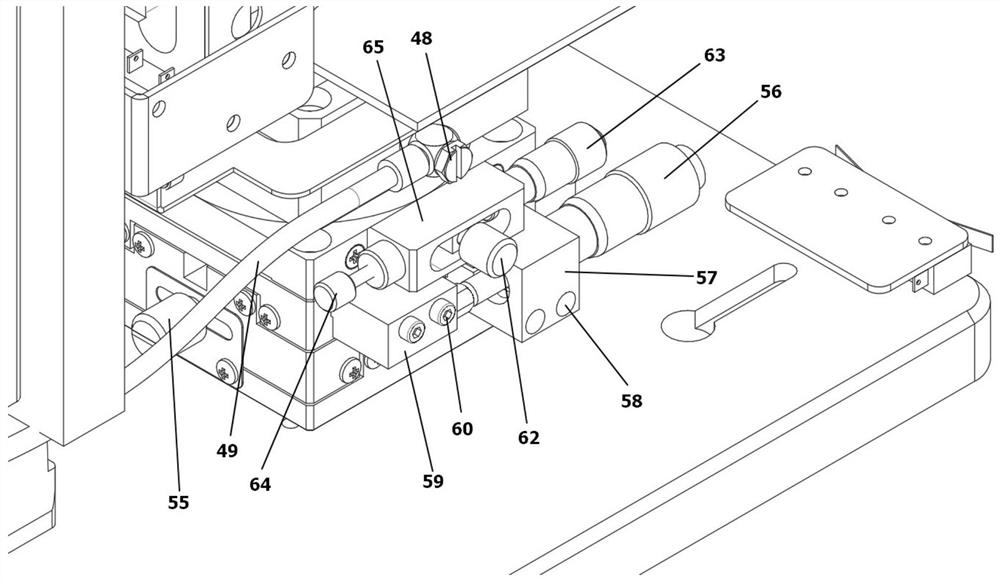

Test platform of flash memory chip

PendingCN112881893AAvoid physical exertionIncrease profitElectronic circuit testingMeasurement instrument housingPower efficientMachine

The invention relates to a test platform of a flash memory chip, and the test platform is characterized in that: the test platform sequentially comprises a test working face (47), a vacuumizing assembly (46), a horizontal rotating sliding block (45), a horizontal rotating outer frame (44), a front-back moving sliding block (43), a left-right moving sliding block (42), a test platform base (41) and a test machine base (31) from top to bottom. According to the test platform, electric equipment is adopted, physical power consumption of hand-cranking lifting of an operator is solved, the problems of high speed, low speed, yield fluctuation and efficiency loss of manual operation are also solved, and the equipment utilization rate is greatly improved.

Owner:深圳市卓然电子有限公司

High-efficiency embroidering, printing and dyeing integrated machine for silk fabric

PendingCN107558032ASolve production inefficienciesSimple structureTypewritersAutomatic machinesEngineeringMechanical engineering

The invention discloses a high-efficiency embroidering, printing and dyeing integrated machine for silk fabric. The high-efficiency embroidering, printing and dyeing integrated machine is provided with a rack; two linear electric cylinders are arranged on the rack in parallel and are used for respectively mounting a swing embroidery machine and a swing spraying, printing and dyeing machine; two winding rollers are arranged at the middle part of the rack and are driven by a feeding motor to rotate for enabling the silk fabric to pass through the lower parts of the swing embroidery machine and the swing spraying, printing and dyeing machine; the swing embroidery machine is used for embroidering the silk fabric by an embroidery needle head; the swing spraying, printing and dyeing machine is used for spraying and printing the silk fabric by a printing and dyeing spraying head; the swing embroidery machine, the swing spraying, printing and dyeing machine and the two winding rollers are arranged and are controlled by an analysis processing module to sequentially embroider, print and dye, thereby improving production efficiency and economic benefits of the silk fabric, and solving the problem that the production efficiency is low as a current production device for the silk fabric only performs singly embroidery or printing and dyeing. Therefore, the high-efficiency embroidering, printing and dyeing integrated machine has good practical value.

Owner:SUQIAN JIUJIU WIRE

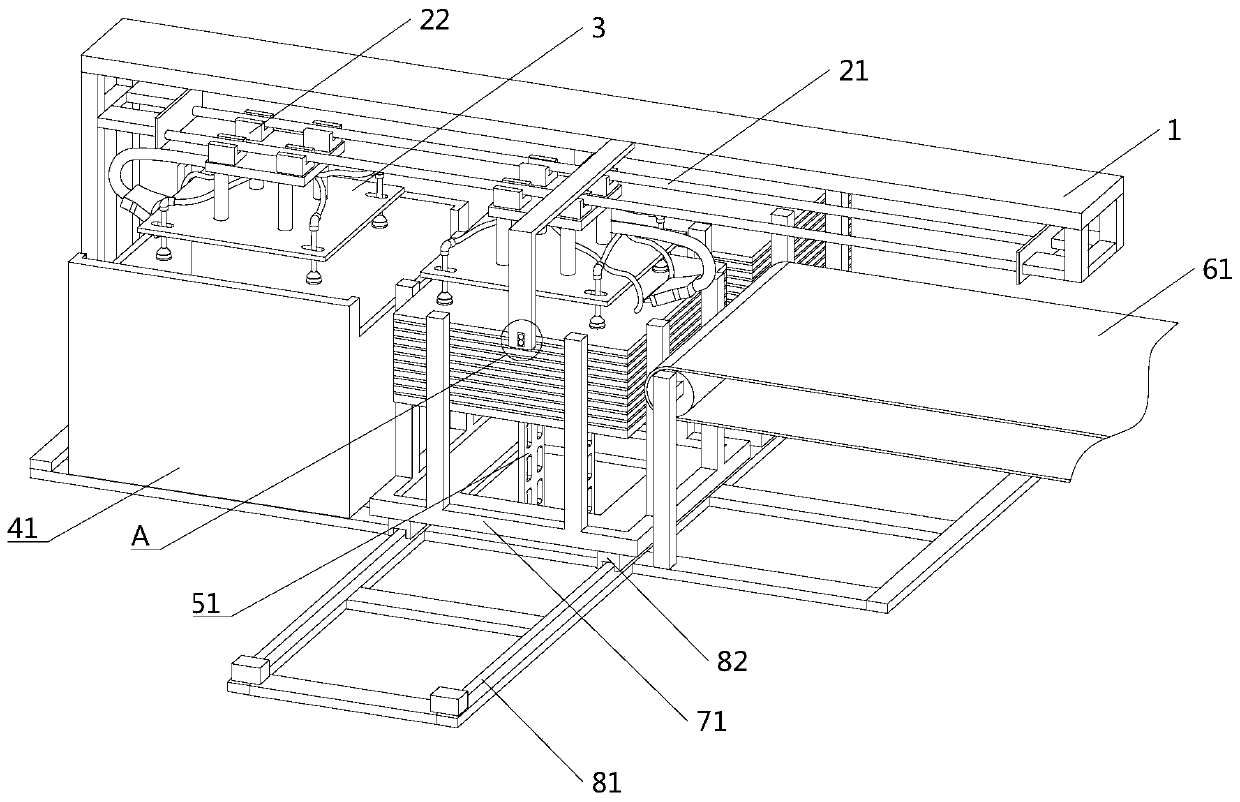

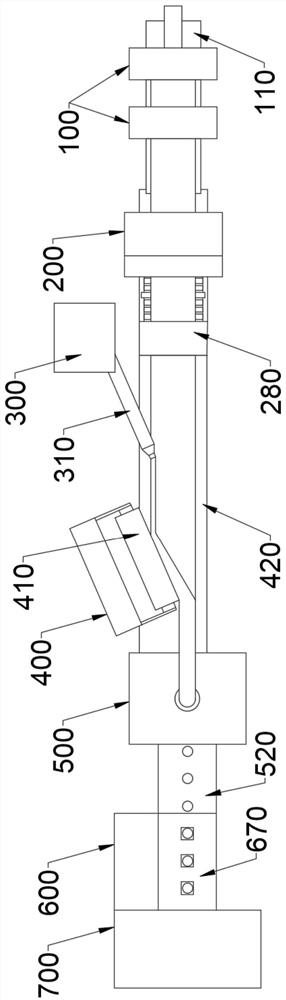

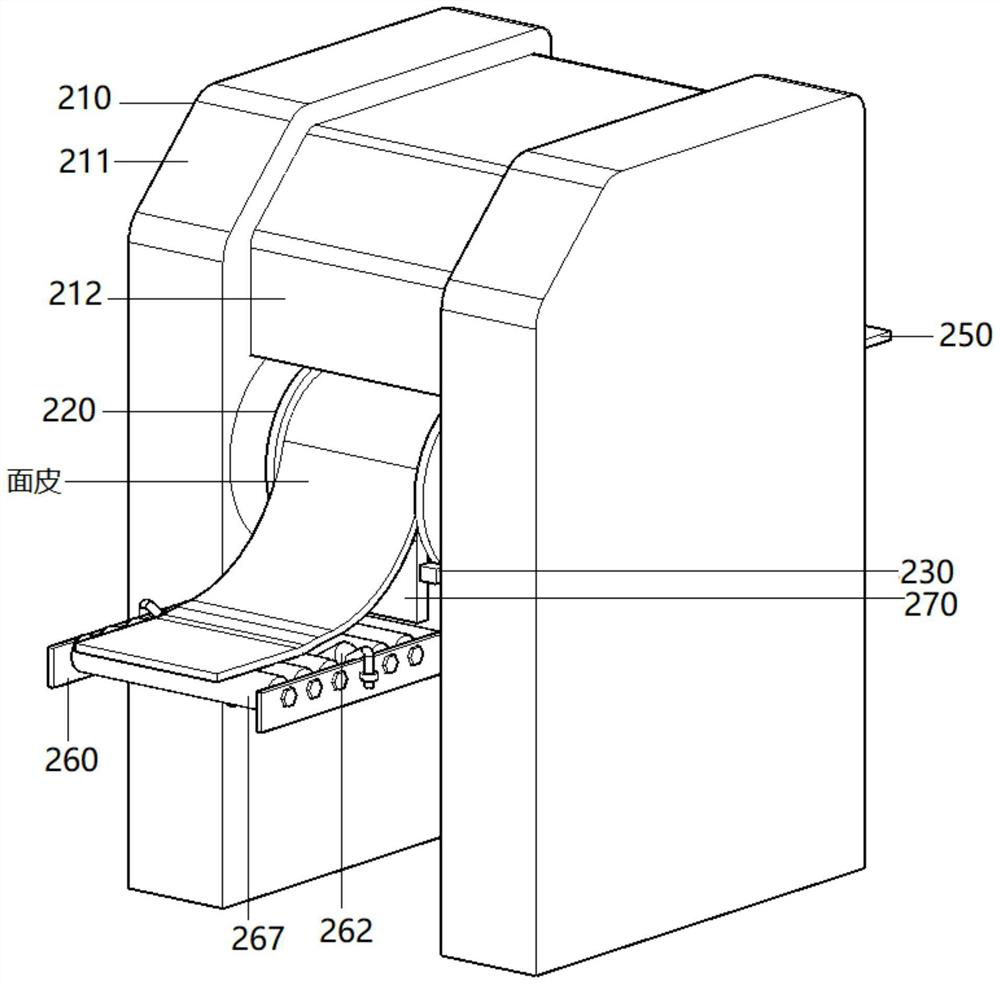

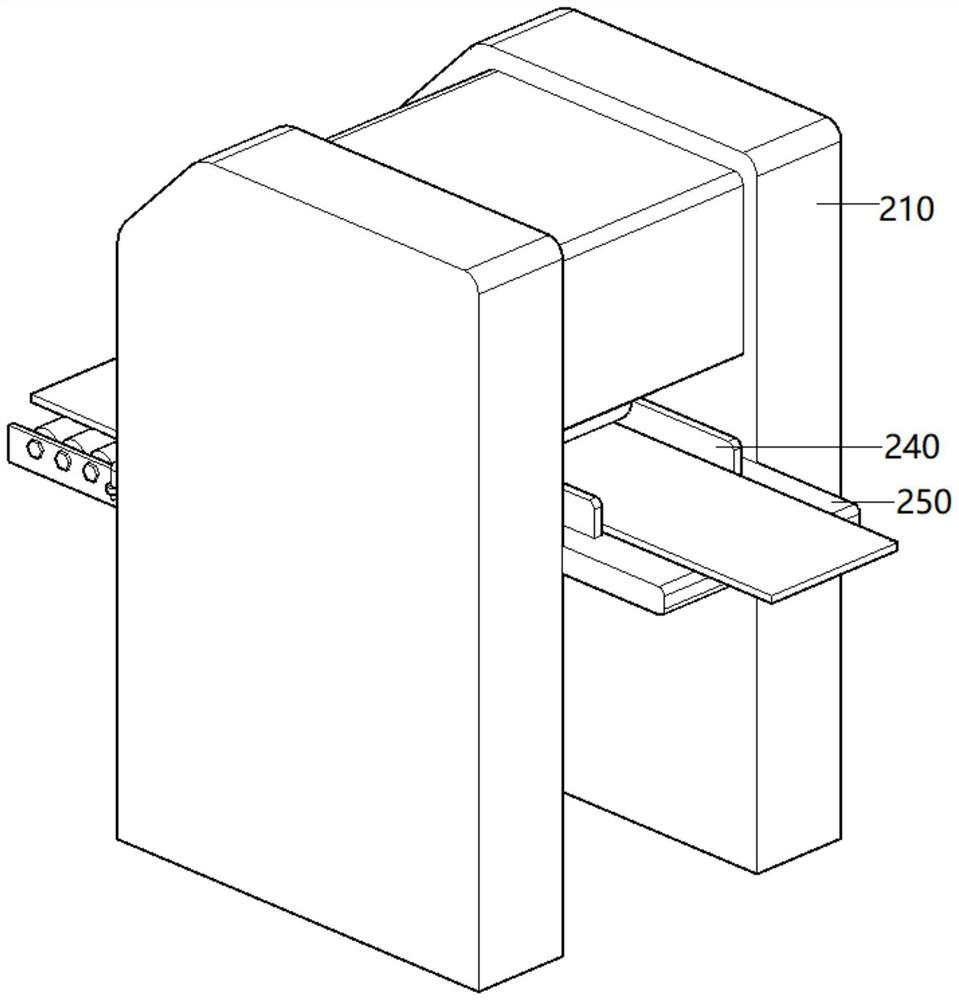

Bag point forming production line

ActiveCN114223681AReduce manual operationsIncrease productivityDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusControl systemProcess engineering

The invention relates to the technical field of food processing equipment, in particular to a steamed stuffed bun forming production line which comprises a dough pressing machine, a dough kneading machine, a stuffing injection machine, a stuffing wrapping machine, a forming cutting machine, an automatic paper packing machine, an automatic tray arranging machine and an integrated control system. The integrated control system comprises a dough kneading controller; the dough kneading machine comprises a device main body, a dough kneading device and a sensor; the device main body is provided with a dough kneading cavity, and the dough kneading cavity is provided with a dough outlet and a dough inlet; the dough kneading device is used for pressing the wrappers entering from the dough inlet and then conveying the wrappers to the dough outlet; the sensor is electrically connected with the dough kneading controller and is used for sending a sensing signal to the dough kneading controller when sensing that an object appears in a preset range; the dough kneading controller is connected with the dough kneading device and is used for controlling the dough kneading device to stop when the sensing signal is received and controlling the dough kneading device to start when the sensing signal is not received. The technical problem that the production efficiency is low due to the fact that wrappers or wrapping points are easy to accumulate in the production process of existing equipment is effectively solved.

Owner:GUANGZHOU RESTAURANT GRP LIKOUFU FOOD +1

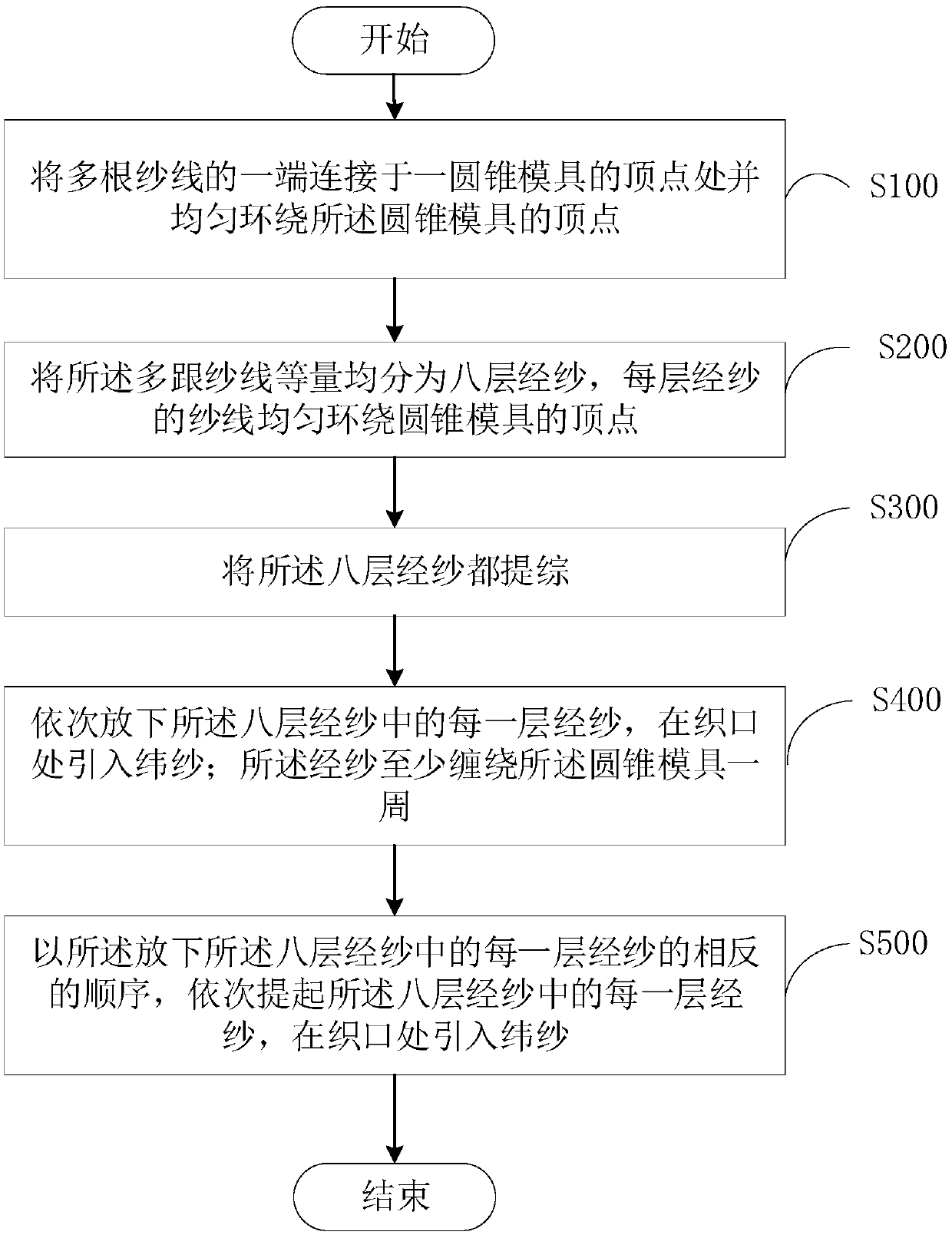

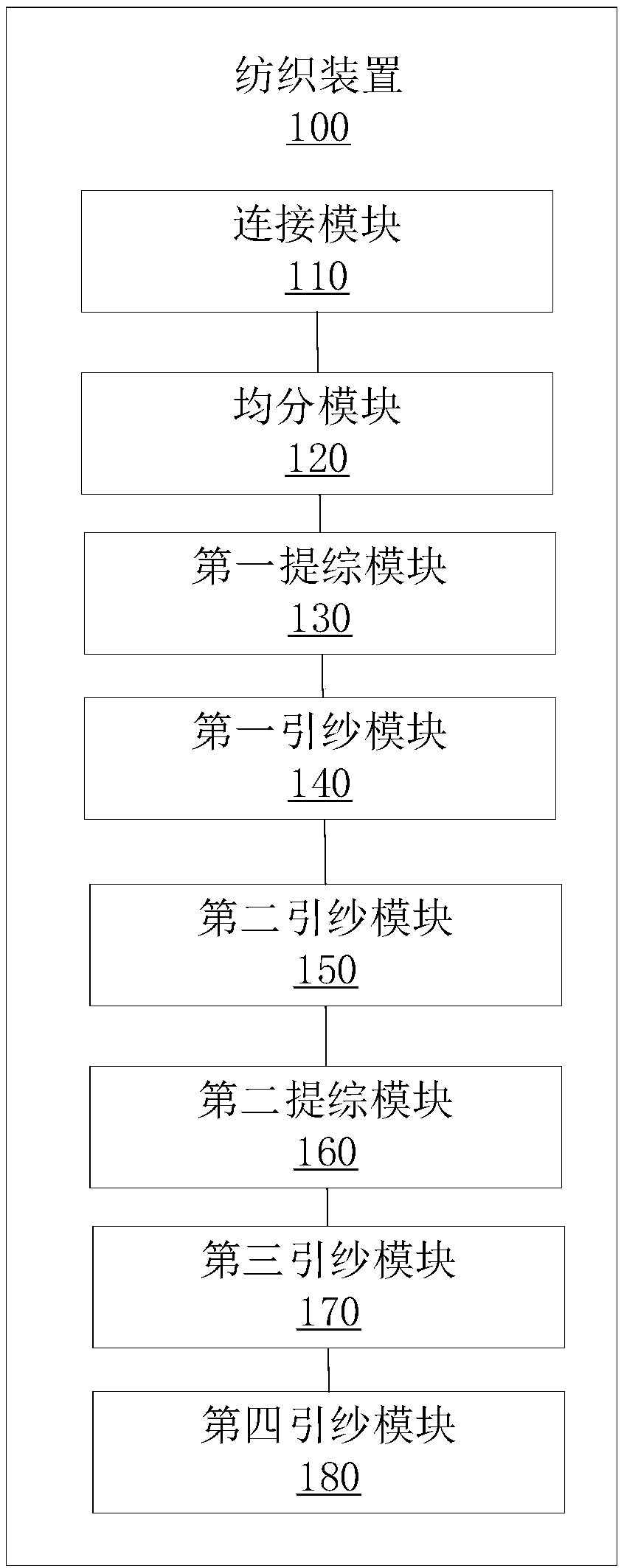

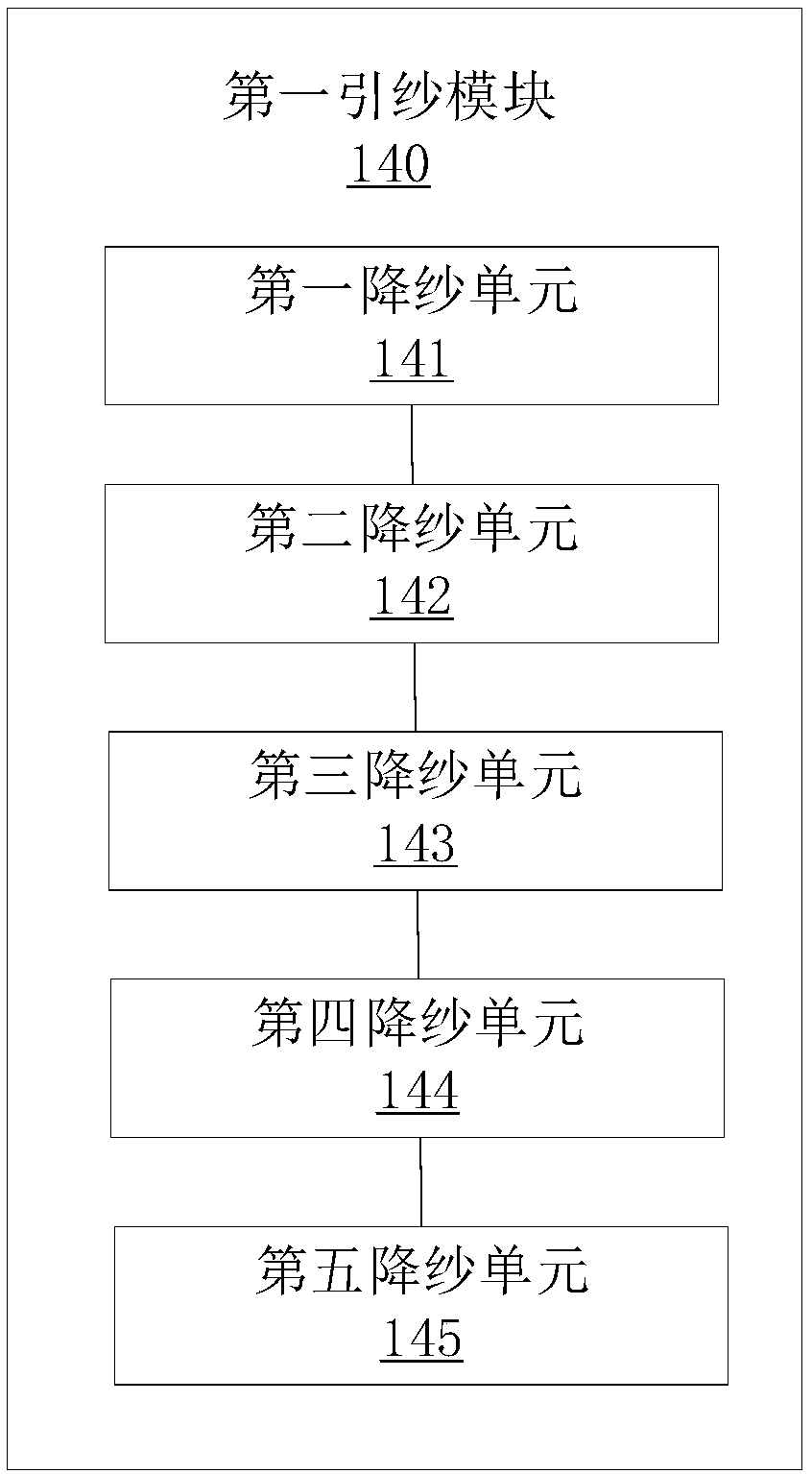

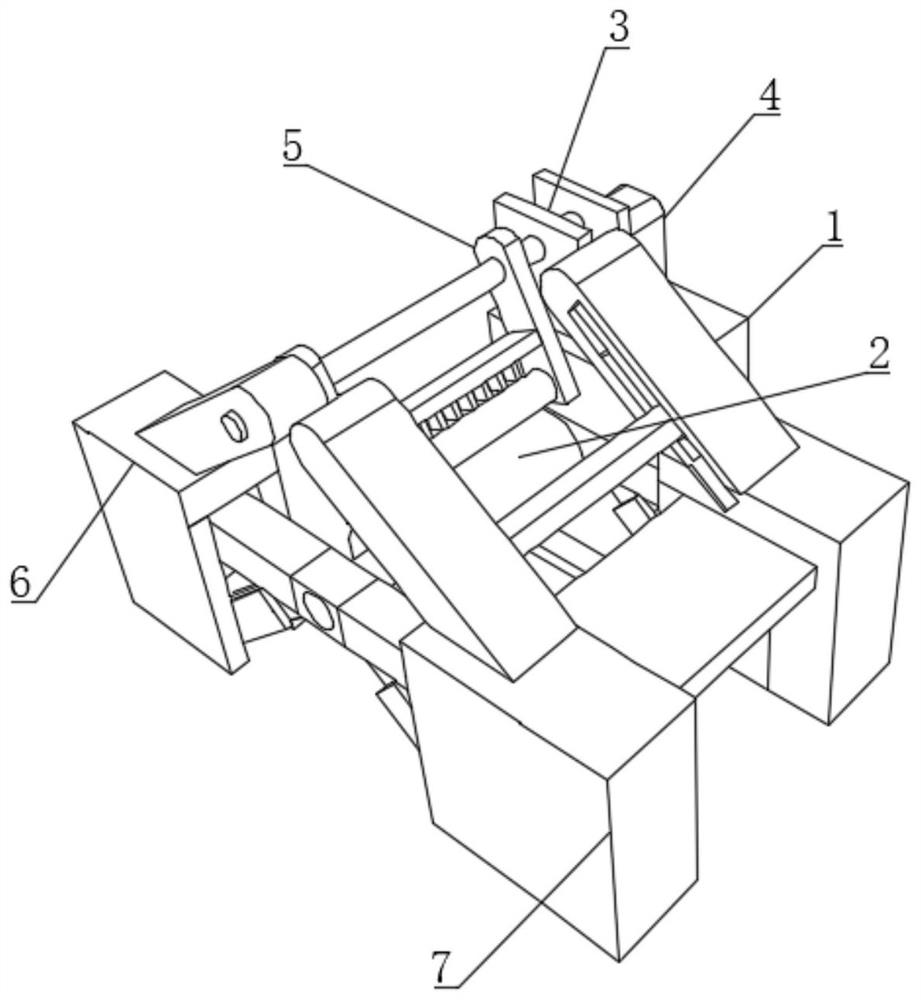

Textile method and device

InactiveCN108677352ASolve production inefficienciesQuality assuranceLoomsWoven fabricsYarnReverse order

An embodiment of the invention provides a textile method, and relates to the field of textiles. The method includes the steps: laying a plurality of yarns at the peak of a conical die and uniformly surrounding the peak of the conical die; equivalently dividing the yarns into eight layers of warp yarns and enabling the yarns on each layer of warp yarns to uniformly surround the peak of the conicaldie; lifting healds of the eight layers of warp yarns; sequentially laying down each layer of warp yarns and leading in weft yarns at a cloth fell position; at least winding the weft yarns on the conical die by one circle; sequentially lifting each layer of warp yarns according to a sequence opposite to the sequence of laying down each layer of warp yarns, and leading in weft yarns at the cloth fell position. By multilayer repeated leading and interweaving, the problem of low production efficiency of special-shaped fabrics such as conical three-dimensional fabrics is effectively solved, and the quality of the fabrics is effectively ensured.

Owner:WUHAN TEXTILE UNIV

Method for Feed for artificially raising Dastarcus helophoroides in large scale

The invention provides a feed for artificially raising Dastarcus helophoroides in a large scale and a matched breeding technology of the feed. The invention discloses the feed for artificially raising the Dastarcus helophoroides in the large scale. The feed is prepared by taking yellow mealworm larva dry powder, barley pest larva dry powder and sterile water as raw materials and matching with various amino acids, linoleic acid and glucose; and the preparation manner is simple, raw materials are cheap and are easily available, and the feed has high economic value. Meanwhile, the invention further discloses the matched breeding technology of the feed for artificially raising the Dastarcus helophoroides in the large scale; the feed is matched with a preservation box and de-greased cotton to carry out hatching operation of the Dastarcus helophoroides; an artificial weather box is matched to obtain a shorter breeding period when being compared with the prior art; and meanwhile, high mature larva survival rate can be obtained.

Owner:NANJING FORESTRY UNIV +2

Coating roller replacing device of strip steel production line

ActiveCN114308520AEasy to replaceEasy to storeLiquid surface applicatorsCoatingsElectric machineryStrip steel

The invention discloses a coating roller replacing device of a strip steel production line, and relates to the technical field of strip steel production, the coating roller replacing device comprises a transmission mechanism, one side of the transmission mechanism is movably connected with a conveying roller, the top of the transmission mechanism is fixedly connected with a supporting frame, and one side of the supporting frame is fixedly connected with a first motor; the first motor extends to the outside of the supporting frame, and the outer surface of an output shaft of the first motor is fixedly connected with a smearing mechanism. Through cooperation of a telescopic rod and a cleaning rod, the telescopic rod controls the cleaning rod to move within the range of a third sliding groove, so that a cleaning brush makes contact with the outer surface of the coating roller, paint and other substances adsorbed on the outer surface of the coating roller are conveniently cleaned, and meanwhile the area for cleaning the coating roller is enlarged through an arc-shaped plate; and the rubber pad is convenient for reducing friction force during rotation of the coating roller and uniformly removing impurities such as anti-rust oil adsorbed on the outer surface of the coating roller, so that the problem that the coating roller cannot be cleaned and the yield of strip steel is influenced is solved, and the effect of cleaning the coating roller is achieved.

Owner:DEQING JIUGANG METAL PROD

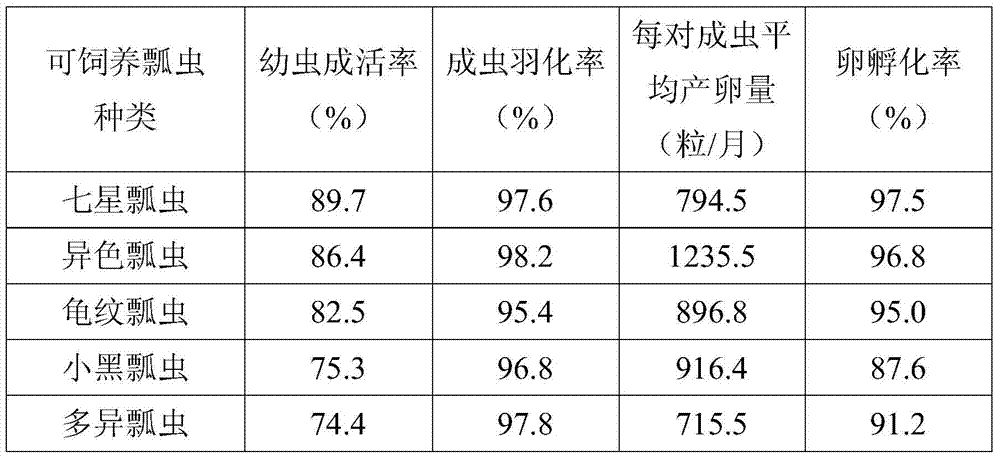

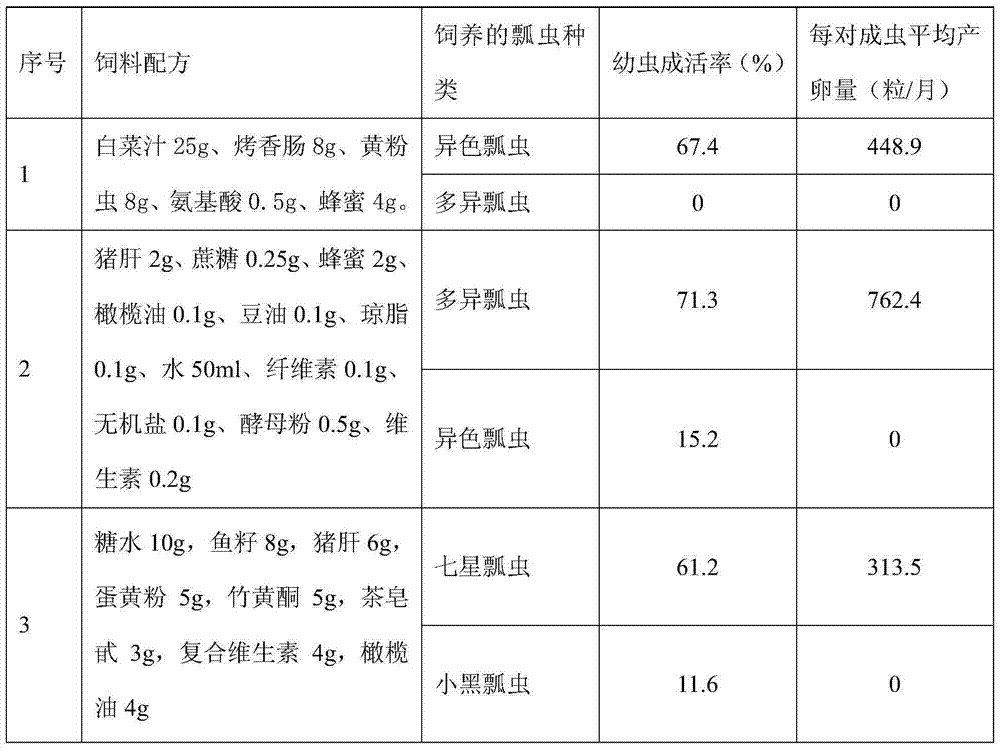

A kind of universal artificial feed for ladybugs and its preparation and application method

ActiveCN104642792BNutritional diversityLow priceAnimal feeding stuffAccessory food factorsBiotechnologyArtificial rearing

Owner:LIUYANG BRANCH OF CHANGSHA COMPANY OF HUNAN TOBACCO +2

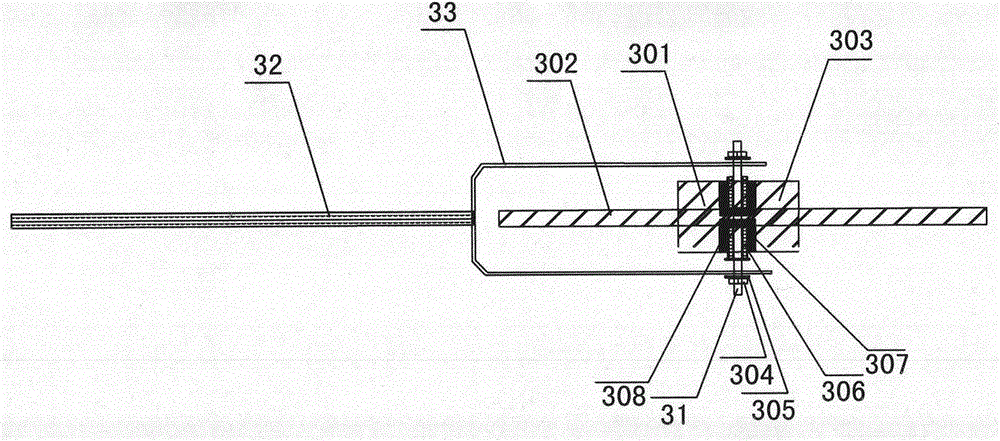

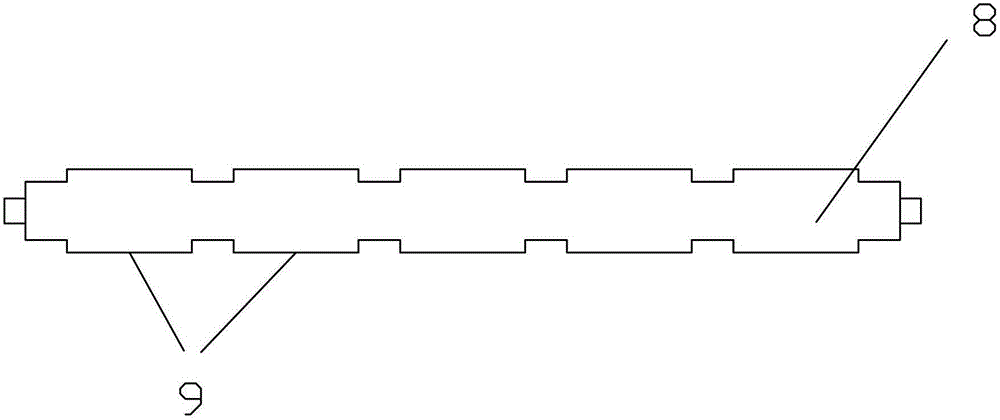

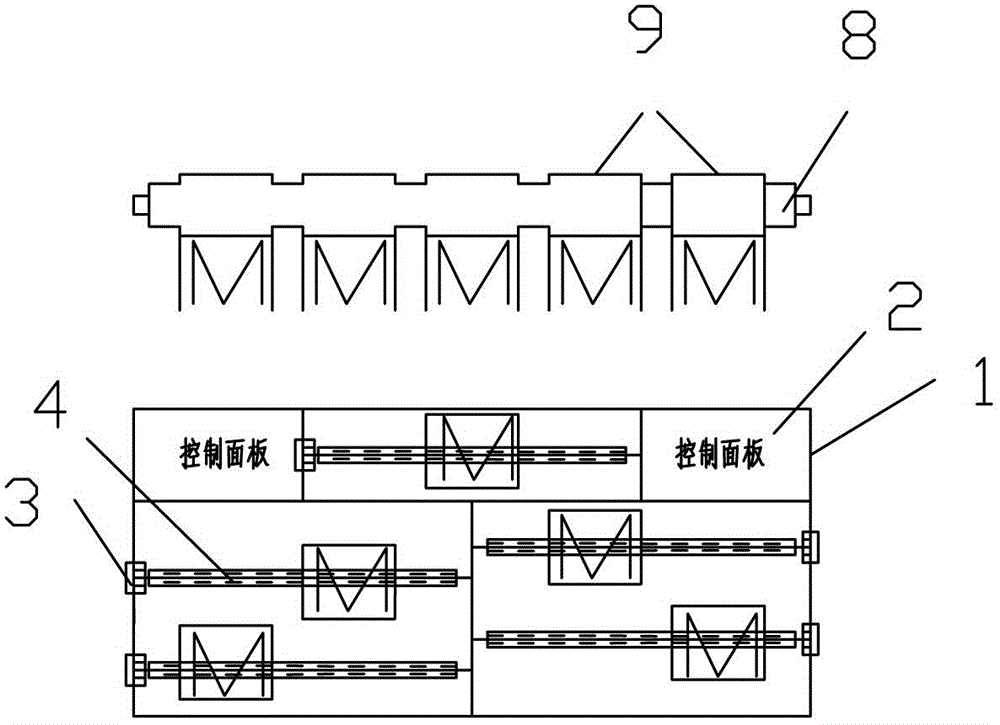

A centered air-permeable composite film centered unwinding device and its processing method

InactiveCN103112742BSolve production inefficienciesOvercoming the poor control of unwinding tensionLamination ancillary operationsLaminationComposite filmEngineering

The invention discloses a centered breathable composite film centered unwinding device and a processing method thereof. The device comprises a rack, a control panel, an actuator and more than one unwinding inflatable short shaft are mounted on the rack, and the control panel is connected with the actuator which is connected with the unwinding inflatable short shafts. The centered breathable composite film centered unwinding device and the processing method thereof solve the problem of low production efficiency of centered composite film production equipment, centered composite film production can be realized to the greatest extent on a small occupied area, and the defect of poor unwinding tension control caused by nonuniform surface tension due to winding diameter changes and contractility of a plastic thin film during winding of the plastic thin film when multiple centered composite films are produced synchronously is overcome.

Owner:马勇强

High-efficiency reducing furnace electrode repairing method

InactiveCN110923692ASolve production inefficienciesImprove cleanlinessPressure inorganic powder coatingMachiningBonding strength

The invention discloses a reducing furnace electrode repairing method. The reducing furnace electrode repairing method comprises the following steps that firstly, cleaning and grinding treatment is conducted on the surface of a to-be-repaired area on a reducing furnace electrode; secondly, inert gas is used for loading to-be-sprayed particles, and after heating is conducted to 200-800 DEG C, the to-be-sprayed particles are sprayed to the surface of the to-be-repaired area; and thirdly, mechanical machining is conducted on a reducing furnace electrode surface coating according to the actual usage size, and a repaired reducing furnace electrode is obtained. According to the reducing furnace electrode repairing method, a repairing body can be dense, and the bonding strength between the repairing body and an electrode base body material is high; based on the electrode component shape, the electrode material deposition precision can be optimized by controlling the nozzle size, spraying parameters, tracks and the like, and the subsequent machining amount is reduced; the thickness and the shape of the repairing body are not limited, and the reducing furnace electrode repairing method canbe used for repairing of electrodes different in damage degree; applicable materials are wide, a base body and the coating can be repaired at the same time, and efficiency is high; and the spraying process is simple, heat treatment is not needed, cost is low, and the production efficiency is high.

Owner:GUANGDONG INST OF NEW MATERIALS

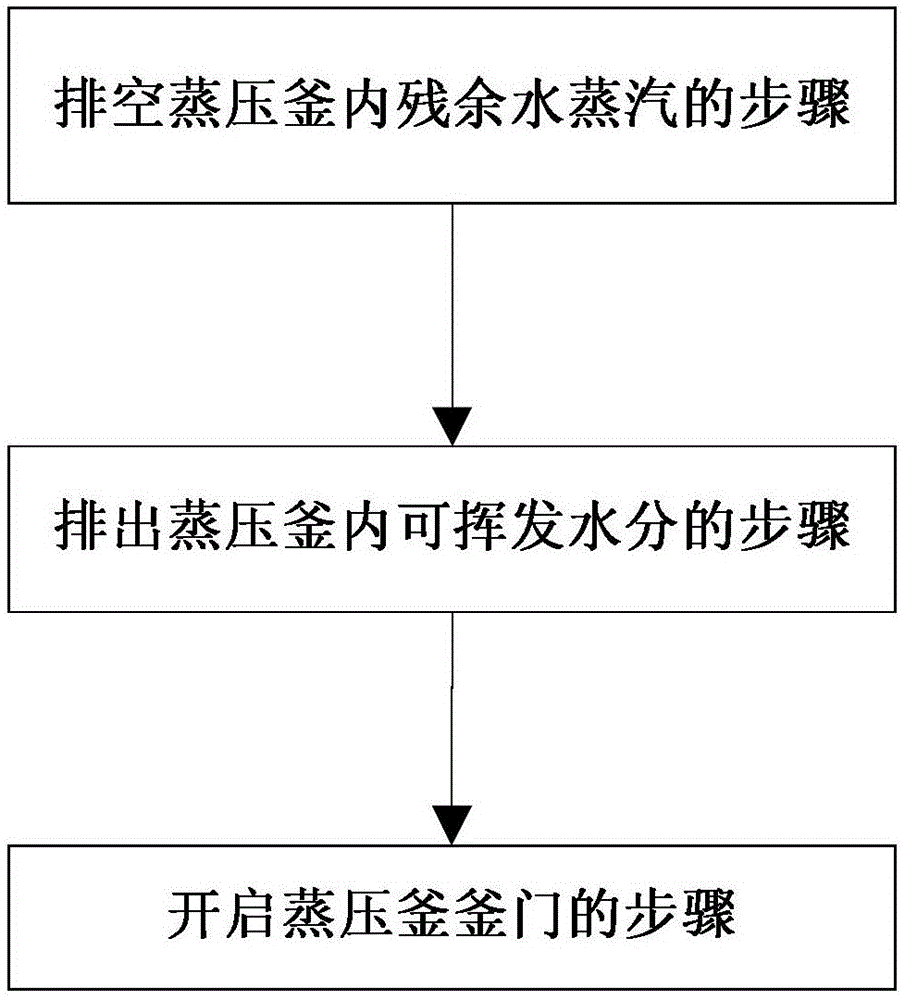

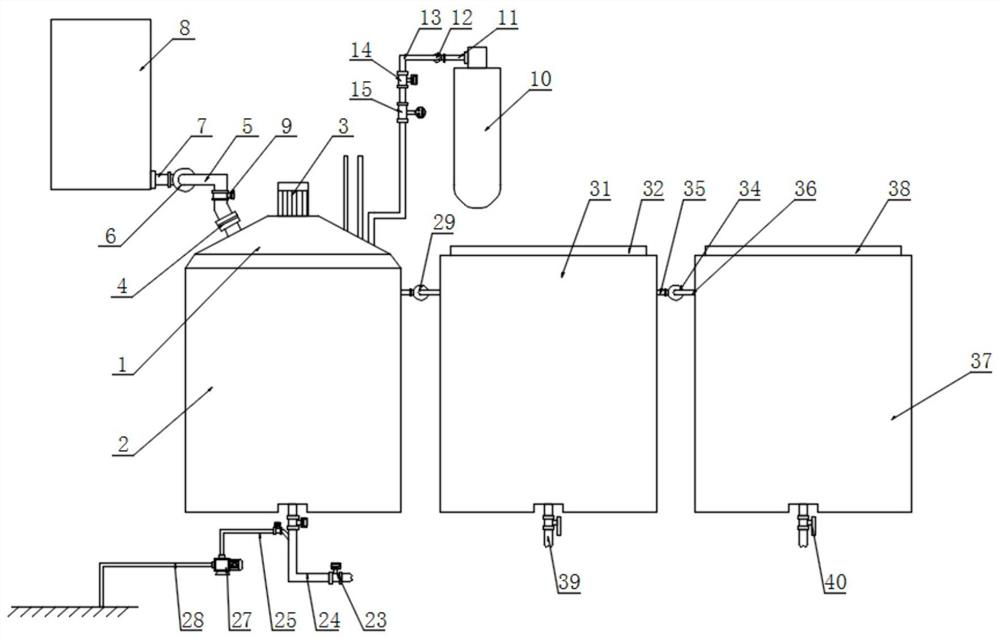

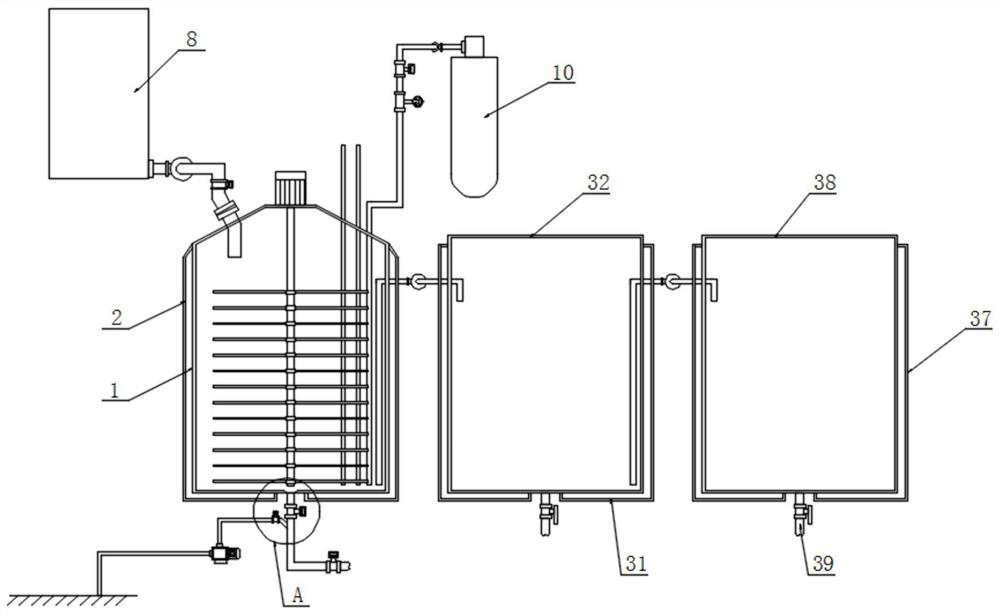

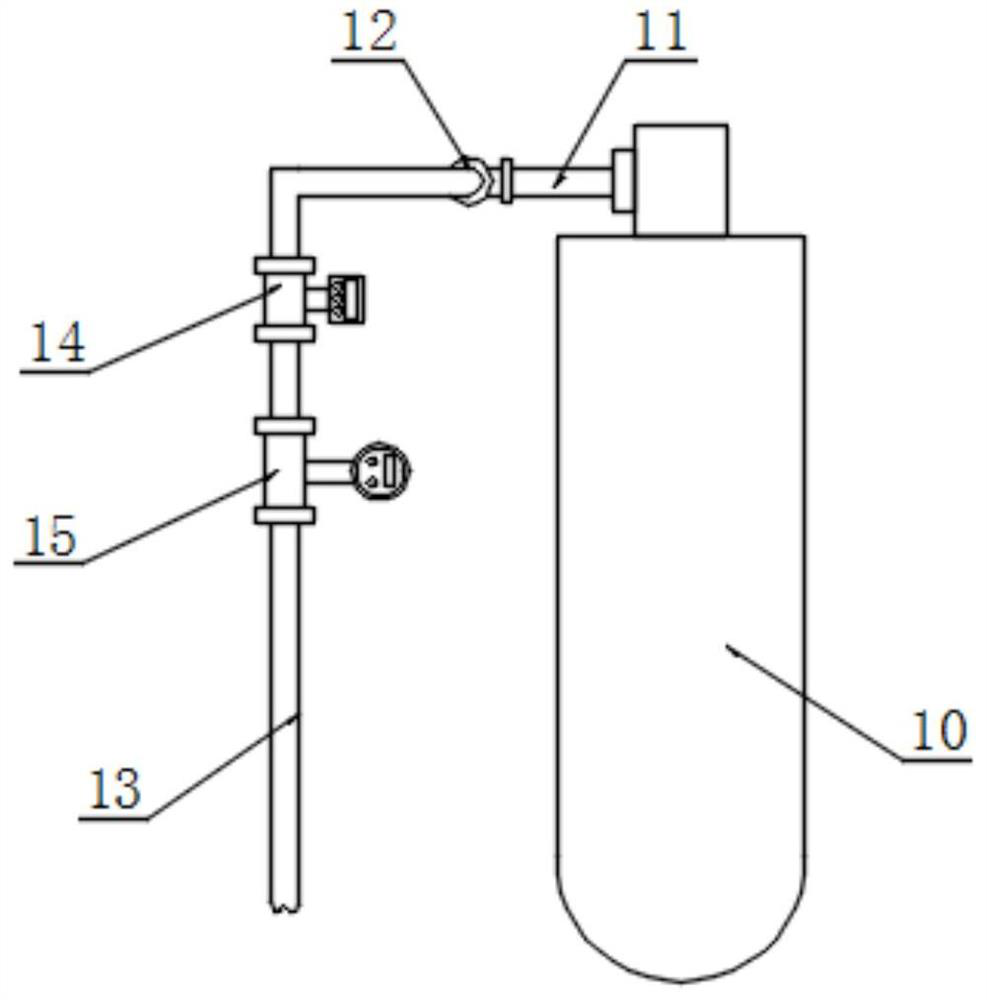

A kind of autoclave vacuum pumping process

The invention discloses a still kettle vacuumizing technology. After a cement product is subjected to autoclaved curing, the still kettle vacuumizing technology sequentially comprises a step of emptying residual water vapor in a still kettle, including, keeping the still kettle in a sealed state, and emptying residual water vapor in the still kettle within 1-2 hours through vacuumizing; a step of discharging volatilizable moisture in the still kettle, including, volatilizing residual moisture on the surface of the cement product and in the still kettle through vacuumizing and discharging the moisture out of the still kettle; a step of opening a door of the still kettle, including, opening a blow-off valve of the still kettle, and releasing a negative pressure in the still kettle. With the adoption of the still kettle vacuumizing technology, occurrence of cracks of the cement product during the still kettle maintenance can be avoided, and production efficiency can be improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

A kind of hypochlorous acid hand sanitizer manufacturing device

ActiveCN112593253BPromote withdrawalAvoid wastingElectrolysis componentsTransportation and packagingHand sanitizerElectric machinery

Owner:山东消博士消毒科技股份有限公司

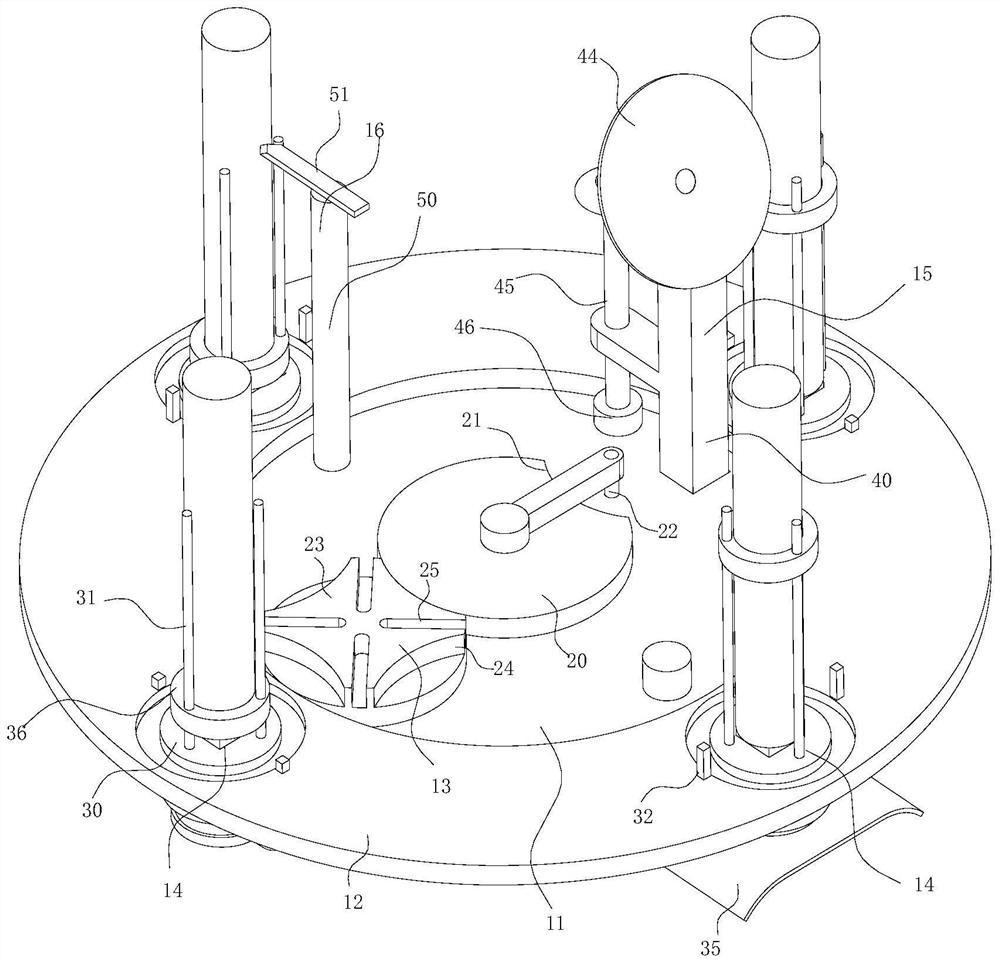

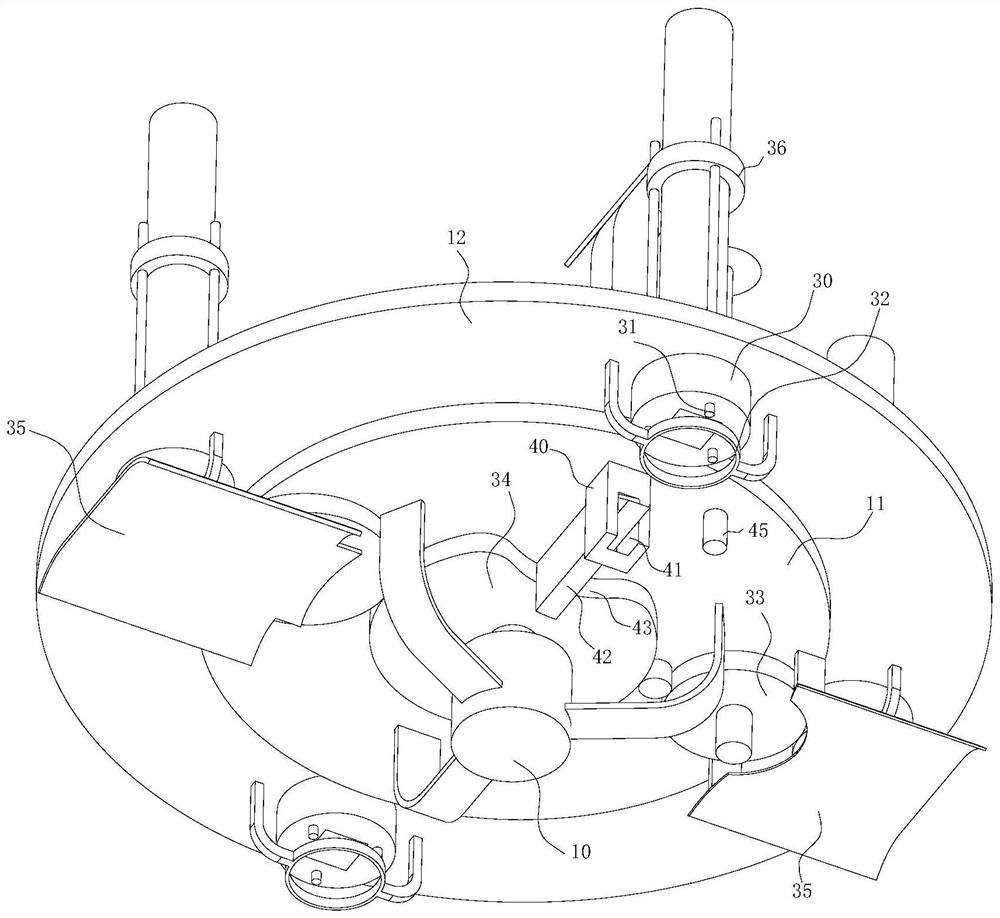

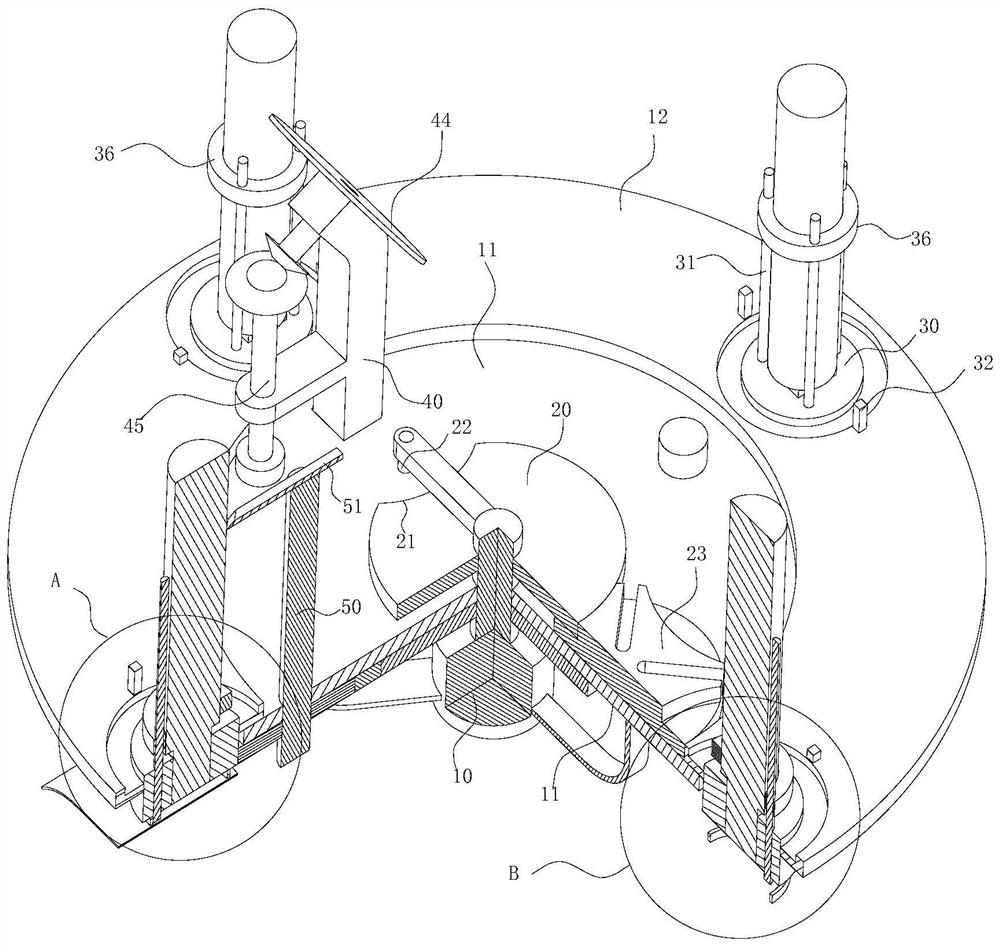

Intelligent manufacturing and producing system for screw taps

ActiveCN113579749AAvoid breakingSolve production inefficienciesOther manufacturing equipments/toolsElectric machinerySmart manufacturing

The invention discloses an intelligent manufacturing and producing system for screw taps in the technical field of intelligent screw tap manufacturing. The intelligent manufacturing and producing system for the screw taps comprises a motor and a base ring plate, the motor is fixedly arranged at the lower end of the base ring plate through a bracket, and a working ring plate is coaxially and rotatably arranged at the upper end of the base ring plate; a transposition device used for switching the working ring plate to carry out production process transposition is arranged between the base ring plate and the working ring plate, the transposition device is in transmission connection to a output shaft of the motor, a supporting device used for fixing the middle of a screw tap is arranged at the upper end of the working ring plate, and a cutting device used for continuously cutting the screw tap is arranged at the upper end of the base ring plate. According to the intelligent manufacturing and producing system for the screw taps, the problems that in existing screw tap manufacturing equipment, the bottom end of the screw tap is generally fixedly arranged on a rotatable clamp, then the screw tap is polished, slotted and unscrewed, and as unscrewing and slotting of the screw tap are concentrated at the same height, all mechanisms cannot work at the same time and need to be carried out one by one according to working procedures,.and the production efficiency is low are solved.

Owner:珠海市技师学院

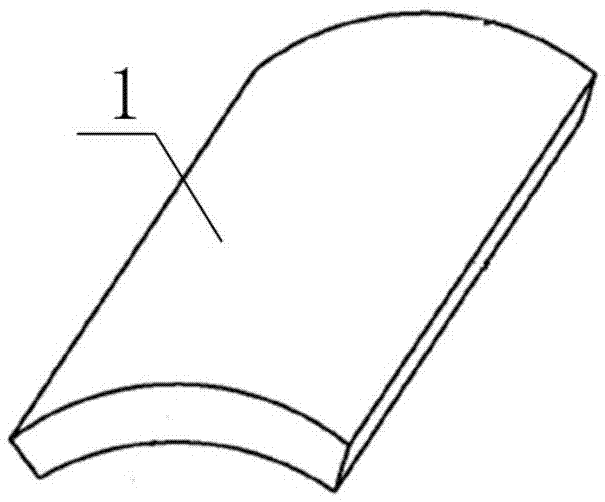

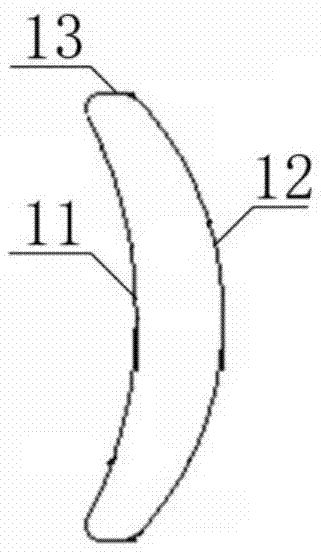

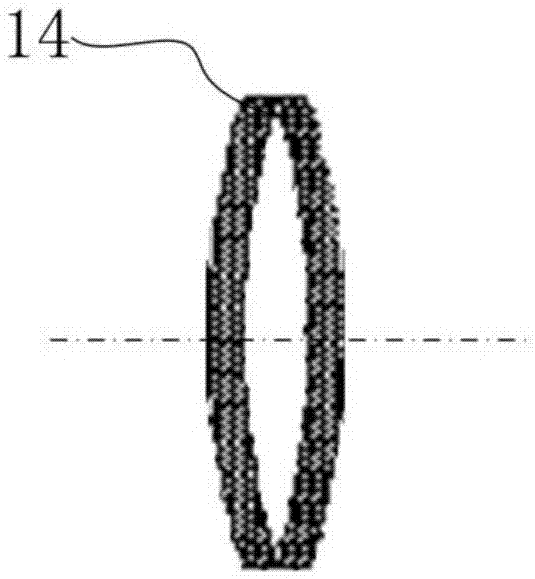

Tile-shaped magnet forming die, magnet forming method and motor magnet

ActiveCN106891000ASmall machining allowanceLarge space for powder distributionSintered magnetsEngineering

The invention discloses a tile-shaped magnet forming die and a magnet forming method. The die comprises a first side plate, a second side plate, a bottom press head, a top press head and a stop block, wherein a first side plate bulge part is arranged on the first side plate; the structure of the second side plate and the structure of the first side plate are mirror images; a bottom press head bulge part is arranged at one end of the bottom press head, and the structure of the bottom press head bulge part is the same as the structure of a cavity encircled by one half divided by a central line, of a second magnet pair, and the second magnet pair; a top press head bulge part is arranged at one end of the top press head, and the structure of the top press head bulge part is the same as the structure of a cavity included by the second curved surfaces of two tile-shaped magnets of the second magnet pair; and the shape of the stop block is the same as the structure of a cavity encircled by the first curved surfaces of the two tile-shaped magnets of a first magnet pair. According to the tile-shaped magnet forming die and the magnet forming method, the problem of low production efficiency of direct pressing forming for a magnetic product and the problem that a tile space is not easily fully filled with a magnetic powder due to a small size are solved; and meanwhile, the sintered magnets have a low working allowance, and a high material yield is achieved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com