PVC pipe production line

A PVC pipe and production line technology, applied in metal processing and other directions, can solve the problems of low production efficiency, the incision can not be guaranteed to be flat, and the continuity is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

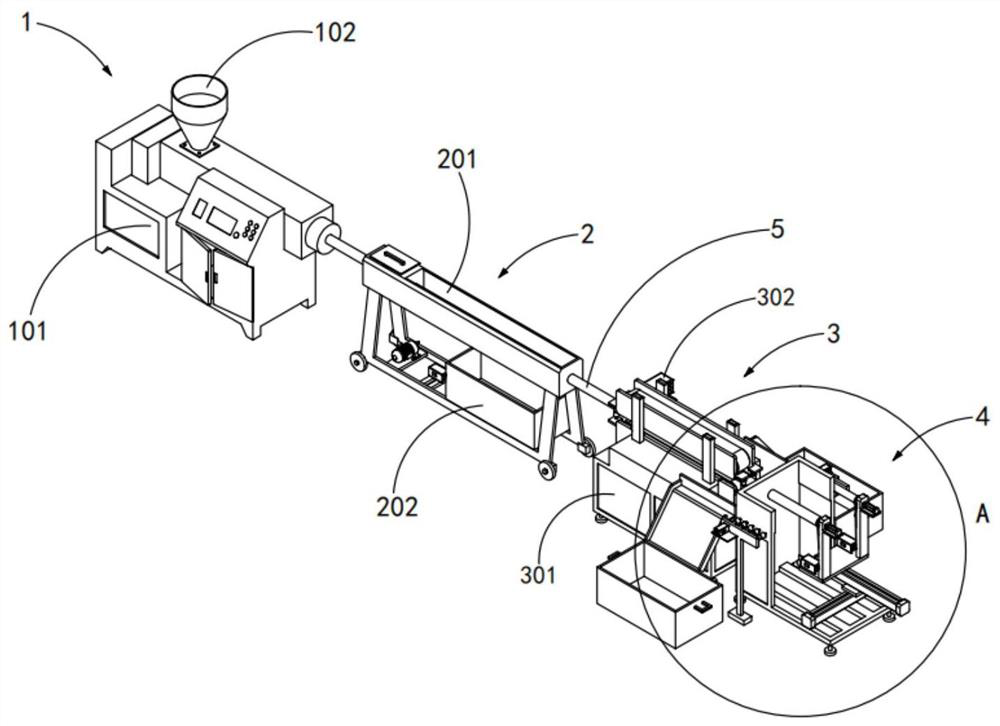

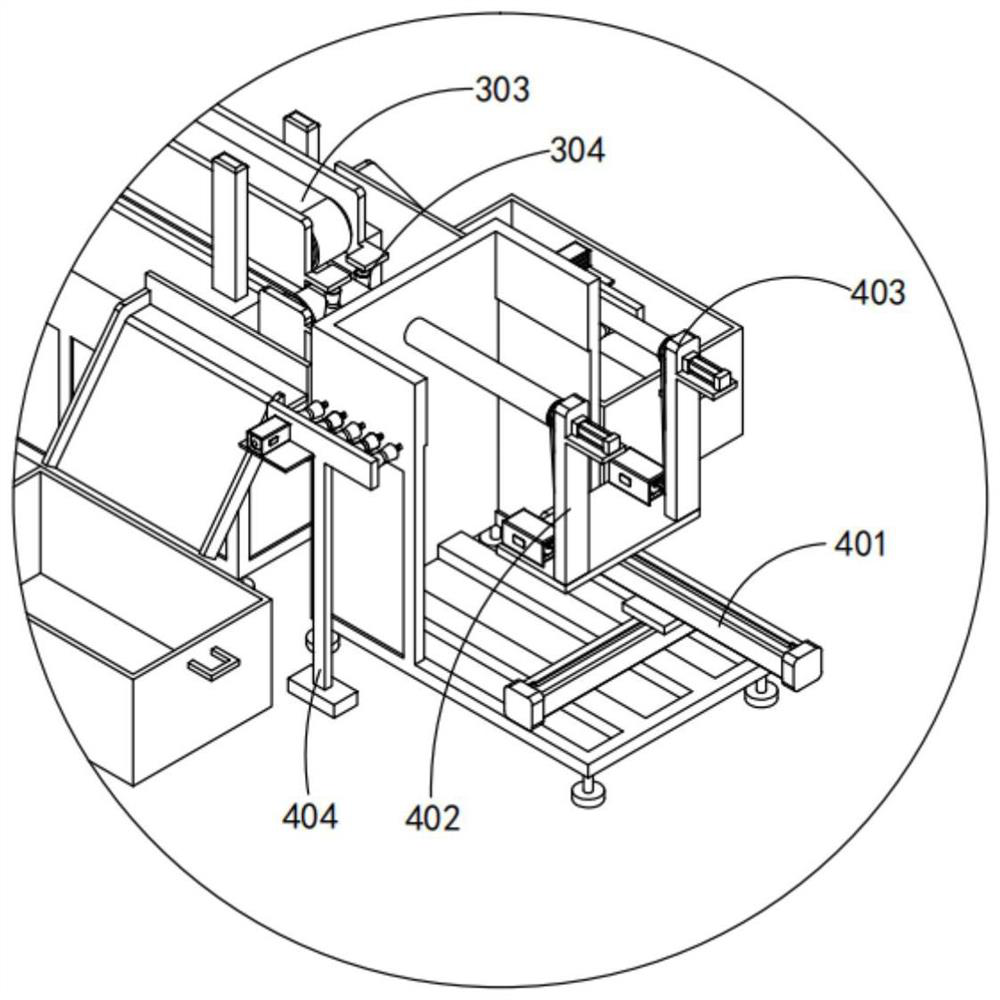

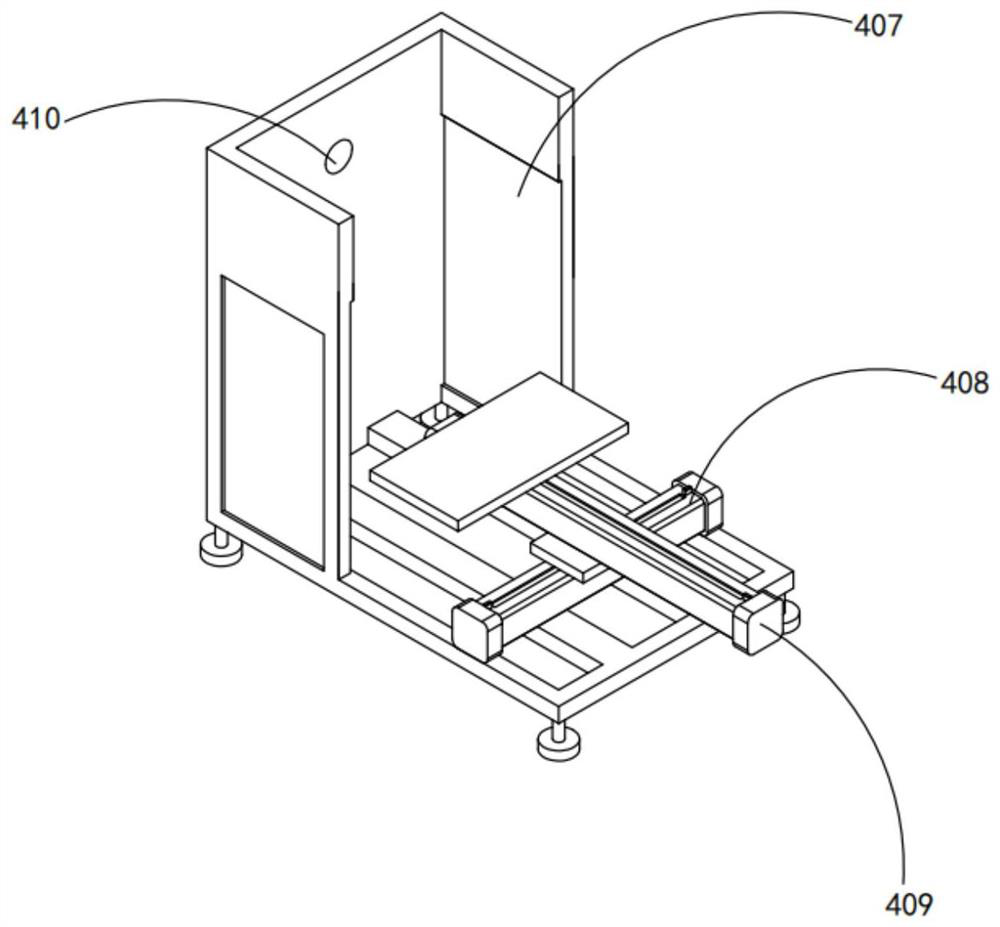

[0042] like Figure 1 to Figure 16 As shown in the figure, a PVC pipe production line includes an extrusion device 1, a shaping device 2 arranged at the end of the extrusion device 1, and a traction device 3 arranged at the end of the shaping device 2. The trailing end of the traction device 3 is provided with a slitting device 4. The slitting device 4 includes a pushing mechanism 401, a cutting mechanism a402 and a cutting mechanism b403 arranged above the pushing mechanism 401, and a feeding mechanism 404 arranged on both sides of the pushing mechanism 401. The cutting mechanism a402 and the cutting mechanism b403 Both include a rotating assembly 405 and a cutter assembly 406 arranged inside the rotating assembly 405. The pushing mechanism 401 realizes the switching of the cutting mechanism a402 and the cutting mechanism b403 by means of translation, and the rotating assembly 405 is used to drive the cutting mechanism. The knife assembly 406 rotates, and the cutter assembly ...

Embodiment 2

[0057] like Figure 9 As shown in the figure, the same or corresponding parts as in the first embodiment are marked with the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment The point is that baffles 434 are provided on both sides of the material guide plate 433 .

[0058] In this embodiment, baffles 434 are provided on both sides of the material guide plate 433 to avoid the problem that the cut PVC pipe 5 falls out of the collecting box 435 during the blanking process and causes damage, so that the cut PVC pipe 5 can be Accurately fall into the collection box 435.

[0059] work process

[0060] Firstly, the raw material is loaded into the extruder 101 through the hopper 102, the raw material is extruded into the prototype through the extruder 101, and then the PVC pipe 5 is shaped by the cooling and sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com