A kind of autoclave vacuum pumping process

An autoclave and vacuuming technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve problems such as affecting the strength and performance of products, cracking, reducing production efficiency, etc., and achieve the effect of solving easy cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

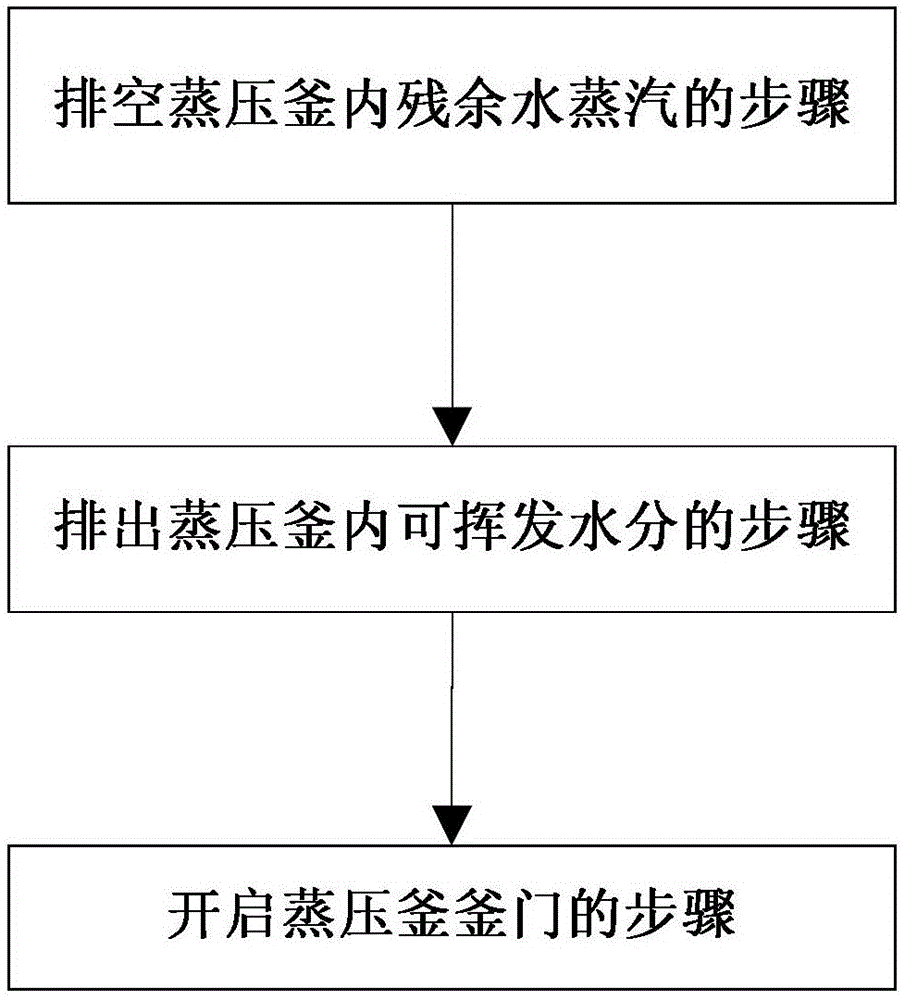

[0024] The invention provides a vacuumizing process for an autoclave, such as figure 1 As shown, after the autoclave curing of cement products is completed, the following steps are carried out in sequence:

[0025] The step of emptying the residual water vapor in the autoclave: keep the autoclave airtight, and empty the residual water vapor in the autoclave within 1-2 hours by vacuuming;

[0026] The step of discharging the volatile moisture in the autoclave: by vacuuming, the residual moisture on the surface of the cement product and in the autoclave is volatilized and discharged from the autoclave;

[0027] Steps to open the autoclave door: After the volatile water in the autoclave is discharged, open the autoclave emptying valve to remove the negative pressure in the autoclave.

[0028] Further, in the step of emptying the residual water vapor in the autoclave, the temperature in the autoclave is reduced from the initial temperature (100-105° C.) to the first temperature r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com