A centered air-permeable composite film centered unwinding device and its processing method

A technology of unwinding device and composite film, which is applied in lamination devices, chemical instruments and methods, winding strips, etc., and can solve problems such as uneven surface tension, change of roll diameter, and low production efficiency of centered composite film production equipment. , achieve the effect of overcoming uneven surface tension and solving low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

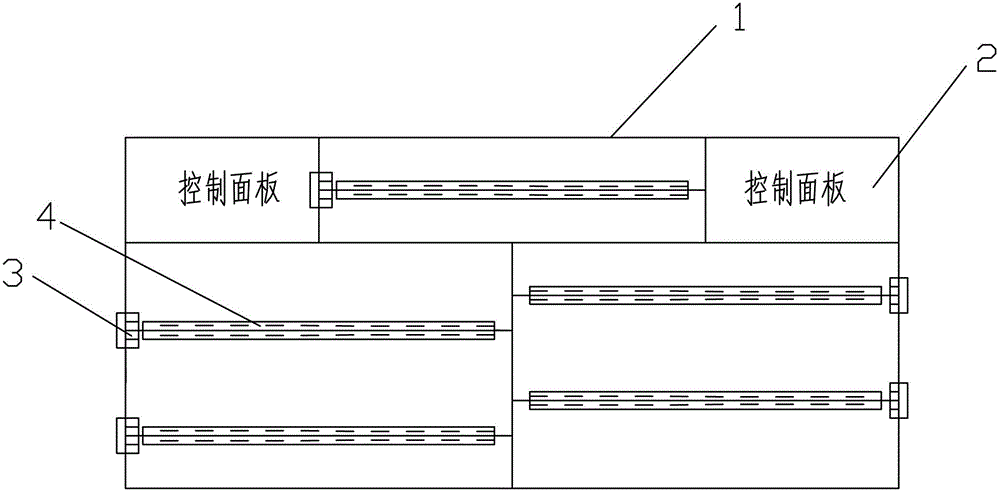

[0024] Such as figure 1 As shown, a centered air-permeable composite film centered unwinding device provided in this embodiment includes a frame 1 on which a control panel 2, a driver 3, and an unwinding inflatable short shaft 4 are installed respectively; The control panel 2 described above is connected to the driver 3, and the driver 3 is connected to the short shaft 4 of the unwinding air expansion; 5 short shafts 4 of the unwinding air expansion are installed on the frame 1, and every 2 unwinding air expansion shafts The short shafts 4 are misplaced and installed, and each of the unwinding inflatable short shafts 4 is connected to a driver 3 . The width of the unwinding short axis 4 is 200mm.

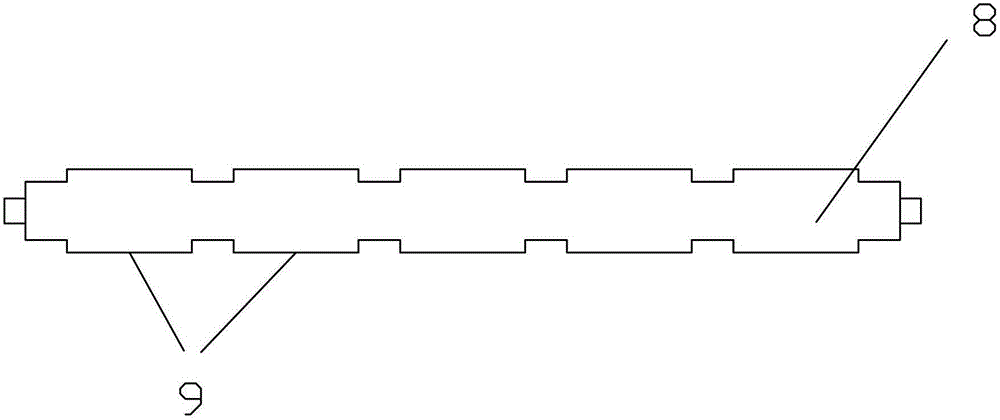

[0025] Such as figure 2 As shown, the concave-convex roller 8 corresponding to the central unwinding device of a centered air-permeable composite film is provided with five convex surfaces 9 on the concave-convex roller 8 .

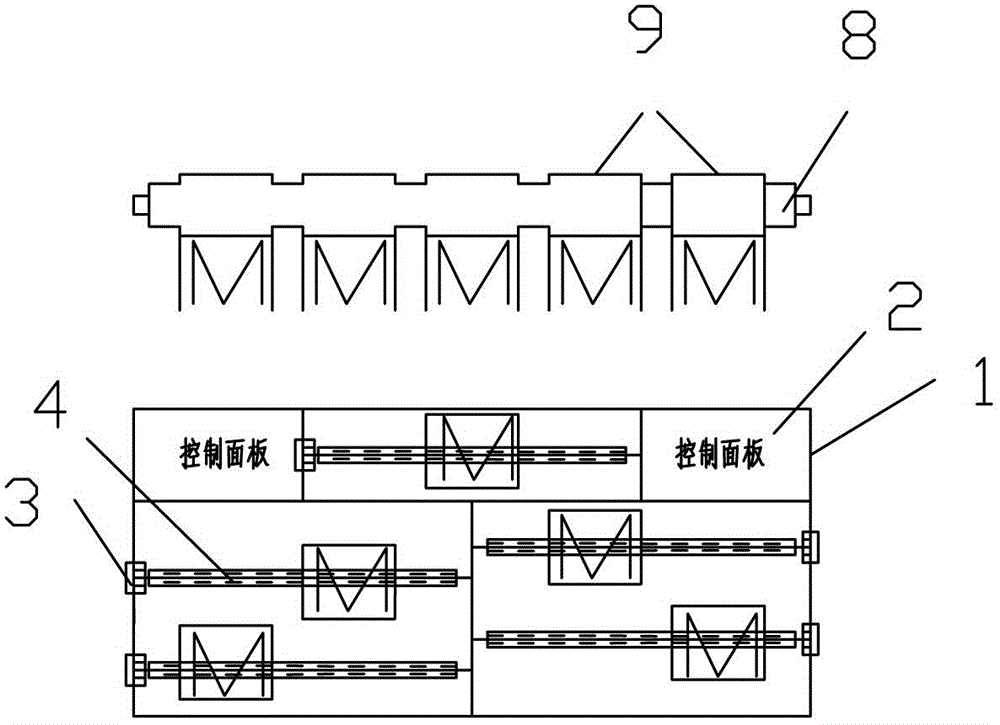

[0026] Such as image 3 , Figure 4 , Figure 5 As...

Embodiment 2

[0029] Such as figure 1 As shown, a centered air-permeable composite film centered unwinding device provided in this embodiment includes a frame 1 on which a control panel 2, a driver 3, and an unwinding inflatable short shaft 4 are installed respectively; The control panel 2 described above is connected to the driver 3, and the driver 3 is connected to the unwinding air expansion short shaft 4; 4 unwinding air expansion short shafts 4 are installed on the frame 1, and every two unwinding air expansion shafts The short shafts 4 are misplaced and installed, and each of the unwinding inflatable short shafts 4 is connected to a driver 3 . The width of the unwinding short axis 4 is 300mm.

[0030] Such as figure 2 As shown, the concave-convex roller 8 corresponding to the central unwinding device of a centered air-permeable composite film is provided with four convex surfaces 9 on the concave-convex roller 8 .

[0031] Such as image 3 , Figure 4 , Figure 5 As shown, the ...

Embodiment 3

[0034] Such as figure 1As shown, a centered air-permeable composite film centered unwinding device provided in this embodiment includes a frame 1 on which a control panel 2, a driver 3, and an unwinding inflatable short shaft 4 are installed respectively; The control panel 2 described above is connected to the driver 3, and the driver 3 is connected to the short shaft 4 of unwinding air expansion; 3 short shafts 4 of unwinding air expansion are installed on the frame 1, and every 2 unwinding air expansion shafts The short shafts 4 are misplaced and installed, and each of the unwinding inflatable short shafts 4 is connected to a driver 3 . The width of the unwinding short axis 4 is 400mm.

[0035] Such as figure 2 As shown, the concave-convex roller 8 corresponding to the central unwinding device of a centered air-permeable composite film is provided with three convex surfaces 9 on the concave-convex roller 8 .

[0036] Such as image 3 , Figure 4 , Figure 5 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com