Paddy field film laminating machine with side pressing wheel

A paddy field mulching machine and the technology of the mulching machine are applied to plant protection covers, botany equipment and methods, gardening, etc., and can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

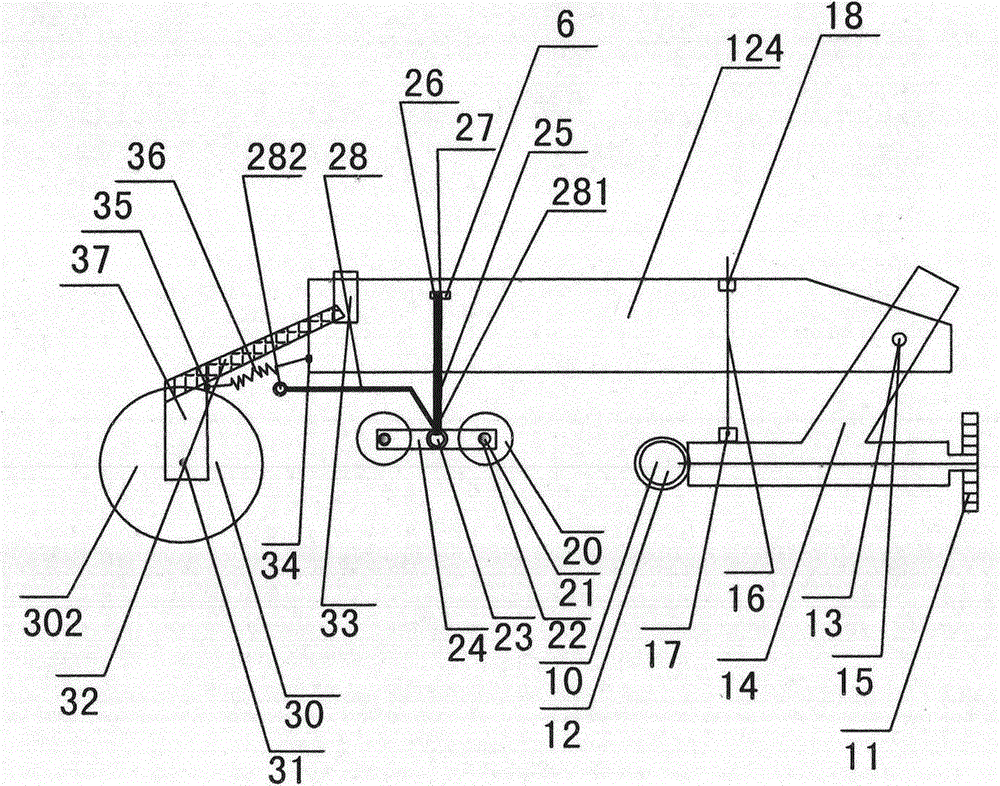

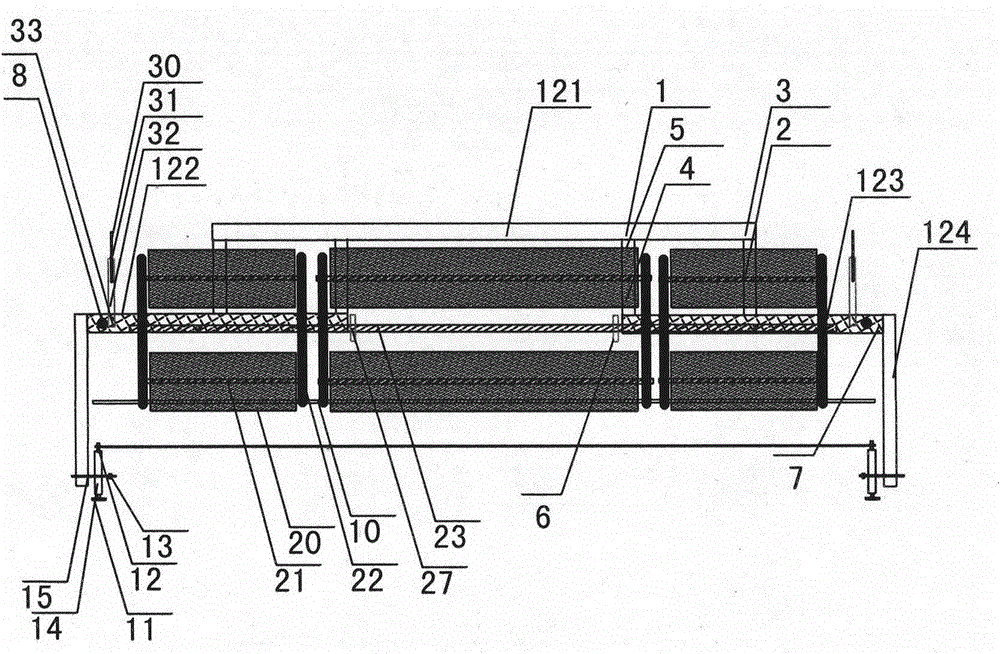

[0071] In order to make the present invention easy and simple mode is described as follows:

[0072] The front end of the main frame 1 is connected with a boat-shaped mud scraper 72, which plays the role of scraping the paddy field soil when the paddy field mulching machine moves forward.

[0073] On the main frame 1, there is a mulch shaft connecting rod 16, and the upper end of the mulch shaft connecting rod 16 is provided with a mulch shaft fastening handle 11, and the mulch shaft 10 can be fastened on the main frame 1 by adjusting the mulch shaft fastening handle 11 , the film shaft 10 is perforated with a film.

[0074] The mulch shaft fastening handle 11 is arranged on the main frame 1, and the mulch shaft fastening handle 11 is rotated counterclockwise to release the screw, and then the mulch shaft locking hole 12 is released, and the mulch shaft connecting rod 16 can be lifted, and the mulch shaft 10 is released from the mulch shaft. Take off the main body 14 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com