Cutting equipment for producing PVC pipes

A PVC pipe and cutting equipment technology, applied in metal processing and other directions, can solve the problems that the processing incision cannot be guaranteed to be smooth, the cutting efficiency is low, and the labor cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

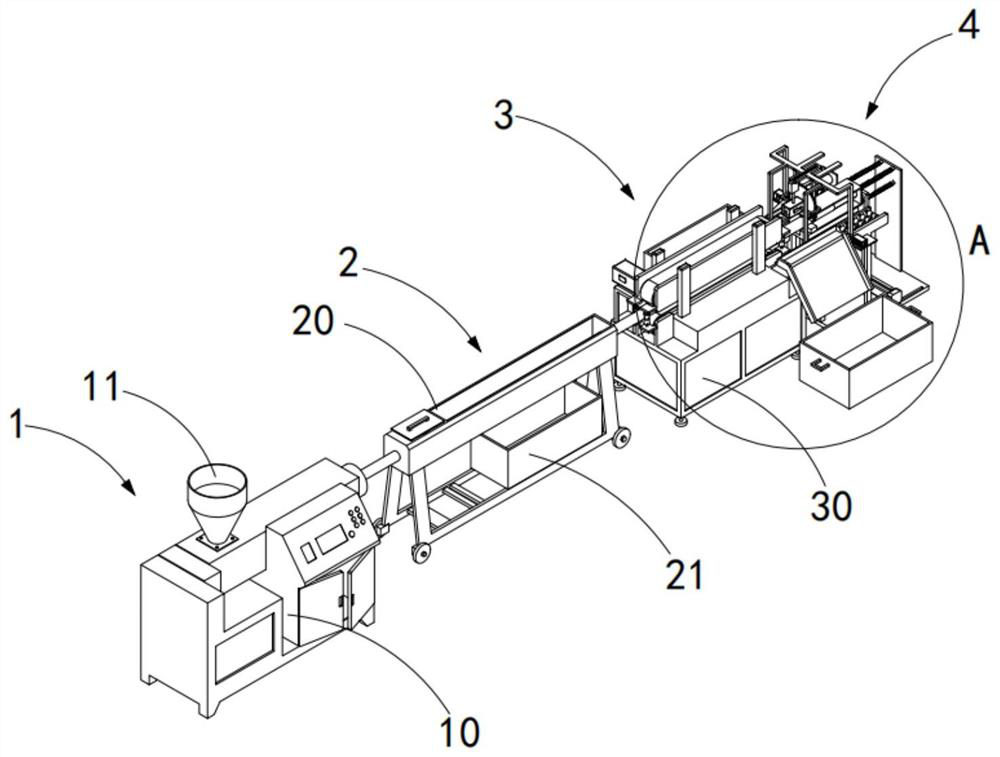

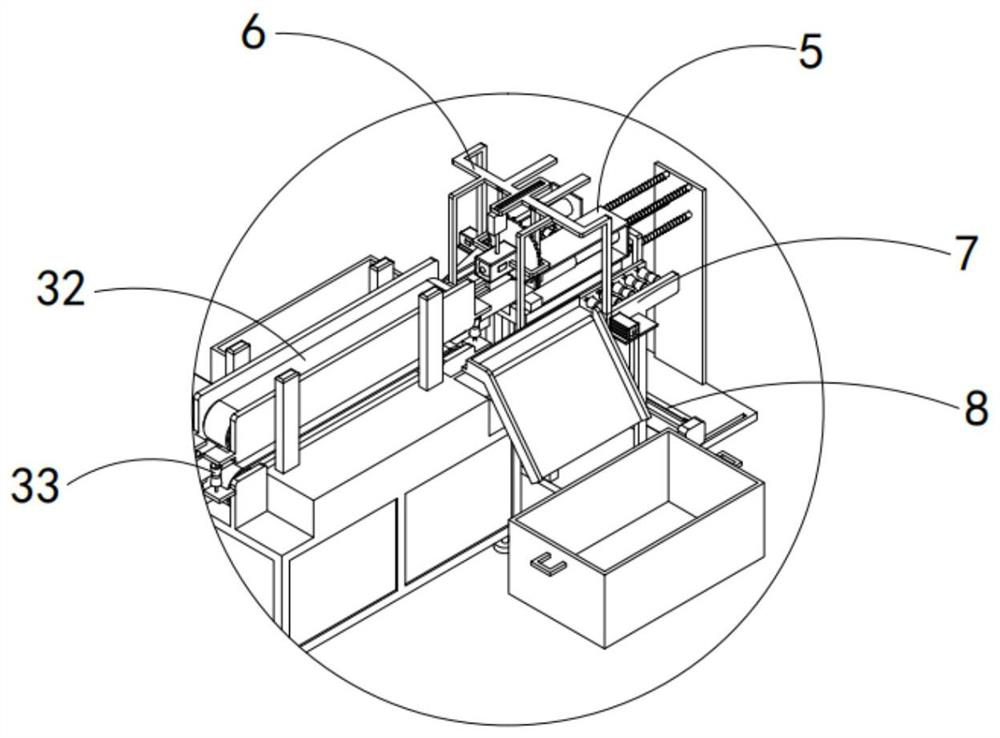

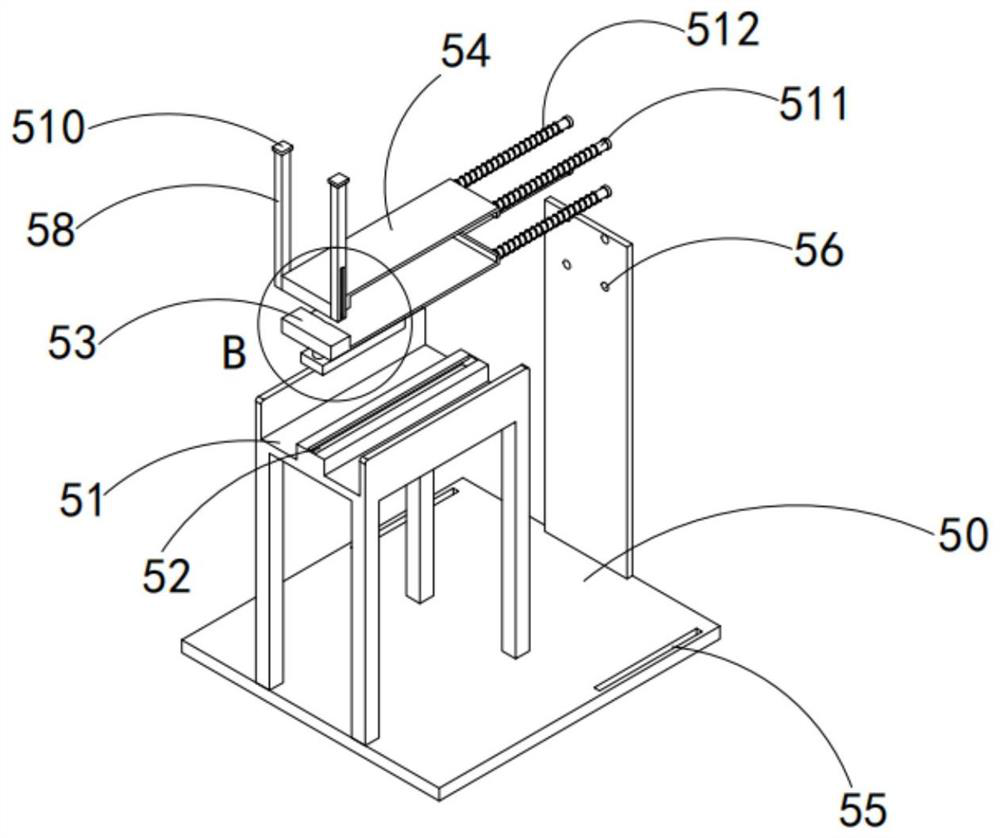

[0038] Such as Figure 1 to Figure 12 As shown, a PVC pipe production and cutting equipment includes an extrusion device 1, a shaping device 2 arranged at the tail end of the extrusion device 1, and a traction device 3 arranged at the tail end of the shaping device 2, and the tail end of the traction device 3 is provided with a branch Cutting device 4, described cutting device 4 comprises carrier mechanism 5, the cutting mechanism 6 that is arranged on carrier mechanism 5 front ends, the transfer mechanism 7 that is arranged on carrier mechanism 5 tail ends and the blanking mechanism 8 that is arranged on carrier mechanism 5 both sides, The carrying mechanism 5 is used to accept the PVC pipe 9 transported on the traction device 3, the cutting mechanism 6 includes a guide rail 60 and a saw blade 61 arranged below the guide rail 60, and the transfer mechanism 7 includes a baffle a70 and a baffle plate b71, the PVC pipe 9 is in contact with the baffle plate a70 and the baffle pla...

Embodiment 2

[0053] Such as Figure 9 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that a baffle 86 is arranged on the blanking plate 85 .

[0054] In this embodiment, the baffle plate 86 is set on the blanking plate 85 to avoid the problem that the cut PVC pipe 9 falls outside and causes damage to the PVC pipe 9 during the transmission process through the roller a82, so that the cut PVC pipe 9 can be damaged. Pipe 9 can accurately fall in the receiving box 87.

[0055] work process

[0056]First, the raw material is loaded into the extruder 10 through the hopper 11, and the raw material is extruded into a prototype through the extruder 10, and then the PVC pipe 9 is finished shaping by the cooling shaping machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com