Environmentally-friendly and energy-saving type automatic oil pressing equipment

An oil-pressing equipment and energy-saving technology, applied in the field of environmental protection and energy-saving automatic oil-pressing equipment, can solve the problems of low energy recycling rate and low production efficiency, so as to solve the problem of low energy recycling rate, improve production efficiency, and improve energy efficiency. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

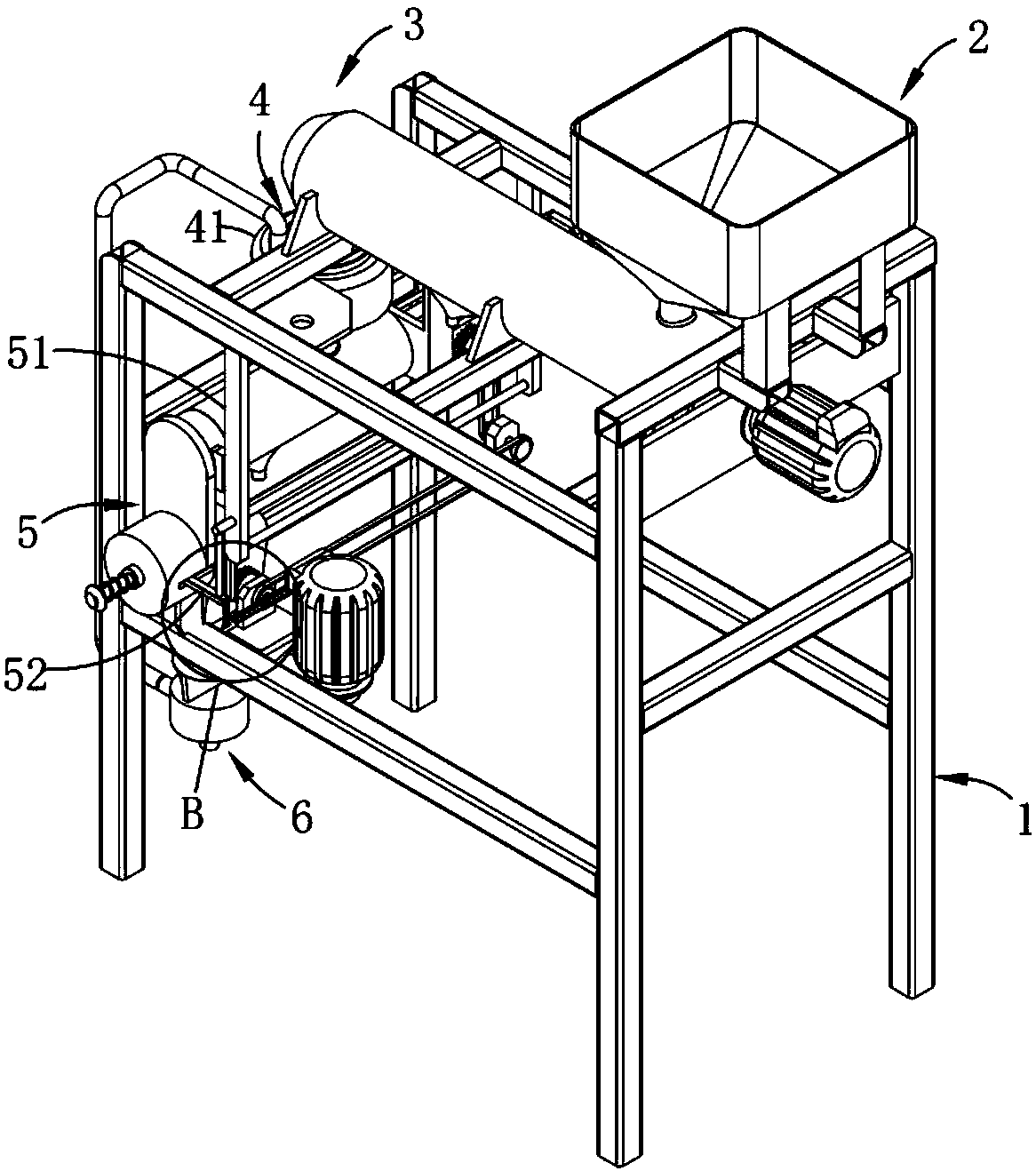

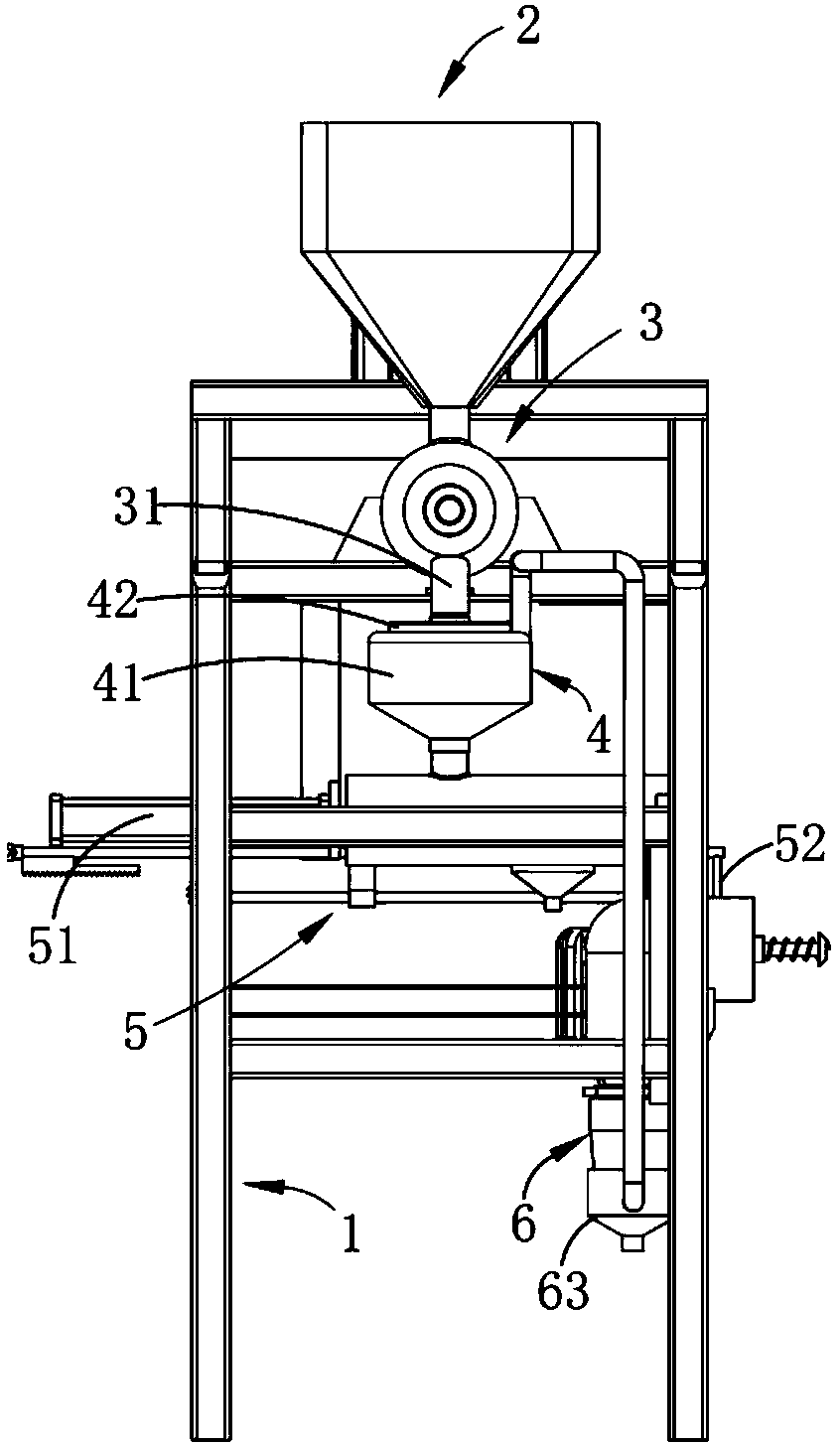

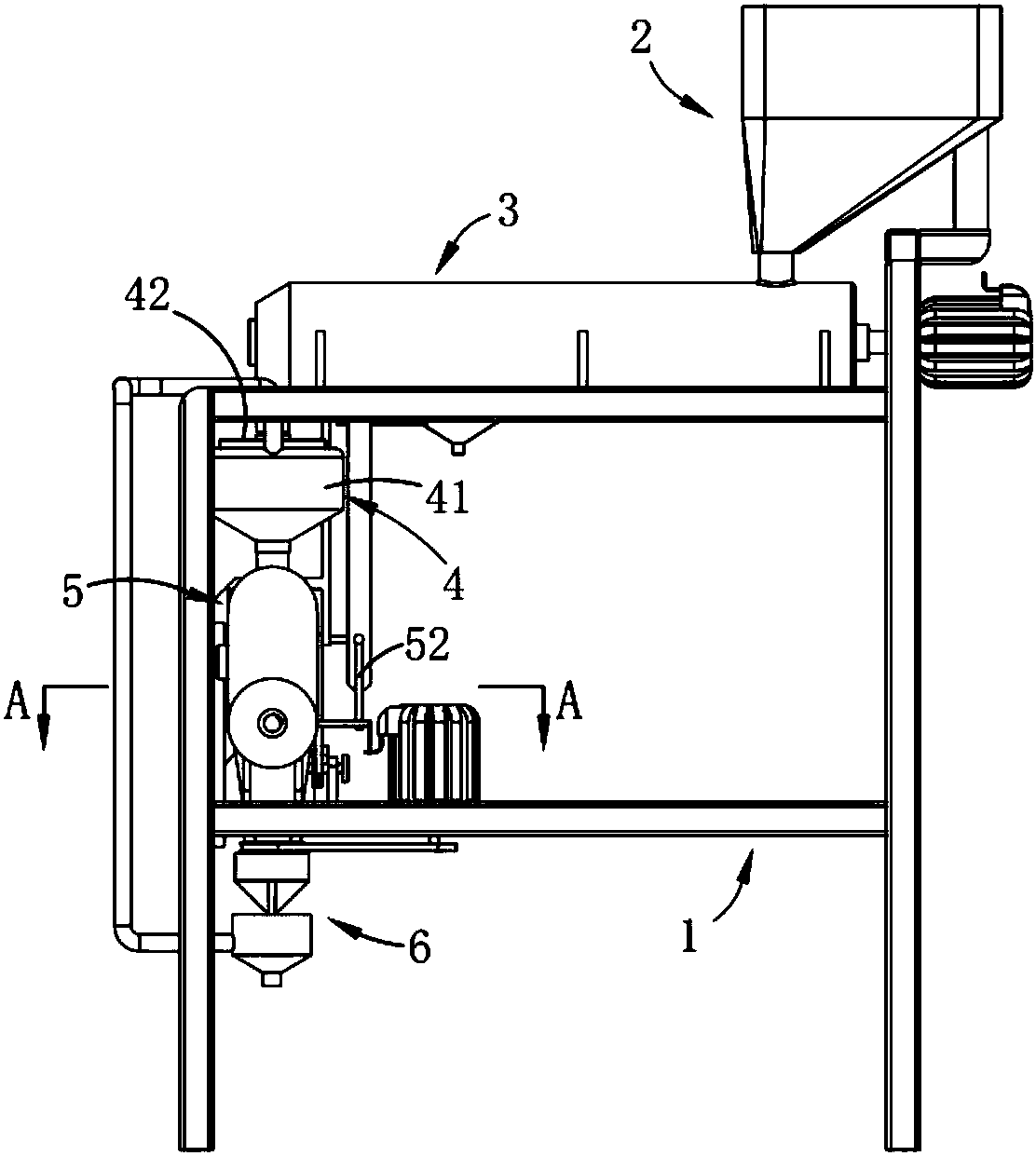

[0040] Such as figure 1 , 2 , 3, 4, 5 and 6, a kind of environment-friendly and energy-saving automatic oil pressing equipment, including a frame 1 and a feeding bin 2 installed on the frame 1, also includes:

[0041] A first-stage oil press mechanism 3, the first-stage oil press mechanism 3 is arranged on the frame 1 and communicates with the feed bin 2, and its end is provided with an output pipe 31 for oil cake output. In this embodiment Among them, the primary oil pressing mechanism 3 is the same as the screw type oil press...

Embodiment 2

[0053] Such as Figure 4 and 5 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The feature is that the oil squeezing assembly 51 includes a squeezing chamber 511, a piston disc 512 arranged in the squeezing chamber 511 to squeeze the oil cake and a driving part 513 that drives the piston disc 512 to reciprocate; in this embodiment Among them, the driving part 513 is preferably set as an oil cylinder, and the squeeze chamber 511 is set with openings at both ends.

[0054] Further, as Figure 4 , 9 As shown in and 10, the transfer assembly 52 includes a transfer part 521 and a control part 522 for controlling the movement of the transfer part 521. The top cone 5212 for internal waste discharge, the top cone 5212 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com