Rapid adjustable tip

An adjustable, top-notch technology, applied in the direction of tailstock/top, turning equipment, tool holder accessories, etc., can solve the problems of low production efficiency, time-consuming adjustment of the coaxiality of the thimble and the mandrel, etc., and achieves easy cleaning and shortening. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

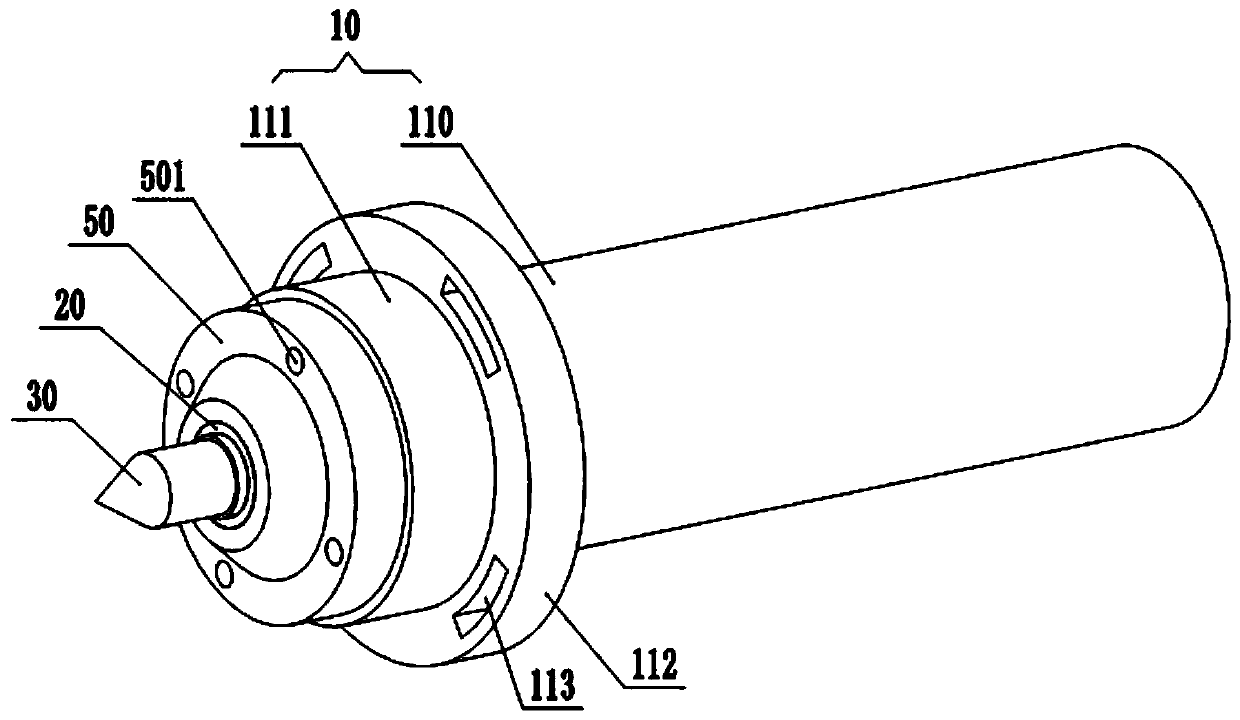

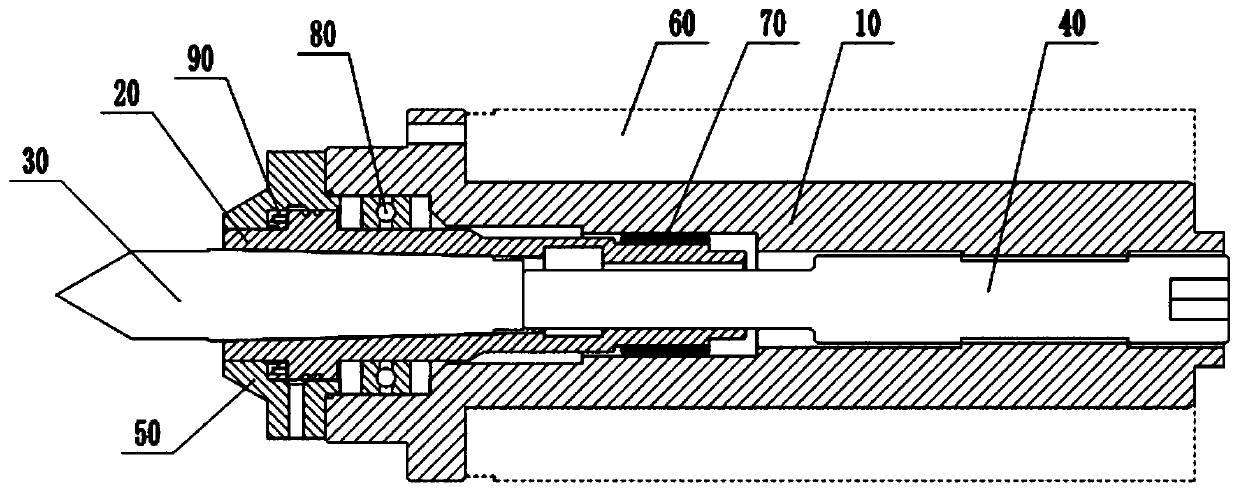

[0038] Embodiment 1 is basically as attached figure 1 and figure 2 Shown:

[0039] A quick-adjustable center, including a sleeve 10, a mandrel 20, a thimble 30, a push rod 40 and a sealing cover 50, the sleeve 10 is used to connect with the outer cylinder 60 on the tailstock of the machine tool, and the mandrel 20 is rotatably connected to the sleeve Inside the cylinder 10, the thimble 30 fits with the inner taper of the mandrel 20, and the ejector rod 40 includes a pressing section and a threaded section, wherein the threaded section is threaded with the inside of the sleeve 10, and the left end of the pressing section is pressed against the right end of the thimble 30 . The specific structure and assembly method of the sleeve 10, the mandrel 20, the ejector rod 40 and the sealing cover 50 are as follows:

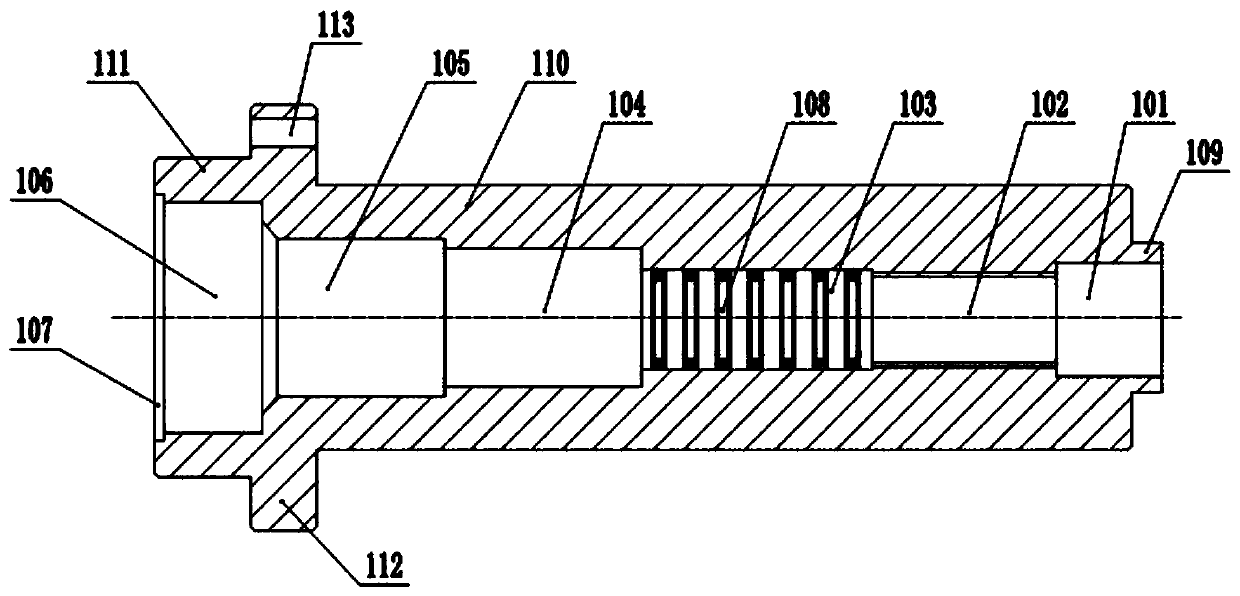

[0040] combine image 3 As shown, a guide hole 101, a threaded hole 102, an eccentric hole 103, a bearing installation hole 104, a mandrel passing hole 105, a positio...

Embodiment 2

[0051] Embodiment 2 is basically as attached figure 1 and Figure 5 Shown:

[0052] The difference between Embodiment 2 and Embodiment 1 is that a support mechanism is provided on the inner wall of the support hole 209, the support structure includes a plurality of strip-shaped airbags 1, and each airbag 1 is bonded to form a columnar tube, and the columnar tube is connected to the support hole. 209 coaxial, when the push rod 40 stretched into the support hole 209, the side wall of the push rod 40 extruded the airbag 1, as Figure 6 As shown, in each airbag 1, along the radial direction of the cylindrical tube, the support spring 11 is fixed, and the left end of the airbag 1 is provided with an exhaust check valve 12, and the right end of the airbag 1 is provided with an intake check valve 13; 1 When the squeezed internal volume decreases, the exhaust check valve 12 opens, and the gas inside the airbag 1 is discharged, and when the airbag 1 resumes deformation and the volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com