High-efficiency embroidering, printing and dyeing integrated machine for silk fabric

An integrated machine and embroidery machine technology, applied in the field of silk machinery, can solve the problems of single embroidery or printing and dyeing, low production efficiency, etc., and achieve the effects of solving low production efficiency, simple structure, improving efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

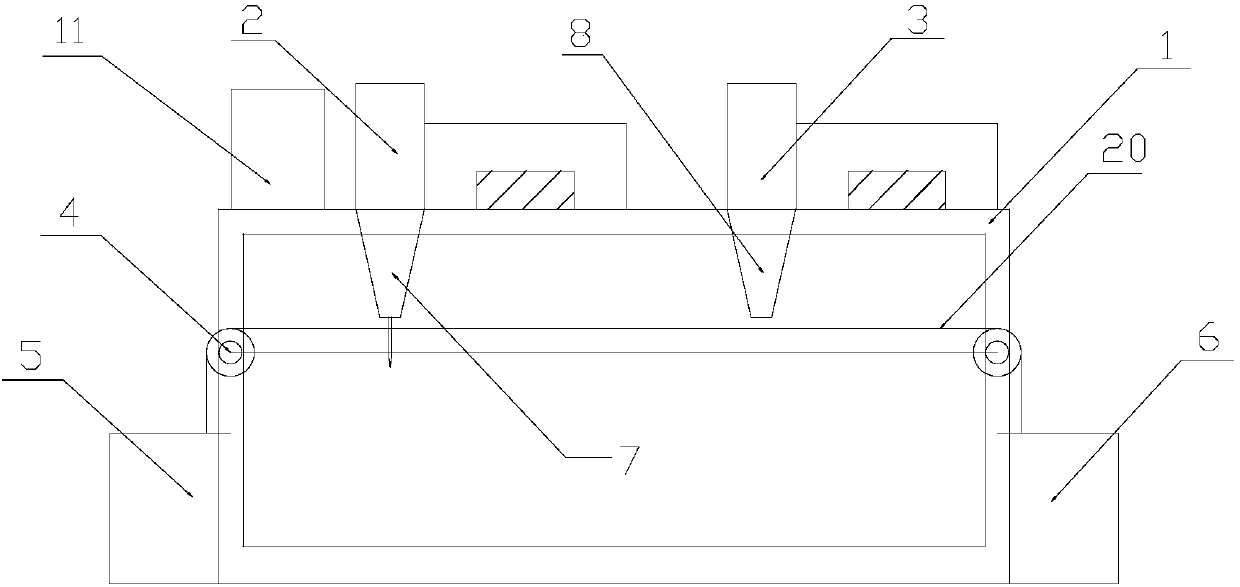

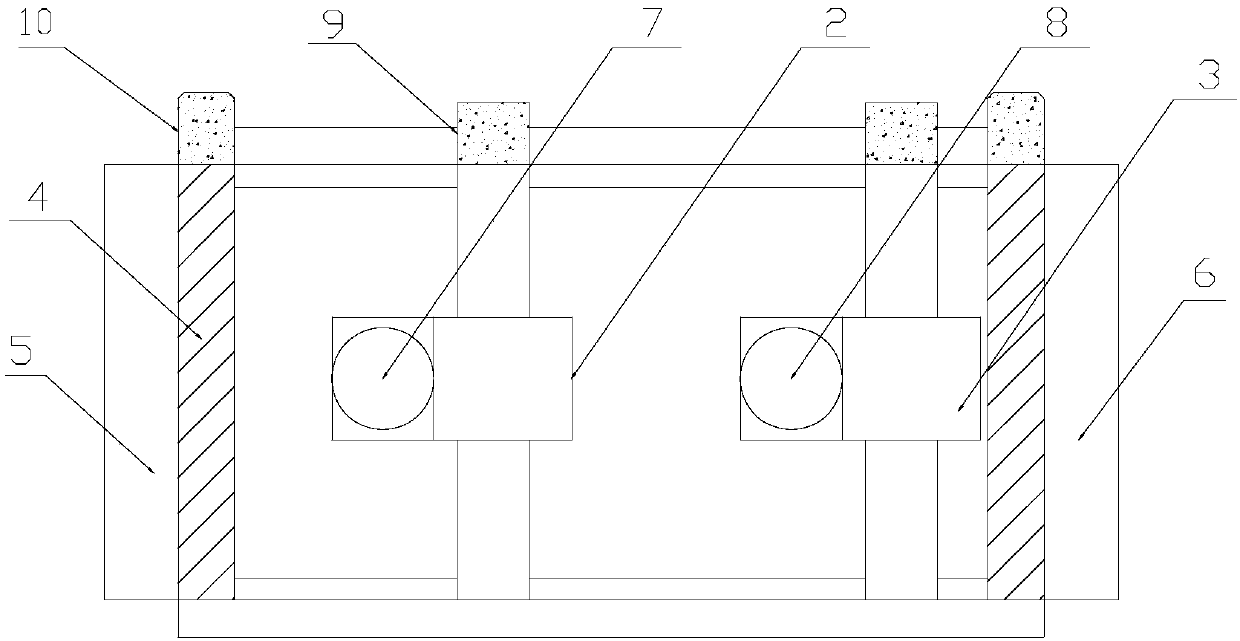

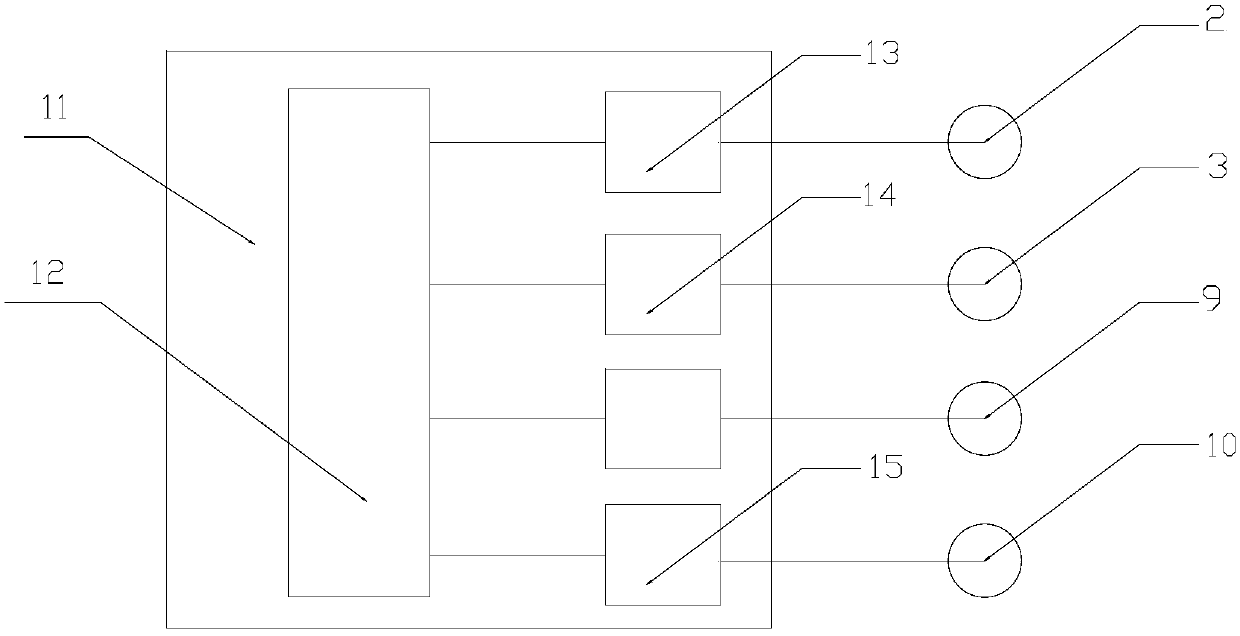

[0025] Such as Figure 1-4 As shown, the present invention provides an efficient silk fabric embroidery printing and dyeing integrated machine, comprising a frame 1, a swing embroidery machine 2, a swing spraying printing and dyeing machine 3 and an electrical control cabinet 11, the frame 1 is a rectangular frame structure, and the frame 1 The top is fixed with a swinging embroidery machine 2 and a swinging spraying and dyeing machine 3 in turn. The middle part of the frame 1 is fixed with two winding rollers 4 through bearings. The bottom of one end of the frame 1 is fixed with a raw material storage box 5. The bottom of one end is fixed with a finished product storage box 6, and the silk fabric extends out of the raw material storage box 5, and the silk fabric runs through two winding rollers 4 to the middle of the finished product storage box 6 in turn, and the swing embroidery machine 2 is provided with embroidery needles 7. There is a printing and dyeing nozzle 8 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com