Textile method and device

A technology of weaving fell and warp, which is applied in textiles, textiles, papermaking, fabrics, etc., and can solve problems such as low production efficiency and difficulty in ensuring fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

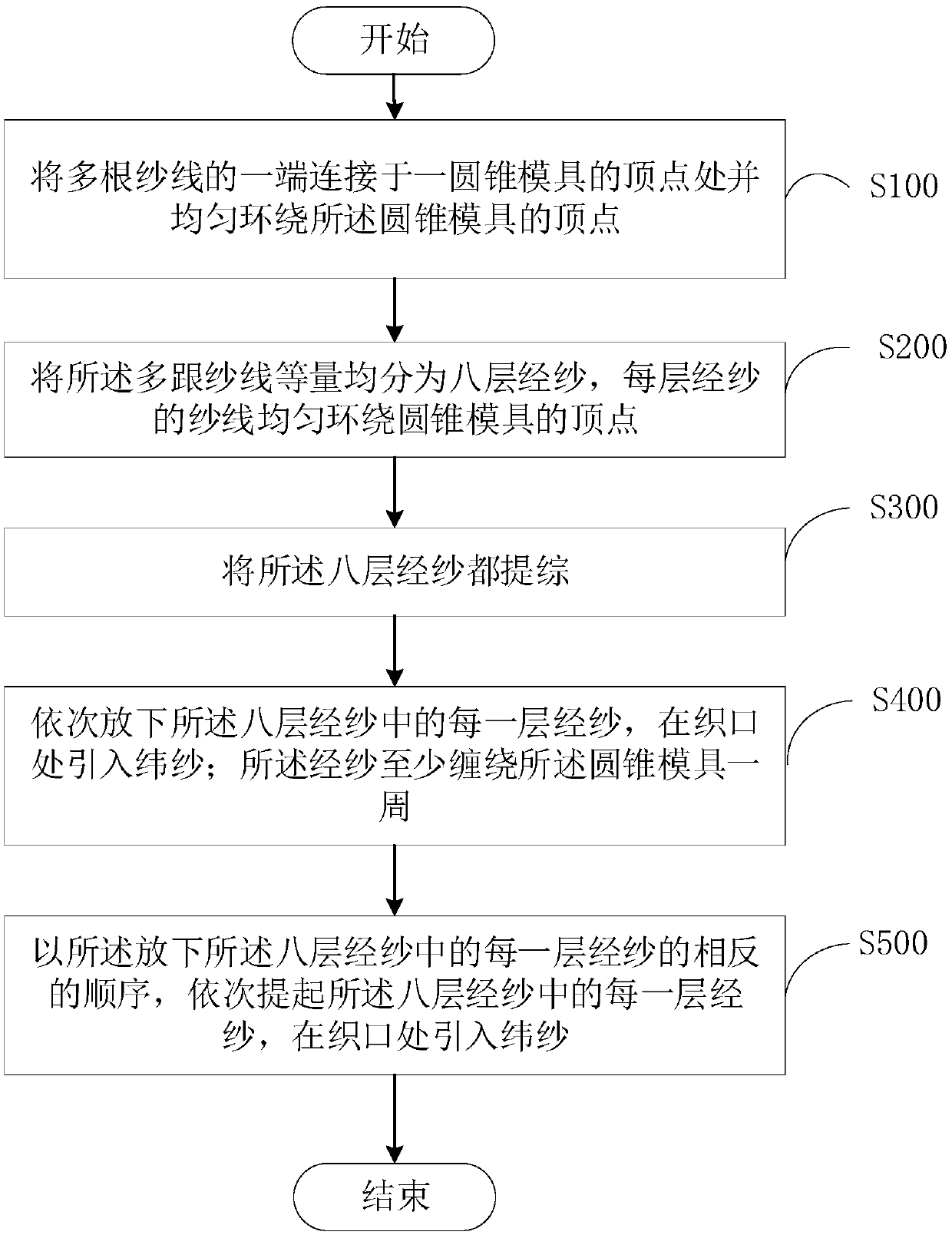

[0025] Please refer to figure 1 , a weaving method provided by the first embodiment of the present invention, the method includes: step S100, step S200, step S300, step S400 and step S500.

[0026] Step S100: laying a plurality of yarns at the apex of a cone mold and uniformly surrounding the apex of the cone mold.

[0027] The plurality of yarns will reserve a section of length on the vertex, as the warp yarn when the body is spun.

[0028] Step S200: Divide the plurality of yarns into eight layers of warp yarns in equal amounts, and the yarns of each layer of warp yarns evenly surround the apex of the cone mold.

[0029] The layer of warp yarn close to the cone mold, that is, the innermost warp yarn is the first layer of warp yarn, from inside to outside, it is the second layer of warp yarn, the third layer of warp yarn, the fourth layer of warp yarn, the fifth layer of warp yarn, the sixth layer of warp yarn Layer warp, seventh layer warp and eighth layer warp.

[0030] ...

no. 2 example

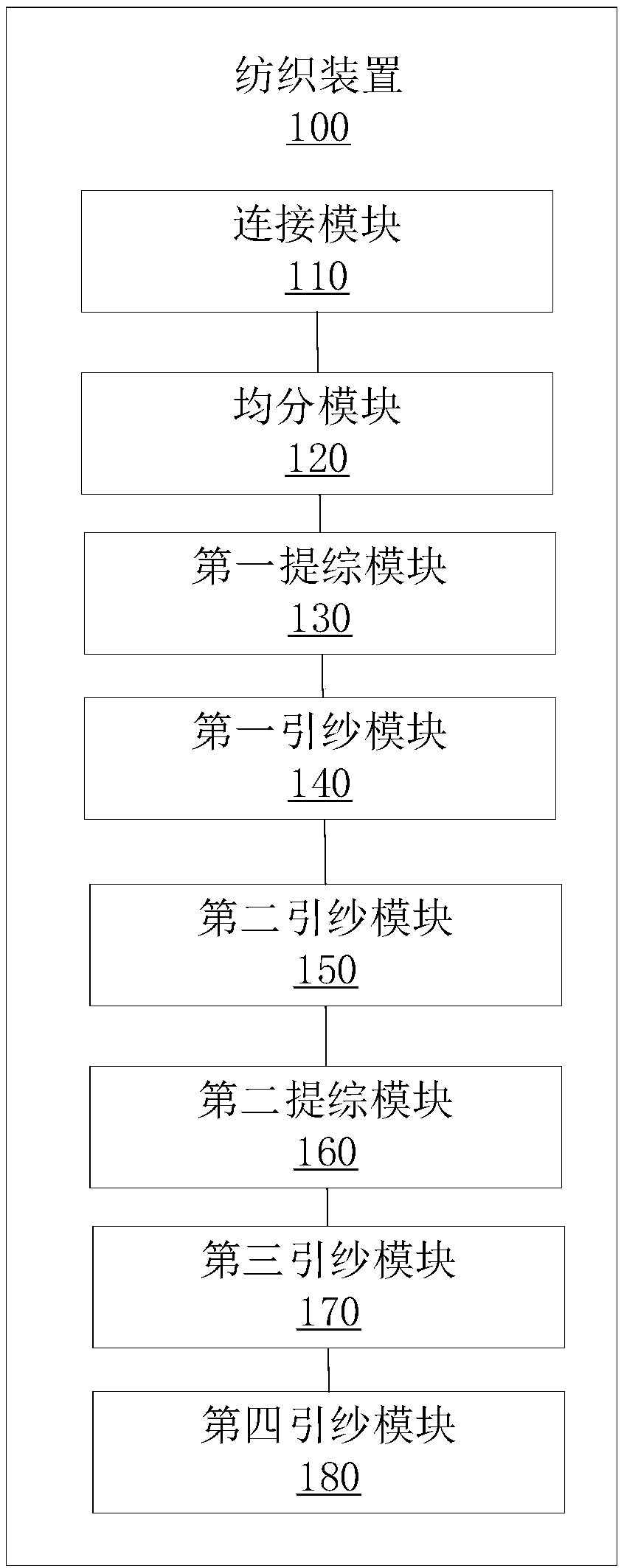

[0057] The second embodiment of the present invention provides a textile device 100, comprising: a connecting module 110, an equalizing module 120, a first hedging module 130, a first yarn drawing module 140 and a second yarn drawing module 150;

[0058] The connection module 110 is used for laying a plurality of yarns at the apex of a conical mold and uniformly surrounding the apex of the conical mold;

[0059] The said equalizing module 120 is used to equally divide the plurality of yarns into eight layers of warp yarns, and the yarns of each layer of warp yarns evenly surround the apex of the cone mould;

[0060] The first heald lifting module 130 lifts the heddles of the eight layers of warp yarns;

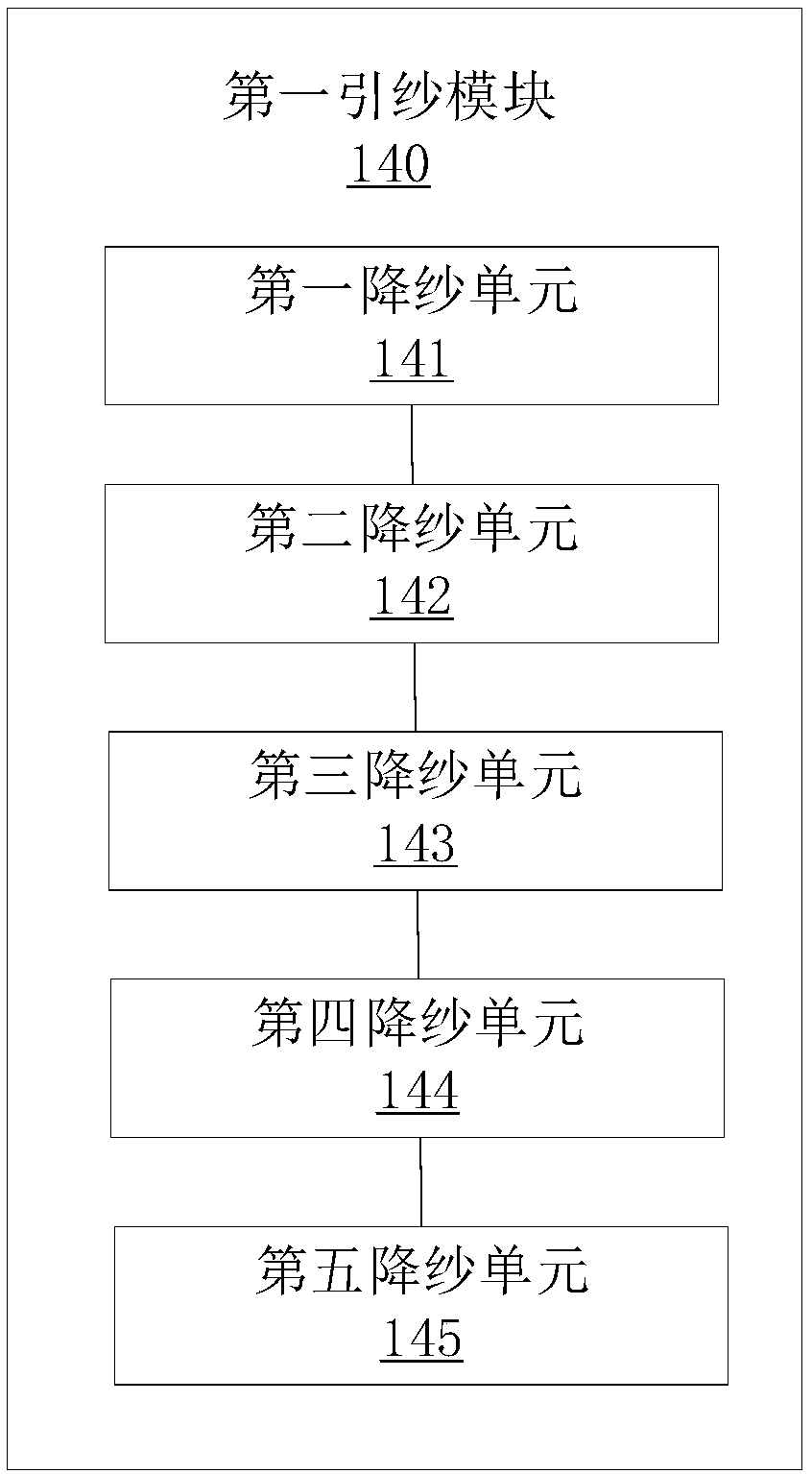

[0061] The first yarn introduction module 140 is used to sequentially lay down each layer of warp yarns in the eight layers of warp yarns, and introduce weft yarns at the cloth fell; the warp yarns are at least wrapped around the conical mold for one week;

[0062] The second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com