Point molding method for full silica gel hemodialysis catheter

A technology of catheter tip and forming method, applied in metal processing and other directions, can solve the problems of rough processing surface and unstable size, and achieve the effects of smooth processing surface, improved appearance and size, and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

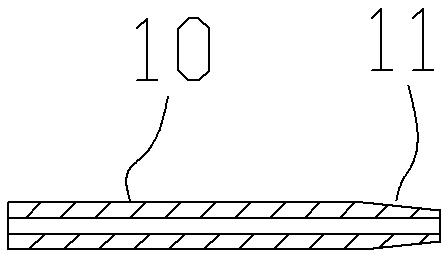

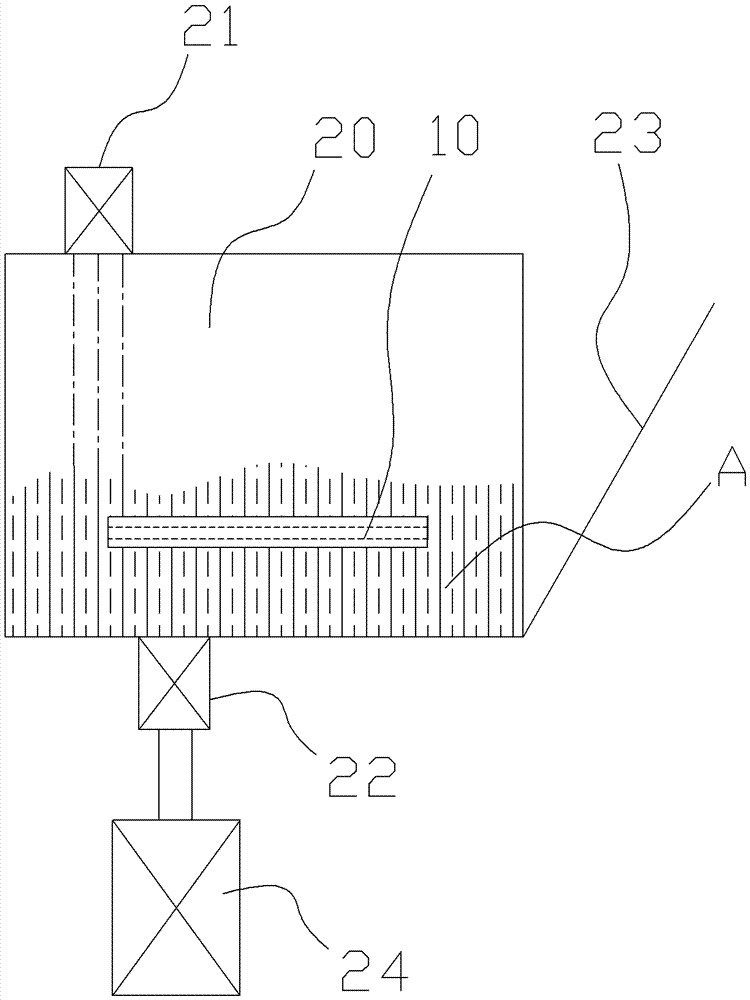

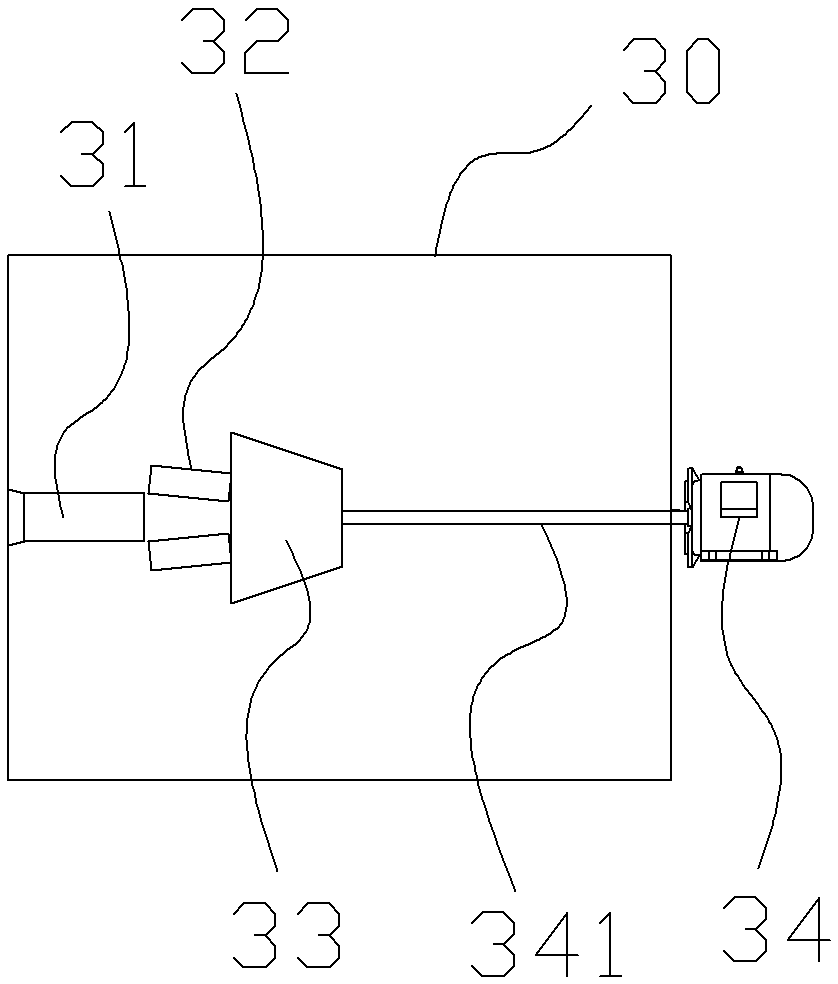

[0015] the following figure 1 , figure 2 , image 3 As a preferred specific implementation example of the present invention, a method for forming the tip of an all-silicone hemodialysis catheter comprises the following steps,

[0016] Step 1, place the silicone rubber catheter 10 in an airtight container 20, the airtight container 20 has a valve 21 for liquid nitrogen A to be inserted, a release valve 22 for releasing the liquid nitrogen A, and a flip for the silicone rubber catheter 10 to enter and exit door 23.

[0017] Step 2, filling the airtight container 20 with liquid nitrogen A, immersing the liquid nitrogen A into the silicone catheter 10 for at least one minute, and hardening the silicone catheter 20 by cooling the liquid nitrogen A.

[0018] Step 3: Quickly release the liquid nitrogen in A in the airtight container, then take out the hardened silicone catheter 10 from the airtight container 20, and immediately process the hardened silicone catheter 10 into a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com