Patents

Literature

101results about How to "Solve the blocking problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

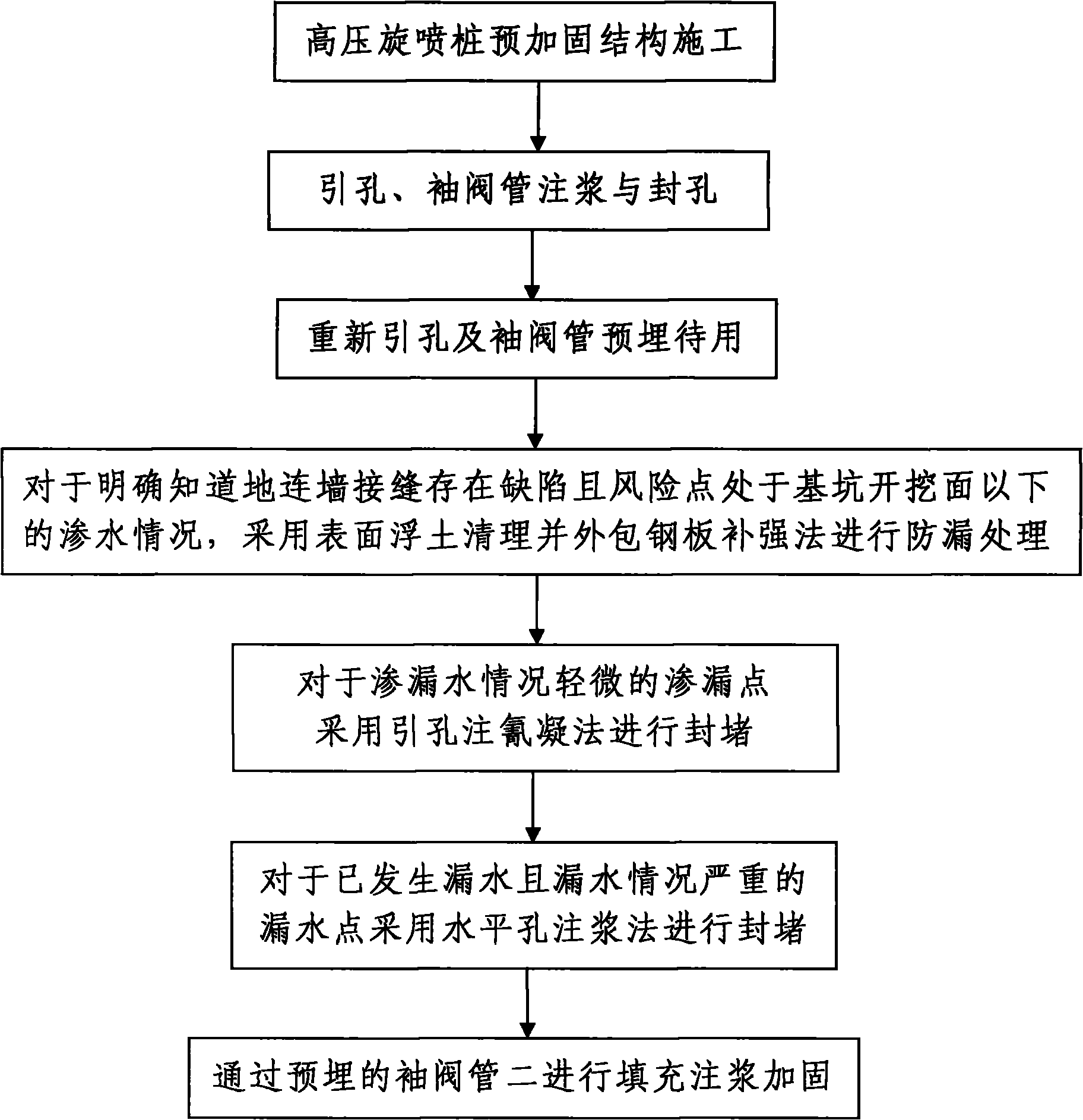

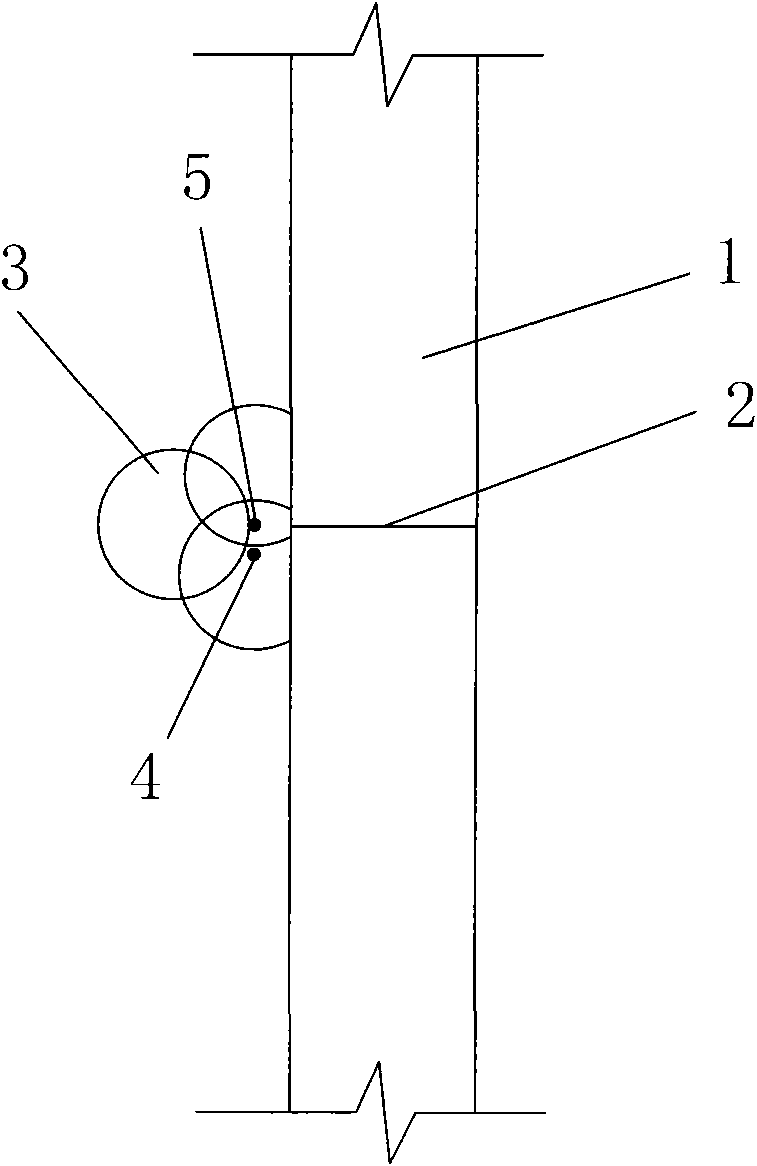

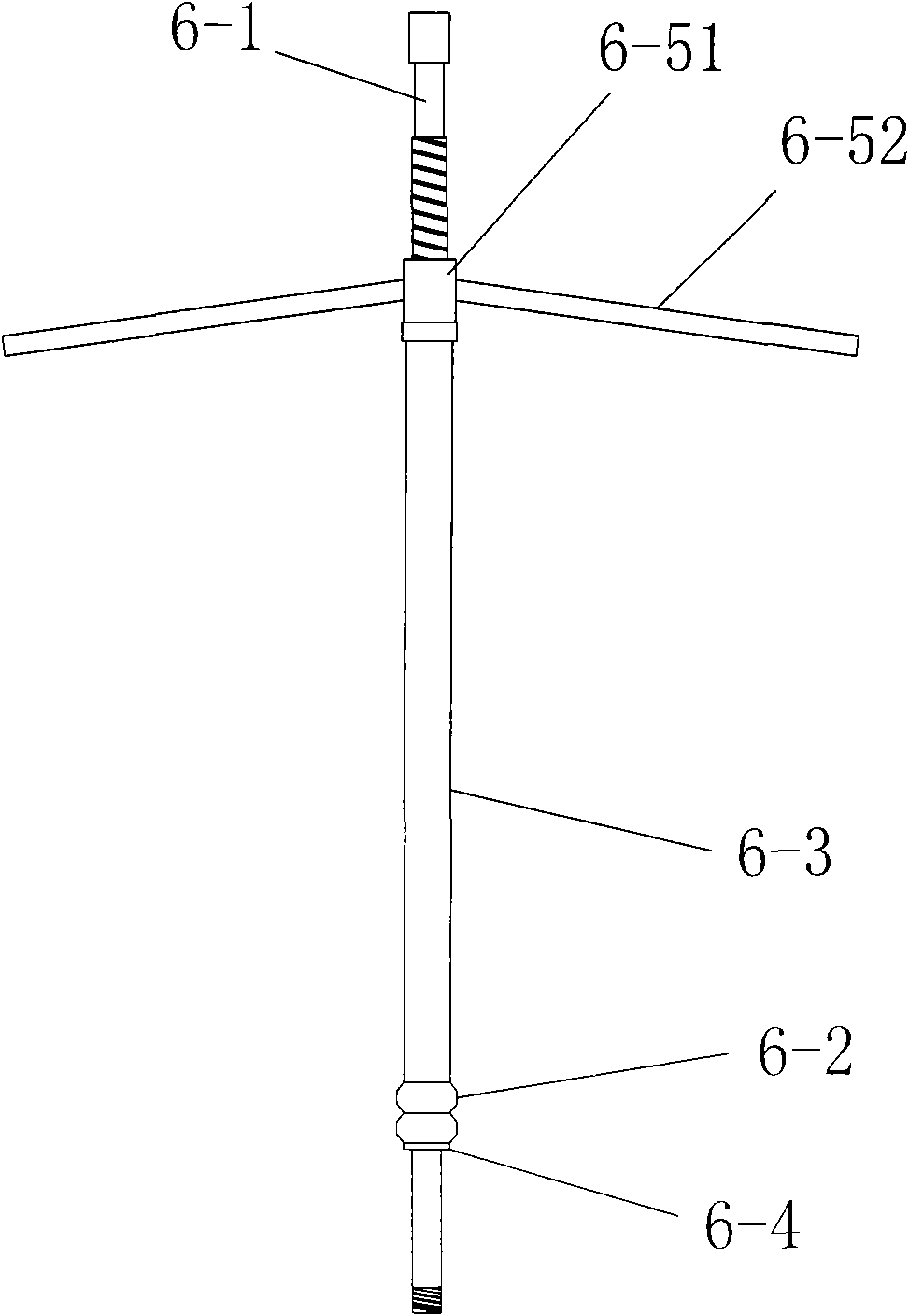

Anti-seepage and leak-blocking construction method for excavation of subway foundation pit in soft soil area

The invention discloses an anti-seepage and leak-blocking construction method for excavation of a subway foundation pit in a soft soil area, which comprises the following steps: 1) joint pre-reinforcement construction of an underground continuous wall: constructing a pre-reinforcement structure of a high-pressure rotary jet grouting pile, guiding holes, grouting by a sleeve valve pipe, sealing the holes, guiding the holes again and pre-burying the sleeve valve pipe for standby; and 2) the excavation of the foundation pit and the anti-seepage and leak-blocking construction: using surface floating earth for clearing and using the encased steel plate reinforcement method for anti-leak treatment for the situations that joints of the underground continuous wall have defects definitely and risk points are positioned below the excavation surface of the foundation pit, adopting the hole-guiding cyanogen injection condensing method for blocking of leak points with slight water leakage situation, adopting the horizontal hole grouting method for blocking for the water leak points with serious water leakage situation, and carrying out filling, grouting and reinforcement through the pre-buried sleeve valve pipe after completing the blocking. The method has reasonable design, convenient construction, comprehensive consideration, good anti-leak and leak-blocking effect, fast leak-blocking speed and can solve the problems of pipe blocking, poor anti-leak and leak-blocking effect, slow construction progress and the like in the existing anti-leak and leak-blocking construction.

Owner:TIANJIN CONSTR ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

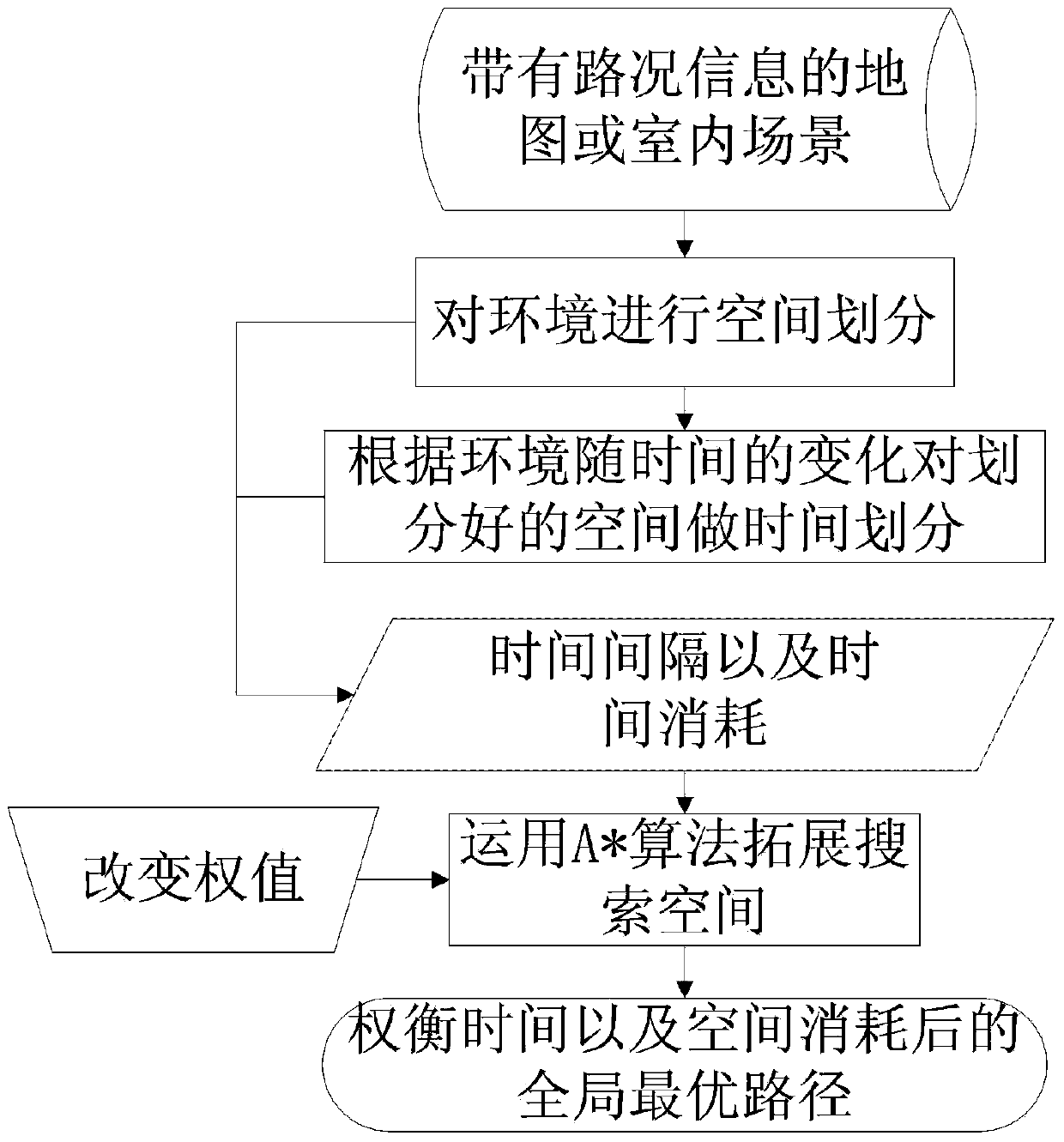

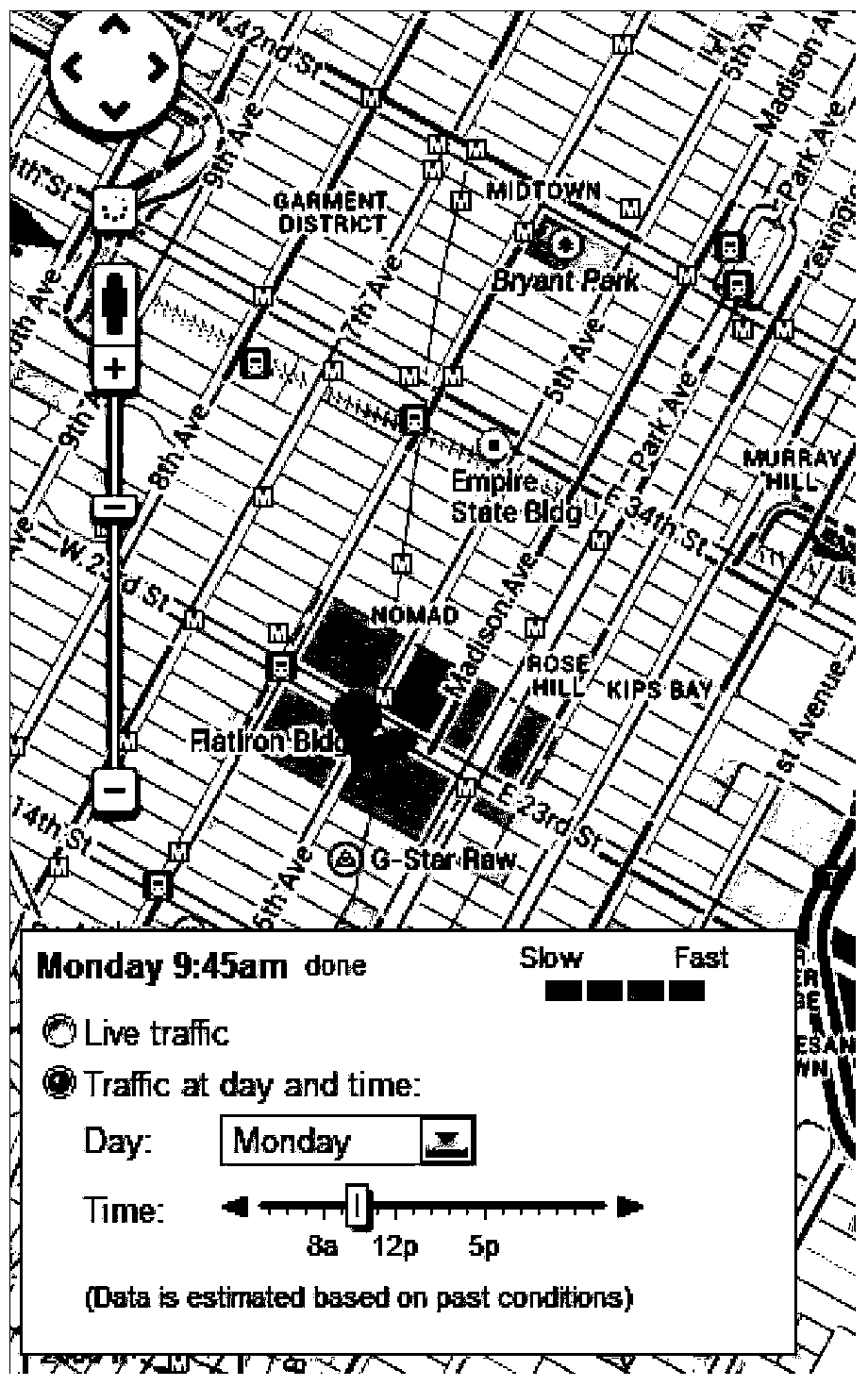

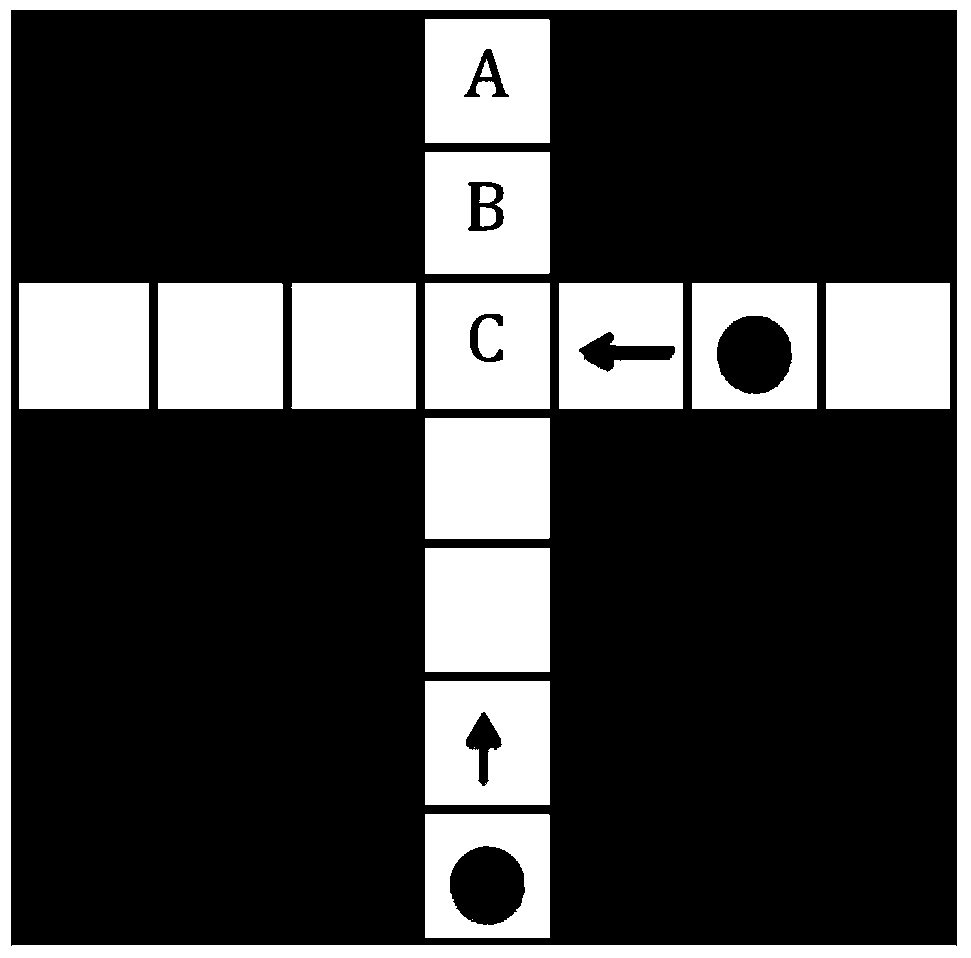

Method for seeking for overall situation time optimal path under dynamic time varying environment

ActiveCN103994768AMeets requirementsSolve the blocking problemInstruments for road network navigationNavigational calculation instrumentsOptimum routeTime cost

The invention discloses a method for seeking for an overall situation time optimal path under a dynamic time varying environment. The method comprises the following steps: extracting environment state information; molding the space of the environment; carrying out time division on the environment according to the environment state information, namely dividing a time axis into a plurality of time intervals and utilizing time consumption to represent an environment state of each time interval; utilizing an improved A* algorithm to search the environment state to obtain the overall situation time optimal path; introducing weight to realize a multi-scale path planning aim. The method can be used for realizing the aims of obstacle avoidance of indoor robots and path optimization of the complicated time varying environment of outdoor road traffic; the weighing can be carried out between time cost and distance cost according to different requirements of users to formulate the optimal path and accurately calculate the time spent for the route.

Owner:BEIJING JIAOTONG UNIV

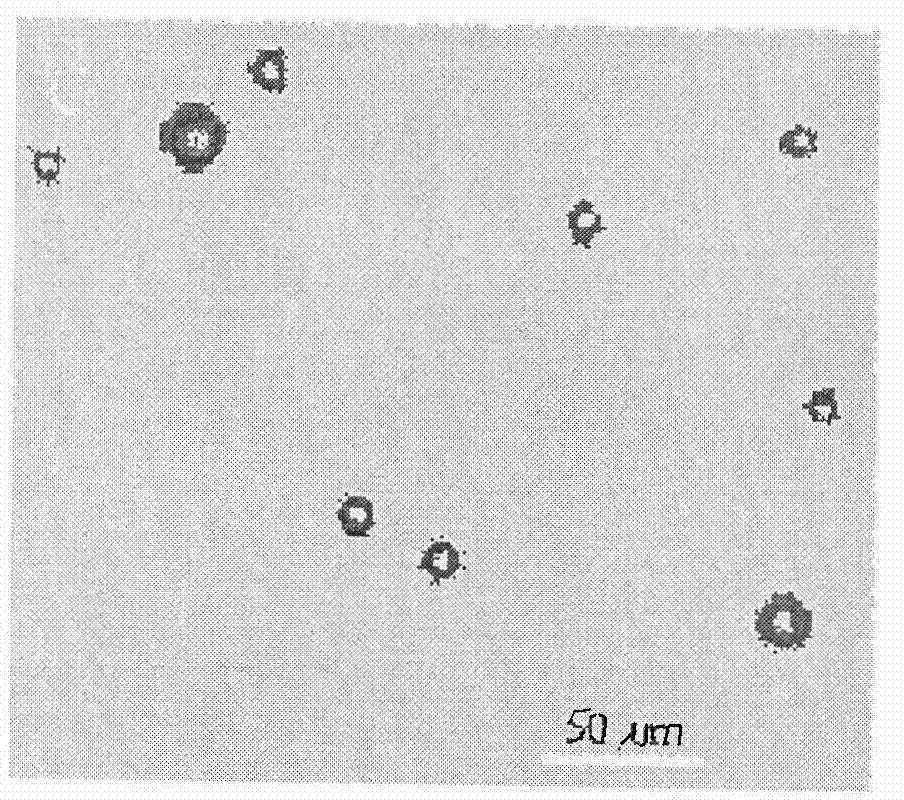

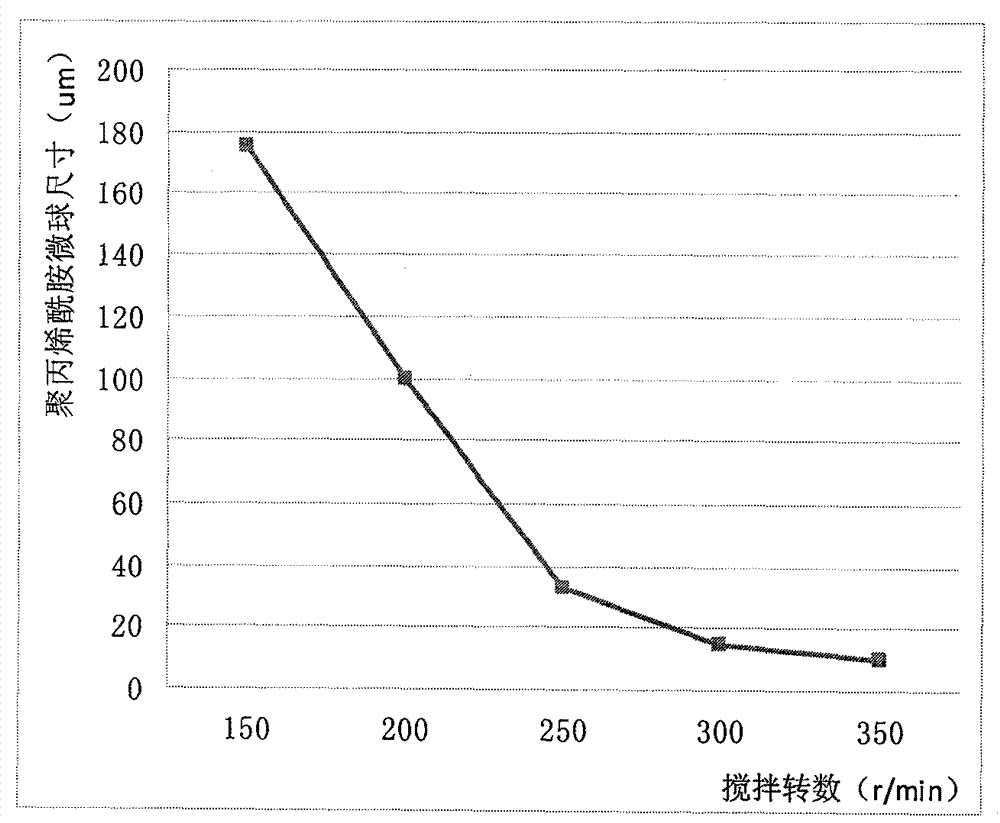

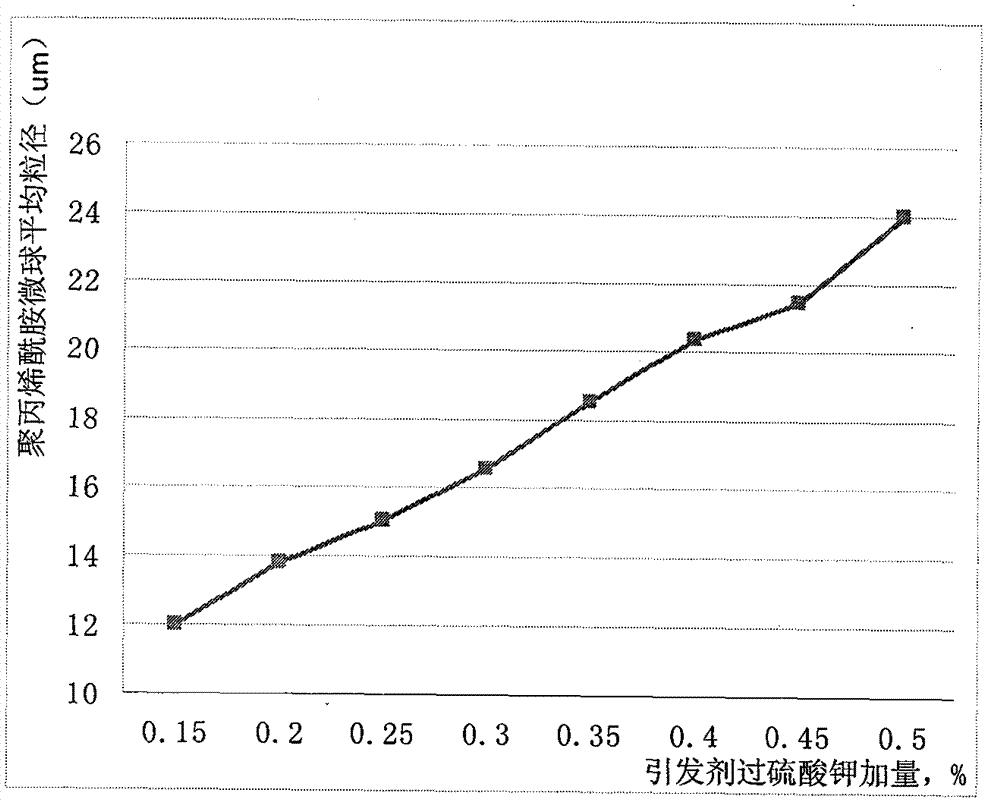

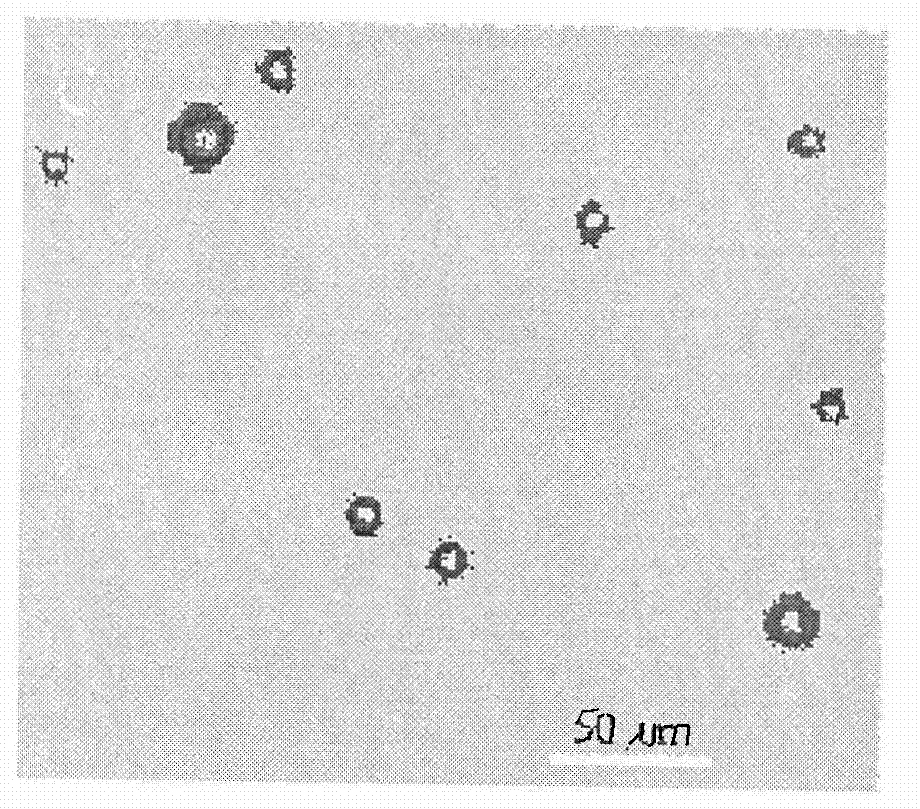

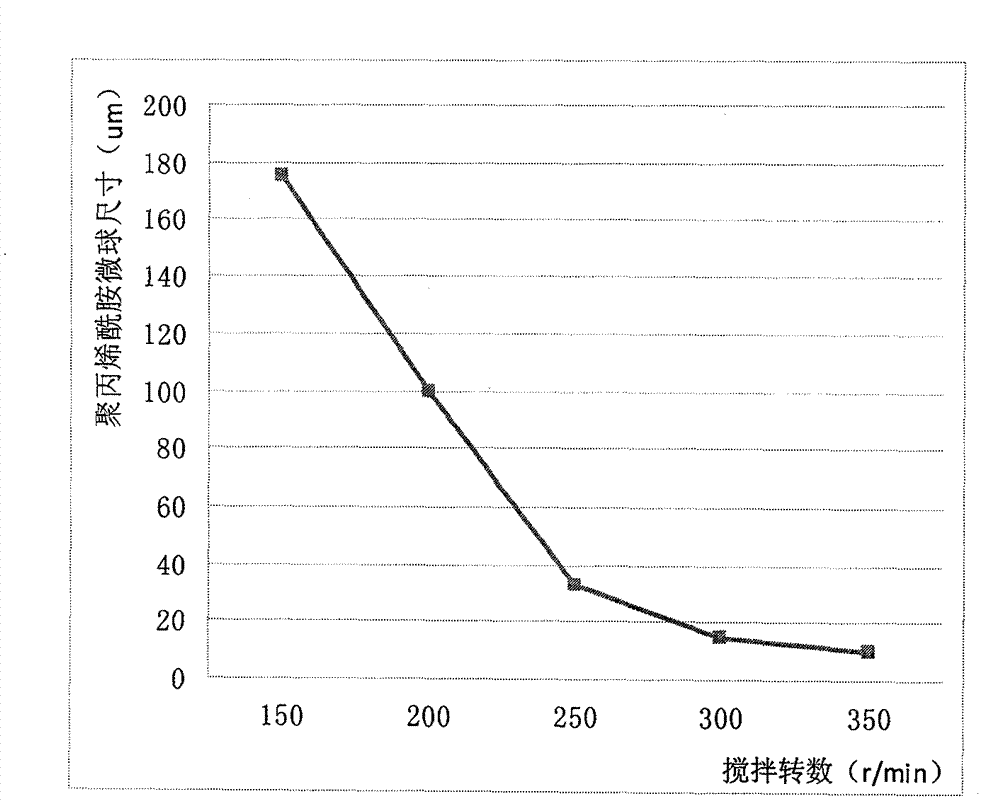

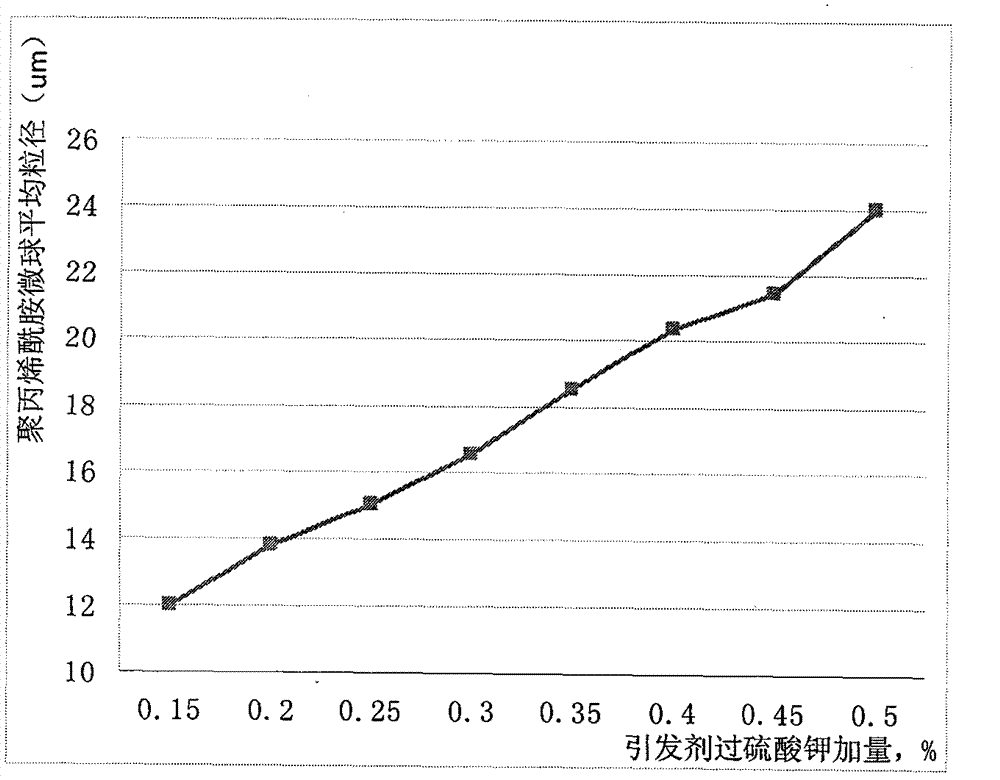

Method for producing polyacrylamide microsphere water shutoff agent

The invention discloses a method for producing a polyacrylamide microsphere water shutoff agent. The method comprises the following steps: weighing raw materials of acrylamide, salt tolerance monomers, N and N-methylene-bis-acrylyl, span 80, potassium persulfate, hexamethylene and deionized water; stirring and mixing a dispersing agent and the hexamethylene in a polymerizable monomer; and performing initiation and polymerizing to form the water shutoff agent. Compared with the prior art, the method process of the invention is simple and environmental-friendly, the particle diameter of the polyacrylamide microsphere water shutoff agent is controlled in the particle size range within 8-175 Mum, the maximum oil reservoir temperature can reach 170 DEG C, swelling rate and the salt tolerance performance are significantly improved, and the plugging problem of injected liquid in the more-than-ten-meter depth profile control can be effectively solved.

Owner:北京希涛技术开发有限公司

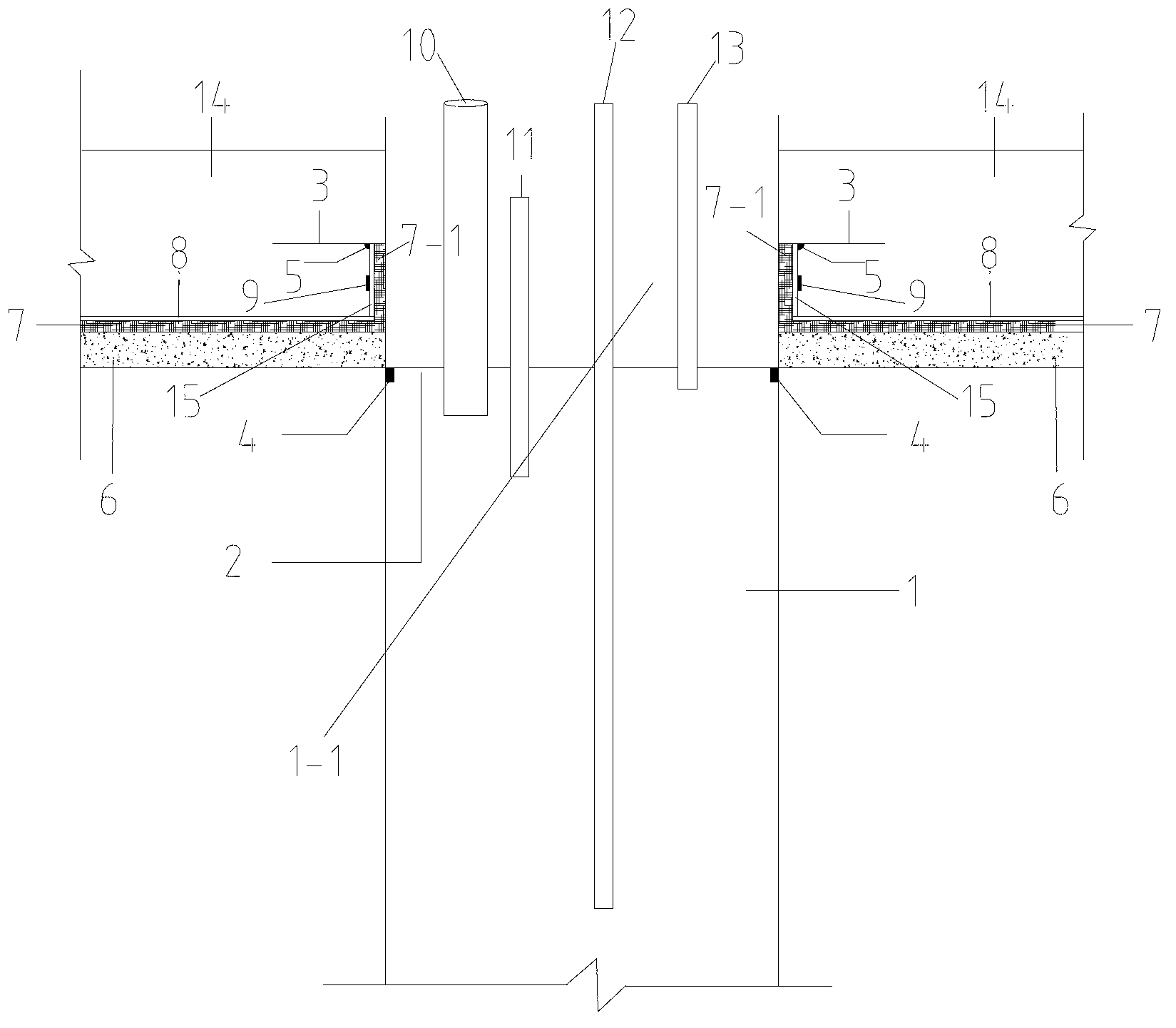

Well sealing waterproof construction method for dewatering well

The invention discloses a well sealing waterproof construction method for a dewatering well. The method comprises the following steps of: (1) constructing a foundation bed on the surrounding of the dewatering well; (2) embedding a steel sleeve for sealing the dewatering well in a foundation pit; (3) laying a waterproof roll material on the foundation bed, and then pouring a fine aggregate concrete protective layer on the waterproof roll material; (4) clamping a waterproof plate on the outer wall of the waterproof roll material on the outer wall of the steel sleeve in an abutted way; (5) clamping the waterproof plate by using a copper strip; (6) injecting a sealing adhesive to the waterproof plate; (7) pouring bottom plate concrete to the fine aggregate concrete protective layer; (8) pumping water; (9) embedding a sealing plate in the steel sleeve; (10) after filling gravels into a filling pipe, injecting a cement paste into a cement paste injection pipe, and stopping the injection of the cement paste until the paste in an overflow pipe flows out; and (11) pouring concrete into the steel sleeve above the sealing plate. Through the adoption of the well sealing waterproof construction method disclosed by the invention, a waterproof treatment problem at the connection of the dewatering well in the foundation pit and the foundation bottom plate in the whole dewatering well sealing waterproof system is solved.

Owner:天津住宅集团建设工程总承包有限公司

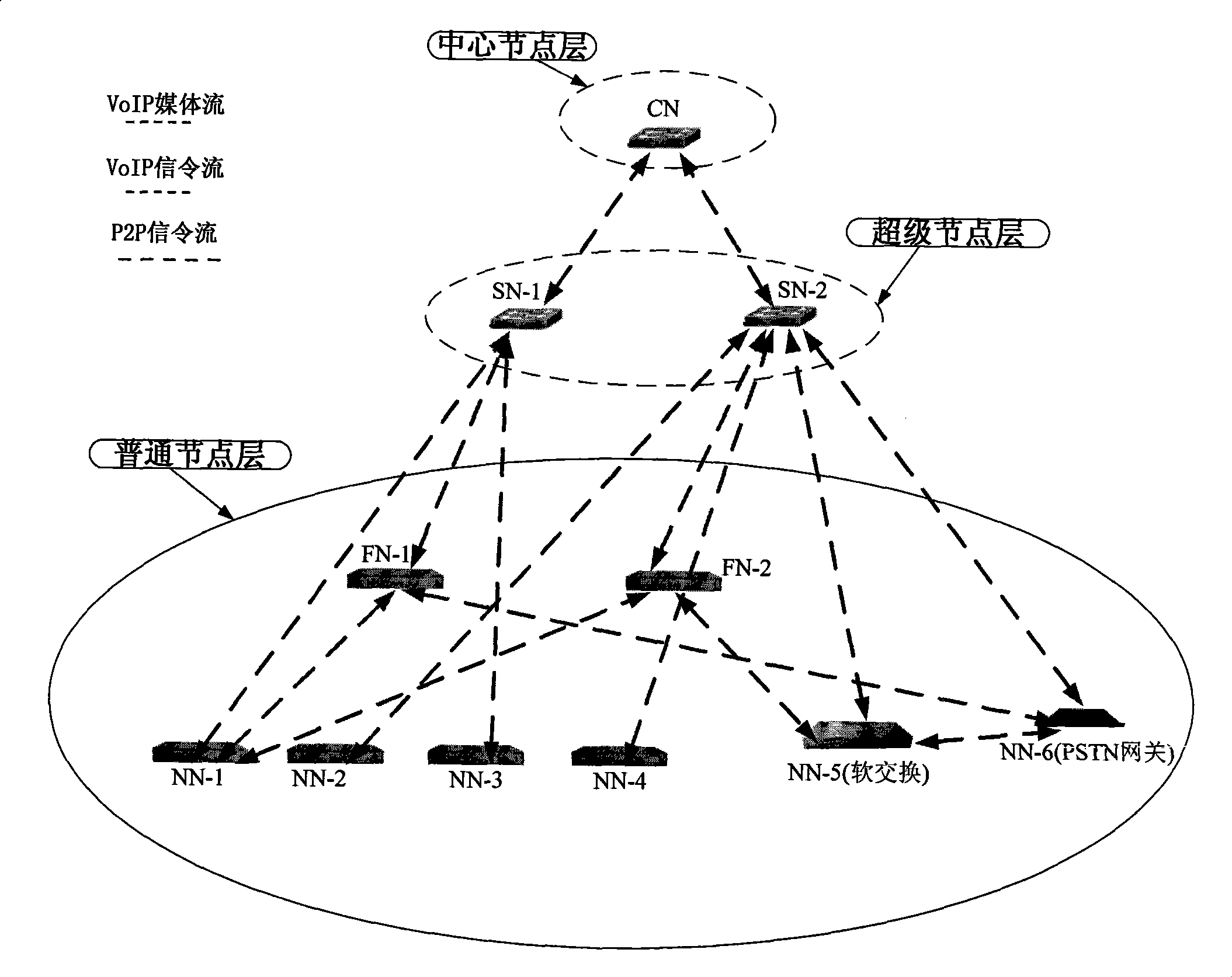

P2P method for supporting VoIP communication

InactiveCN101420434ASolve the blocking problemQuality assuranceInterconnection arrangementsTransmissionOverlay networkInformation exchange

The present invention provides a P2P method supporting VoIP communication. A VoIP terminal and a server are all one node in the P2P network, and all nodes form an overlay network in the P2P network. The method of the invention comprises establishing the P2P network, selecting and establishing path. The whole P2P network is divided into three layers and four roles, wherein the three layers are a common node layer, a super node layer and a middle node layer. The four roles of P2P nodes are the following: NN: common node, FN: forwarding node, SN: super node, and CN: middle node of P2P network. Firstly the NN needs to be registered to SN. The SN receives the registration of NN / FN. The CN takes charge of establishing various regulations and strategies, at the same times takes charge of information exchange between SN-1 and SN-2, receives the registration of SN, manages the total network FN list, transmits an FN list to the SN and transmits a strategy to NN / FN. The VoIP and medium flow are all transmitted through a virtual path combined between NN / FN.

Owner:深圳市欢乐酷享网络科技有限公司

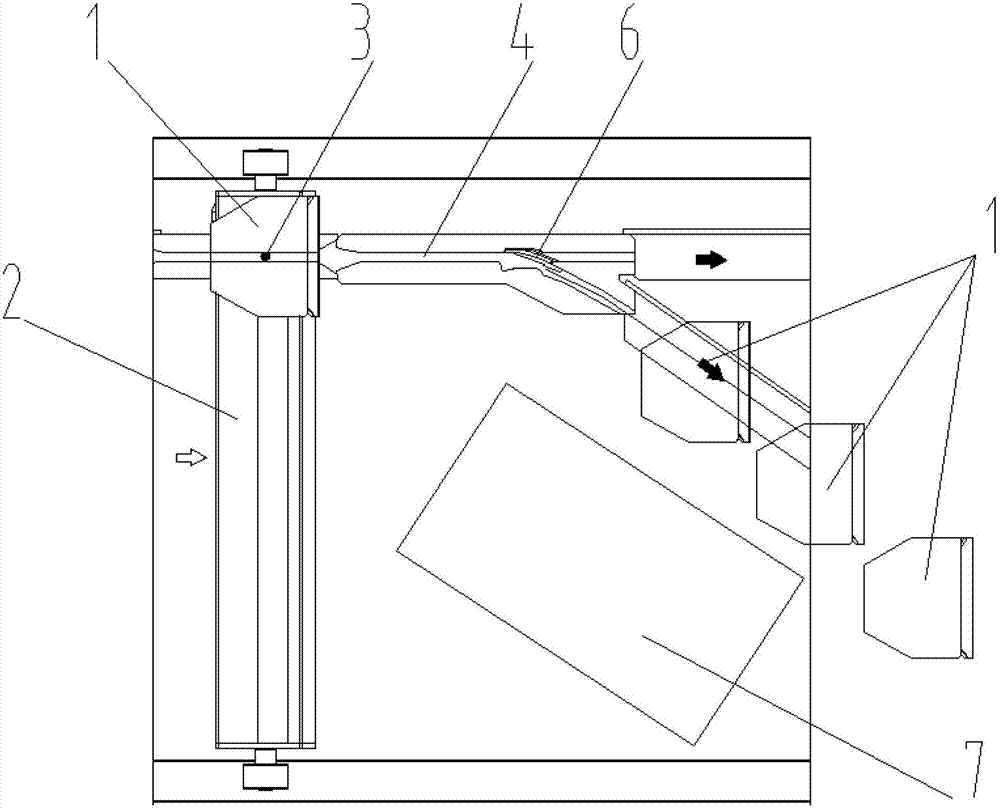

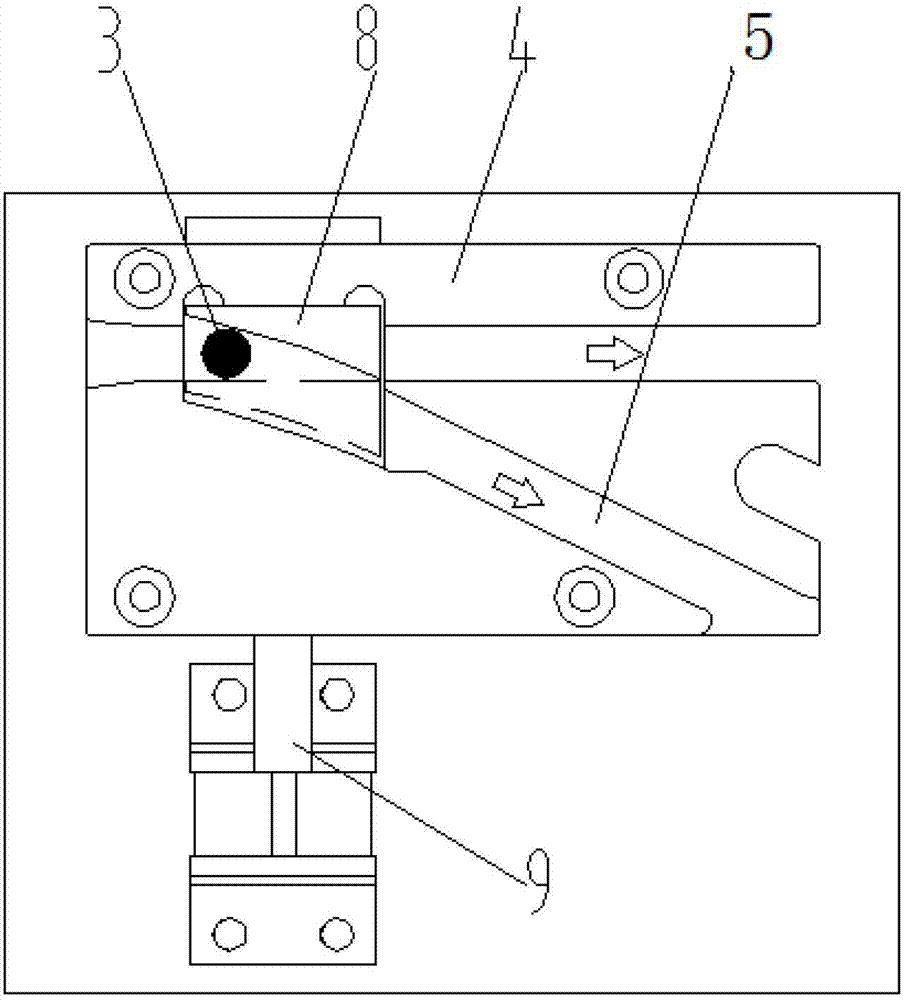

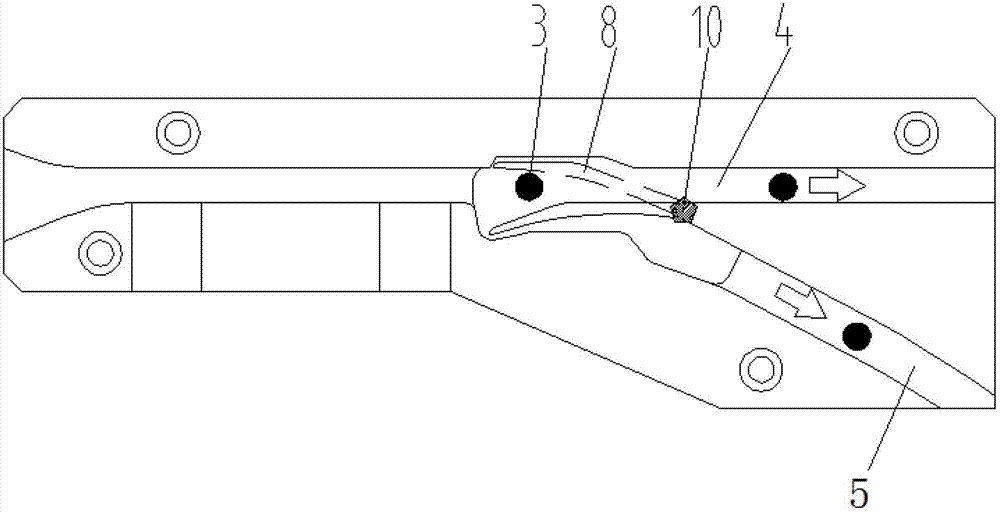

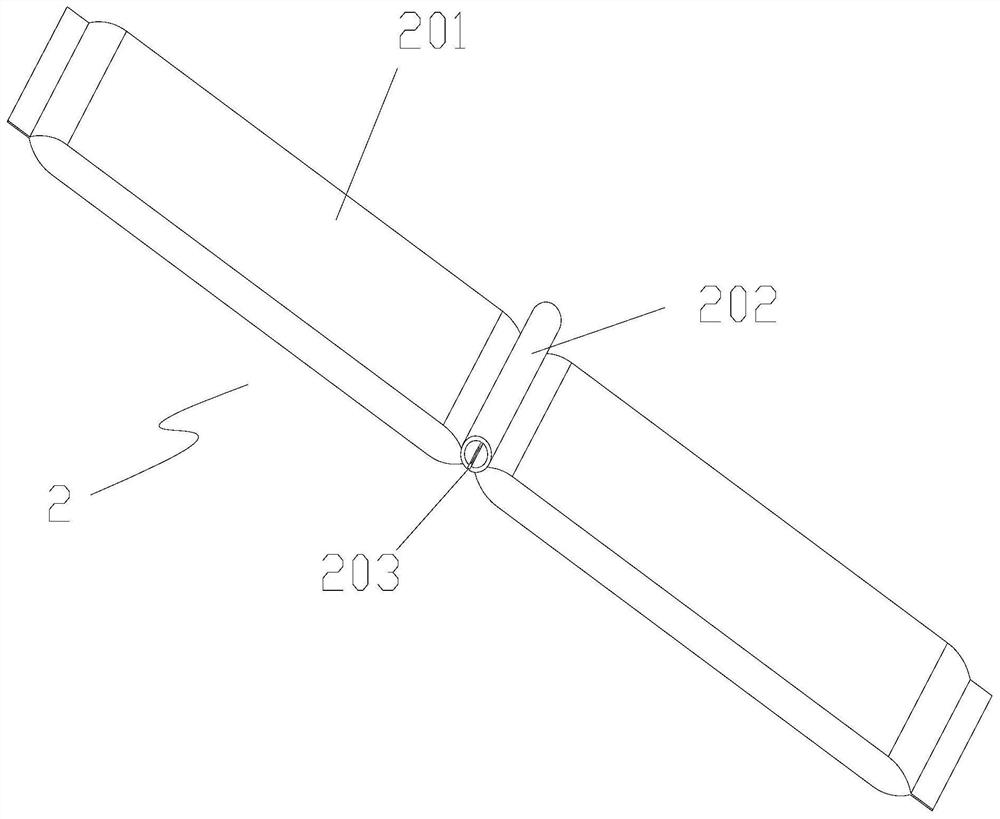

Electrically-driven high-speed turnout reversing device

ActiveCN102815529AIncrease operating frequencyLow roughness requirementsConveyor partsElectricityCross connection

The invention relates to a slider type sorting machine, particularly relates to an electrically-driven high-speed turnout reversing device for the slider type sorting machine, and belongs to the technical field of logistics equipment. The electrically-driven high-speed turnout reversing device is characterized in that one end of a strip shifting fork is fixed to a cross joint of two guide rails through a rotary shaft, the other end of the strip shifting fork can be electrically driven in arc movement along the rotary shaft to shift back and forth between two guide grooves, and an electromagnetic solenoid driving mode is adopted by a shifting fork driving device. By means of electrical driving, single-time shifting fork reversing action can be completed in 8ms which is much lower than air cylinder action time of 30ms. The strip shifting fork in arc movement along the rotary shaft instead of linear movement can greatly reduce operating amplitude, improve reversing efficiency and increase conveying speed; the requirement on roughness of the contact face of the shifting fork with a rail can be lowered, and safety reliability of equipment is greatly improved; and air source compression is not needed, and utilization cost and maintenance cost of the equipment can be reduced.

Owner:SHANGHAI DAMON LOGISTICS TECH

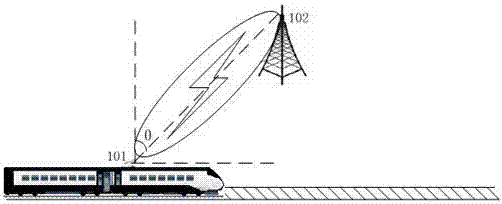

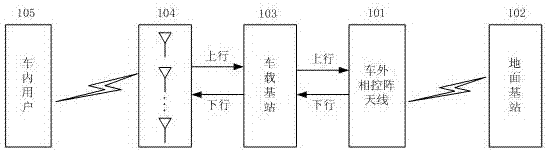

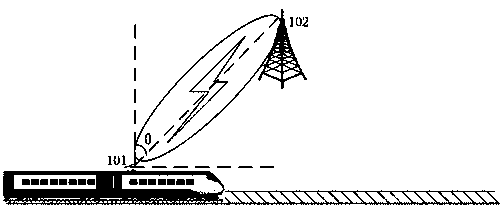

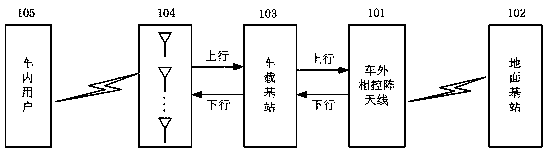

Train-mounted base station mobile communication system for high speed railways

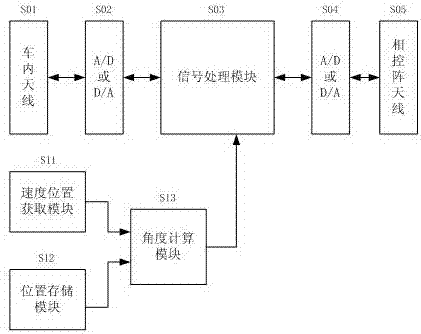

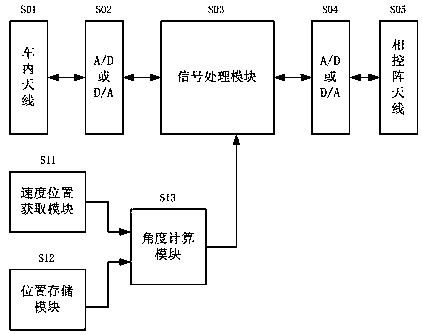

ActiveCN106899984AHigh gainImprove communication qualityNetwork planningCommunication qualityMobile communication systems

The invention discloses a train-mounted base station mobile communication system for high speed railways. The train-mounted base station mobile communication system for high speed railways comprises a train-mounted base station, a train internal antenna, a train external phased-array antenna and a ground base station. The train-mounted base station is communicated with the inside user through the train internal antenna and is connected wirelessly with the ground base station through the train external phased-array antenna. Each array of the train external phased-array antenna is adjustable, so that a main lobe beam that always points to the ground base station can be formed. According to the invention, the main lobe beam of the phased-array can always point to the ground base station through adjusting the phase of the antenna array, the effect that the signal strength received by the train base station is the higher can be ensured, and the communication quality of the users on the train can be improved.

Owner:WUHAN HONGXIN TECH DEV CO LTD

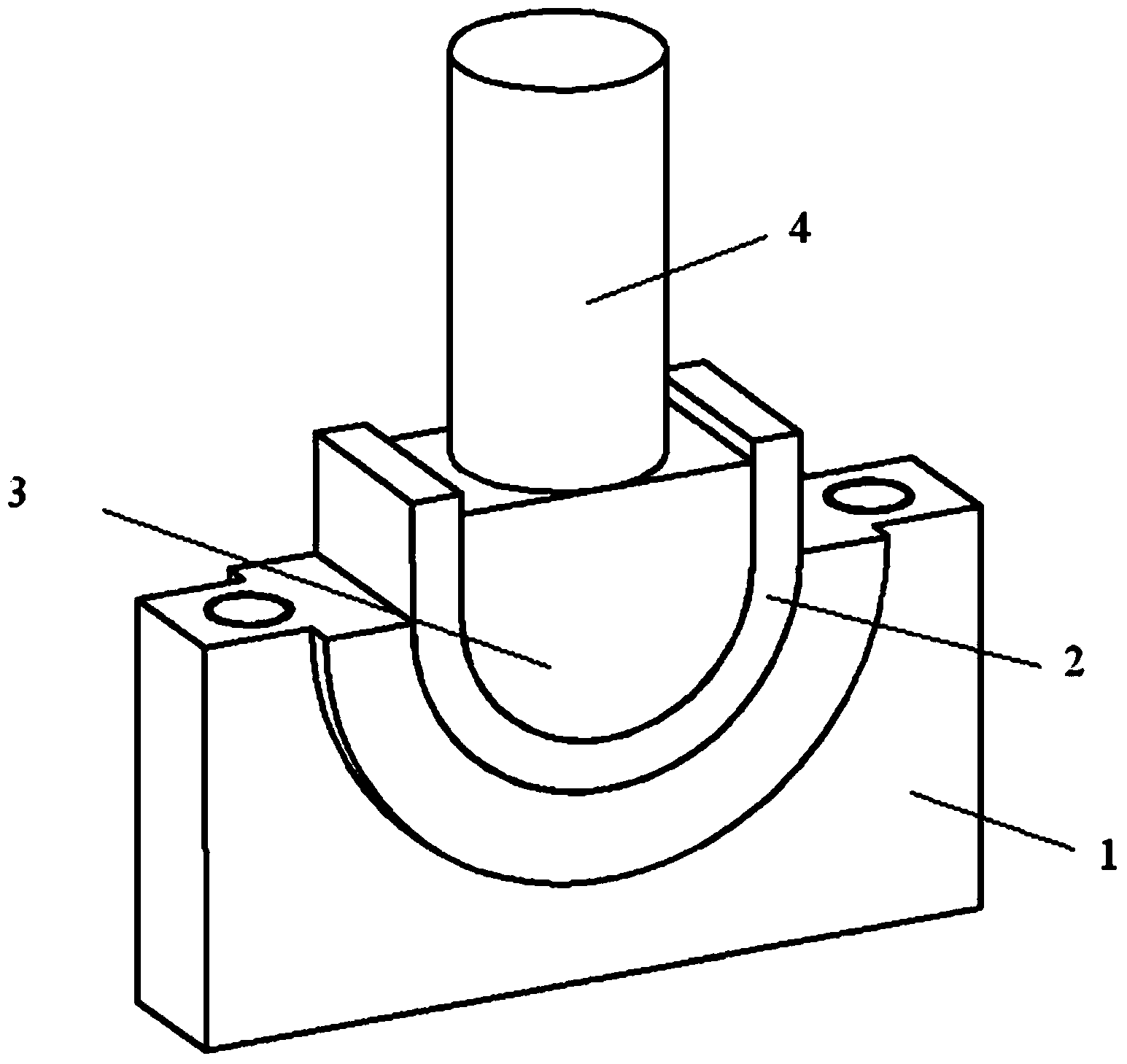

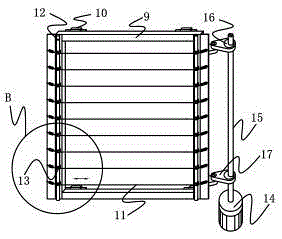

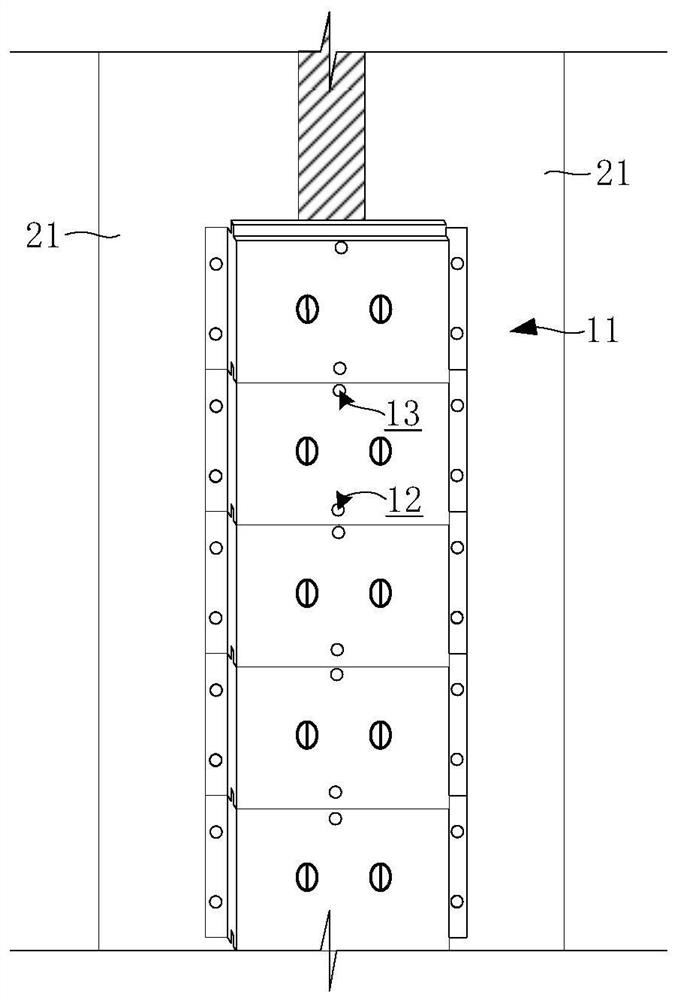

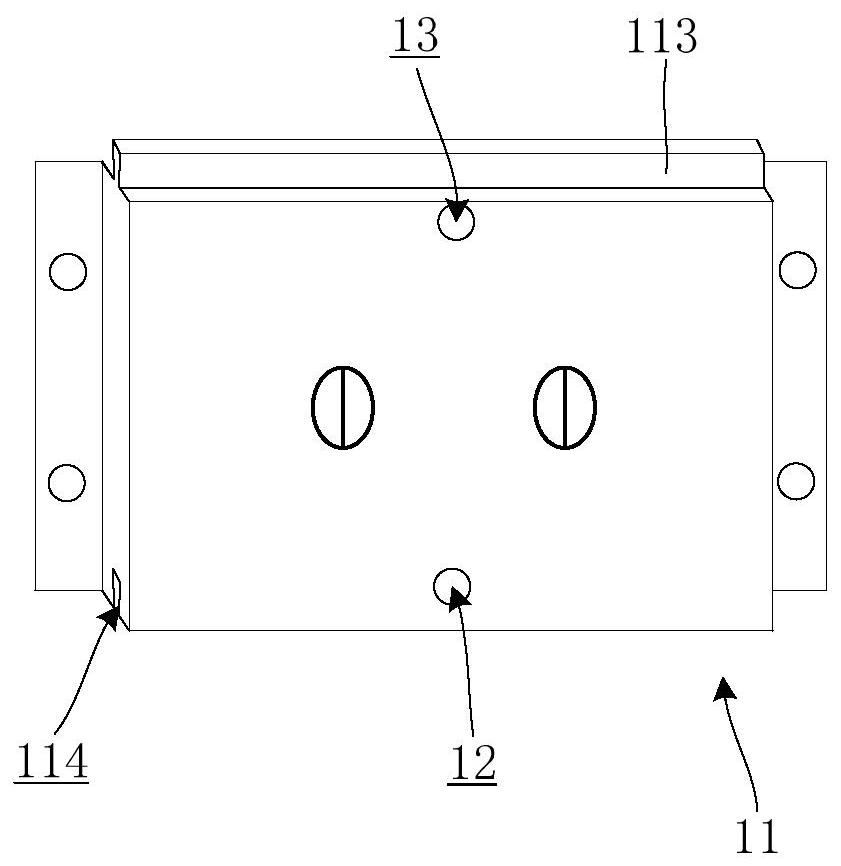

Internal expansion plugging device for cam shaft hole

ActiveCN103759006ASolve the blocking problemPlug firmlyEngine sealsFluid-tightness measurement using fluid/vacuumThermal expansionCam

The invention relates to an internal expansion plugging device for a cam shaft hole. The internal expansion plugging device for the cam shaft hole comprises a pull rod, a rear end inner sleeve, inner sleeves, a front end inner sleeve, outer sleeves, O-shaped rings, a pin, a handle and springs, wherein a boss structure with the increased outer diameter is arranged at one end of the pull rod, the other end of the pull rod is movably connected with the handle through the pin, a cam structure is arranged at the position of connection between the handle and the pull rod, and the pull rod penetrates through the rear end inner sleeve, the first O-shaped ring, the first outer sleeve, the second O-shaped ring, the first inner sleeve, the third O-shaped ring, the second outer sleeve, the fourth O-shaped ring and the front end inner sleeve in sequence. According to the internal expansion plugging device for the cam shaft hole, the purpose of plugging an oil hole formed in the multi-gear cam shaft hole can be effectively achieved, and plugging is reliable.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A construction method for new pipe connection and original pipe plugging in large-scale sewage pipeline relocation

PendingCN109208737ASolve the blocking problemGuarantee the quality of plugging constructionSewer pipelinesSewageSteel frame

The invention provides a construction method for new pipe connection and original pipe plugging in large-scale sewage pipeline relocation. The construction method comprises the following steps: firstly, a new pipe receiving well is constructed beside an existing working well adjacent to the original sewage pipe, and the shaft wall of the existing working well is sawn, so that the new pipe receiving well is communicated with the existing working well; and then the original sewage pipe is temporarily plugged by adopting temporary plugging gate in the existing working well, wherein the temporaryplugging gate comprises a grille steel frame and a steel baffle. After the temporary plugging gate is installed, the diver goes down the shaft and plugs the original sewage pipe at the downstream partof the temporary plugging gate with brick masonry stone. After the plugging is completed, the underwater concrete is poured between the temporary gate valve and the plugs. The method adopts a temporary gate for temporary blocking, which can reduce the impact force of water flow on the diver and the blocking wall, reduce the operation risk, improve the blocking construction quality, and reduce theconstruction risk in the excavation process of the deep foundation pit of the metro.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

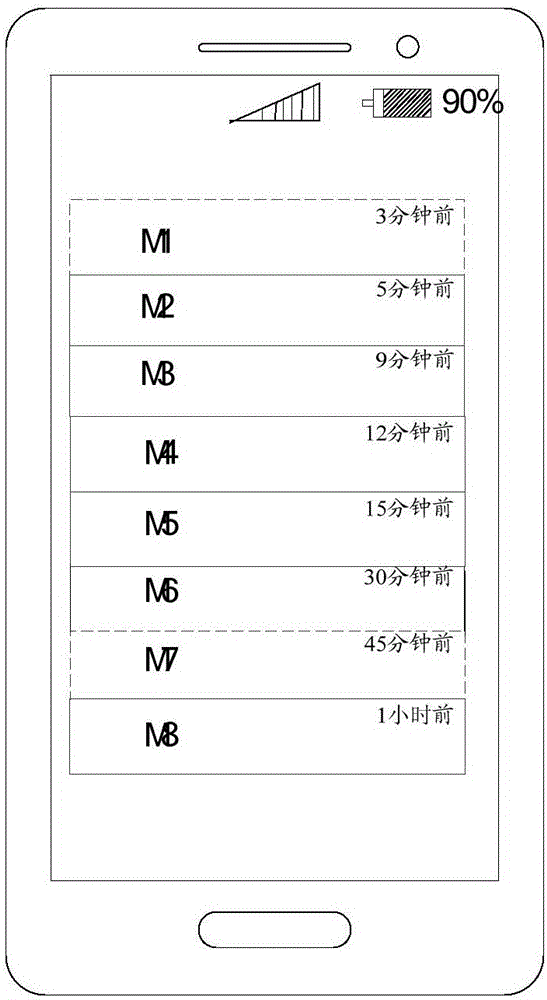

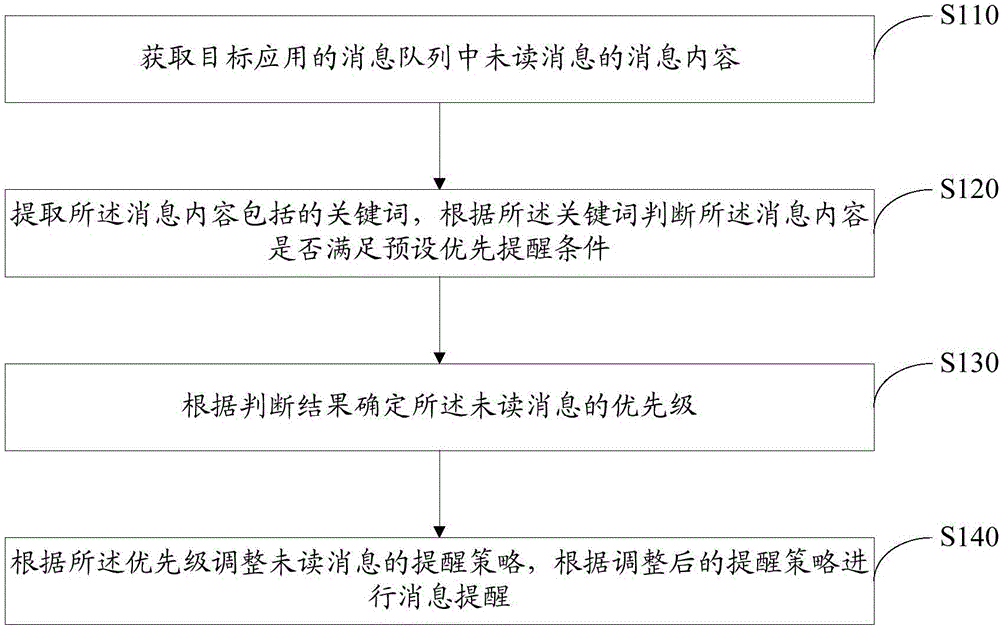

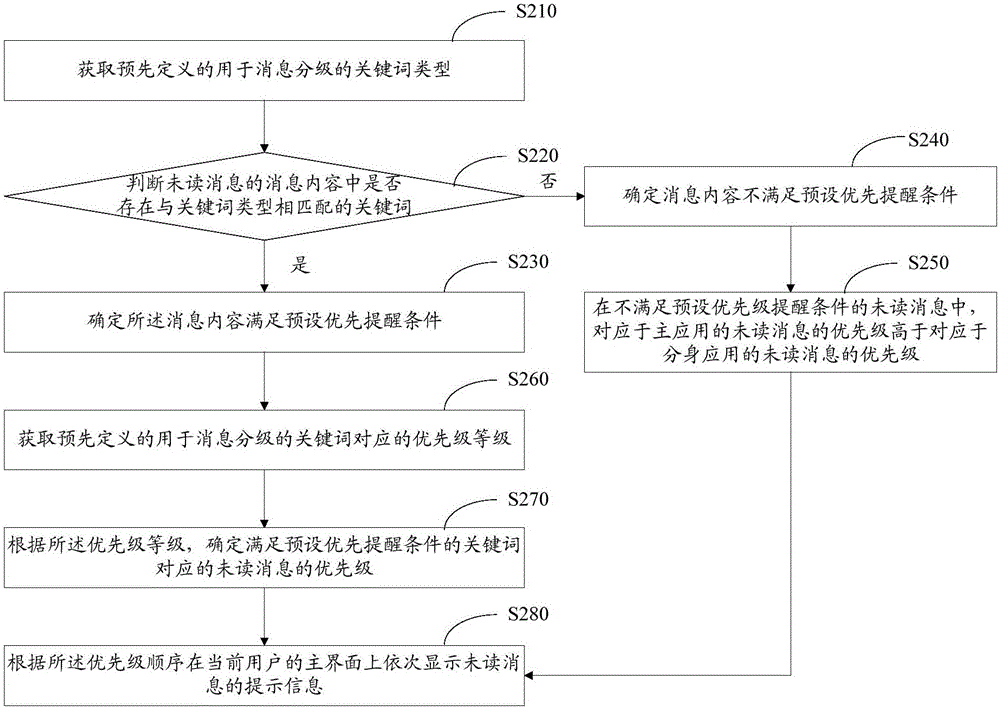

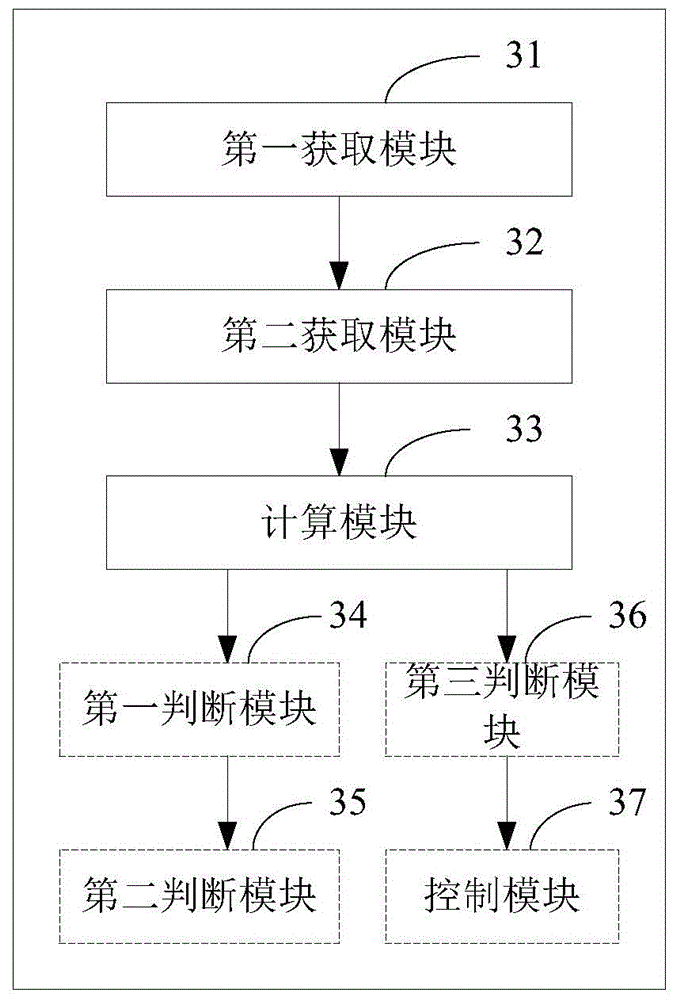

Message alert method and message alert device for multi-open applications, and mobile terminal

InactiveCN106657589ASolve the blocking problemPrioritizeSubstation equipmentExecution for user interfacesMessage queueManagement efficiency

The embodiments of the invention disclose a message alert method and a message alert device for multi-open applications, and a mobile terminal, and relate to the field of mobile terminals. The method comprises the following steps: acquiring the message content of an unread message in a message queue of a target application; extracting keywords contained in the message content, and judging whether the message content meets a preset priority alert condition according to the keywords; determining the priority of the unread message according to the judgment result; and adjusting the alert strategy of the unread message according to the priority, and giving a message alert according to the alert strategy after adjustment. According to the embodiments of the invention, the problem that the messages of a split application of a multi-open application may be shielded is solved, a message with higher priority can be handled first on the basis that all messages can be handled, and the application management efficiency of the mobile terminal is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

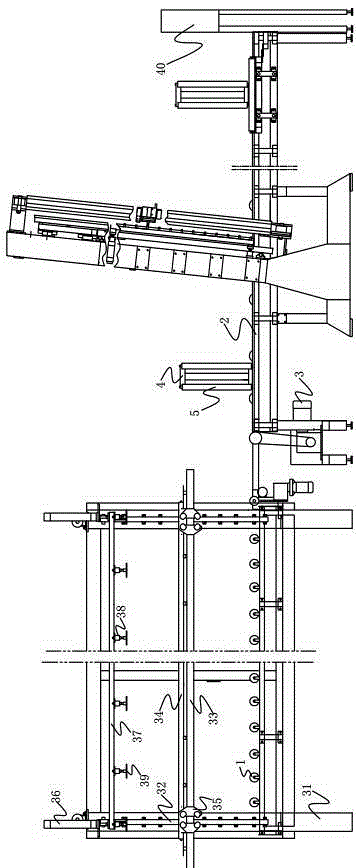

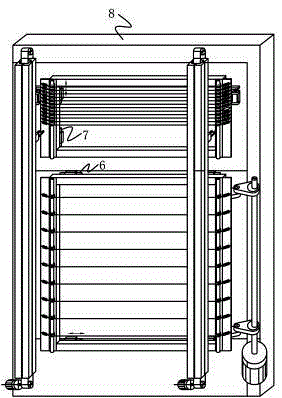

Foam plate cutting machine

ActiveCN105291164ASolve the blocking problemEasy to transportMetal working apparatusAutomationEngineering

The invention discloses a foam plate cutting machine. The foam plate cutting machine comprises a workbench with wheels. The wheels are driven through a motor arranged on the workbench. Linkage cutting devices used for evenly cutting a large plate into a plurality of thin plates are arranged on the two sides of the workbench. The cutting devices are provided with wire adjusting devices used for adjusting the number of cutting wires and the distance between the cutting wires. The workbench is further provided with a segmented cutting device used for cutting the thin plates into finished plates in a segmented manner. The foam plate cutting machine further comprises a control device used for controlling the motor, the cutting devices, the wire adjusting devices and the segmented cutting device. The foam plate cutting machine is high in automation degree, wide in machining range and capable of achieving rapid cutting. The cut planes of the cut plates are smooth, the cutting quality is good, the cutting efficiency is high, the cutting process is free of retardation, and environment friendliness is high.

Owner:QINGDAO HEINOSKY TECH CO LTD

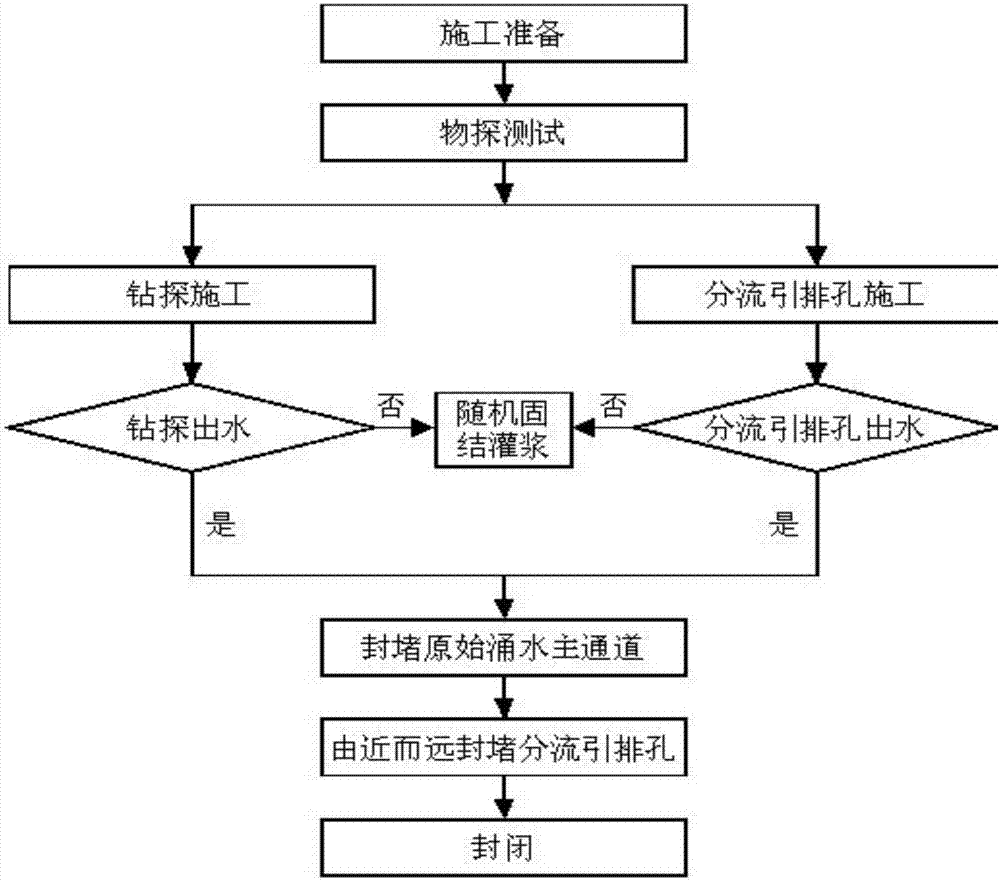

Method for blocking underground water in high-water-pressure and high-flow karst tunnels

InactiveCN107152294ASolve the blocking problemSolve drainage problemsUnderground chambersTunnel liningLeaking waterGeomorphology

A method for sealing underground water in a karst tunnel with high water pressure and large flow rate, comprising the following steps: ① Using geophysical prospecting and drilling to determine the water pressure and water volume; ② Carrying out diversion construction for leaking water; ④ Random grouting reinforcement of the surrounding rock of the tunnel; ⑤ Layered sealing from near to far, top to bottom; ⑥ Sealing and sealing construction of the final water leakage point. The invention solves the plugging and drainage problems of high water pressure and large flow karst tunnels, and reduces the risks of construction and later operation.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

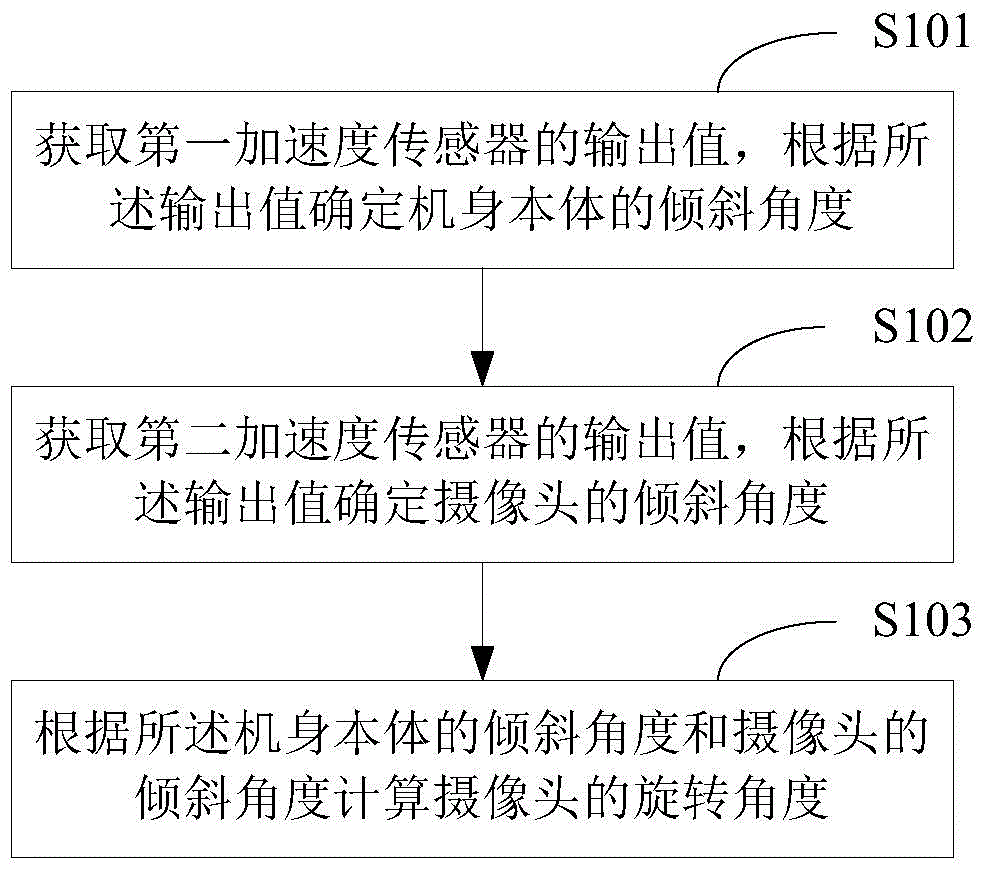

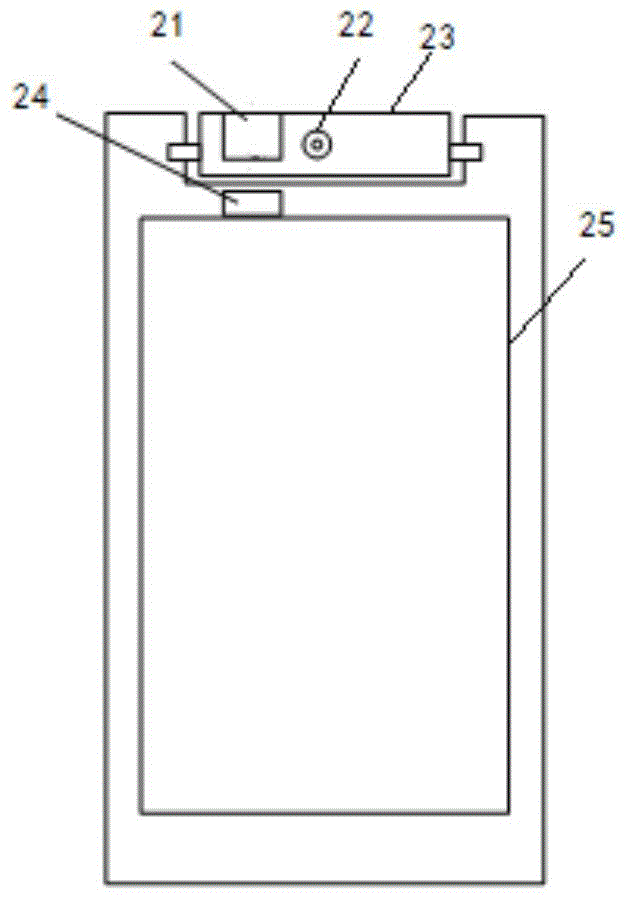

Method and device for detecting rotating angle of camera and mobile terminal

ActiveCN104567791AImprove accuracyImprove stabilityMeasurement devicesComputer terminalComputer science

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

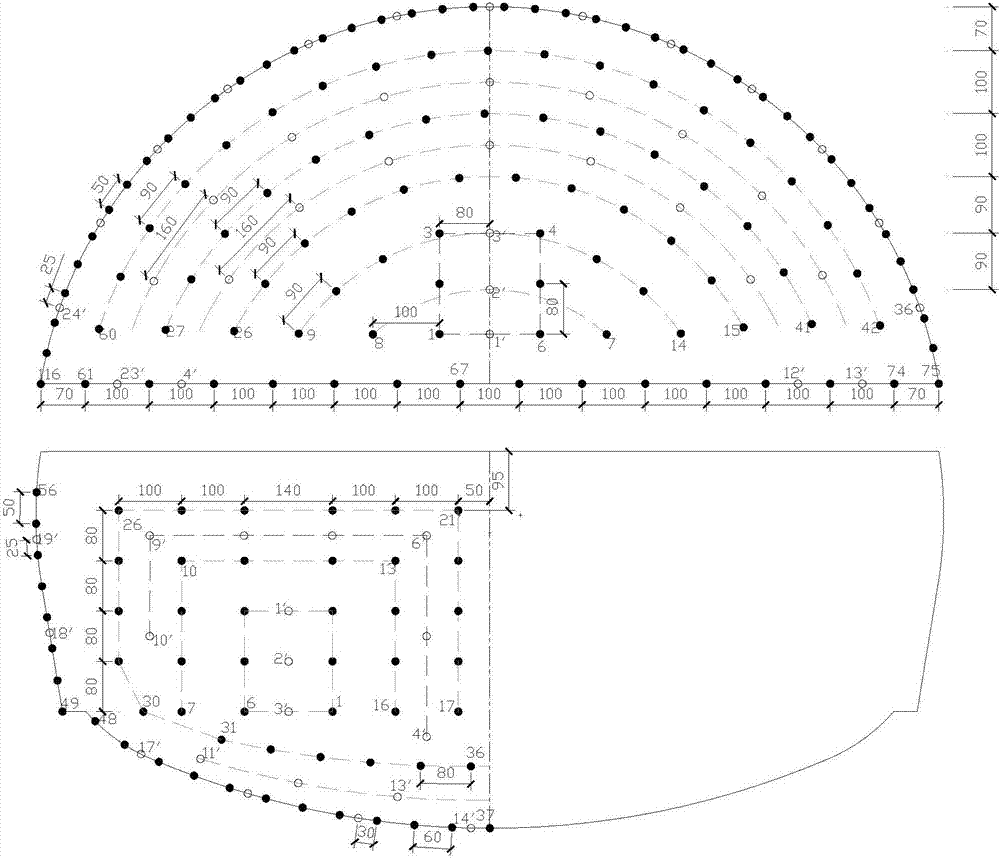

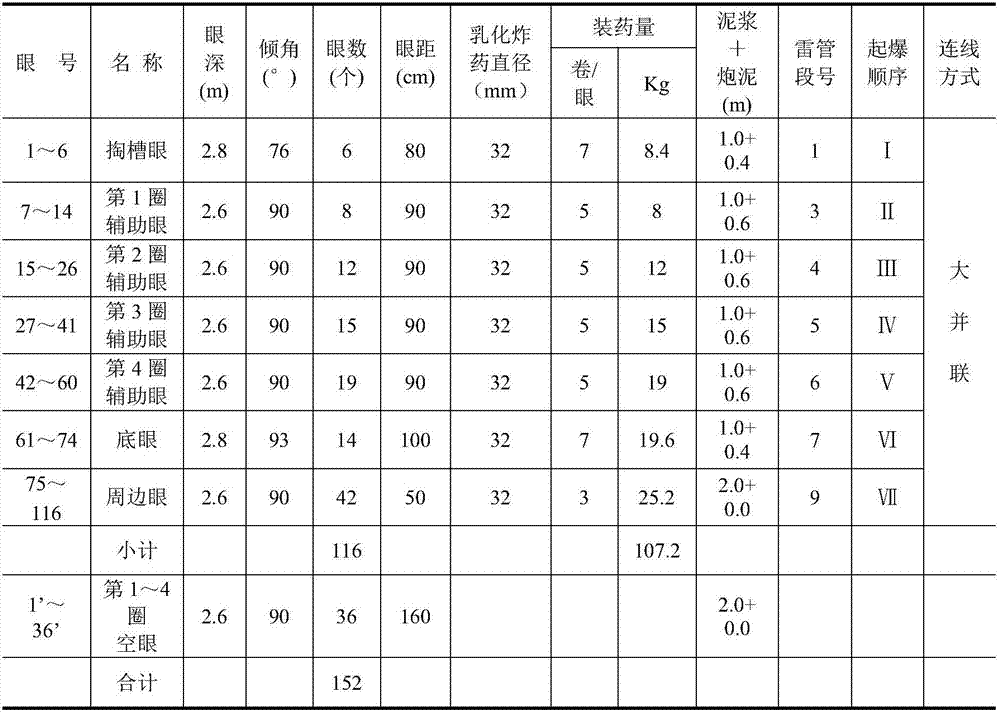

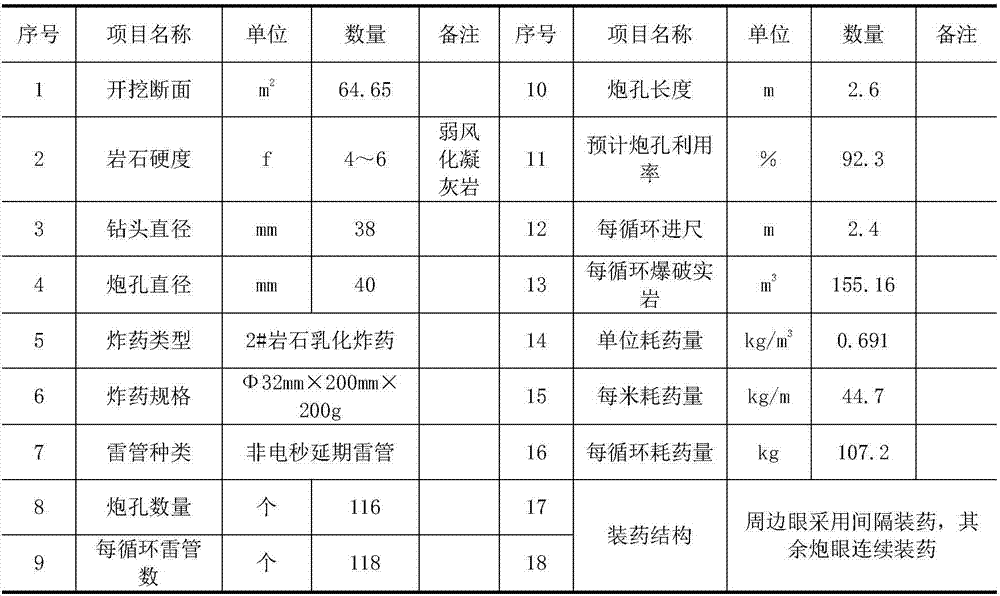

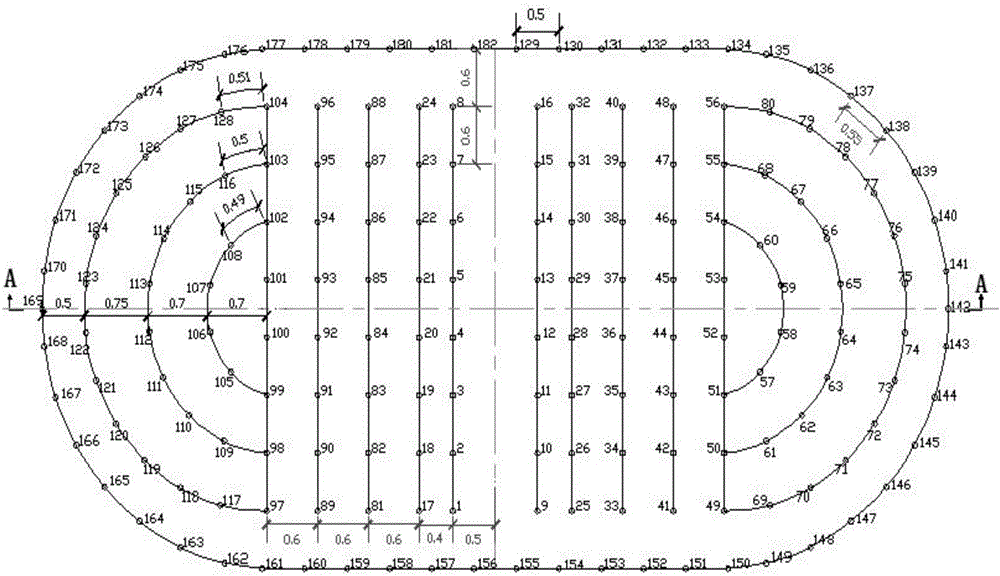

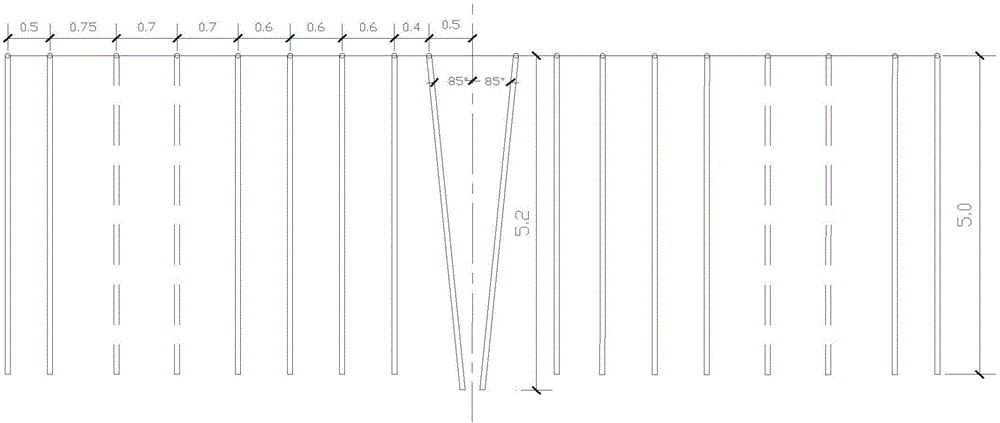

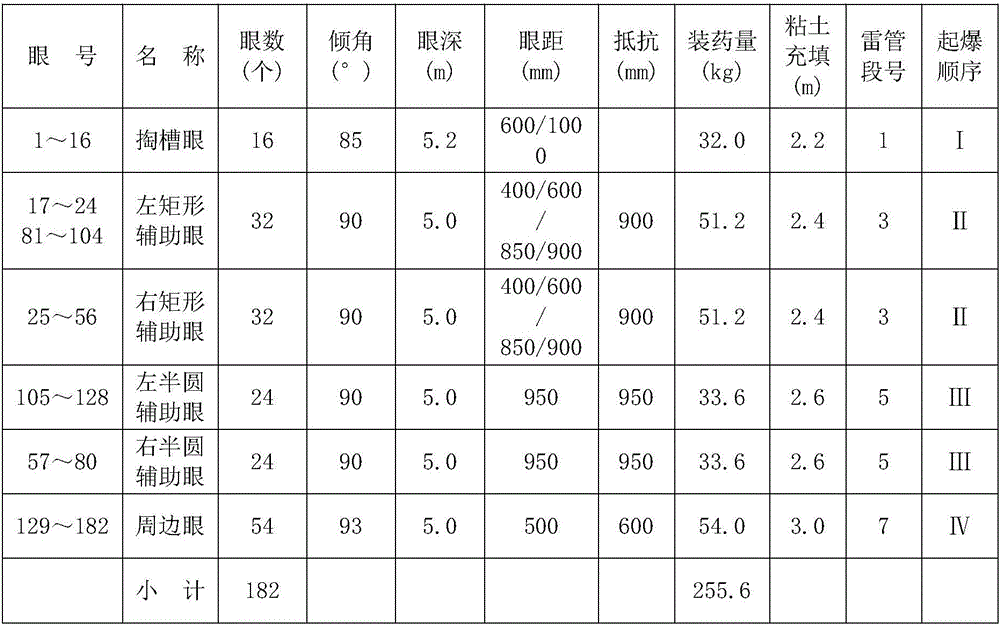

Tunnel empty-hole mud vibration-reduction-control blasting method capable of reducing vibration and noise

The invention relates to a tunnel empty-hole mud vibration-reduction-control blasting method capable of reducing vibration and noise. According to the method, hole drilling is positioned according to a drilling and blasting arrangement diagram; before powder charging, high-pressure air is used for sweeping holes, rock emulsion explosives and non-electric second-delay detonators are respectively selected, the powder charging holes are charged with powder according to a vibration reduction blasting parameter design list, the periphery holes are charged with the powder at intervals, the rest of the blastholes are continuously charged with the powder, the powder are charged to the bottoms of the holes, tamping is used for plugging the holes in place, and the empty holes are filled with plastic bags with mud; and the detonators are connected in place according to requirements, equipment and persons are all evacuated outside the safe distance, and detonation is carried out after the equipment and the persons are confirmed to be safe. The method has the advantages that the hole bottom blasting force can be enhanced, the blasting footage can be increased, particularly, reflection, refraction and absorption of the blasting shock waves can be strengthened, the process of shock wave->attenuating->stress wave->attenuating->seismic wave can be accelerated, the blasting vibration and noise can be greatly reduced, the blasting vibration speed is detected to be lees than 5cm / s, the phenomenon that people are disturbed can be greatly reduced, and the good technical economic effect can be obtained.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

Drift and fill type open stope subsequent backfilling mining method

InactiveCN105370286AEasy to installSimple disassembly processUnderground miningSurface miningMineralogy

The invention provides a drift and fill type open stope subsequent backfilling mining method. The mining method comprises the following steps that 1, a mining area is arranged to be of multiple mining layers (1), and each mining layer is provided with multiple mining roadways (2); 2, after mining is finished in one part of the mining area inside each mining roadway (2), filling is carried out on the part of the mining area, then mining is finished in the other part of the mining area inside the corresponding mining roadway (2), and then filling is carried out; 3, before mining is finished in one part of the mining area of each mining roadway (2), top plates (5) are arranged on the top (3) and the side face (4) of the corresponding mining roadway (2). By the adoption of the mining method, the ore body inside each mining roadway can be supported and fixed, the mining roof-contact arrangement difficulty is lowered, mining can be carried out in each mining roadway conveniently, the mining efficiency is improved, and the mining safety is improved.

Owner:MAGANG (GROUP) HOLDING CO LTD

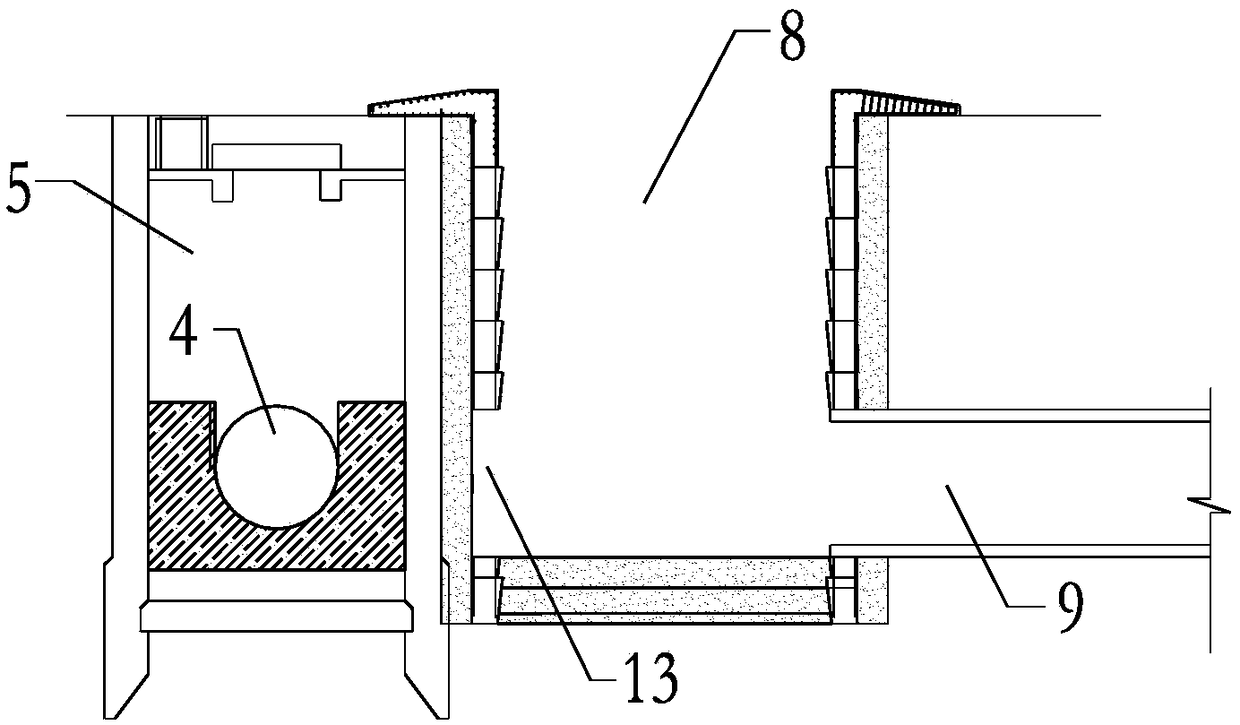

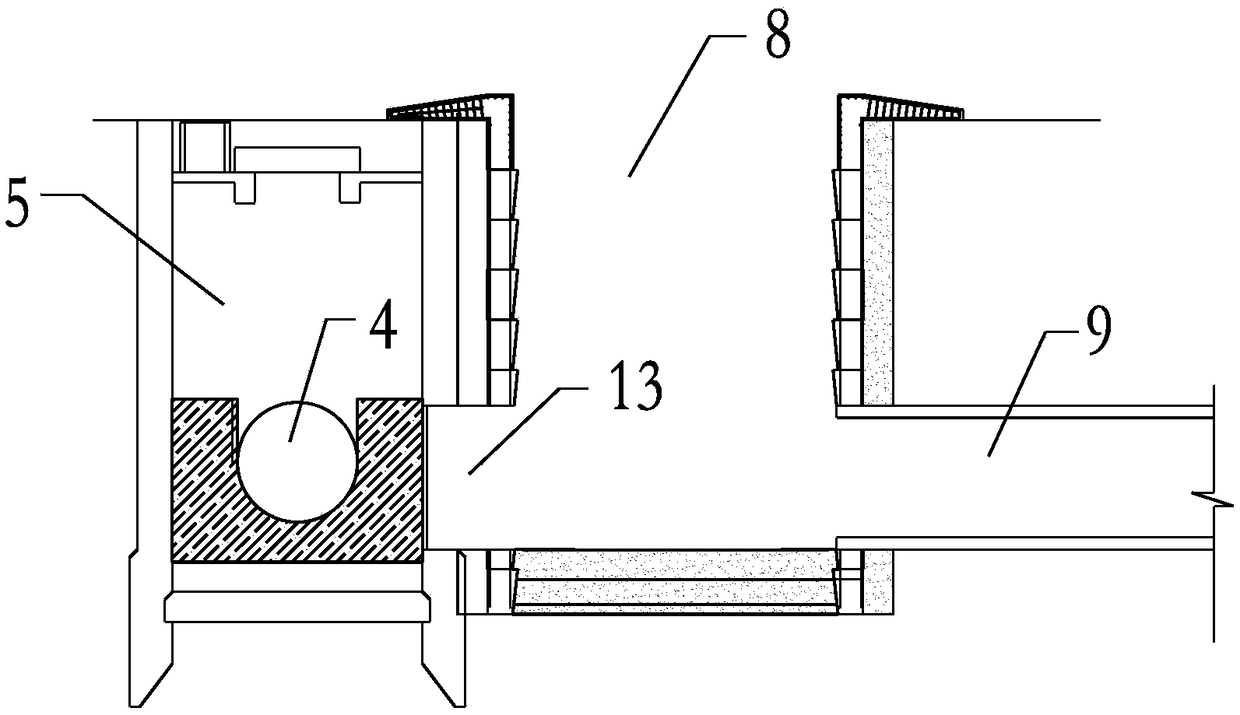

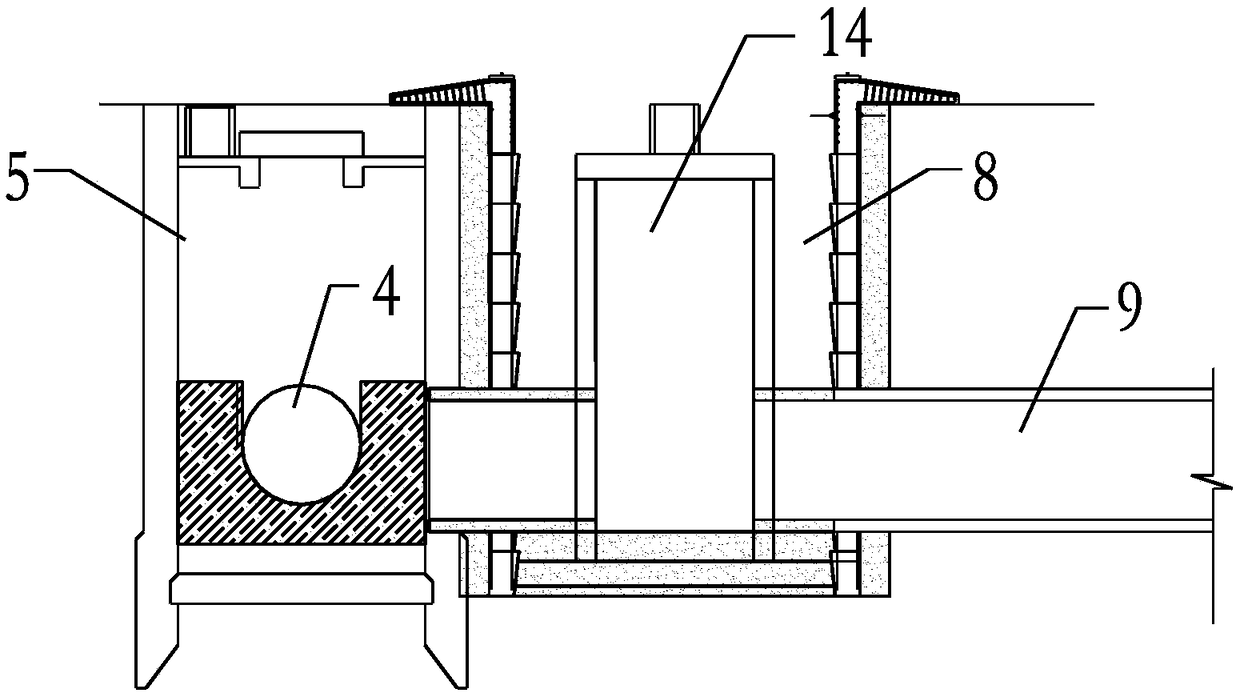

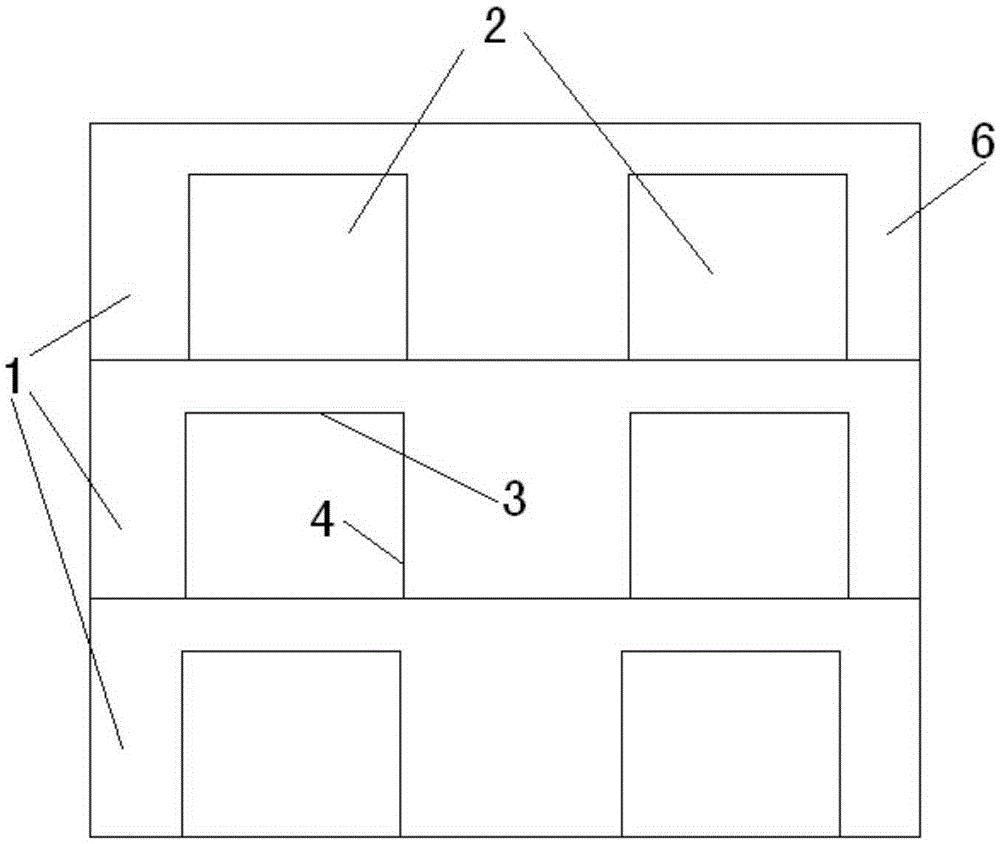

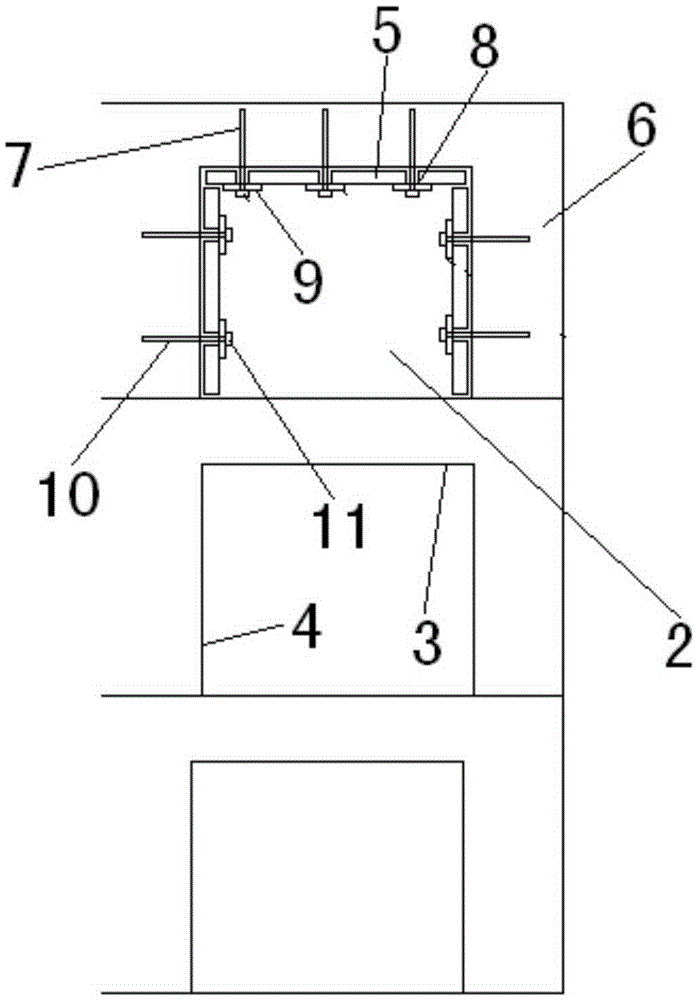

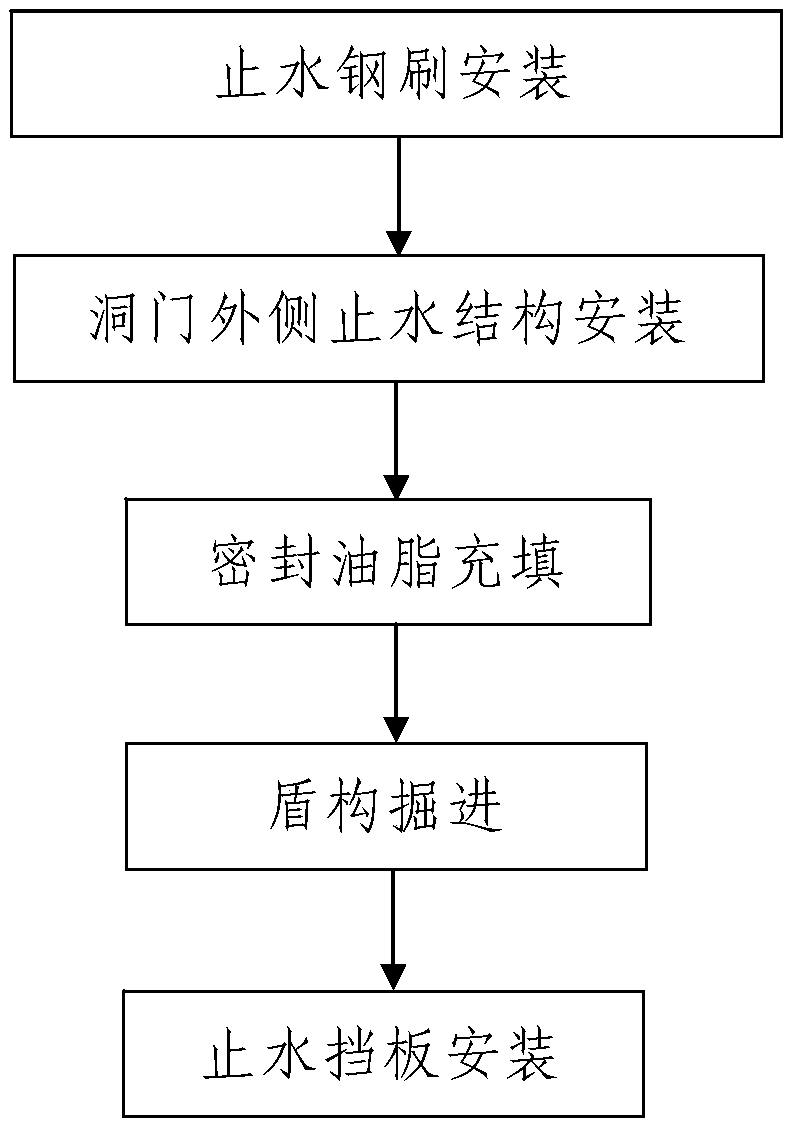

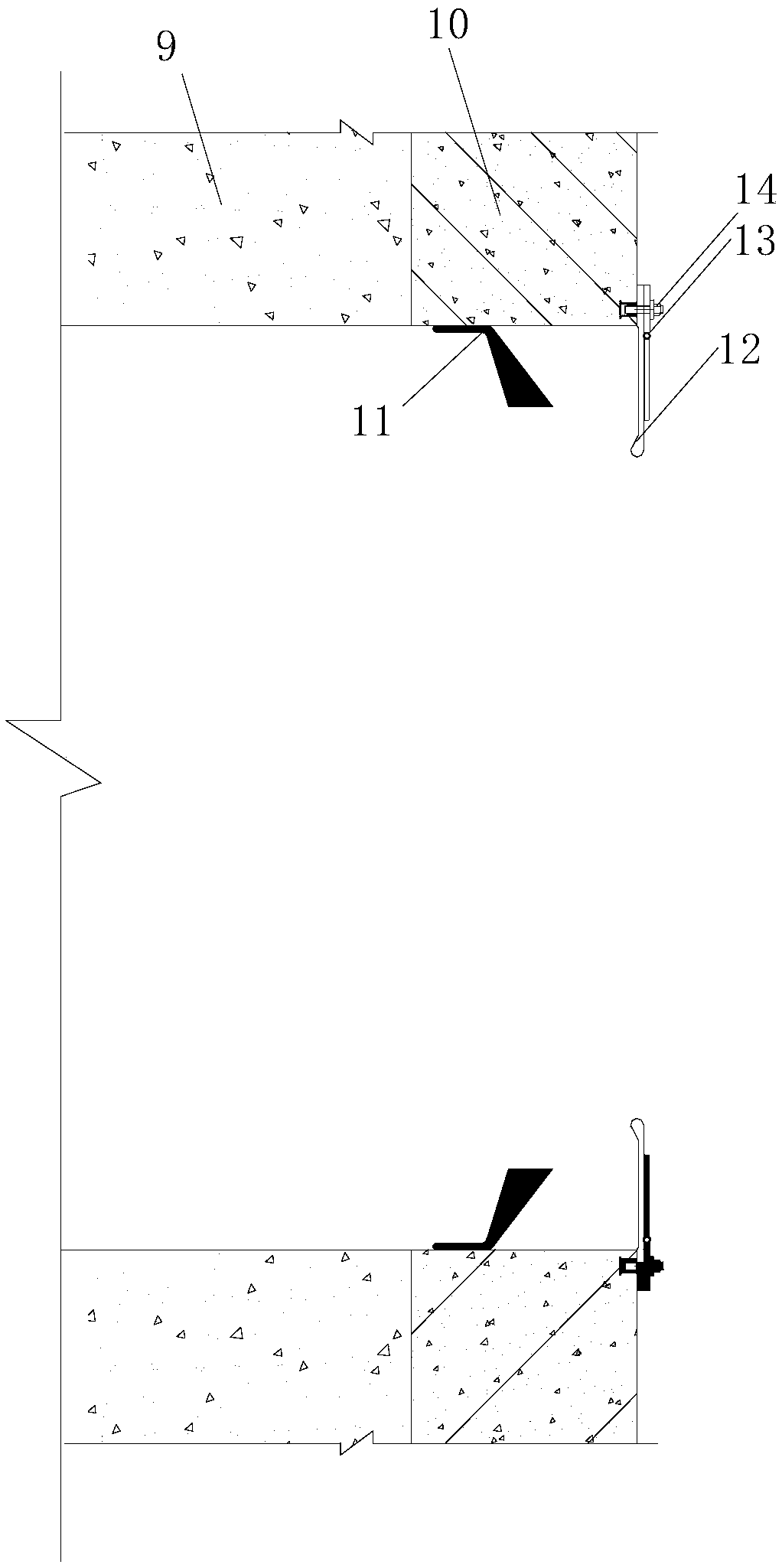

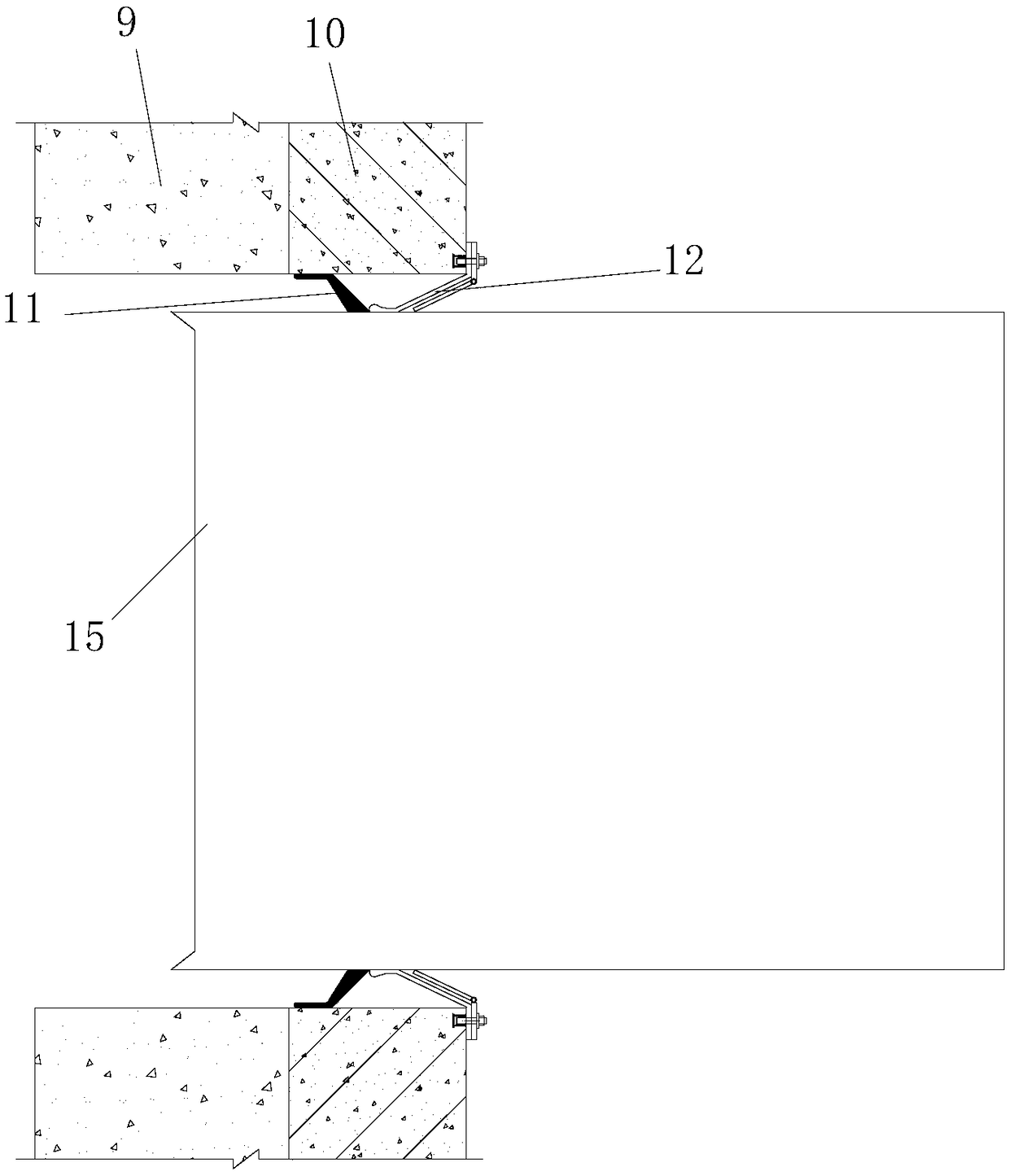

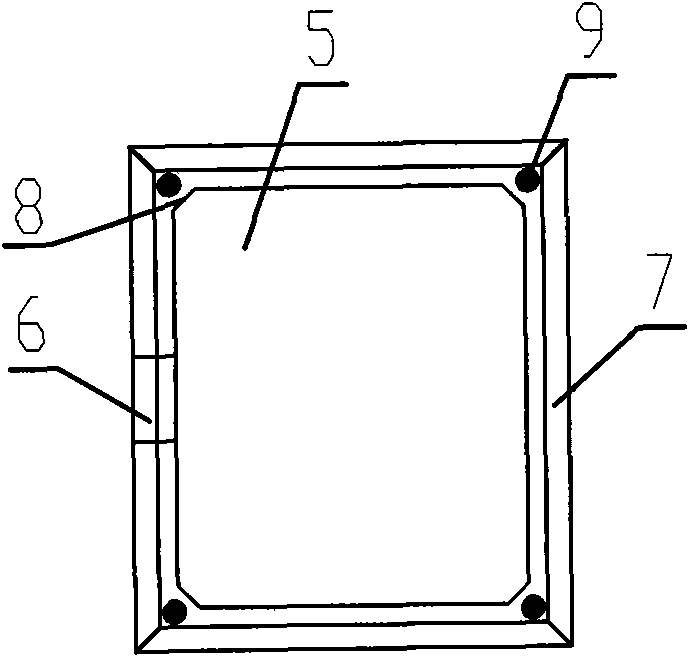

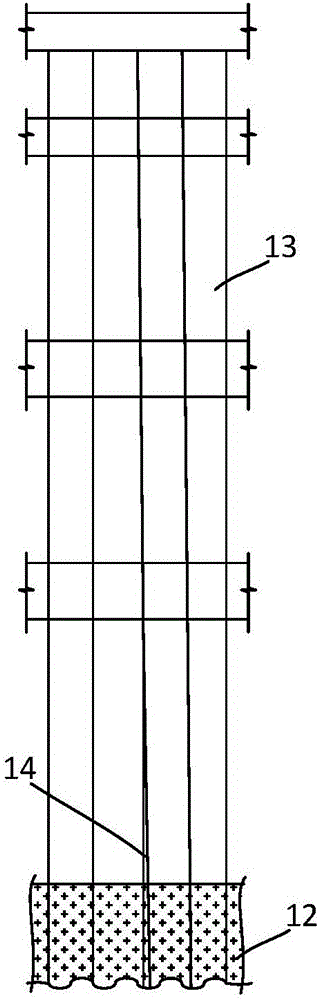

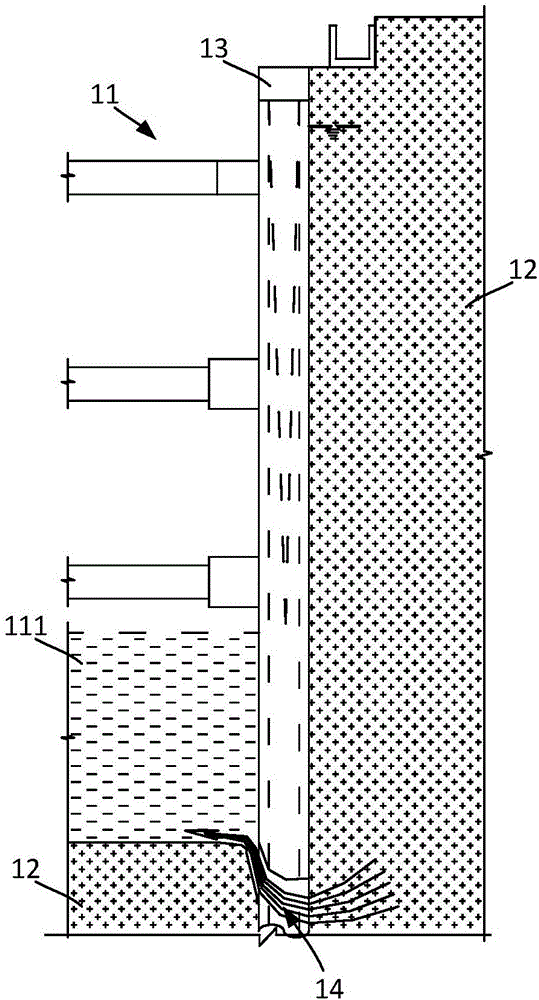

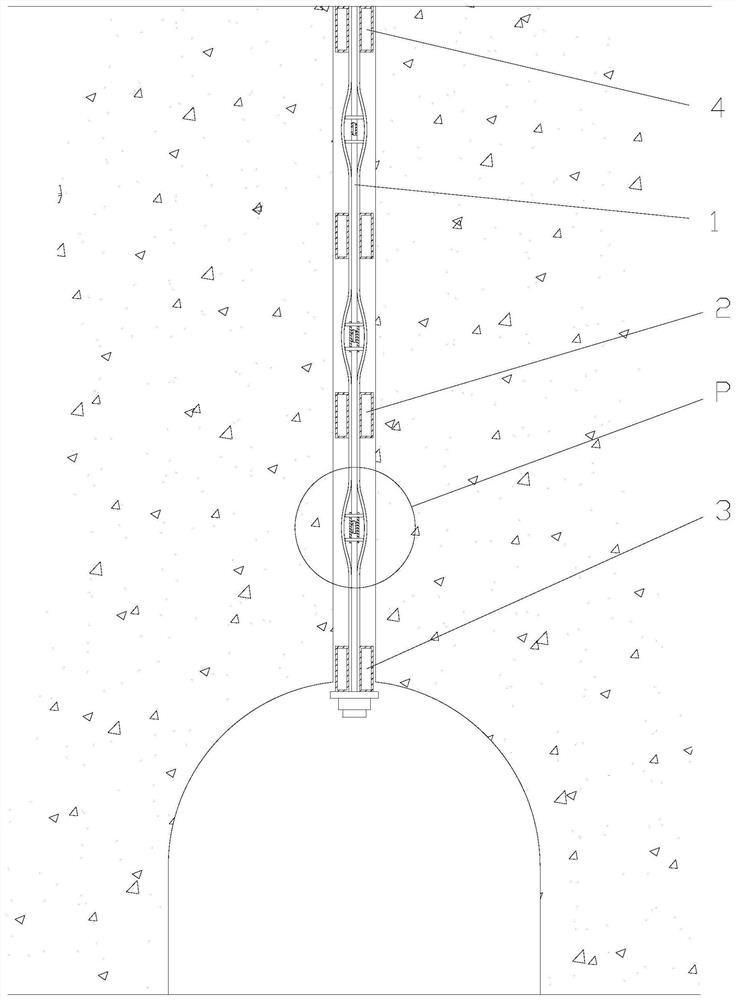

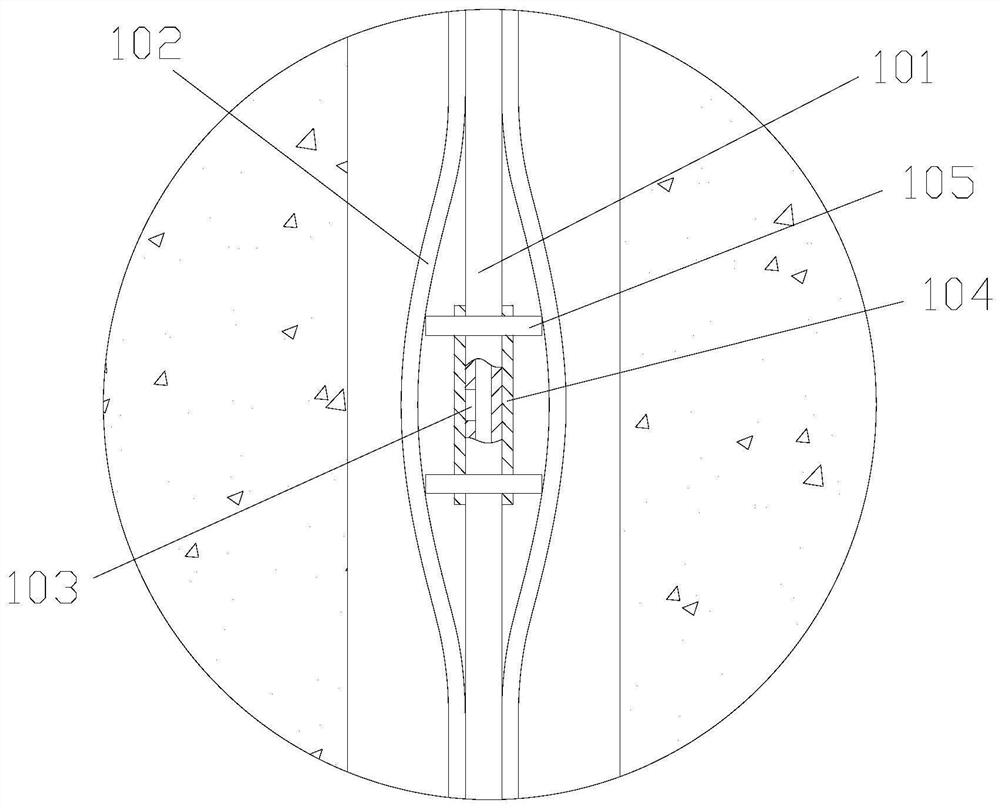

Construction method of tunnel portal water stopping structure for shield excavation and shield arrival

ActiveCN108952775AThe method steps are simpleReasonable designUnderground chambersTunnel liningShield tunnelingBuilding construction

The invention discloses a construction method of a tunnel portal water stopping structure for shield excavation and shield arrival. The construction method includes the steps that firstly, water stopping steel brushes are installed, specifically, before shield tunneling construction, two circles of water stopping steel brushes are installed in the excavation tunnel portal and arrival tunnel portalcorrespondingly, each circle of water stopping steel brushes includes a plurality of water stopping steel brushes arranged on the inner walls of portal steel rings in the circumferential direction and forms inner side water stopping rings; secondly, tunnel portal outer side water stopping structures are installed, specifically, the portal outer side water stopping structures are installed on theouter sides of the tunnel portal steel rings, and each tunnel portal outer side water stopping structure comprises a rubber curtain cloth and a folding pressing plate; thirdly, sealing grease is filled, specifically, each water stopping steel brush is filled with the sealing grease; and fourthly, shield excavation is carried out. According to the construction method of the tunnel portal water stopping structure for the shield excavation and the shield arrival, the design is reasonable, and the use effect is good, inner side water stopping rings on the portal steel rings are combined with the tunnel portal outer side water stopping structures to stop water, the construction is simple, damage is avoided, the problem of water stopping of the excavation tunnel portal and the arrival tunnel portal in the construction of shield tunneling method can be effectively solved, and the effect of the portal water stopping is good.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

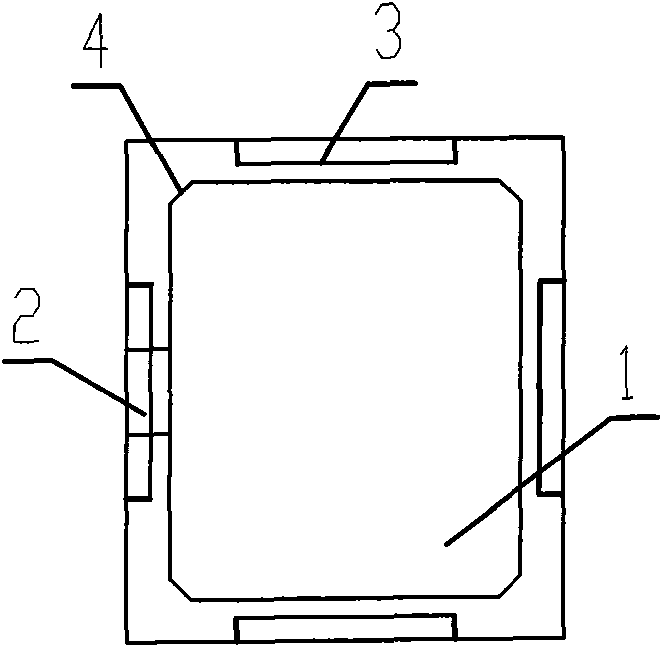

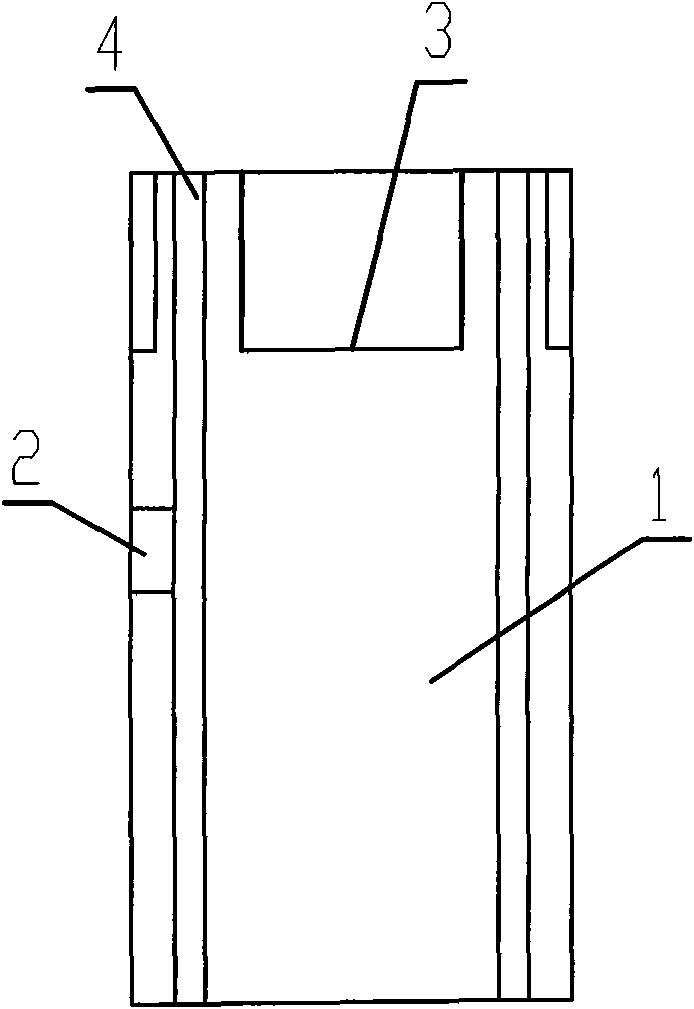

Exhaust duct

An exhaust duct comprises a hollow exhaust duct body, an air intake on the exhaust duct body, one or more than one backoff or projected brace table outside the exhaust duct body; the shaped of the brace tables are same or different; the bearing surface is horizontal or inclined or flattened or rough or normal or abnormal. The brace table is added on the prior exhaust duct body whatever the brace table is backoff or projected, in order to support, fix the bottom formwork between the duct and the floor plate aperture, therefore the aperture slurry sealing problem between the floor plate and the duct is solved, furthermore the gas staining, odor staining, pressure leakage between the layer and layer can be prevented and the invention also provides many preferable executive plans, such as adding various function components, duct material selection and design the material structure.

Owner:张琦

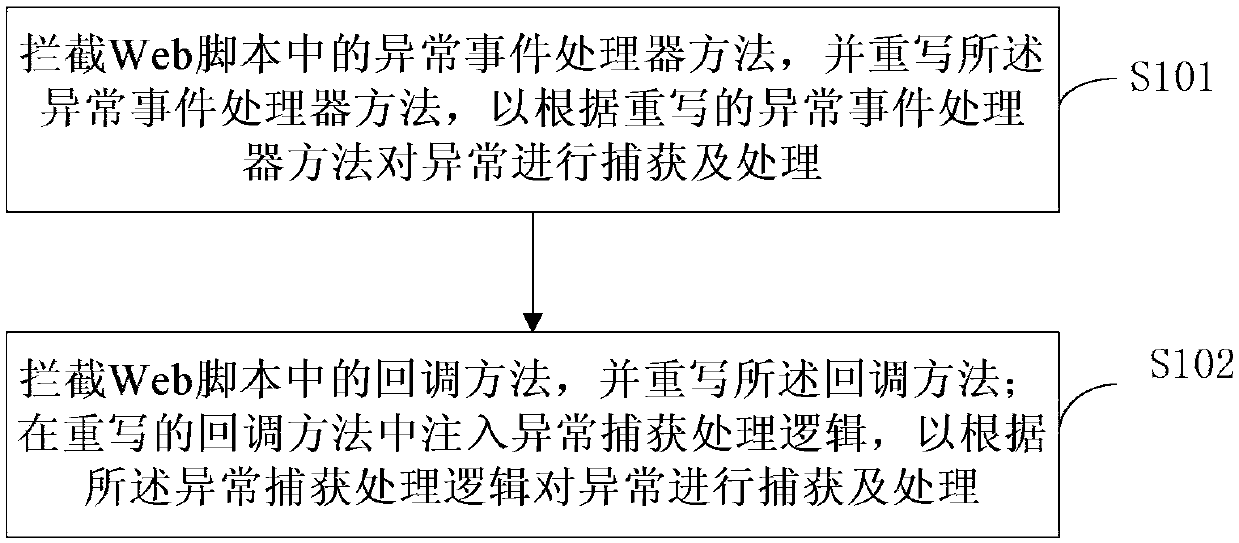

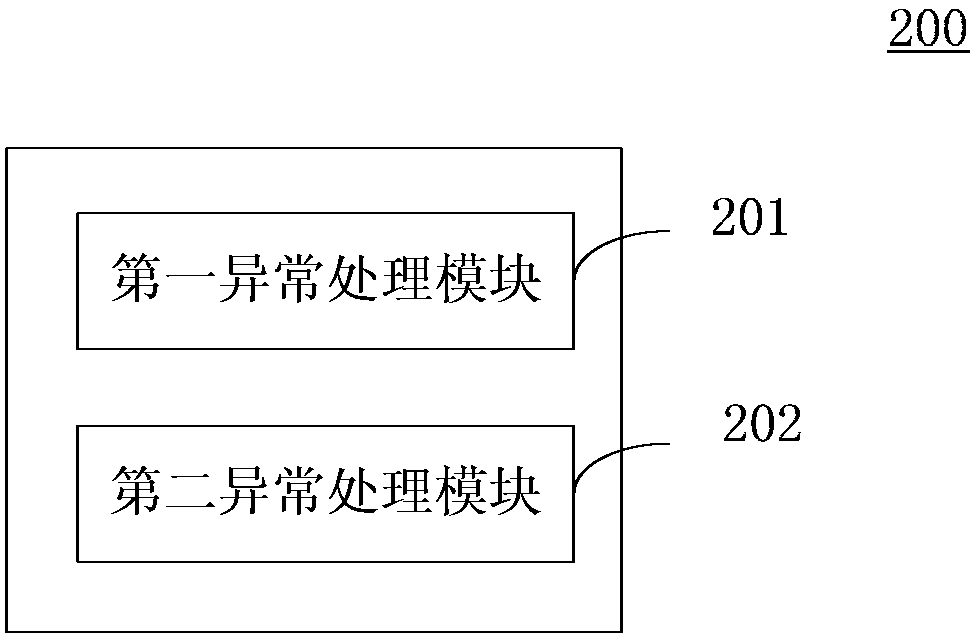

Web script exception handling method and device

InactiveCN107635001ASolve the blocking problemImprove reliabilityTransmissionSpecial data processing applicationsException handling

The embodiment of the invention discloses a Web script exception handling method and device, relating to the technical field of a computer. The method comprises the following steps: intercepting an exceptional event handler method in a Web script, and rewriting the exceptional event handler method to capture and handle exceptions according to the rewritten exceptional event handler method; intercepting a callback method in the Web script, and rewriting the callback method; and injecting exception capture handling logic into the rewritten callback method to capture and handle the exceptions according to the exception capture handling logic. Through the steps implemented by the invention, exception capture code logic and service code logic can be highly separated, and the blocking of the exception capture code logic to the service code logic can be effectively solved, and the reliability of Web script exception handling can be improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Water leakage point blockage method in foundation pit water stop curtain

ActiveCN106592614ASolve the blocking problemFast condensationFoundation engineeringWater leakageEngineering

The invention relates to a water leakage point blockage method in a foundation pit water stop curtain. The method comprises the following steps: back-pressure sand bags are stacked in a water leakage point in a foundation pit near the water stop curtain, and are used for blocking the water leakage point; a first grouting pipe is drilled in soil near the water stop curtain, and first grouting slurry is filled to block a recess area in the soil corresponding to the water leakage point until the first grouting slurry cannot be filled; a second grouting pipe is drilled near the first grouting pipe, and second grouting slurry is filled in a gap formed by the first grouting slurry; and the back-pressure sand bags are removed, and steel plate piles are driven in the foundation pit near the water leakage point of the water stop curtain, are bonded on the surface of the water stop curtain, and are fixedly connected with the water stop curtain. The combination of construction measures preferably solves the blockage problem of the water leakage point, is short in construction time, and cannot influence the construction progress.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Deep foundation pit earth pressure controlled blasting method

InactiveCN106595410AImprove construction efficiencyIncrease the speed of excavationBlastingDetonatorSlag

The invention discloses a deep foundation pit earth pressure controlled blasting method which comprises the following steps: before hole drilling, cleaning up floating slag, living stones and hydrops on a working face; perpendicularly drilling holes in a designated position, wherein the bottoms of shot holes are basically on the same horizontal plane; clearing the holes after hole drilling; producing stemming, selecting standard emulsion explosive for powder charging, using non-electric millisecond delay detonators and detonating cords, and carrying out firm wiring; covering blasting bodies with steel plates and sandy soil, and finally, releasing water to fill gaps in the shot holes and the up-down gaps of the steel plates; arranging sandy soil piles to surround the side, close to a high-tension cable, an existing line, a residential area and a workshop, of a bridge pier, especially the sections close to the high-tension cable and the existing line; arranging a blasting guard at each crossing; after a monitor sends out a blasting command, picketing and starting to carry out blasting after ensuring that the surrounding is safe by a blasting staff; and removing the guard after ensuring that a danger is removed. With adoption of the method, the construction speed is accelerated, the blasting shaking speed, blasting dust and noise are reduced, safety of the residential area and the workshop is ensured, the work hindrance problem by villagers is solved, and the economic loss of an enterprise is reduced.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD

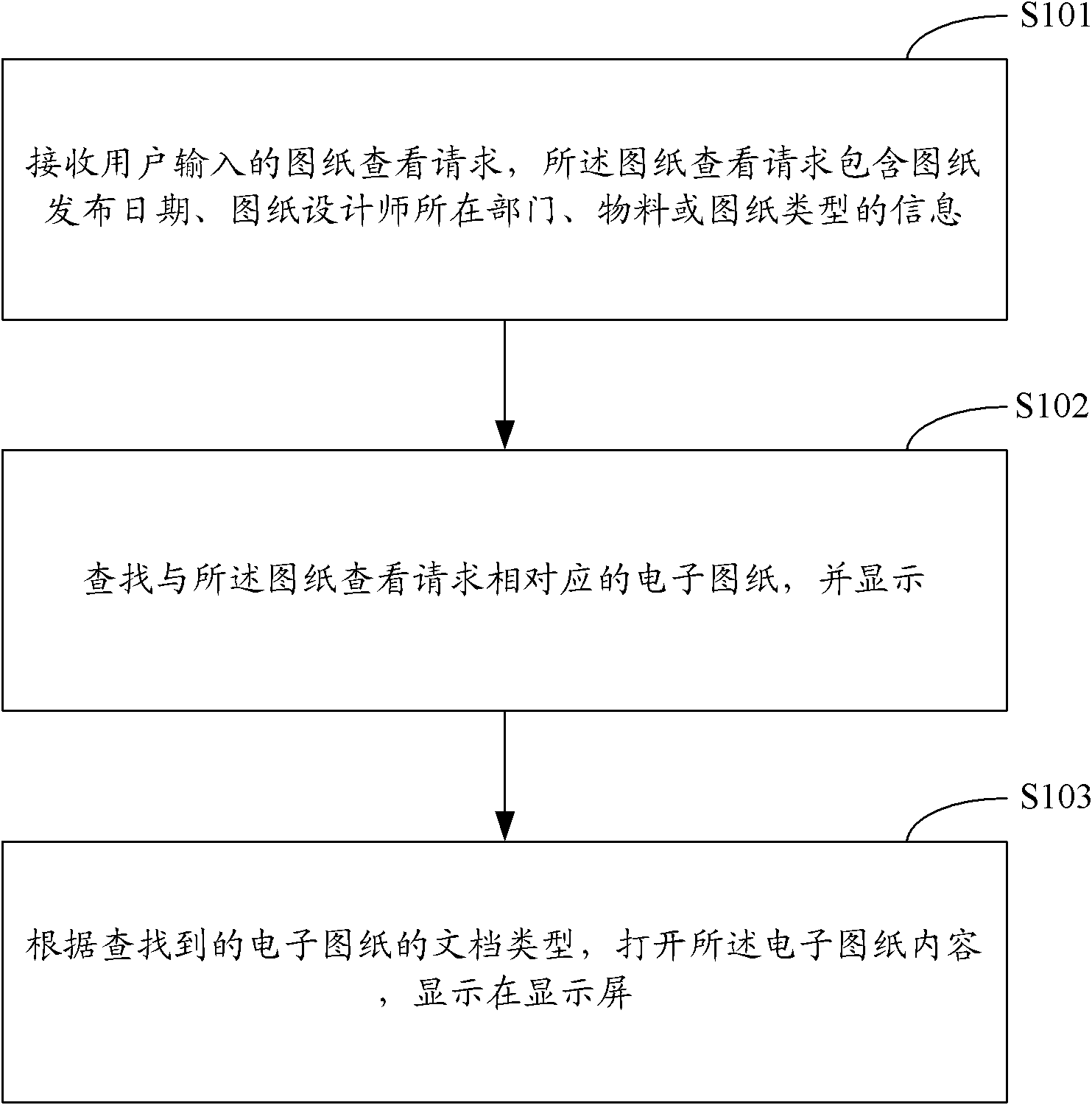

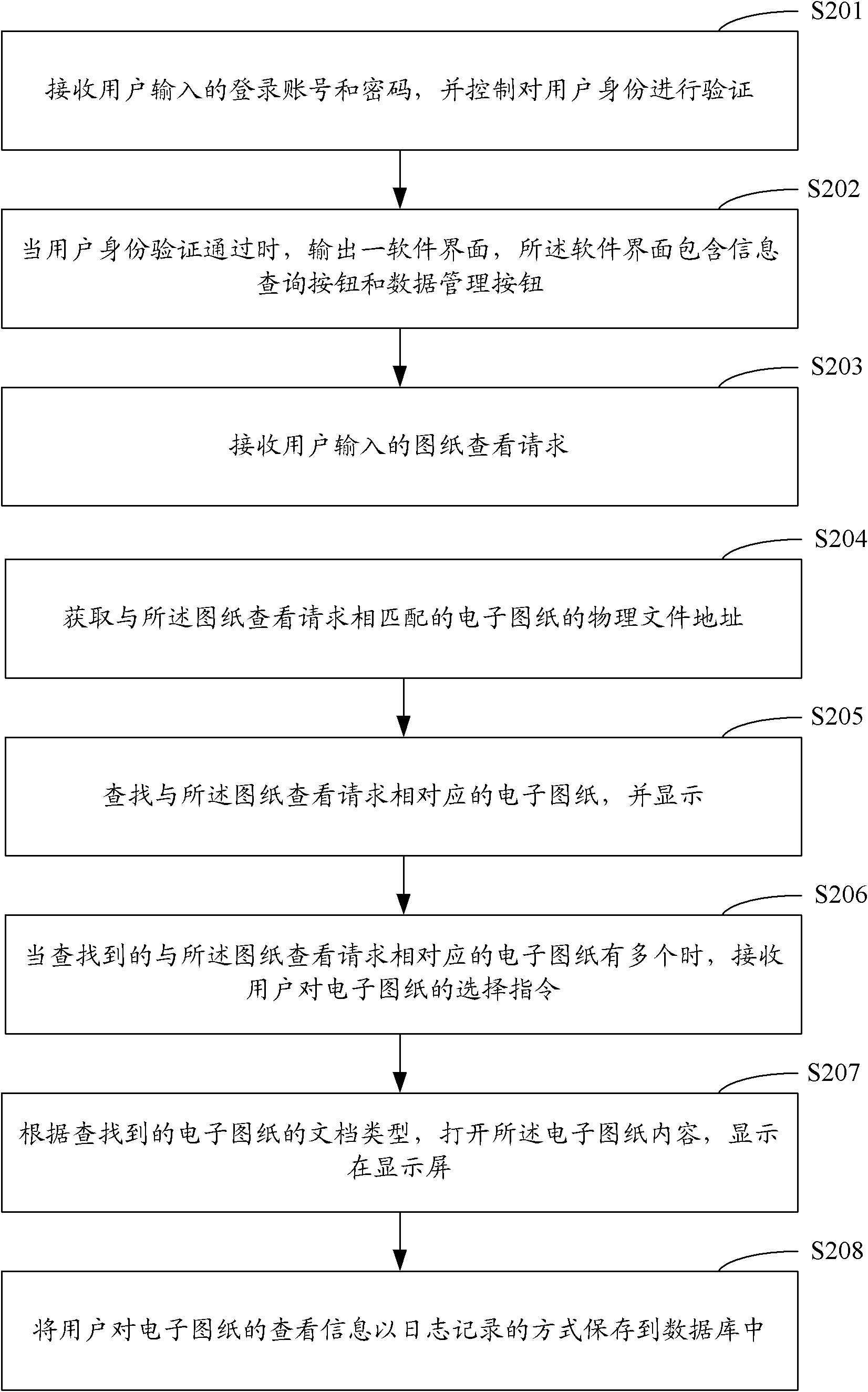

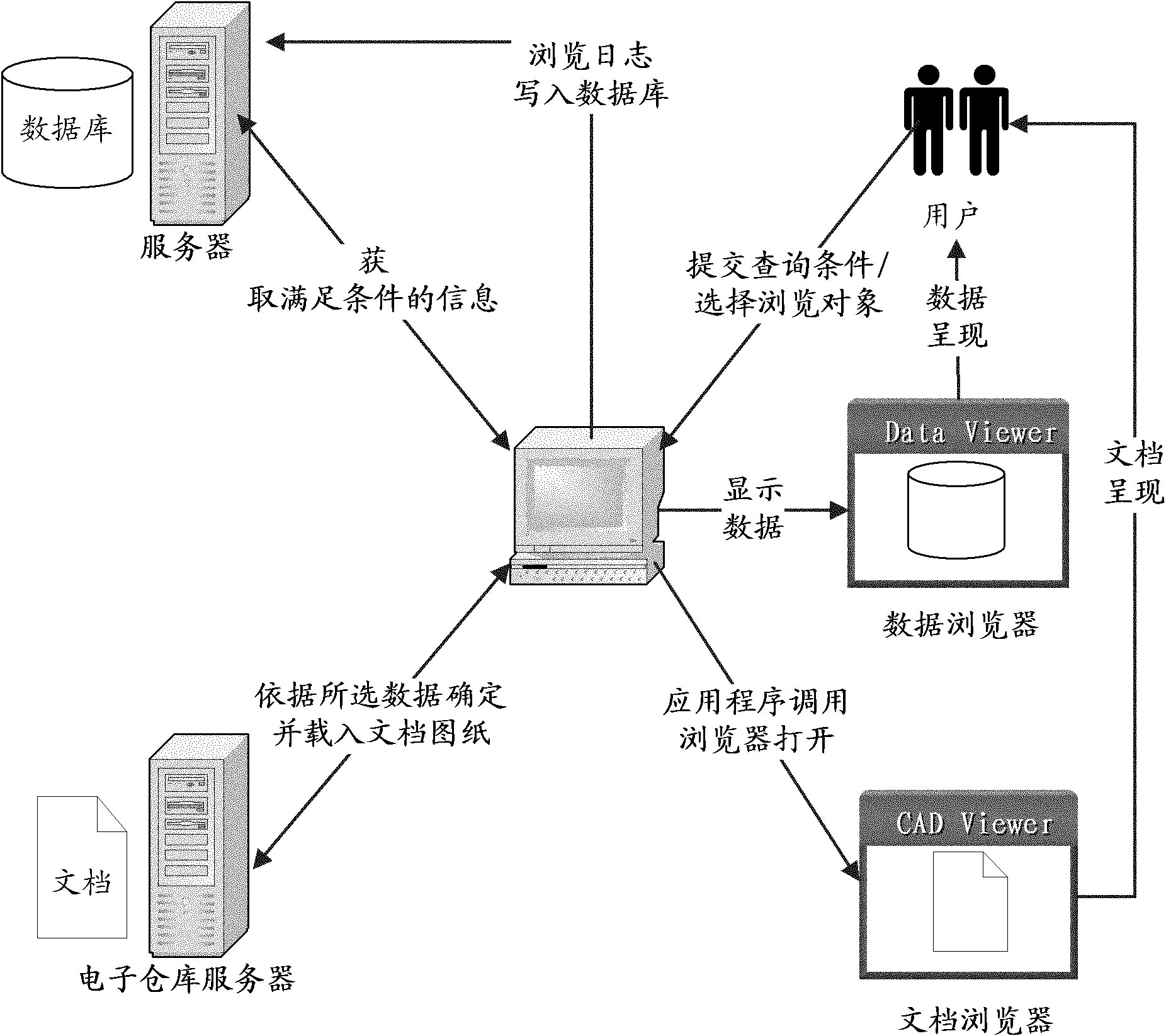

Method and system for viewing drawing

InactiveCN102436444ASolve the blocking problemResourcesSpecial data processing applicationsUser inputDocumentation

The invention is applied to the technical field of enterprise management and provides a method and system for viewing a drawing. The method comprises the following steps of: receiving a drawing viewing request input by a user, wherein the drawing viewing request contains information about drawing issuing data, a department where a drawing designer is positioned and material or drawing types; searching an electronic drawing corresponding to the drawing viewing request and displaying the electronic drawing; and opening the contents of the electronic drawing according to the document type of the searched electronic drawing and displaying the contents of the electronic drawing on a display screen. In the embodiment of the invention, the drawing viewing request input by the user is received and contains the information about the drawing issuing data, the department where the drawing designer is positioned and the material or drawing types; the electronic drawing corresponding to the drawing viewing request is searched and the contents of the electronic drawing are opened according to the document type of the searched electronic drawing and the contents of the electronic drawing are displayed on the display screen. The method and system provided by the invention provide a self-service mode for the user to view the electronic drawing conveniently and quickly.

Owner:KEDA INDUSTRIAL GROUP CO LTD

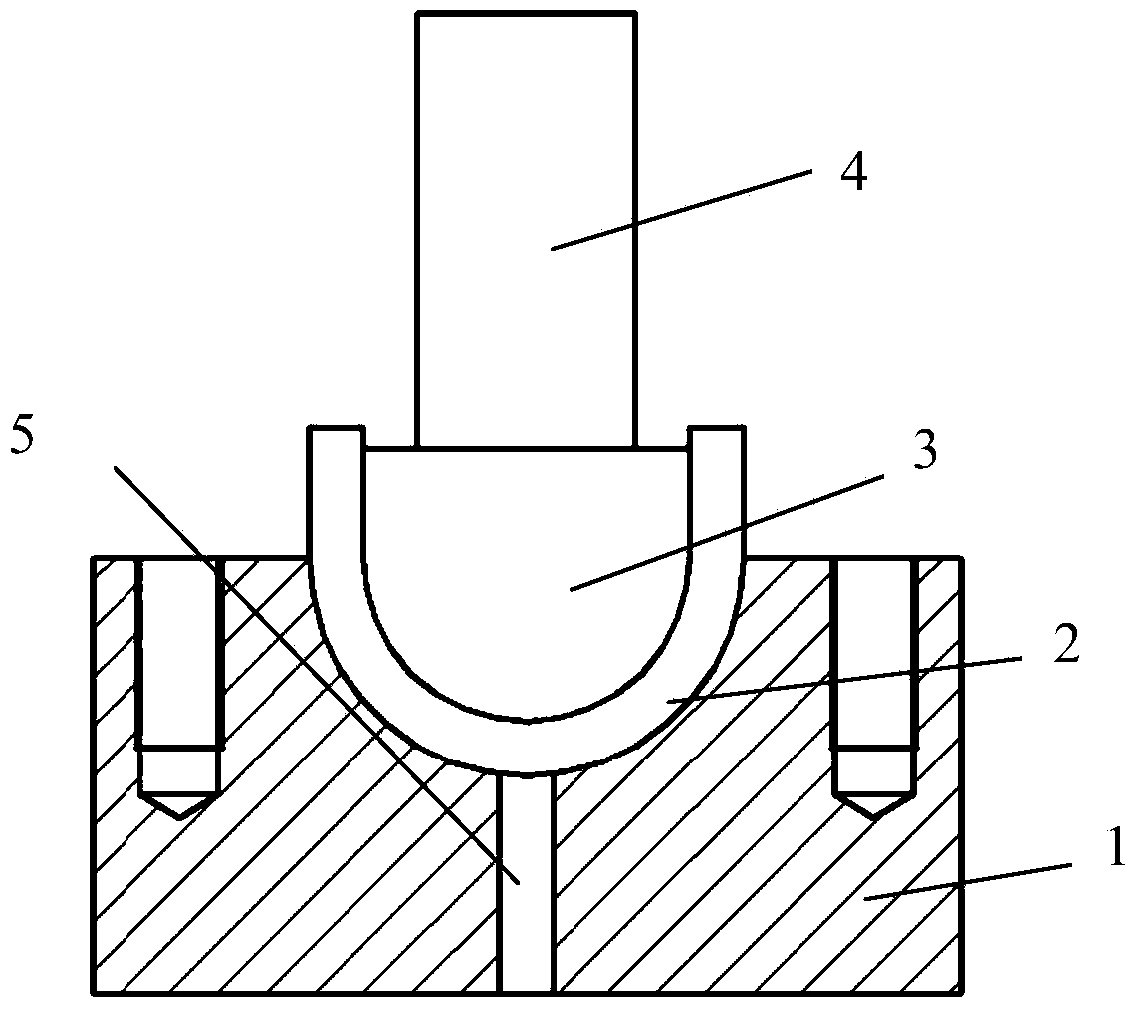

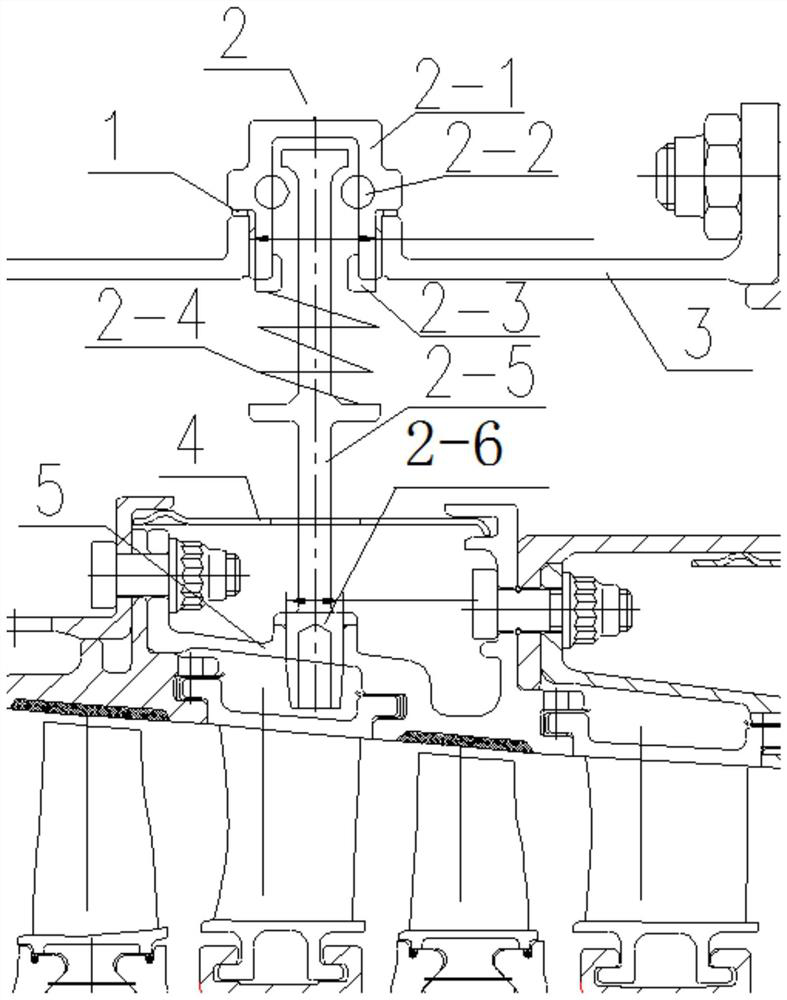

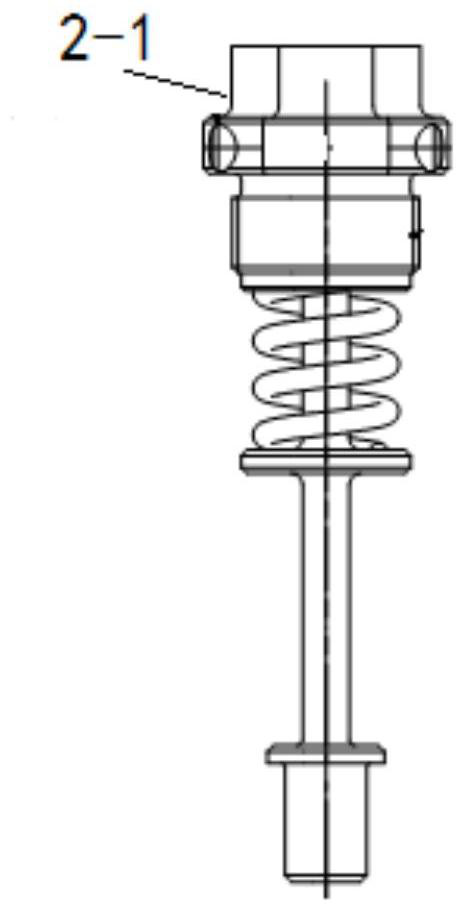

Plug assembly of borescope and cartridge receiver plugging method

ActiveCN112228558ASolve the blocking problemEffective blockingEngine sealsNuclear energy generationEngineeringBorescope

The invention provides a plug assembly of a borescope. The plug assembly (2) comprises a nut (2-1), a positioning piece, a gasket (2-3), an elastic piece and a plug rod (2-5). According to the plug assembly, effective plugging of holes of the multi-layer cartridge receiver borescope can be realized, the borescope detection efficiency of an engine is improved, and the detection and maintenance costof the engine is saved.

Owner:AECC SICHUAN GAS TURBINE RES INST

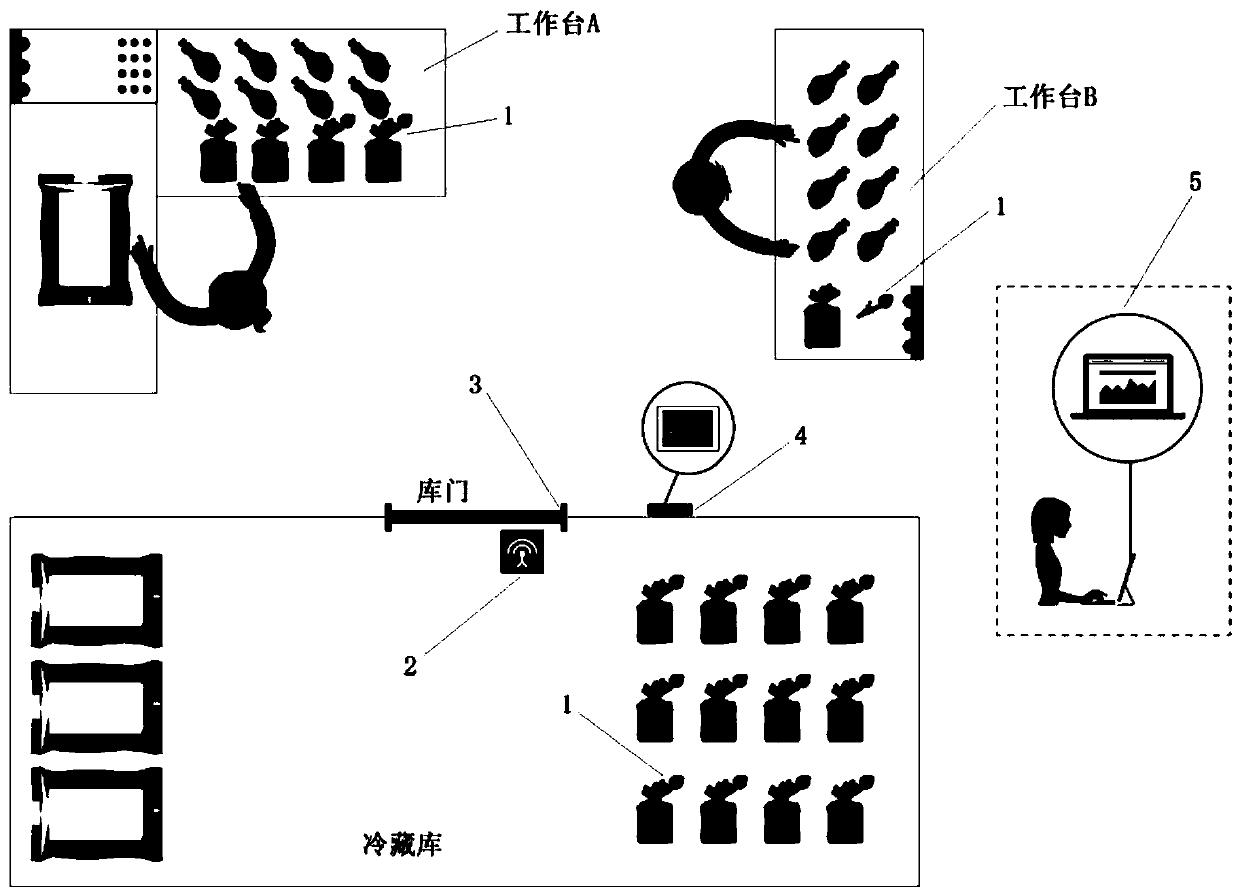

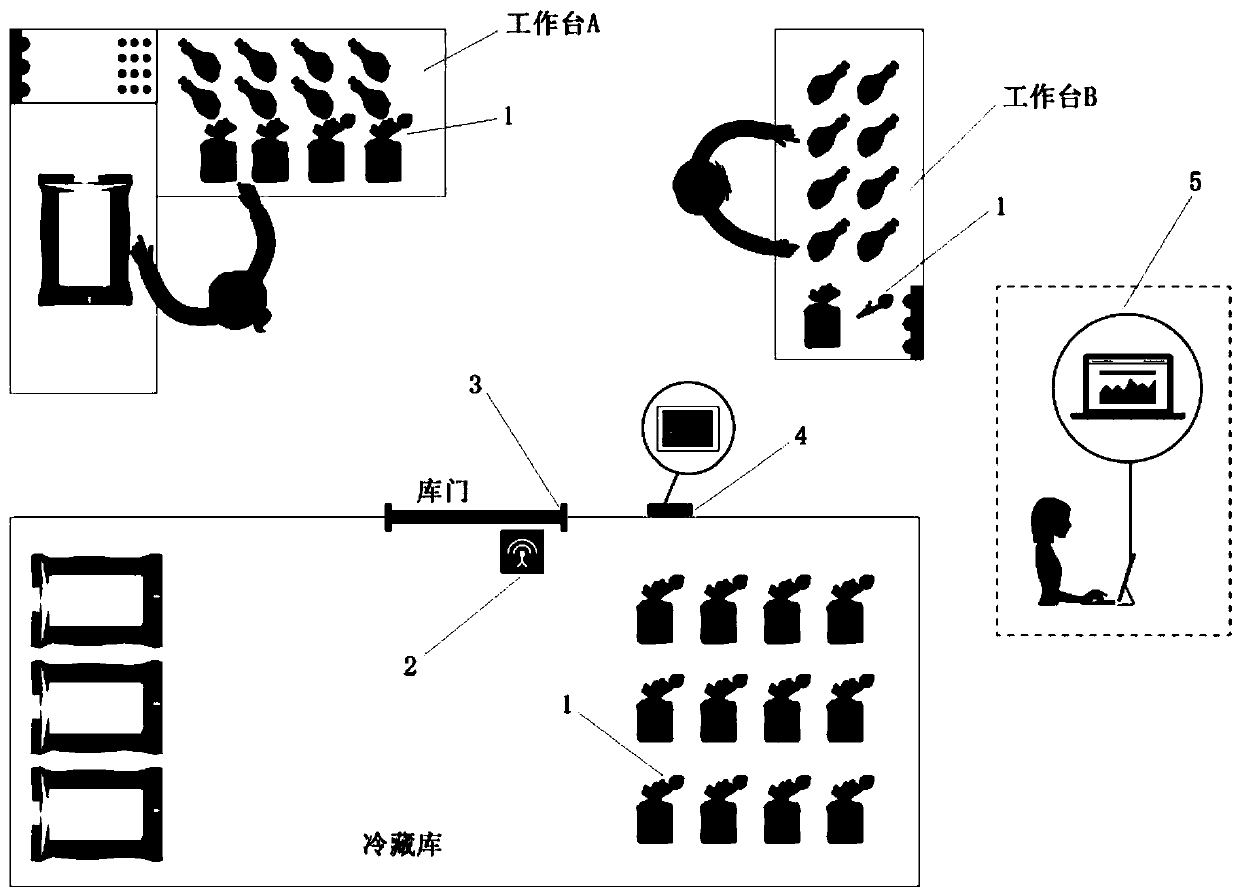

Management system for restaurant refrigerator

PendingCN109993252AImplement updateInventory data obtained in real timeCo-operative working arrangementsSensing record carriersRefrigerator carComputerized system

The invention discloses a management system for a restaurant refrigerator, and the system comprises RFID tags, an RFID reader, a refrigerator door switch sensing device and a computer system. Each RFID tag has a unique electronic code and can be attached to a material. The RFID reader is used for reading data from the RFID tags. The refrigerator door switch sensing device is used for monitoring the refrigerator door state of the refrigerator, so that when the refrigerator door is closed. The RFID reader is triggered to read data from the RFID tag to automatically trigger checking. The computersystem stores stock data of the materials in the refrigerator, and when the refrigerator door switch sensing device monitors that the refrigerator door of the refrigerator is closed, the computer system updates the stock data according to the data obtained by the RFID reader. According to the invention, the inventory data of the restaurant refrigerator is counted and updated by means of the RFIDtechnology, so that the accurate inventory data of a refrigerator can be obtained in real time, and an inventory adjustment strategy can be quickly made.

Owner:SHENGDOUSHI SHANGHAI SCI & TECH DEV CO LTD

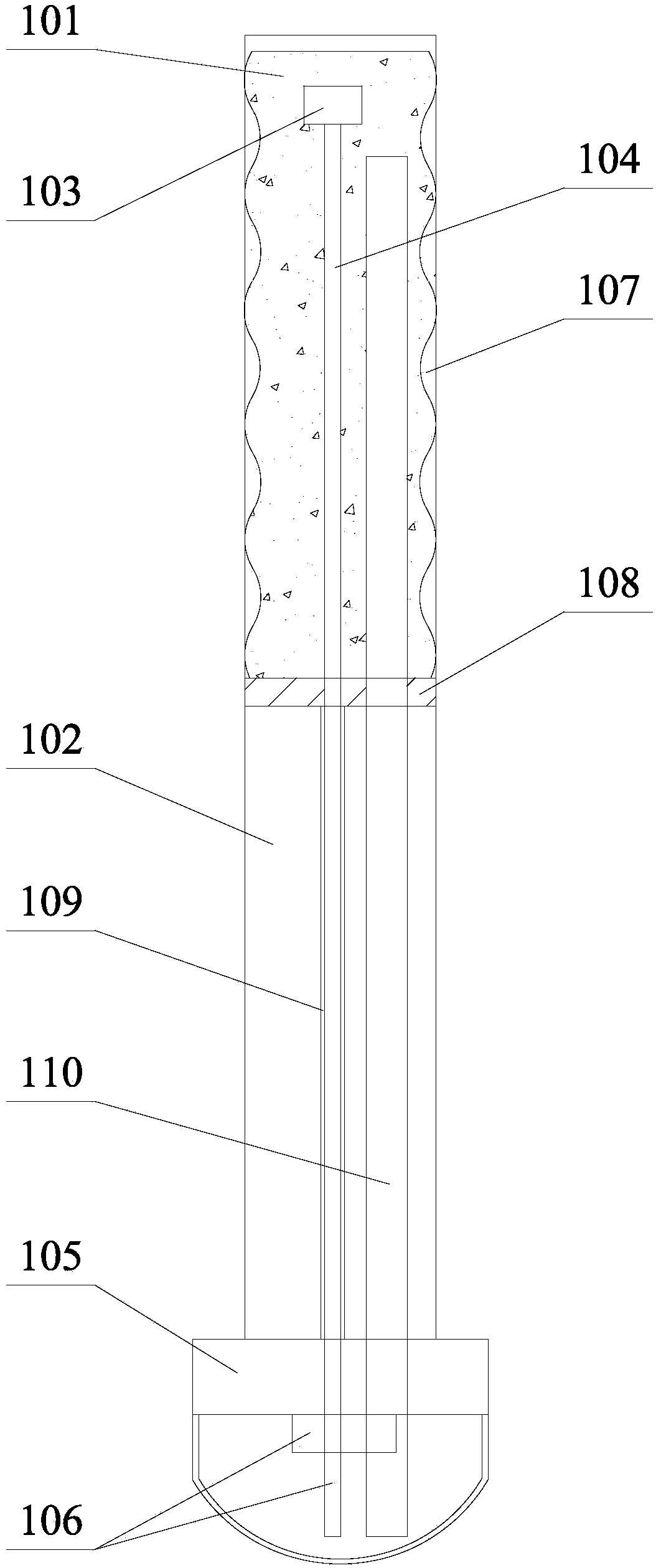

Tension type prestress anchor rod for fixing soft rock stratum rock body and method

PendingCN108385679AAvoid negative effectsReduce the probability of looseningBulkheads/pilesAnchoring boltsPre stressEngineering

The invention discloses a tension type prestress anchor rod for fixing a soft rock stratum rock body and a construction method. The tension type prestress anchor rod comprises an anchor rod hole and aprestress rib, the part, located in the hole, of the prestress rib is divided into an inner anchoring section with an inner anchor and a free section from inside to outside, the anchor rod hole, where the inner anchoring section is located, of the prestress rib is an inversed conical hole large in top and small in bottom, and the part among the prestress rib, the inner anchor and the hole wall ofthe inversed conical hole is filled with a grouting material; the height of the inversed conical hole of the inner anchoring section is 350-500 mm; the height of the free section prestress rib is 1-4m; the hole diameter of the part, where the free section is located, of the prestress rib is 55-65 mm; a device capable of stretching in the inversed conical hole in the radial direction and thus locating an isolation connector is arranged on the isolation connector. The adhering and anchoring strength among the inner anchoring section prestress rib, the condensed grouting material and the hole wall is high, the tension type prestress anchor rod is simple in structure, the material is saved, the construction is convenient, the vibration to the rock body layer in the construction process is small, and the anchor rod is applicable to an environment preventing a rock body rock from generating a collapse geological disaster along the layer.

Owner:宁波它山奇境文化旅游发展有限公司

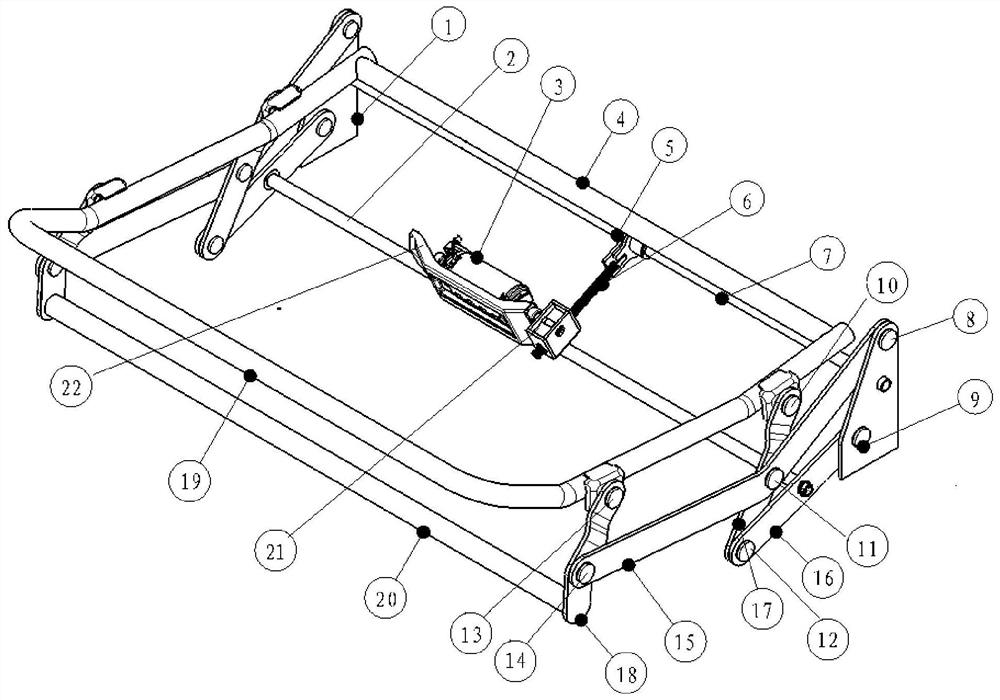

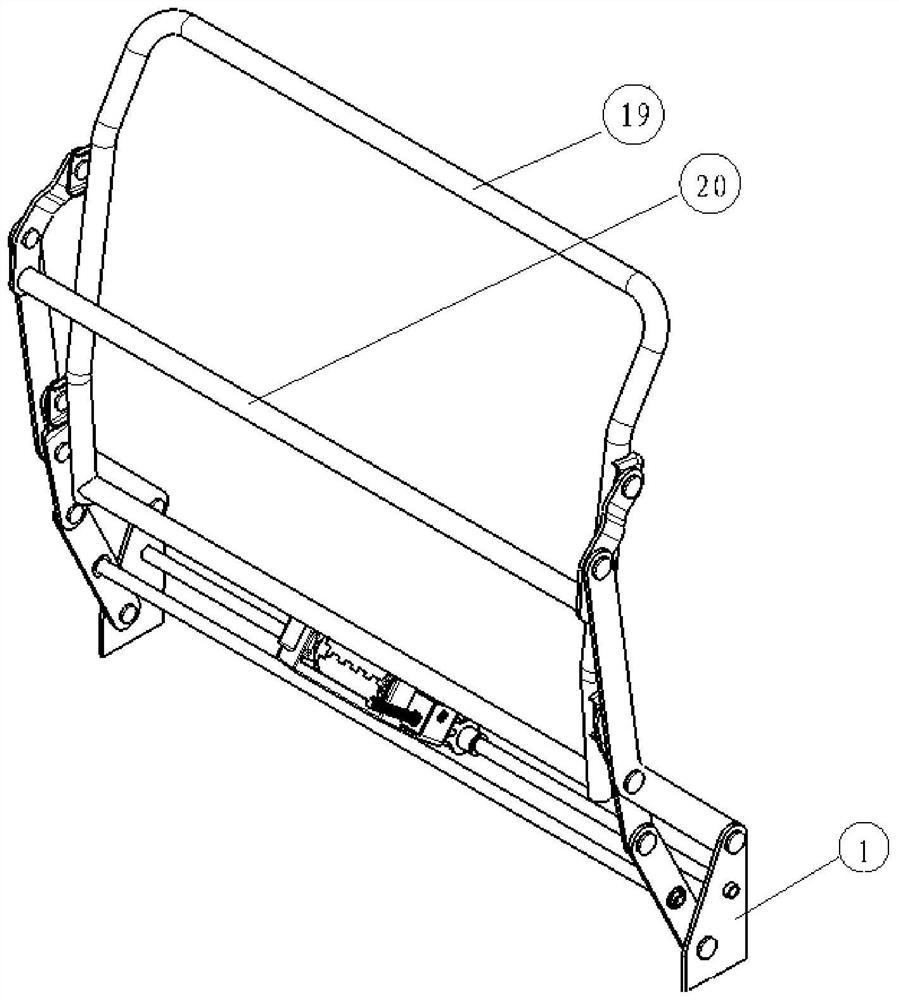

Motor-driven connecting rod type cushion folding mechanism

ActiveCN113263963AIncrease available spaceImprove convenienceMovable seatsElectric machineryEngineering

The invention discloses a motor-driven connecting rod type cushion folding mechanism. Two mounting brackets are symmetrically arranged on two sides of a rear transverse pipe, two connecting rod mechanisms are symmetrically arranged on two sides of a seat frame bent pipe, each connecting rod mechanism comprises four connecting rods, the rear end of the first connecting rod is hinged to the upper side of the mounting bracket, and the rear end of the second connecting rod is hinged to the lower side of the mounting bracket; and the upper end of the third connecting rod is hinged to the rear end of the seat frame bent pipe, the middle of the third connecting rod is hinged to the middle of the first connecting rod, the lower end of the third connecting rod is hinged to the front end of the second connecting rod, the upper end of the fourth connecting rod is hinged to the front end of the seat frame bent pipe, the lower end of the fourth connecting rod is hinged to the front end of the first connecting rod, and the transmission device is connected with the connecting rod mechanism. The folding mechanism is ingenious in design, can be easily folded by 90 degrees or larger than 90 degrees, increases the available space of a rear row seat to the maximum extent, solves the problem that an aisle in a vehicle is blocked by the seat, and improves the use convenience and comfort of the seat.

Owner:MAGNA SEATING RES & DEV (CHONGQING) CO LTD

Method for producing polyacrylamide microsphere water shutoff agent

InactiveCN103073679BSolve the blocking problemSimple processDrilling compositionPotassium persulfateMicrosphere

Owner:北京希涛技术开发有限公司

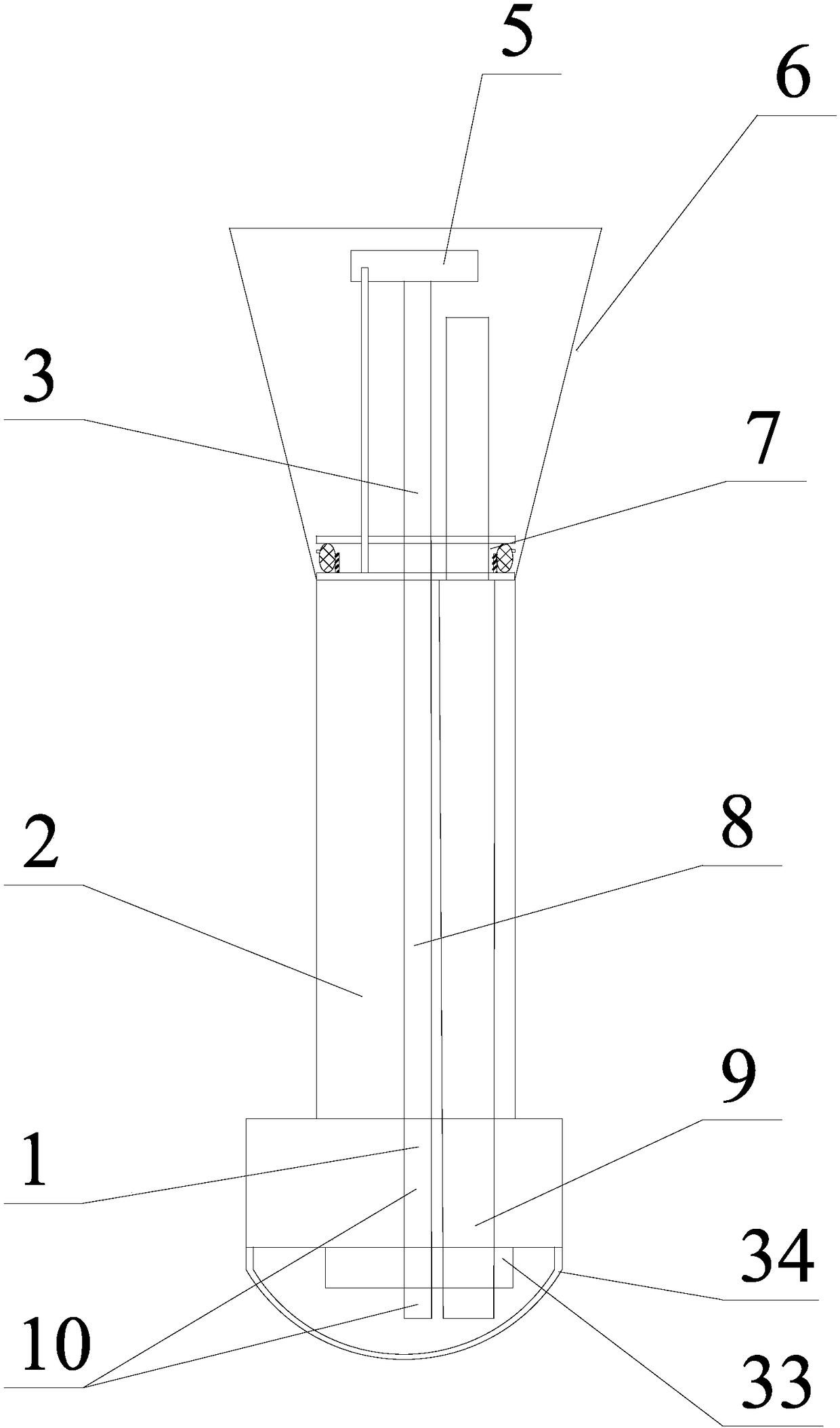

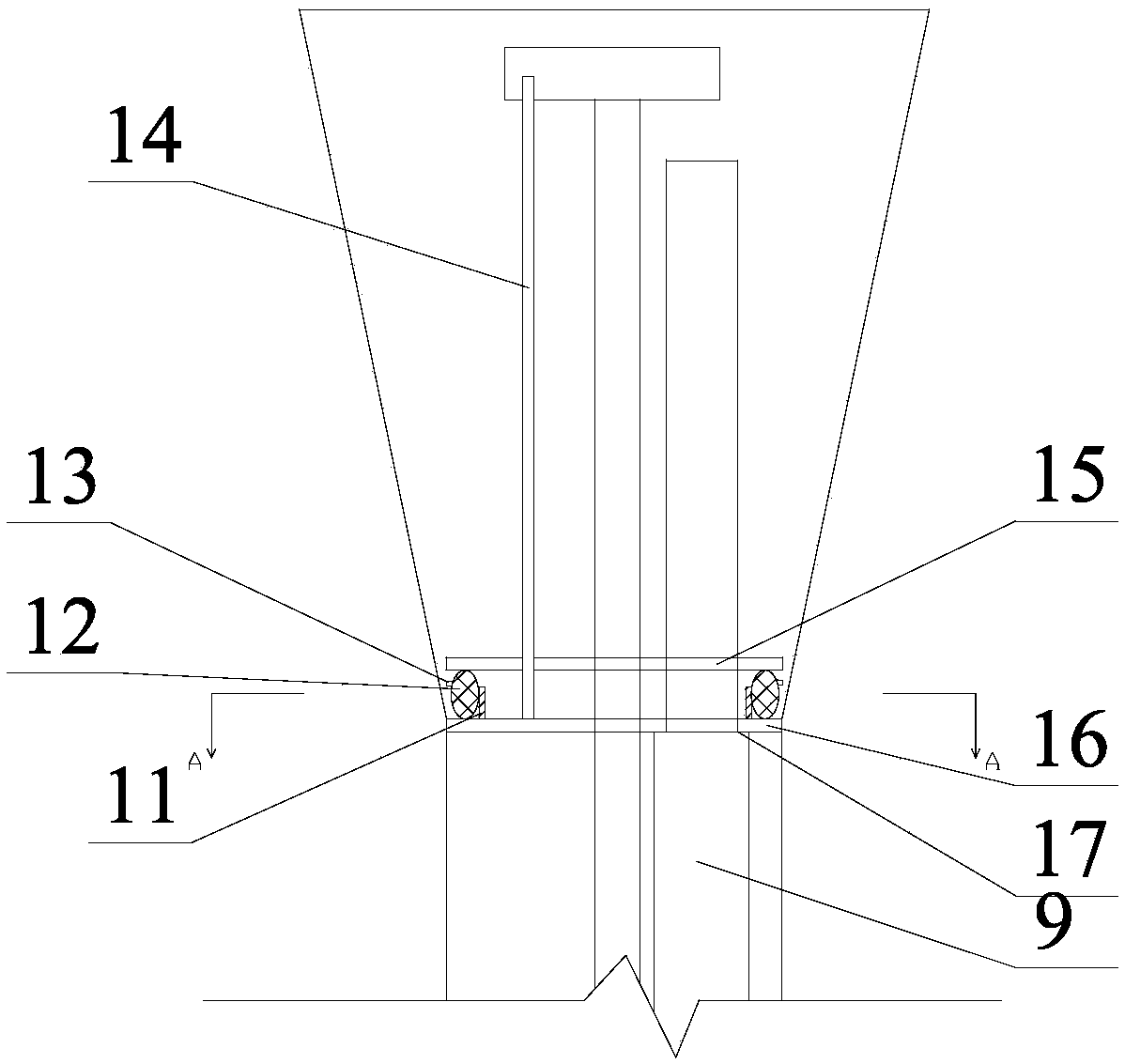

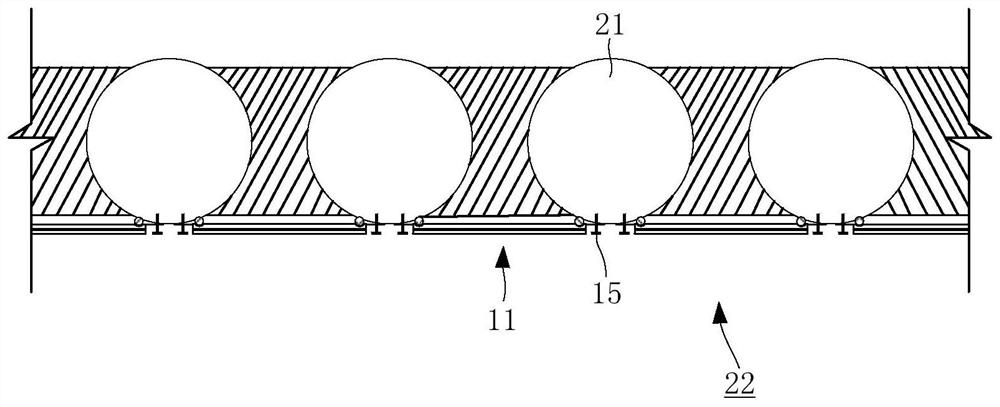

Geotechnical engineering sectional type hollow grouting anchor cable device

ActiveCN112392524AIncrease the amount of groutImprove grouting reinforcementBulkheads/pilesAnchoring boltsGroutWall rock

The invention discloses a geotechnical engineering sectional type hollow grouting anchor cable device. The device comprises a hollow grouting anchor cable or a hollow grouting pipe, and further comprises sectional isolators; the hollow grouting anchor cable comprises a grouting inner pipe and a steel strand; a plurality of grout outlet holes and constant-pressure sealing sleeves used for sealing the grout outlet holes are arranged on the grouting inner pipe or the hollow grouting pipe; the sectional isolators are arranged on the hollow grouting anchor cable or the hollow grouting pipe; and thesectional isolators are arranged among the grout outlets formed in the hollow grouting anchor cable or the hollow grouting pipe. According to the geotechnical engineering sectional type hollow grouting anchor cable device, due to the arrangement of the sectional isolators and the constant-pressure sealing sleeves, corresponding sectional and graded grouting can be conducted according to differentreinforcing or sealing requirements of stratum surrounding rock of different parts, the grouting amount of deep surrounding rock can be increased according to needs, the grouting reinforcing or sealing effect can be remarkably improved, a large amount of re-injection or re-repair cost is saved, and particularly potential safety risks caused by surrounding rock collapse and re-repair can be effectively avoided.

Owner:SHANDONG UNIV OF SCI & TECH

Method for leaking stoppage between foundation pit fender posts

InactiveCN112726626ASolve the blocking problemPrevent inflowExcavationsArchitectural engineeringStructural engineering

The invention relates to a method for leaking stoppage between foundation pit enclosing piles. The method comprises the following steps that a fixing piece is provided, the fixing piece is placed on the bottom surface of an excavated part of a foundation pit, the fixing piece is fixedly connected with the fender posts on the two sides of a leaking part, so that the fixing piece shields the leaking part, and a pouring space is formed by enclosing the fixing piece and a soil body between the two fender posts; and grouting is carried out in the pouring space to block the gap between every two adjacent fender posts, and therefore accumulated water is prevented from leaking into the foundation pit from the leaking part. The problem that the leaking part between the fender posts is difficult to block is effectively solved, the gap between every two adjacent fender posts is blocked, underground water is prevented from flowing into the foundation pit from the gap between the fender posts, the construction quality is guaranteed, and potential safety hazards are eliminated.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A vehicle-mounted base station mobile communication system for high-speed railway

ActiveCN106899984BHigh gainImprove communication qualityNetwork planningCommunication qualityIn vehicle

Owner:WUHAN HONGXIN TECH DEV CO LTD

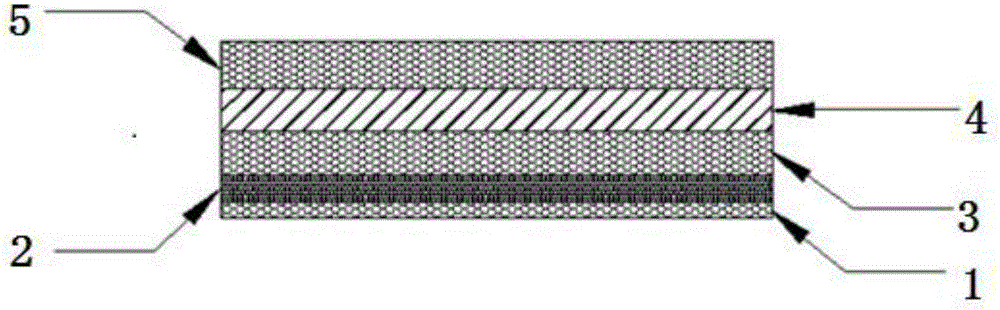

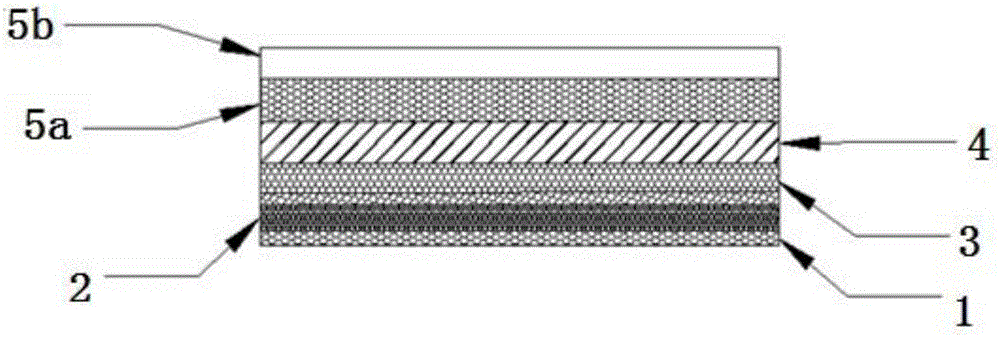

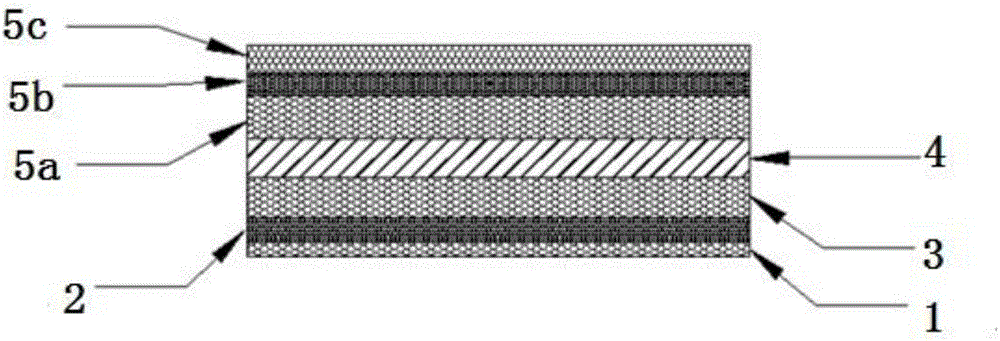

Low-cost solar film reflector material

ActiveCN105929471AReduce manufacturing costSolve the blocking problemMirrorsAdhesiveUltraviolet lights

The invention discloses a low-cost solar film reflector material which comprises a back adhesive protecting film, back adhesive, a substrate film, a plated film reflecting layer and a plated film protecting layer, wherein one side of the substrate film is subjected to sensitization processing and tightly bonded with the back adhesive, the other side of the substrate film is a smooth surface and is combined with the plated film reflecting layer, and the upper surface of the plated film reflecting layer is combined with the plated film protective layer. The plated film reflecting layer comprises three layers of plated films sequentially including an aluminum layer, a silver layer and a magnesium fluoride layer. Sun light reaches the silver layer after passing the plated film protective layer, after being reflected by the silver layer penetrates the plated film protective layer to reach a solar utilization apparatus or device. The low-cost solar film reflector material effectively solves the problems of ultraviolet ray block-out and surface steam block-out. Since no ultraviolet light absorbent is needed, and the optical performance of the low-cost solar film reflector material remains unchanged after long-term use, the manufacture cost of reflection thin film materials can be greatly reduced, and the service lifetime is prolonged.

Owner:邓运明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com