Geotechnical engineering sectional type hollow grouting anchor cable device

A technology for grouting anchor cables and geotechnical engineering, applied in the field of anchor cables, can solve the problems of inability to use, operate, and troublesome grouting in sections, save re-injection or repair costs, ensure grouting pressure, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

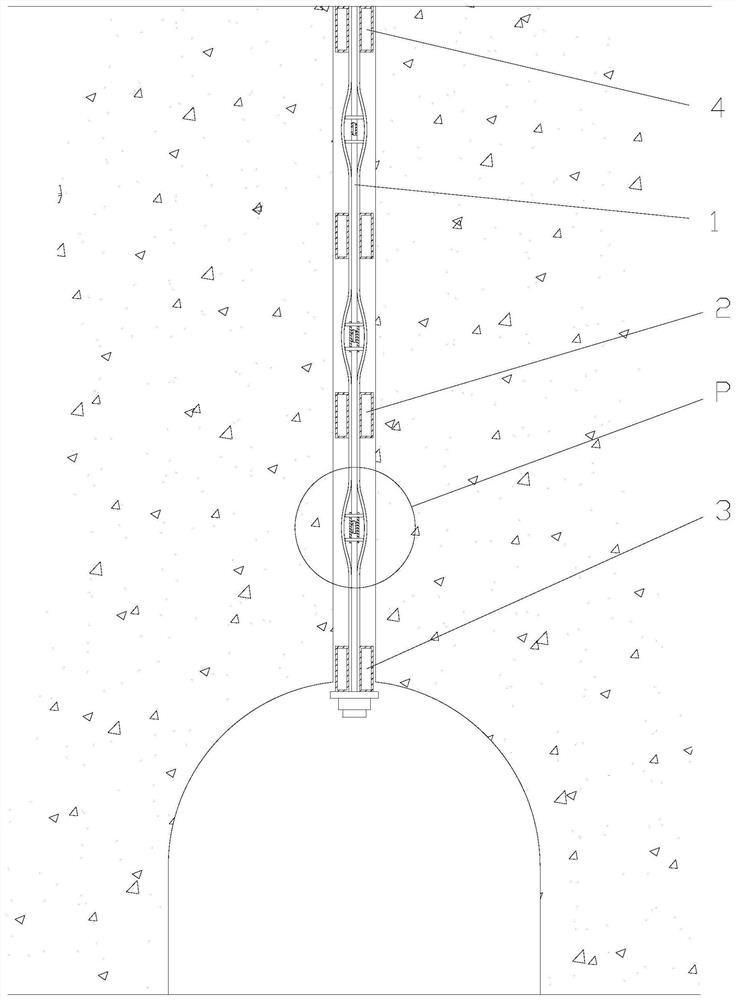

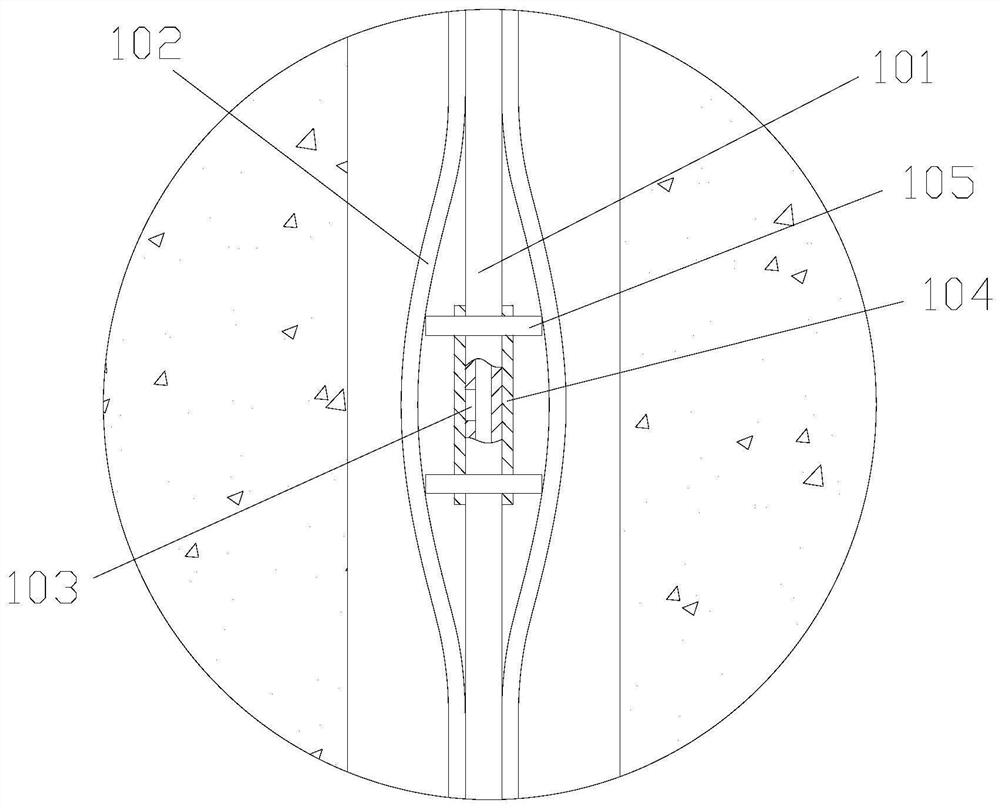

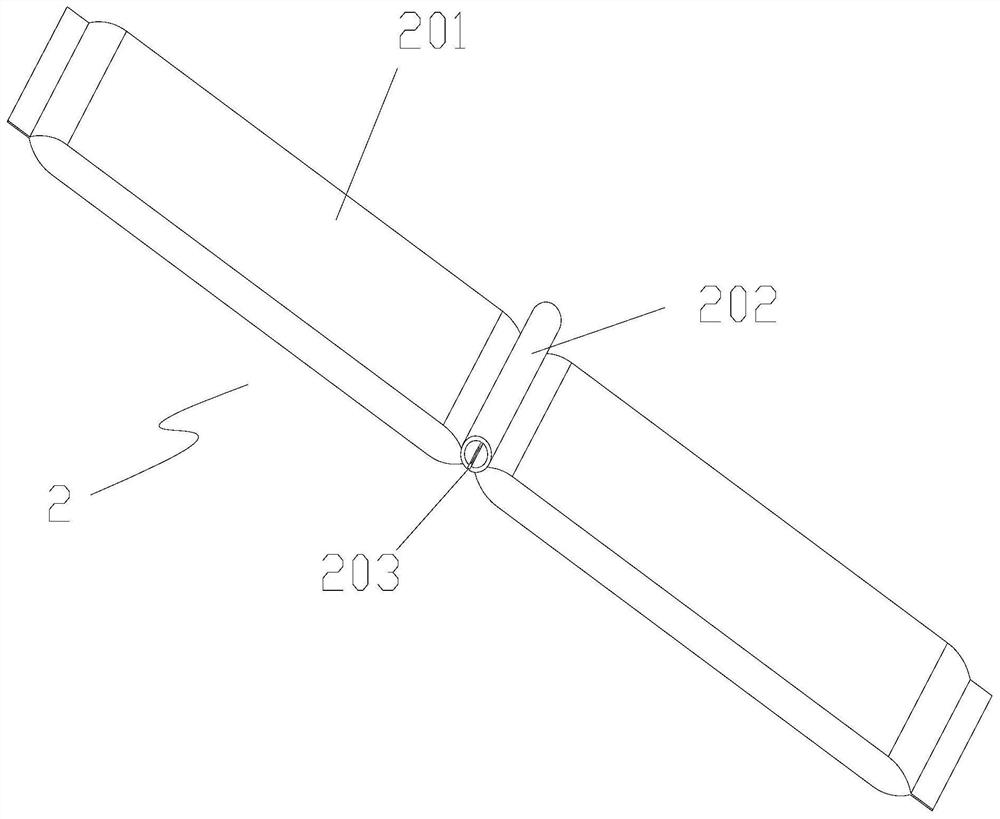

[0028] Embodiment one: if figure 1 As shown, the geotechnical engineering segmented hollow grouting anchor cable device in this embodiment includes a hollow grouting anchor cable 1, and the hollow grouting anchor cable includes a grouting inner tube 101 and is spirally wrapped in the grouting Steel strand 102 around the pipe. The grouting inner pipe is provided with several grouting holes 103 from top to bottom, and the positions of the grouting holes are set according to the specific stratum segmental grouting requirements. The rest of the grouting holes are applied to the constant pressure sealing sleeve 104 for sealing the grouting hole one by one. The part of the stranded wire is stretched to form the grouting part; each constant pressure sealing sleeve has its own standard pressure range, when the grouting pressure is higher than its standard pressure range, the constant pressure sealing sleeve is broken, and when the grouting pressure is The constant pressure sealing s...

Embodiment 2

[0042] Embodiment two: if Figure 5 As shown, the segmented hollow grouting anchor cable device for geotechnical engineering in this embodiment includes a hollow grouting pipe 5, and several grouting holes 103 are arranged on the hollow grouting pipe from top to bottom. The position is set according to the requirements of the specific stratum segmented grouting. The grouting inner pipe is covered with a constant pressure sealing sleeve 104 that is used to seal the grouting holes one by one with the rest of the grouting holes except the uppermost grouting hole. The two ends of the pressure sealing sleeve are fixed on the grouting inner pipe through quick pipe clips 105, and the fast pipe clips partially stretch the steel strands to form the grouting part; each constant pressure sealing sleeve has its own standard pressure bearing range, when the grouting pressure is higher than its standard pressure range, the constant pressure sealing sleeve is broken, and when the grouting pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com