Patents

Literature

56results about How to "Save mixing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

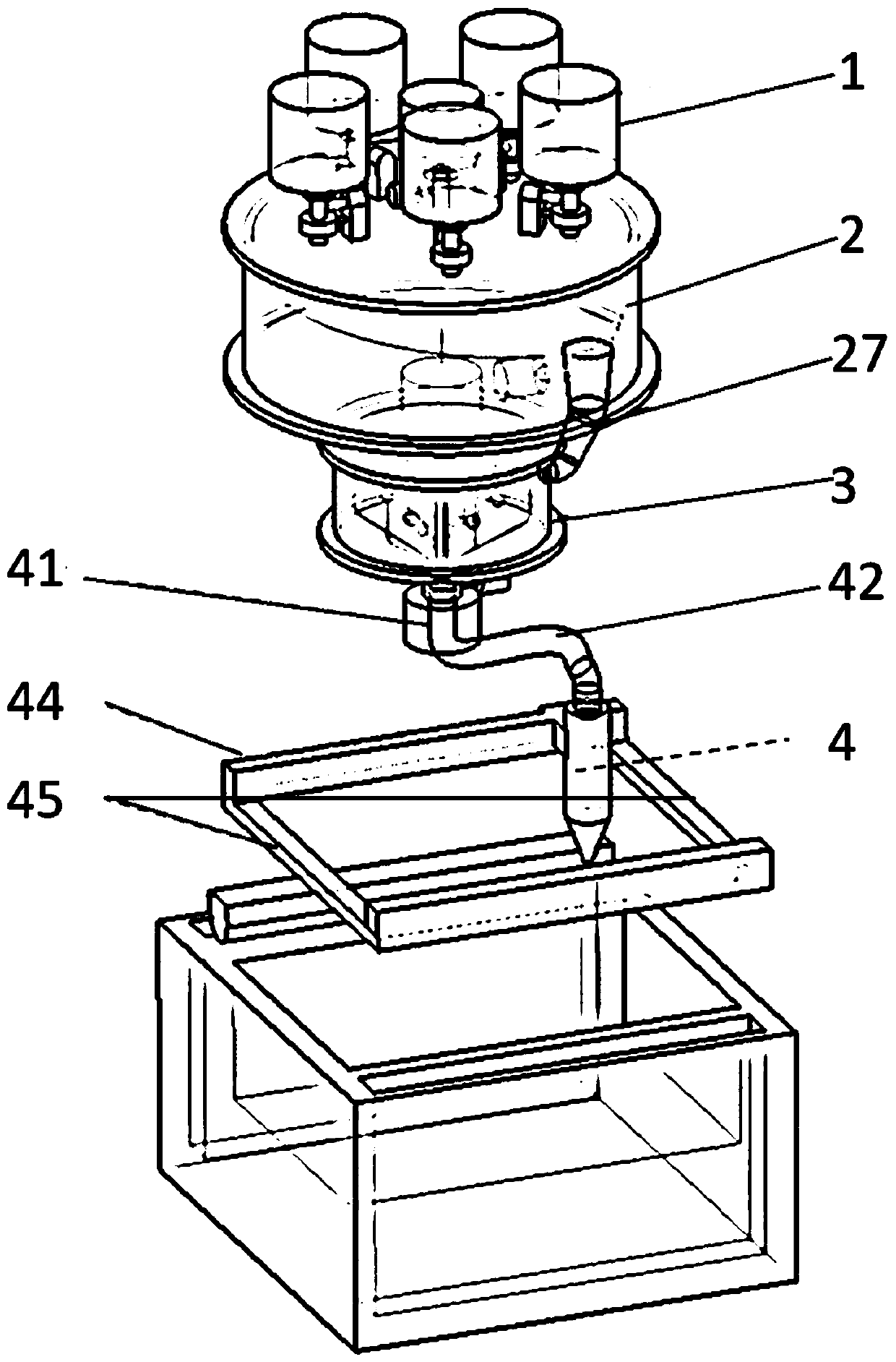

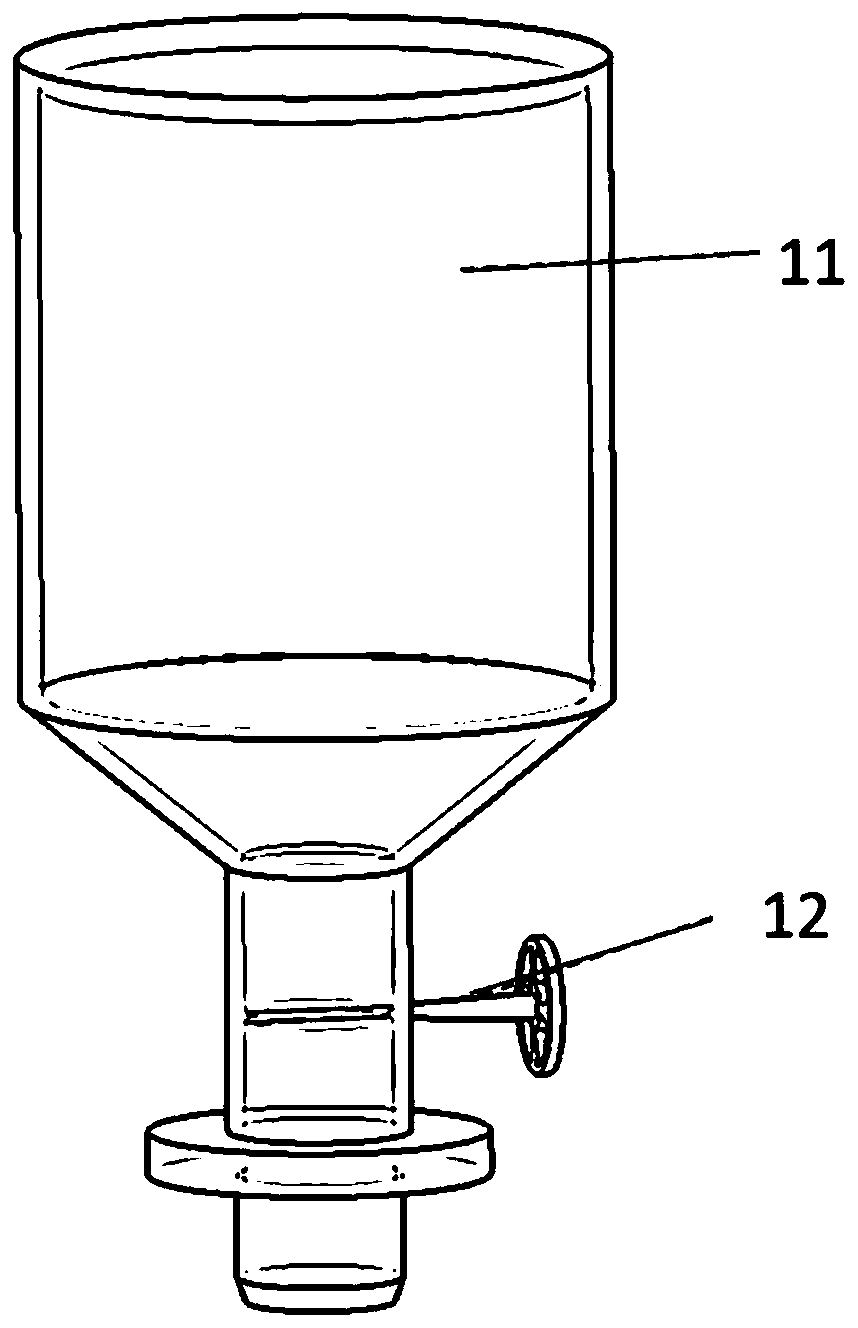

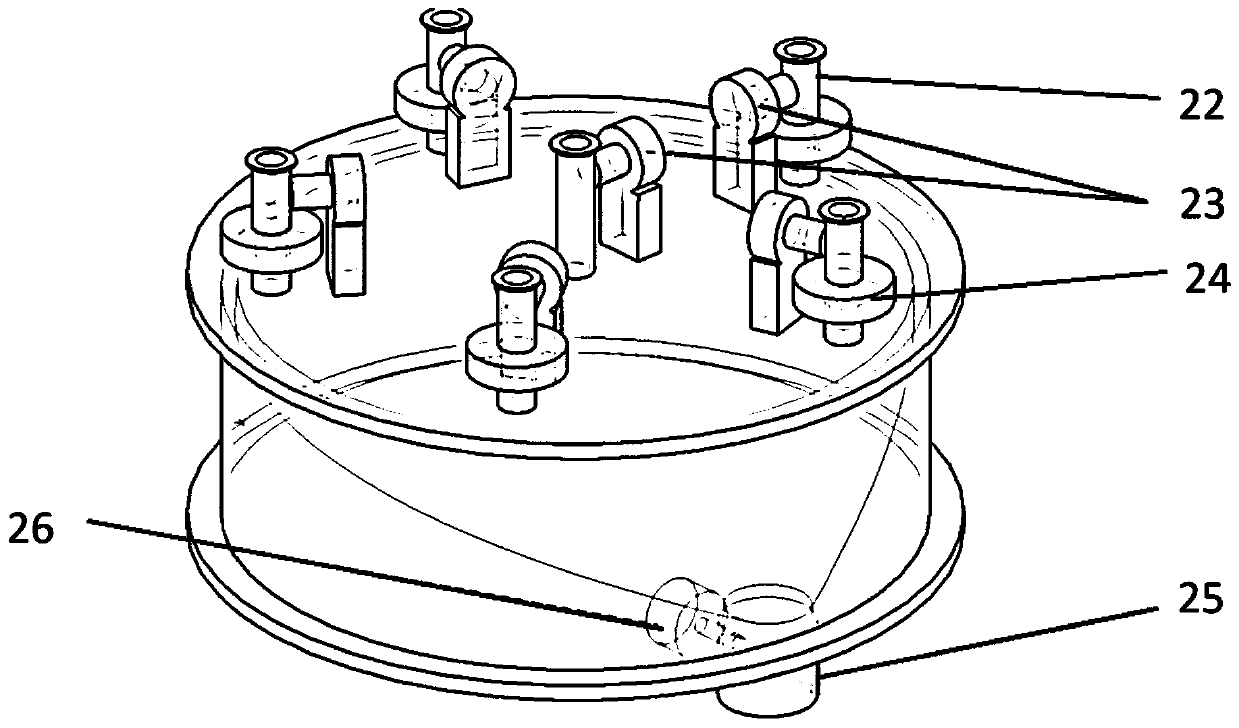

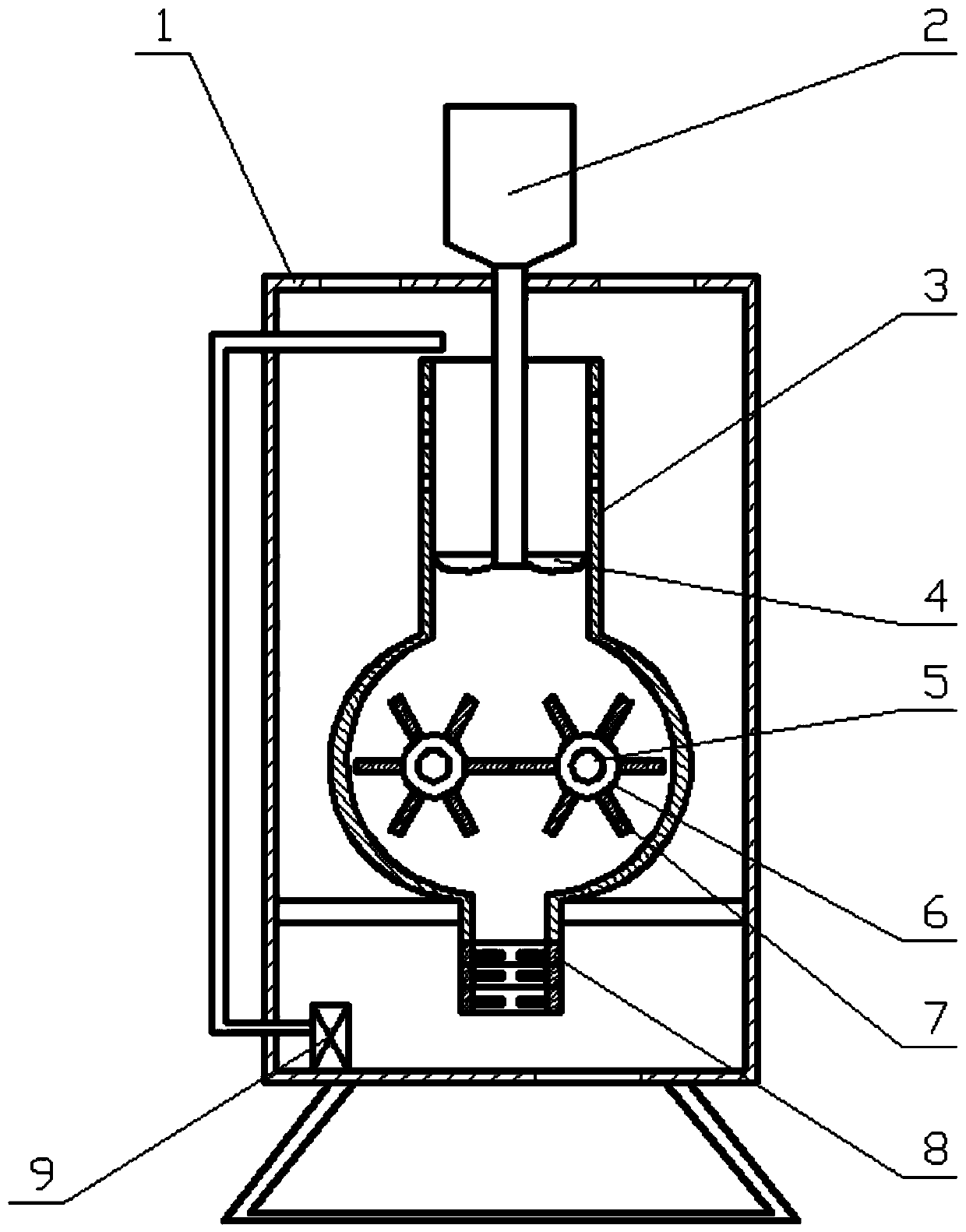

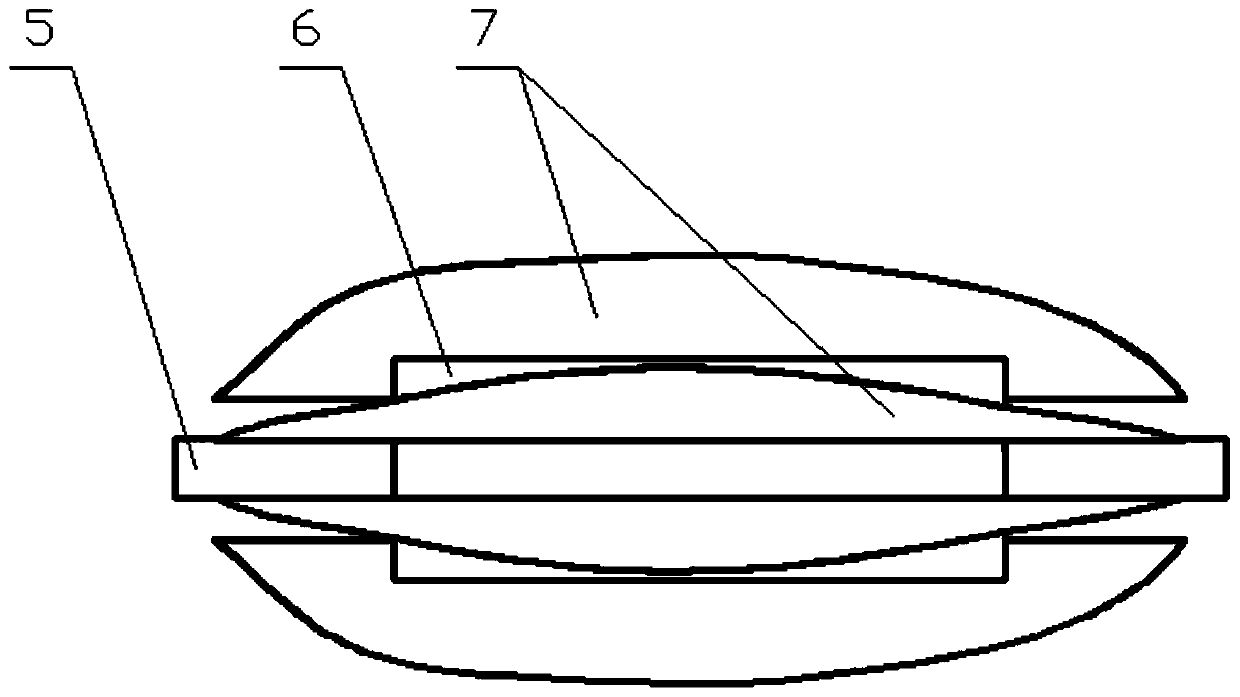

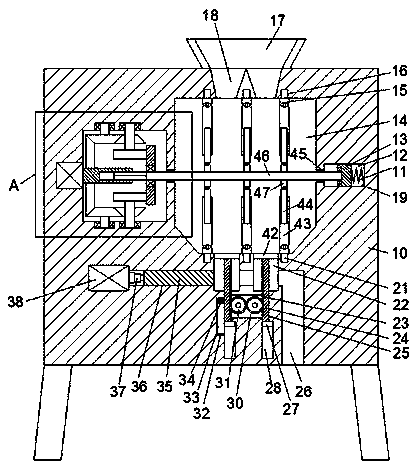

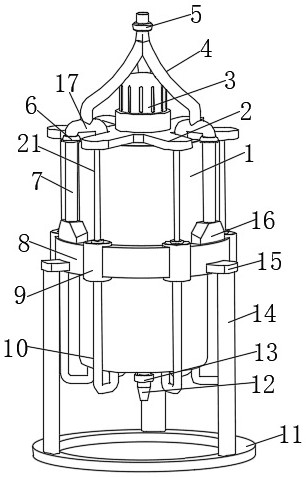

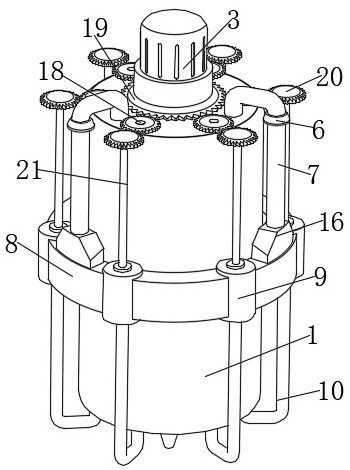

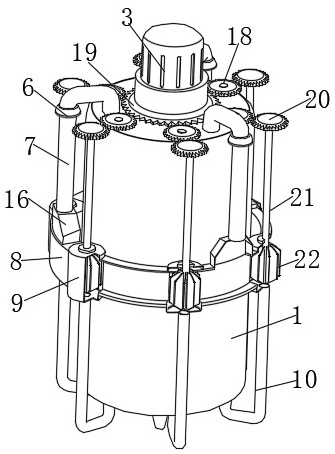

Multi-material powder supplying and laying device for powder bed melting and control method of multi-material powder supplying and laying device

InactiveCN111408718AImprove the efficiency of hybrid printingIncrease productivityAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedHigh entropy alloys

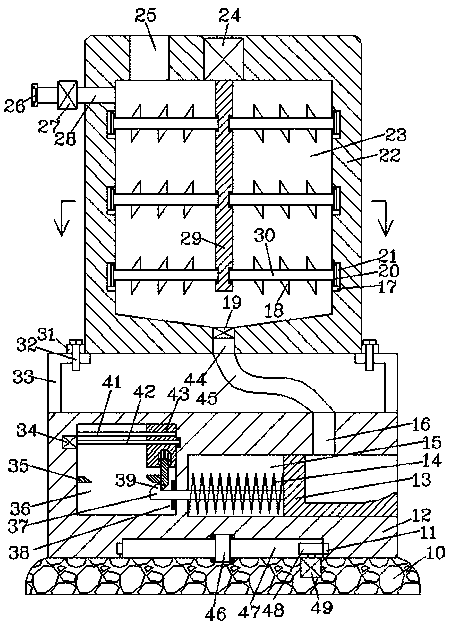

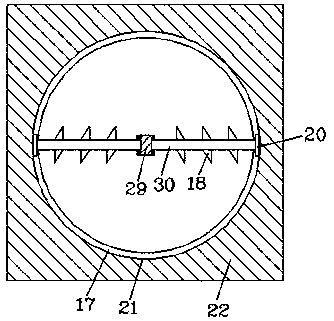

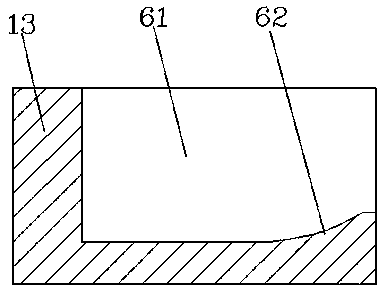

The invention discloses a multi-material powder supplying and laying device for powder bed melting and a control method of the multi-material powder supplying and laying device. A plurality of powderinlets are formed in the upper end of a main powder storage tank, an independent sub-powder storage tank is installed at each powder inlet, and powder in the sub-powder storage tanks are premixed by the main powder storage tank, then a powder mixer in a powder mixing device is used for mixing the premixed mixture, the main powder storage tank and the powder mixing device are adopted for premixingand sufficient mixing respectively, the powder mixing device serves as a buffer section, the powder mixing printing efficiency is improved, and meanwhile printing materials of different mixing contents and types can be added through the plurality of sub-powder storage tanks; and a printing moving frame is used for driving a powder spray head to spray powder, manufacturing of a functionally gradedmaterial and a multi-component alloy / high-entropy alloy-based composite material with components continuously changing in any direction is achieved, long powder mixing time is saved, real-time powderlaying and real-time machining can be achieved, the production cycle is greatly shortened, the production cost is greatly reduced, and the production efficiency is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

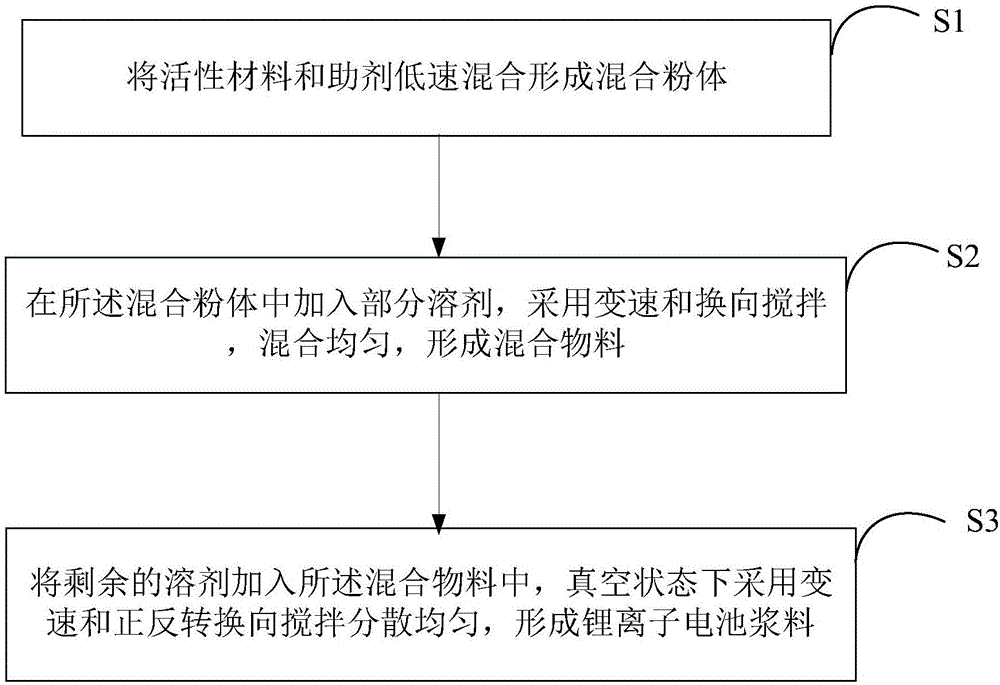

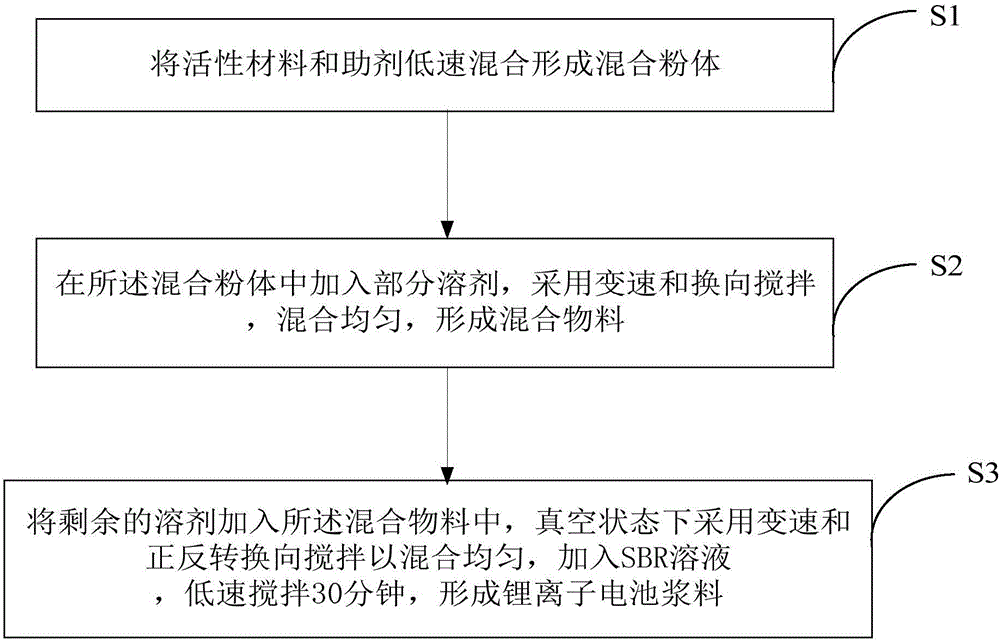

Preparation method of lithium ion battery slurry

InactiveCN106784794AWell mixedGood dispersionFinal product manufactureSecondary cellsPhysical chemistrySlurry

The invention relates to a preparation method of lithium ion battery slurry. The preparation method of the lithium ion battery slurry comprises the following steps: S1, mixing an active material and aids at low speed to form mixed powder; S2, adding part of solvent into the mixed powder, performing variable-speed and positive and negative rotation reversing stirring, and mixing uniformly to form a mixed material; S3, adding the residual solvent into the mixed material, performing variable-speed and positive and negative rotation reversing stirring under the vacuum state, and dispersing uniformly to form the lithium ion battery slurry. The raw materials can be mixed uniformly by adopting variable-speed and positive and negative rotation reversing stirring in the stirring process, the mixing efficiency is improved by utilizing a chaotic mixing principle, and the aims of shorting the mixing and stirring time and improving the mixing uniformity are fulfilled, so that energy consumption is reduced and production efficiency is improved in the production process, and production cost is reduced.

Owner:SHENZHEN TOPBAND NEW ENERGY CO LTD

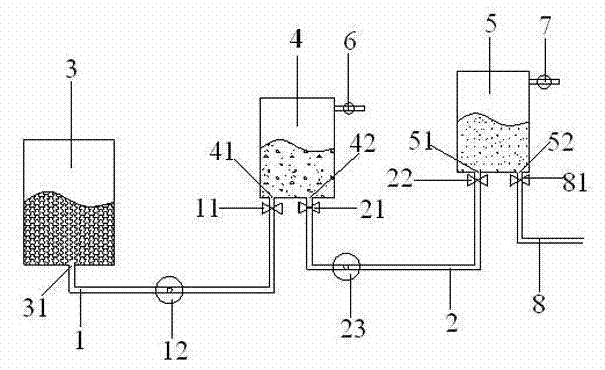

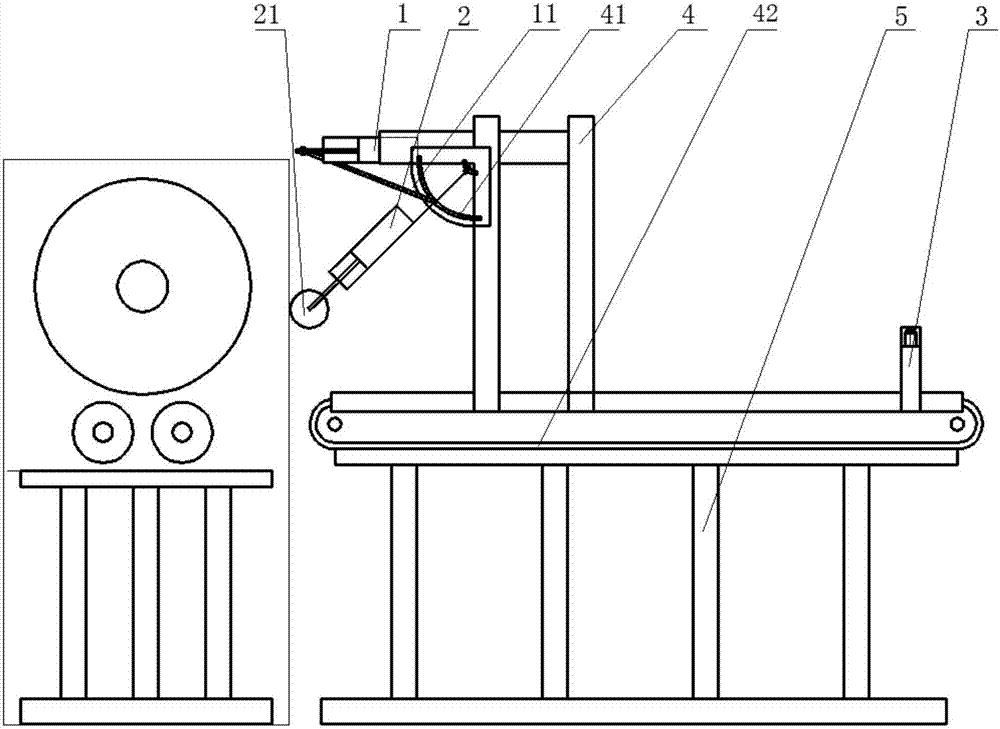

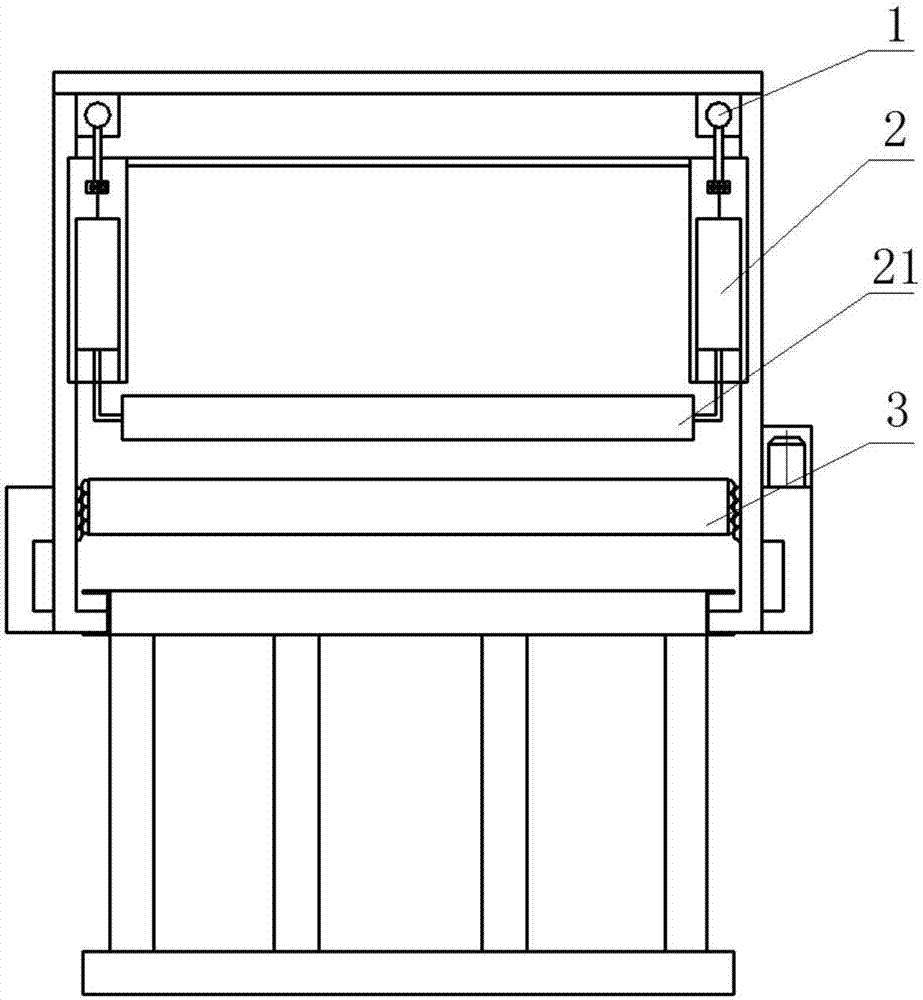

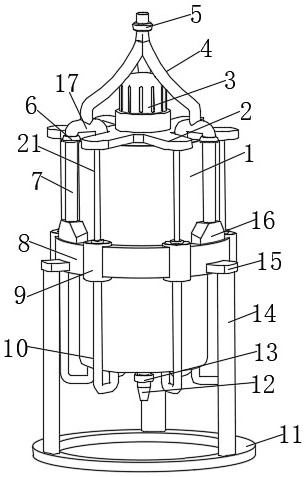

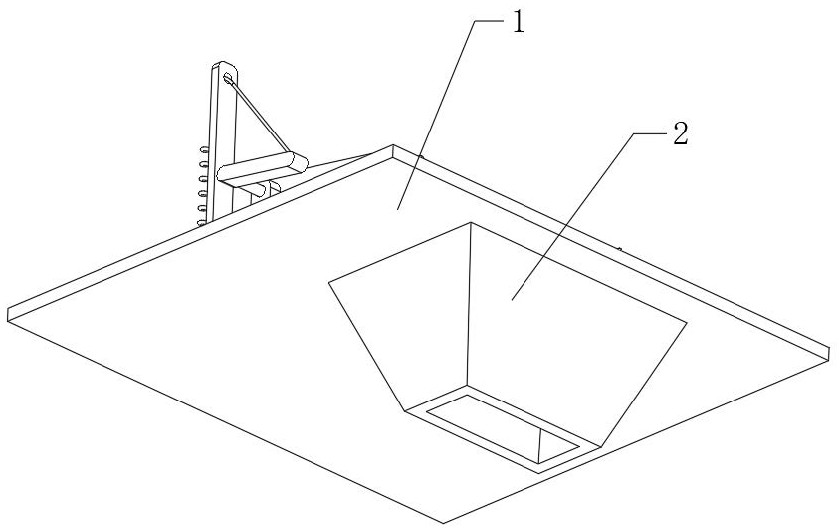

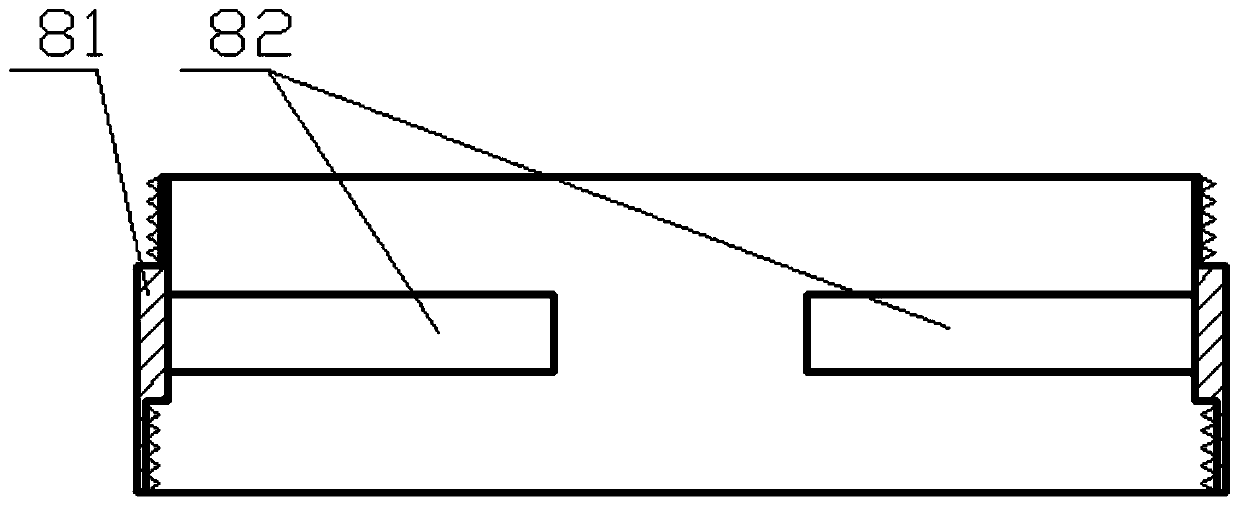

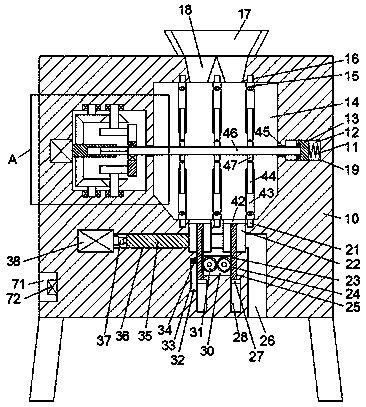

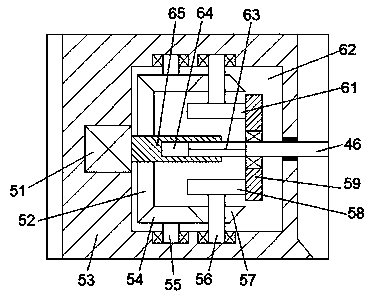

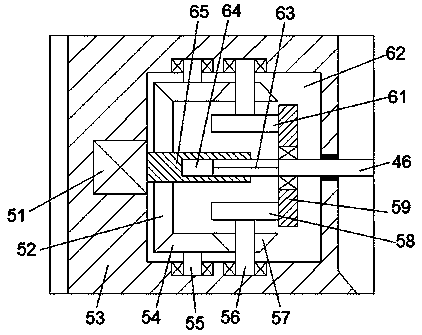

Sand mixer

InactiveCN105478664AGuaranteed blending effectSave mixing timeMould handling/dressing devicesEngineeringSmall arms

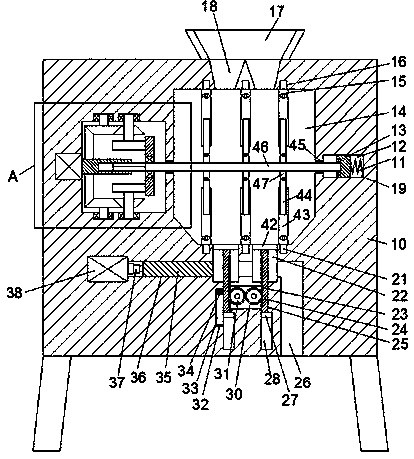

The invention discloses a sand mixer and belongs to the field of casting. The sand mixer comprises a sand warehouse. A discharging opening of the sand warehouse is communicated with a big-arm conveying mechanism. An inlet of the big-arm conveying mechanism is communicated with a storage box. An output opening of the big-arm conveying mechanism is communicated with a small-arm swing mechanism. An outlet of the small-arm swing mechanism is communicated with a sand mixing and stirring cage. An outlet of the sand mixing and stirring cage is communicated with an unloading tank through a sand discharging valve. The bottom end of the unloading tank is provided with a discharging valve. The sand mixer is small in size, original sand, resin and a curing agent are mixed in the sand mixing and stirring cage, sand premixing is carried out in the big-arm conveying mechanism and the small-arm swing mechanism, the sand mixing effect is guaranteed, and the sand mixing time is saved, so that the problems that the occupied area is large due to the large size of an existing sand mixer, and the sand mixing efficiency is lower due to the long sand mixing time of the existing sand mixer in the prior art are solved, the size of the sand mixer is further reduced, the sand mixing efficiency of the sand mixer is improved, and the manufacturing cost of the sand mixer is saved.

Owner:WUXI LINGTONG CASTING CO LTD

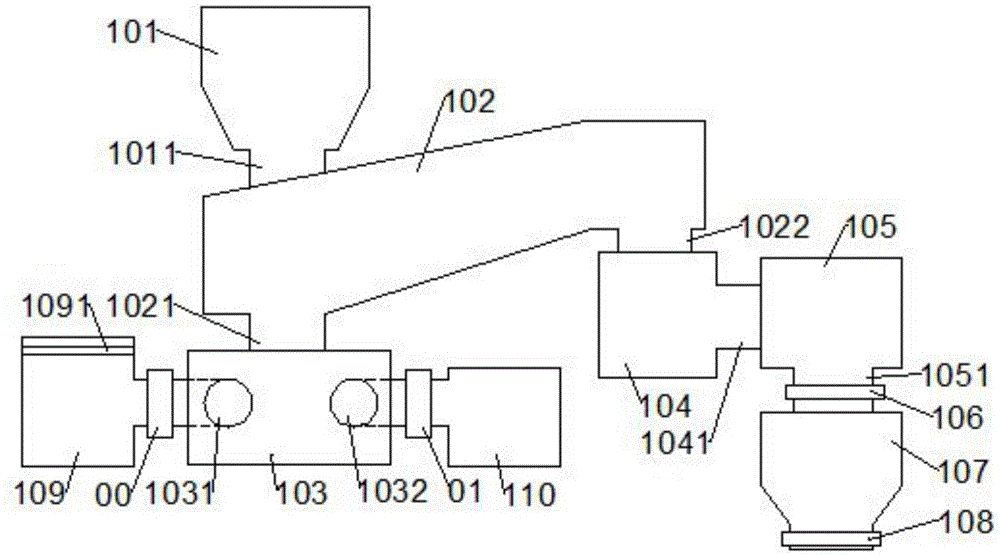

Preparation apparatus and method for lithium ion battery slurry

ActiveCN102824872AWell mixedReduce generationCell electrodesMixing methodsElectrical batteryEngineering

The invention belongs to the technical field of lithium ion batteries and especially relates to a preparation apparatus for lithium ion battery slurry. The apparatus comprises a solvent loading tank and a slurry agitator tank, wherein the slurry agitator tank is connected with a first vacuum pump; the apparatus further comprises a binder premixing tank, wherein the binder premixing tank is connected with a second vacuum pump; a discharge outlet of the solvent loading tank is connected with a feed inlet of the binder premixing tank through a first pipeline, and a discharge outlet of the binder premixing tank is connected with a feed inlet of the slurry agitator tank through a second pipeline. Compared with the prior art, the preparation apparatus provided by the invention has the following advantages: fluids like a solvent and a binder premixed liquid are added from the bottom of a tank to the top of the tank by using vacuum negative pressure, so it is guaranteed that there is only a two-phase interface of a liquid phase and a solid phase, maximum-efficiency mutual infiltration is realized, generation of bubbles in the slurry is reduced, dispersion is promoted, stirring time is shortened and operation is simple, which enables stirring time to be reduced and production efficiency to be improved. Furthermore, the invention also discloses a method of utilizing the apparatus for preparation lithium ion battery slurry.

Owner:DONGGUAN AMPEREX TECH

Positive and negative electrode active substance formulation for valve controlled and sealed lead-acid accumulator

InactiveCN1482695AUnderestimated proportionHigh porosityLead-acid accumulator electrodesPorosityFloating charge

A positive and negative electrode active compound formulation for valve control type sealed lead-acid accumulator, wherein sodium dioxide is used to replace sulfuric acid, and right amount of PTEF isadded into the positive electrode formulation, plumping agent is added into the negative electrode formulation. The invention realizes low cost of manufacture, high production efficiency and improvedutilization ratio of active compound, the invention also reduces the equipment corrosion and environmental pollution, the battery made thereby can be used in the field of floating charge and circulation application. íí

Owner:江苏隆源双登电源有限公司

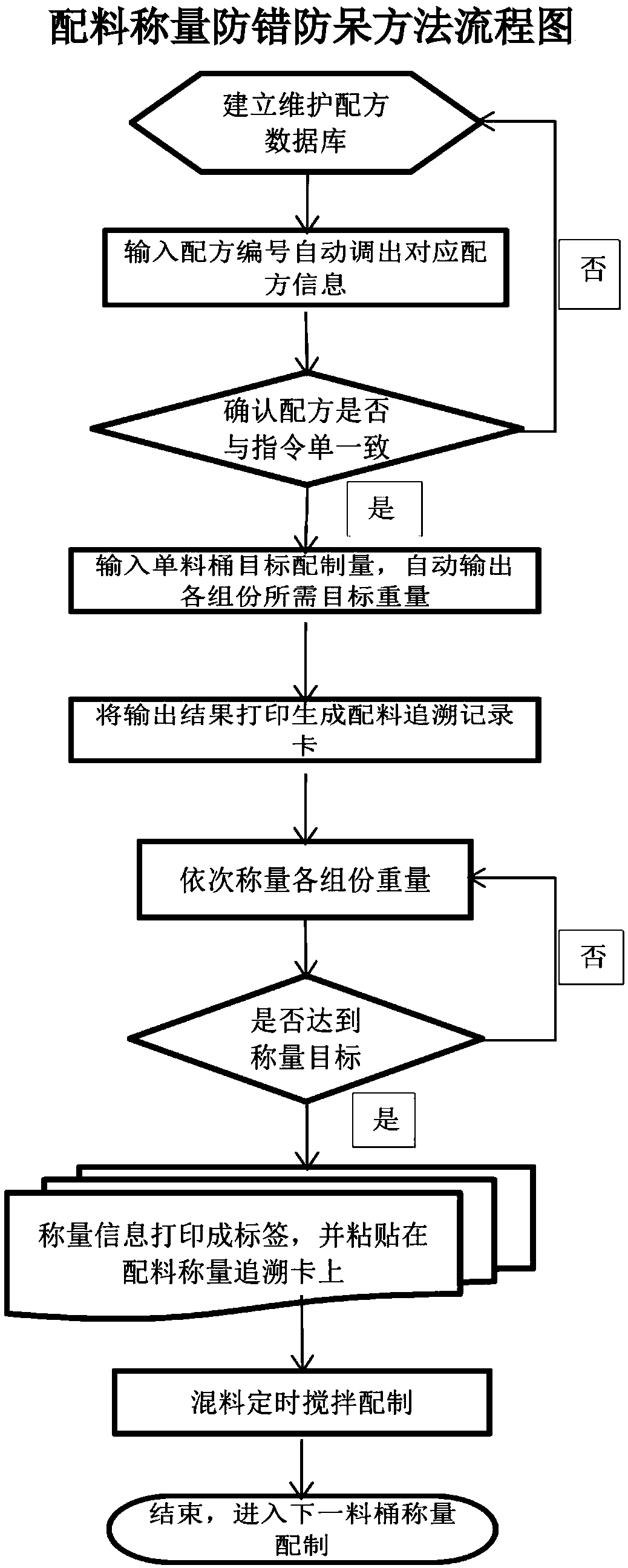

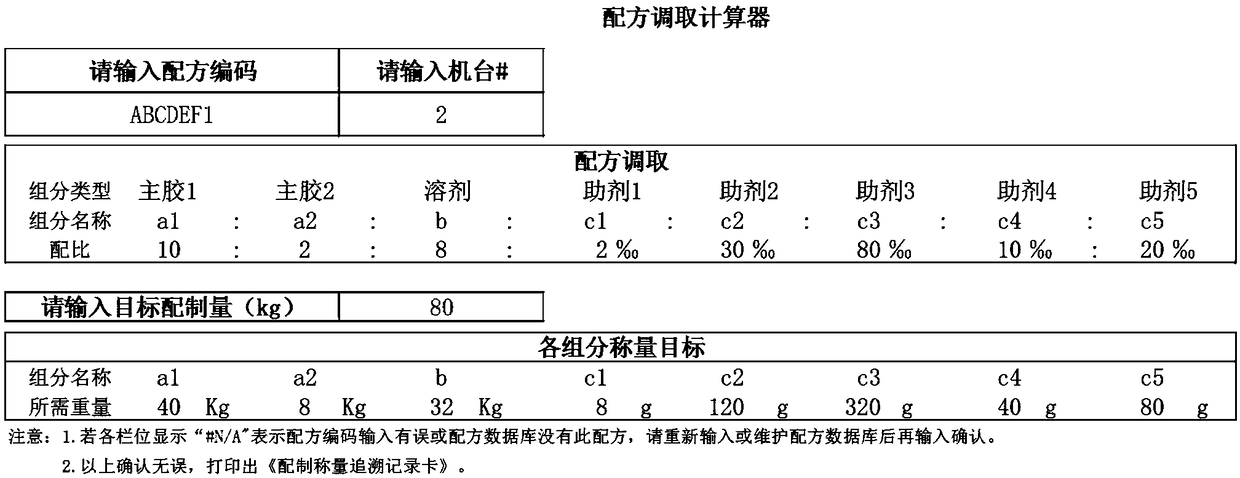

Error-proof and fool-proof control method and system for batching and weighing

InactiveCN109357736AEnhanced ConsistencyPrevent recipe errors or instruction errorsWeighing apparatus with automatic feed/dischargeDatabase indexingCalculatorConfidentiality

The invention discloses an error-proof and fool-proof control method and a system for batching and weighing. The method comprises the steps of: establishing a formula database by a computer; establishing a formula component acquiring calculator associated with the database; inputting the code of a formula to acquire the proportions and the weights of corresponding components; a weighing system capable of alarming and printing and controlled by a PLC performing weighing, and printing and posting the weighing result; creating a retrospective report; and stirring the mixing at regular time and constant speed. According to the error-proof and fool-proof control method and the system for batching and weighing, the consistency, synchronization and confidentiality of formula management are enhanced; the error of formula and the error of instruction are prevented; the batching error caused by manual accounting error is avoided; the deviation caused by excessive measurement fluctuation is reduced, and the consistency between the actual product and theoretical formula performance is ensured; the mixing stirring time is shortened to control the deviation caused by excessive fluctuation; and the stability of the preparation process and the stability of the product quality are ensured.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

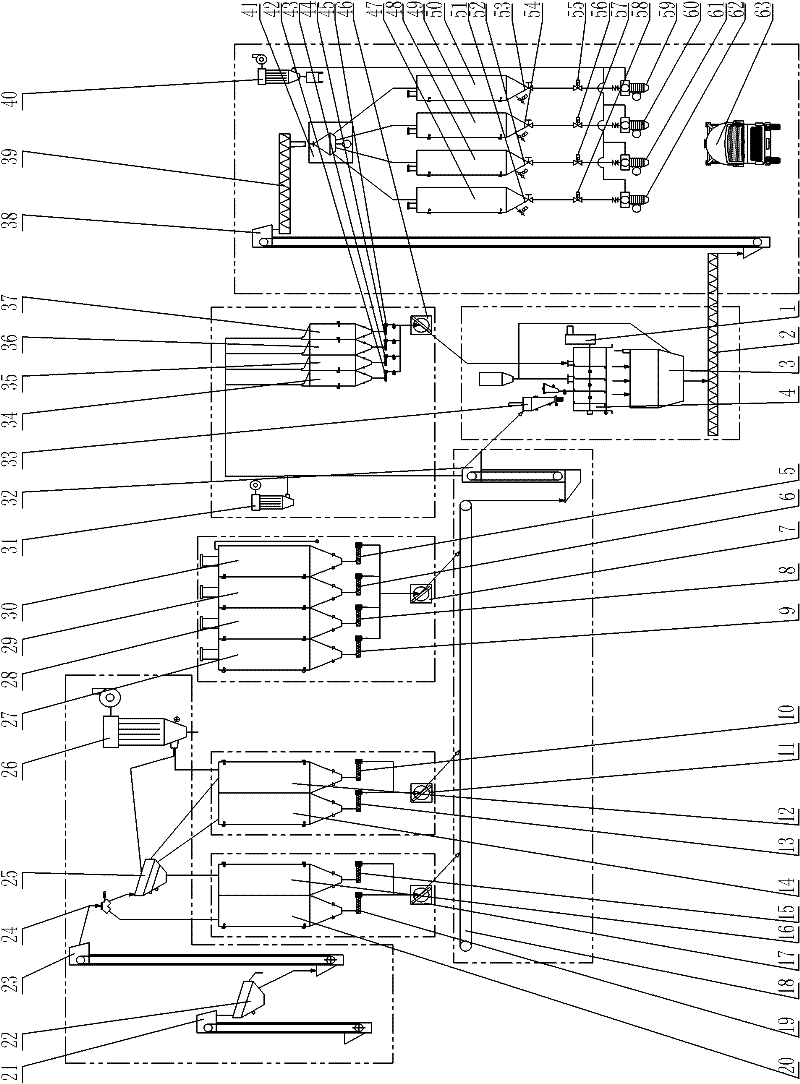

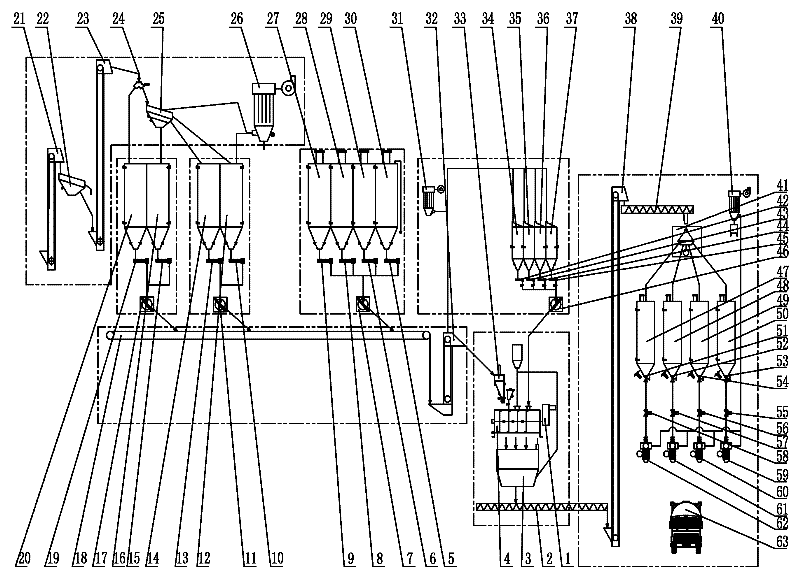

Continuous controllable dry mixed mortar stirring station

InactiveCN102229205AContinuous productionReduce the carrying weightMixing operation plantProcess engineeringField bus

The invention relates to a continuous controllable dry mixed mortar stirring station, which comprises a sand preparation unit, a sand supply unit I, a sand supply unit II, a powder supply unit, a sand conveying unit, an admixture supply unit, a stirring unit and a finished product supply unit, wherein each unit is controlled by adopting an intelligent control system with a field bus and matched with the intelligent control system by adopting an impact flow balance. Compared with the prior art, the stirring station has the advantages that: the production cost of dry mixed mortar is continuous,the weight of equipment is reduced, the manufacturing cost is reduced, the volume of the equipment is simplified, the floor area and the waste of driving electrical energy are reduced, the stirring burden and the mixing and stirring time are reduced, the energy consumption is reduced, the production efficiency of the product is improved, and the stirring station is energy-saving and environment-friendly.

Owner:LIAONING HAINUO CONSTR MACHINERY GROUP

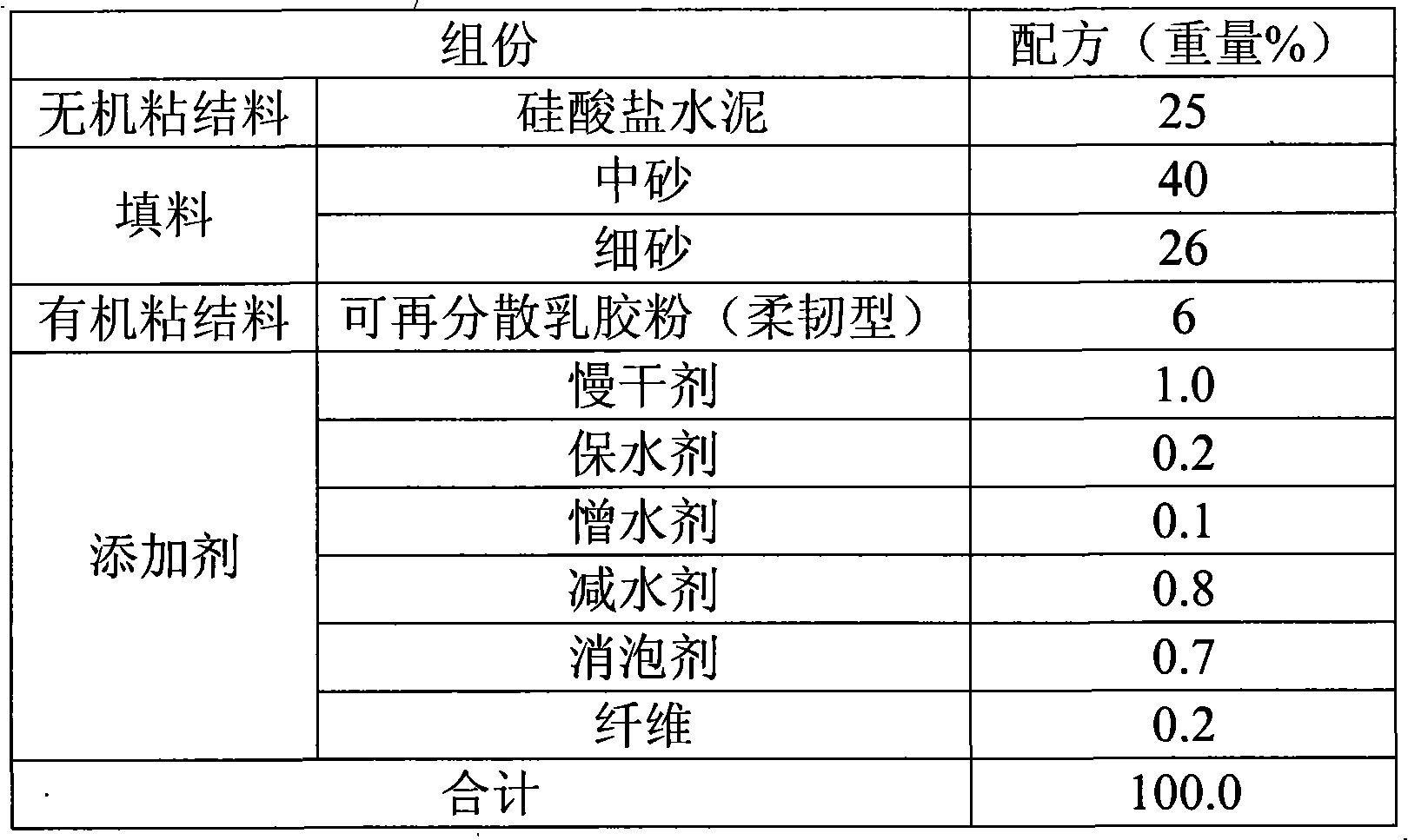

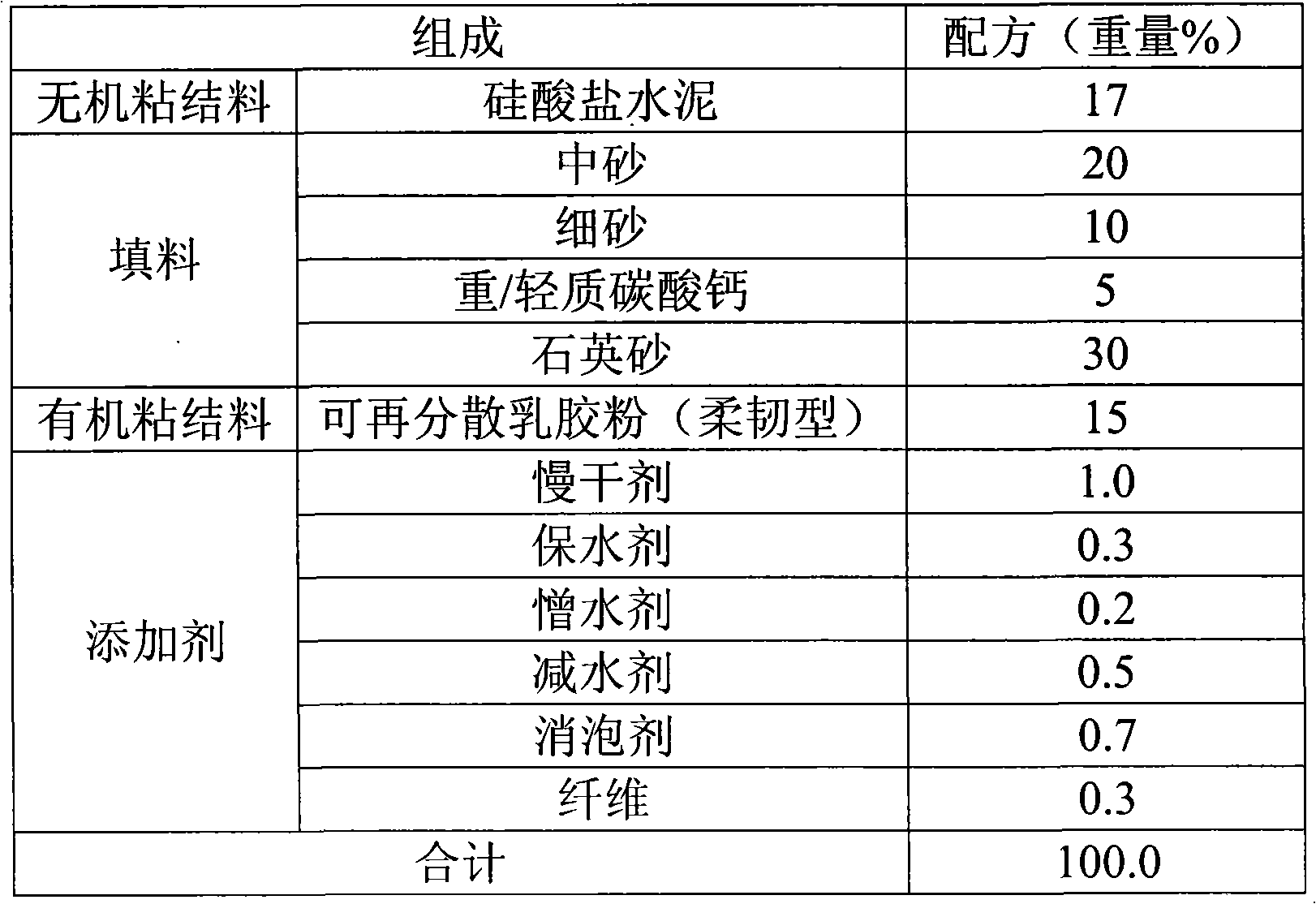

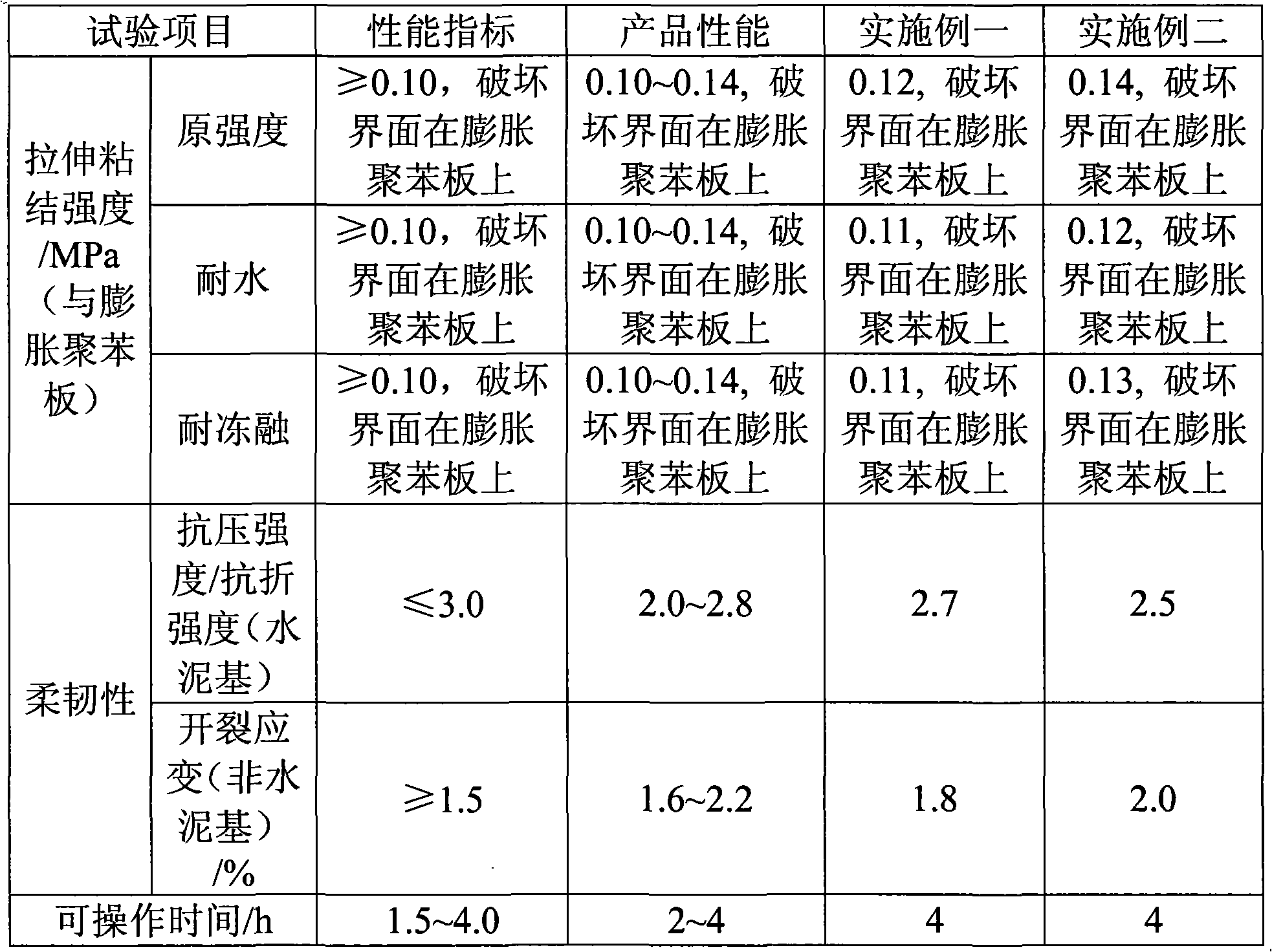

Exterior wall external heat insulation protecting mortar

The invention discloses outer heat preservation protection mortar for an outer wall. The protection mortar comprises the following components: 55 to 80 percent of filler, 10 to 30 percent of inorganic bonding material, 5 to 15 percent of organic bonding material, 0.2 to 1 percent of slow-drying agent, 0.1 to 0.3 percent of water retention agent, 0.01 to 0.3 percent of water retardant, 0.1 to 1 percent of water reducing agent, 0.1 to 1 percent of anti-forming agent and 0.1 to 0.5 percent of fiber, wherein the components are weighed up against a 100 percent total weight. The protection mortar of the invention is the dry mixing mortar prepared by a conventional method, and the raw materials and the mixing ratio can be strictly controlled, a series problems of cracking, leakage, hollow bed and falling-off, etc. can be avoided, so that the bonding mortar has the actions of bonding expanded polyphenylene plates with wall surfaces of substrates or putty and ensures stable and reliable mortar quality; moreover, the prepared outer heat preservation protection mortar for outer walls also has the advantages of saving the on-site material mixing time, improving performance and improving production efficiency and construction efficiency.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

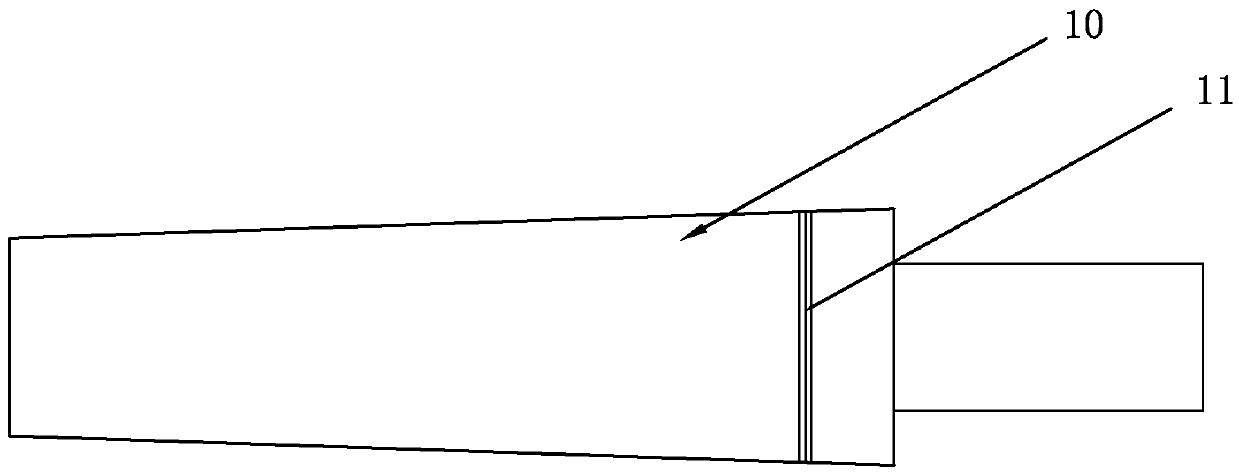

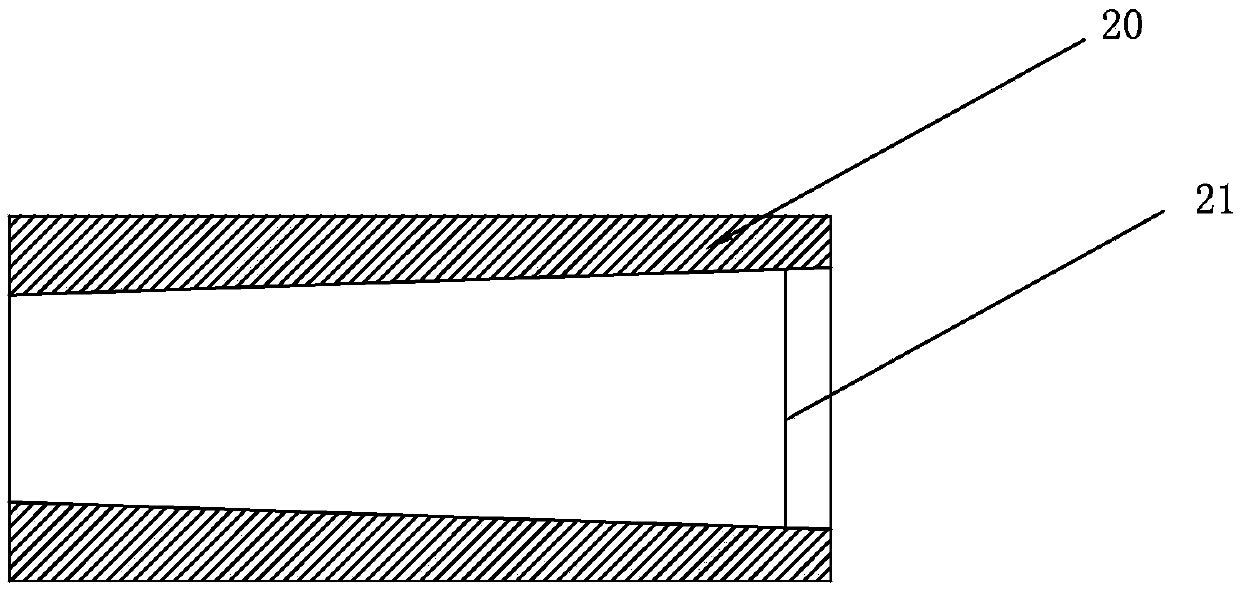

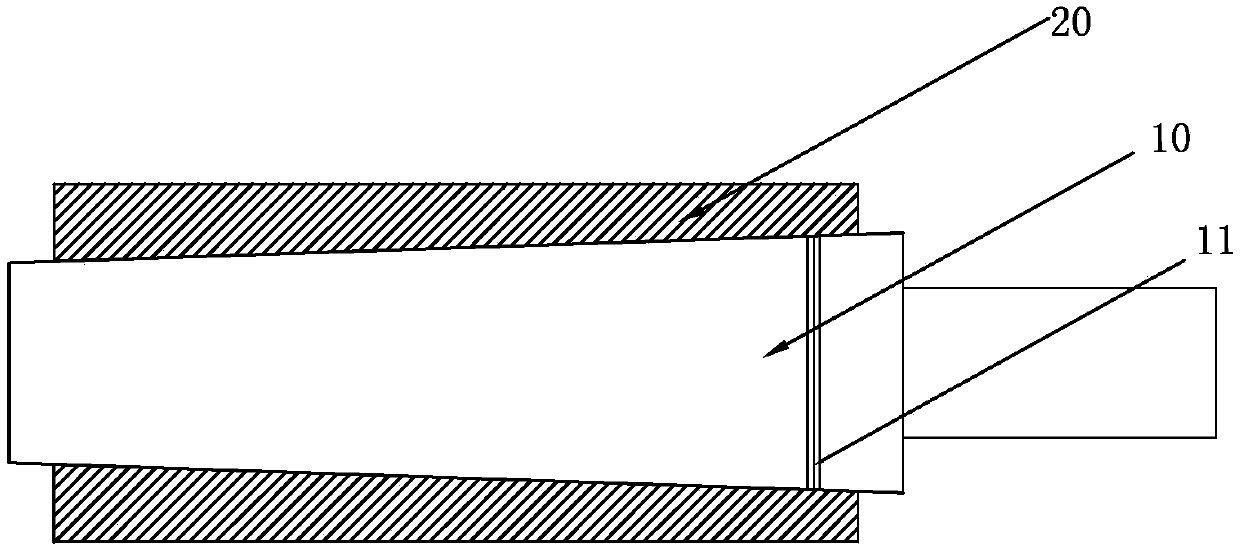

Cone and cone hole machining method

The invention discloses a cone and cone hole machining method. The method comprises the steps that a taper rod and a taper sleeve which are same in taper are made, wherein the cone matching contact area reaches 95% or above; a first marking line is drawn on the portion, with the diameter equal to a standard diameter value of the big end of a preset propeller cone hole, of the taper rod, and a second marking line is drawn on the portion, with the diameter equal to the above-mentioned standard diameter, of the taper sleeve; a propeller cone hole and a screw shaft cone are made, wherein the length of the propeller cone hole is correspondingly smaller than the cone length of the taper rod, and the length of the screw shaft cone is correspondingly smaller than the cone hole length of the taper sleeve; and when the propeller cone hole and the screw shaft cone are machined, the taper rod and the taper sleeve are adopted for replacing the corresponding screw shaft cone and propeller cone hole to check the contact area of the taper rod and the propeller cone hole and the contact area of the taper sleeve and the screw shaft cone and the cone size. The invention provides an efficient propeller cone hole machining method. The method is high in machining precision, good in cone matching contact surface, easy to operate, good in interchangeability, capable of saving labor and low in manufacturing cost.

Owner:ZHUHAI HOLYFORT MARINE EQUIP CO LTD

Method for preparing microcapsule polyurethane premix

InactiveCN107141433ASaving ratioSave mixing timeMicroballoon preparationMicrocapsule preparationPolyurethane elastomerUltraviolet

The invention provides a method for preparing microcapsule polyurethane premix, and belongs to the technical field of polyurethane. The method for preparing microcapsule polyurethane premix comprises the steps that 1, curing agents or other components are respectively prepared into solid microcapsules by utilizing the microencapsulation technology; 2, solid microcapsules are uniformly mixed in polyurethane prepolymer and vacuum degassed after the mixing; 3, when the microcapsules are in use, the shells of the microcapsules are ruptured, curing agents or other components wrapped by the capsules spill, contact is made with polyurethane prepolymer and a polymerization reaction occurs, and polyurethane elastomers are generated. By the microencapsulation technology, curing agents or other components in capsule form are respectively distributed in polyurethane prepolymer, by the obstruction of the capsule shells, the components do not react with each other before use, and long-term stable storage is achieved. When the microcapsules are in use, the capsule shells are ruptured by means of temperature, pressure, ultraviolet or the like, the components are in contact with each other, the rapid polymerization reaction occurs, and polyurethane elastomers are generated, proportioning and mixing are not required at the construction site, the construction time is saved, and the construction facilities are simplified in the meantime.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Formula of positive active material for lead-acid power battery and preparation method of positive active material

InactiveCN103000883AUnderestimated proportionHigh porosityCell electrodesPower batteryLead(II,IV) oxide

The invention discloses a formula of a positive active material for a lead-acid power battery. The formula is characterized in that sodium peroxide, lead tetraoxide and CMC (Carboxy Methylated Cellulose) are added. The invention also discloses a preparation method of the positive active material. The preparation method comprises the steps of: firstly, mixing and stirring lead powder, lead tetraoxide powder and sodium peroxide powder for 3-5min, then adding the CMC, stirring for 5-8min, adding deionized water, stirring for 8-10min, finally adding sulfuric acid with the specific gravity of 1.05g / cm<3>, stirring for 10-15min, coating a positive plate, and drying the coated positive plate for 4-6h in a drying room with the temperature of 60 DEG C and then performing assembly and battery formation processes.

Owner:江苏海宝电池科技有限公司

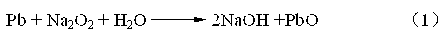

Efficient stirring device for lubricating processing

InactiveCN107930451AImprove stirring efficiencySave workShaking/oscillating/vibrating mixersRotary stirring mixersRotational axisEngineering

The invention discloses an efficient stirring device for lubricating processing. The efficient stirring device comprises a stirring bucket, wherein a stirring motor is fixedly connected with the top of the stirring bucket; a first rotating shaft is arranged inside the stirring bucket; a first bevel gear is fixedly connected with the first rotating shaft; the top of the first rotating shaft is connected with the stirring motor; a fixing rod is fixedly connected with the side wall of the stirring bucket; a bevel gear component matched with the first bevel gear is fixedly connected with the tailend of the fixing rod; a second rotating shaft is fixedly connected with the bottom inside the stirring bucket; a second bevel gear matched with the bevel gear component is fixedly connected with thetop of the second rotating shaft; a support rack is fixedly connected with the first rotating shaft; stirring rods are respectively hinged with the upper end and the lower end of the support rack; anda stirring shaft is hinged with the second rotating shaft. According to the efficient stirring device, the first rotating shaft and the second rotating shaft rotate in opposite directions, so that the stirring efficiency of lubricating oil is greatly improved, the workload of operators is reduced, and the stirring time is shortened, the device is convenient to move, and convenience is brought topeople to move the device.

Owner:WUXI FEITIAN GREASE

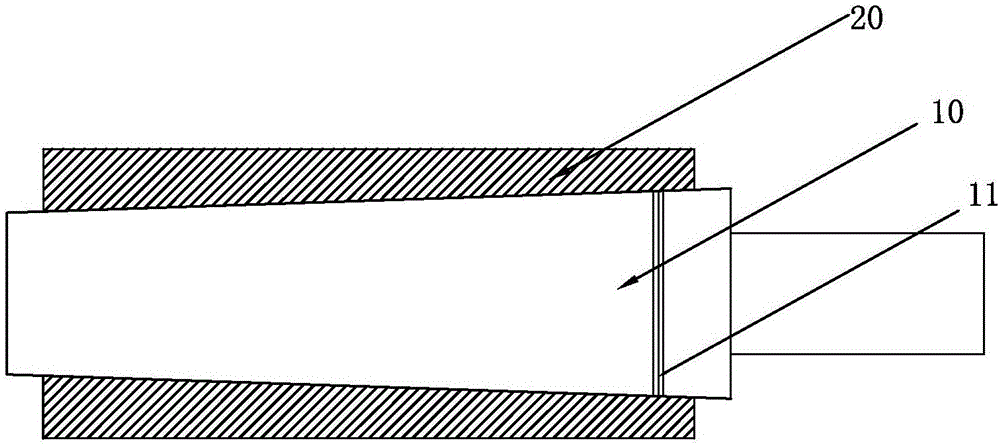

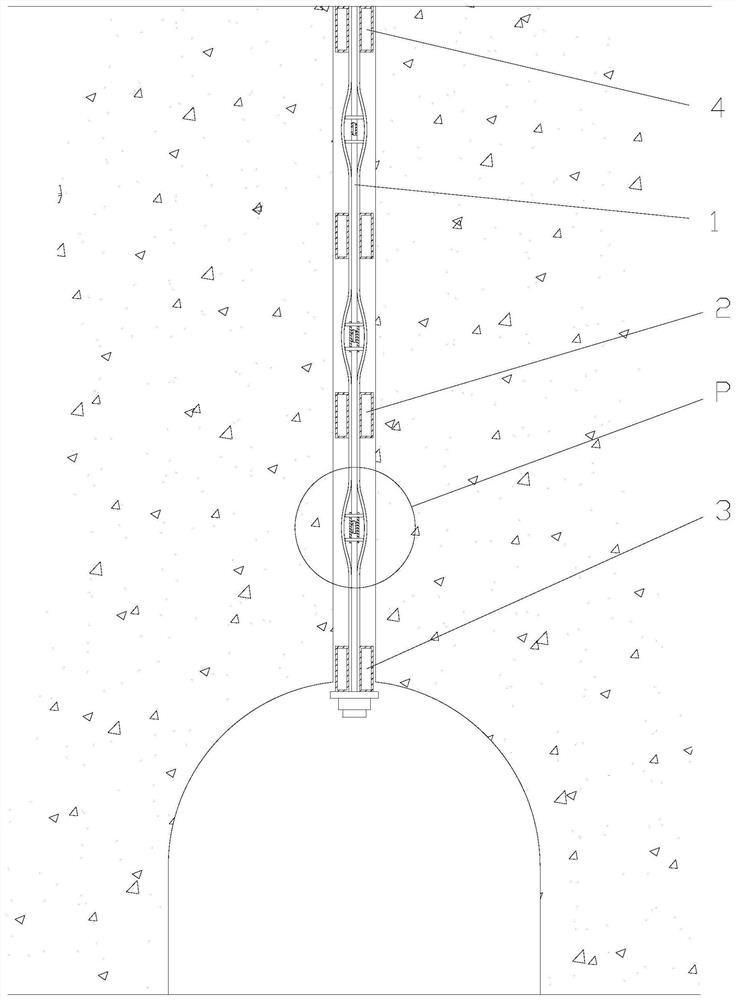

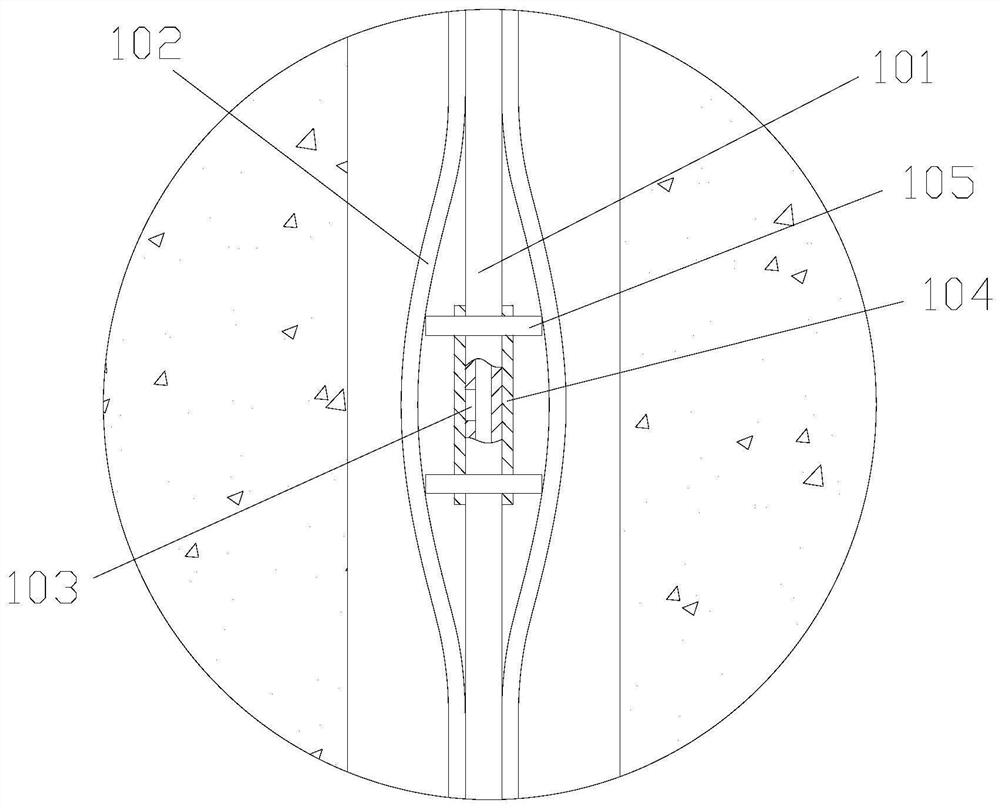

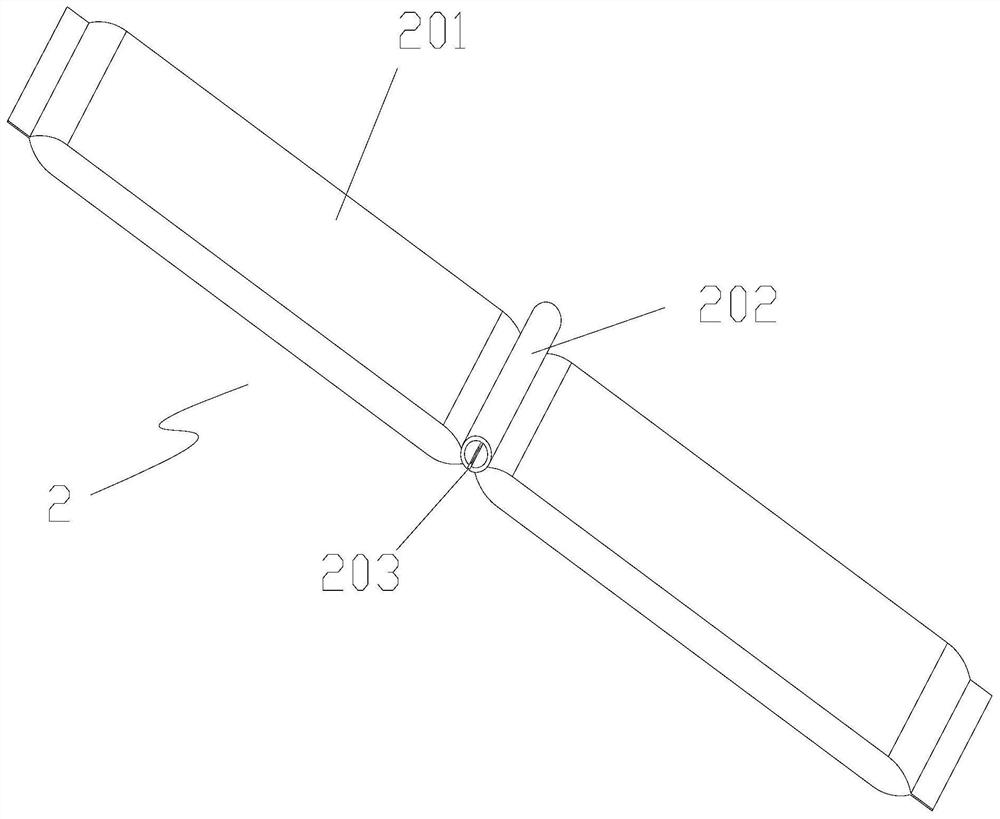

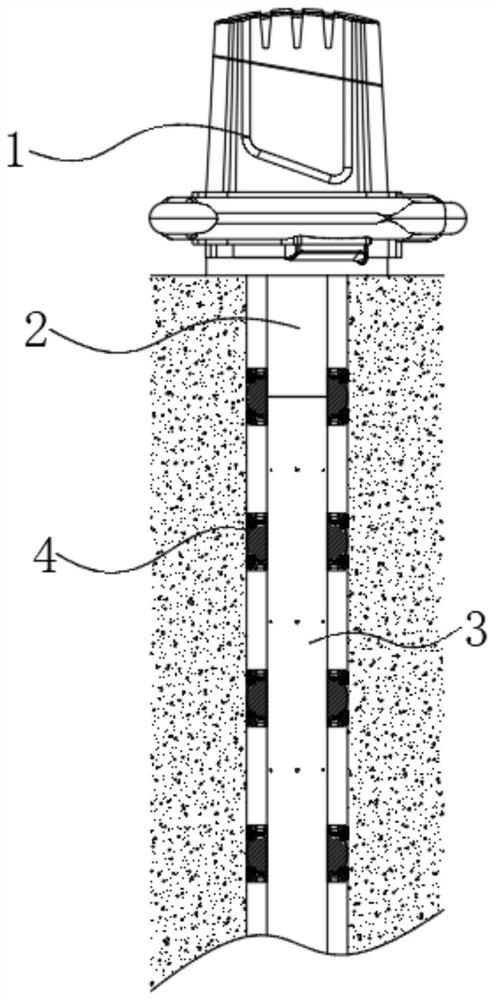

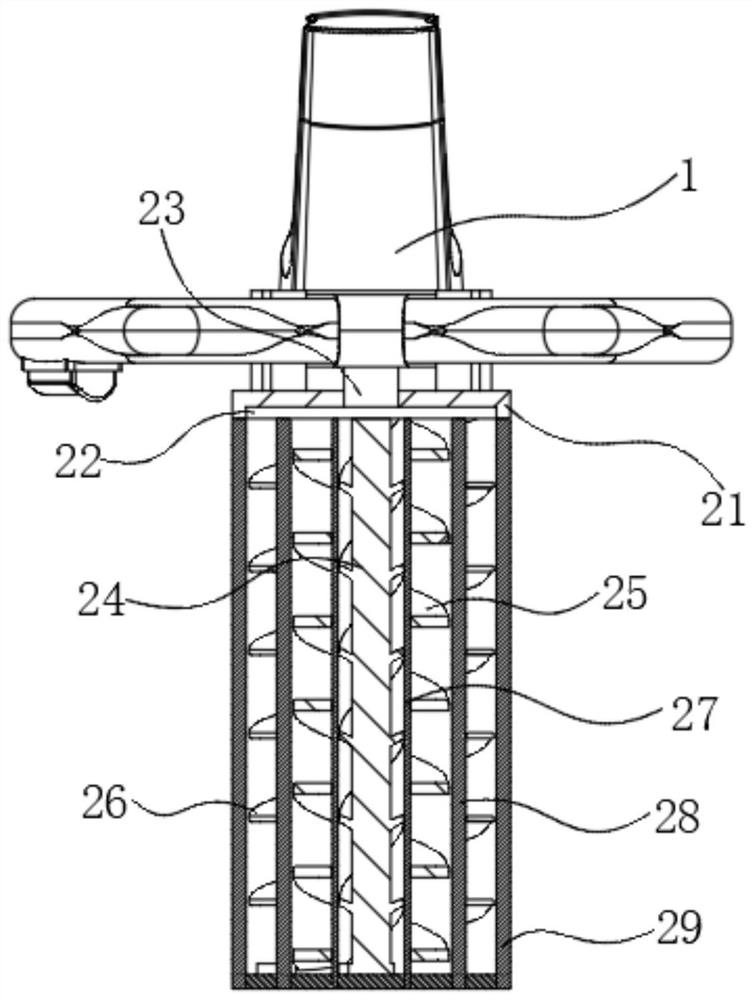

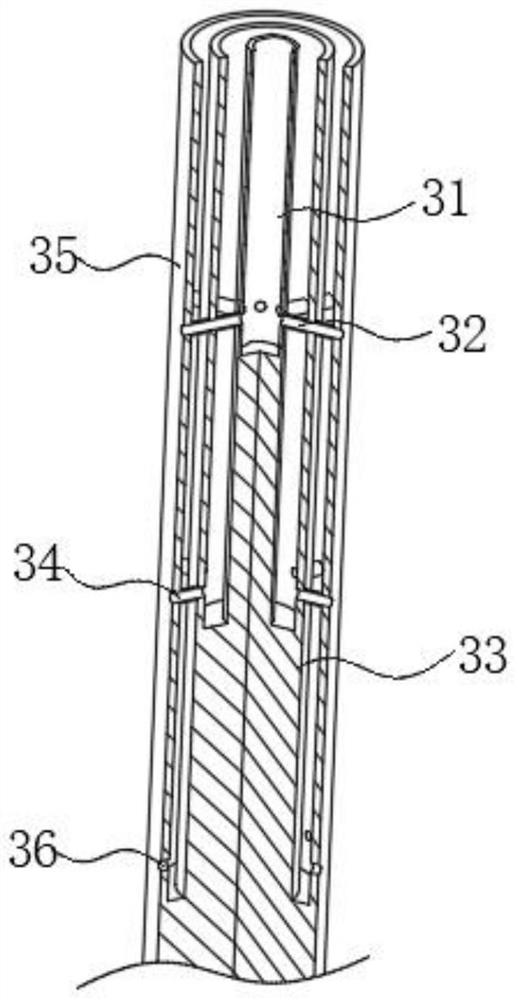

Geotechnical engineering sectional type hollow grouting anchor cable device

ActiveCN112392524AIncrease the amount of groutImprove grouting reinforcementBulkheads/pilesAnchoring boltsGroutWall rock

The invention discloses a geotechnical engineering sectional type hollow grouting anchor cable device. The device comprises a hollow grouting anchor cable or a hollow grouting pipe, and further comprises sectional isolators; the hollow grouting anchor cable comprises a grouting inner pipe and a steel strand; a plurality of grout outlet holes and constant-pressure sealing sleeves used for sealing the grout outlet holes are arranged on the grouting inner pipe or the hollow grouting pipe; the sectional isolators are arranged on the hollow grouting anchor cable or the hollow grouting pipe; and thesectional isolators are arranged among the grout outlets formed in the hollow grouting anchor cable or the hollow grouting pipe. According to the geotechnical engineering sectional type hollow grouting anchor cable device, due to the arrangement of the sectional isolators and the constant-pressure sealing sleeves, corresponding sectional and graded grouting can be conducted according to differentreinforcing or sealing requirements of stratum surrounding rock of different parts, the grouting amount of deep surrounding rock can be increased according to needs, the grouting reinforcing or sealing effect can be remarkably improved, a large amount of re-injection or re-repair cost is saved, and particularly potential safety risks caused by surrounding rock collapse and re-repair can be effectively avoided.

Owner:SHANDONG UNIV OF SCI & TECH

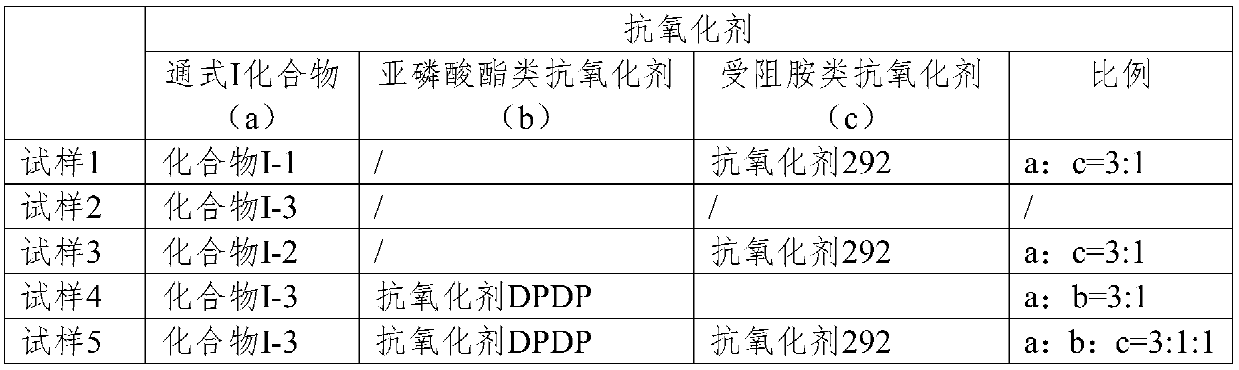

Liquid antioxidant composition for C5 petroleum resins

PendingCN110028700AImprove antioxidant capacityEasy to measureLiquid productHindered amine light stabilizers

The invention relates to a liquid antioxidant composition for C5 petroleum resins, wherein the liquid antioxidant composition comprises, by weight, 30-80 parts of a hindered phenol antioxidant, 10-40parts of a hindered amine light stabilizer, 0-30 parts of a phosphite antioxidant, and 0-30 parts of a thioester antioxidant. According to the present invention, the antioxidant is added during the production of the C5 petroleum resin, and accounts for 0.1-1.0% of the weight of the C5 petroleum resin; and the composition is a liquid product, can directly replace the existing antioxidant system without the modification in the process, has significant anti-oxidation effect compared with the existing antioxidant system, and easily helps the industrial production.

Owner:RIANLON +2

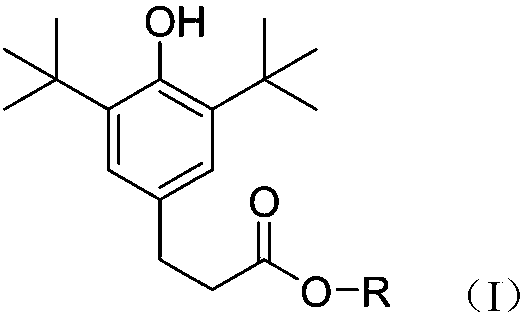

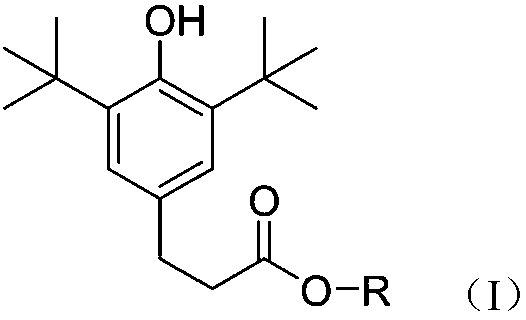

Application of higher alcohol ester hindered phenol antioxidant in C5 petroleum resin

The invention relates to application of one or more of compounds of general formula I, in which R is a C8-18 alkyl group, as an antioxidant in the stabilization of C5 petroleum resins. According to the invention, the C5 petroleum resin is stabilized by adopting the higher alcohol ester hindered phenol antioxidant or a composition of the higher alcohol ester hindered phenol antioxidant and a phosphite ester antioxidant and / or a hindered amine antioxidant, and effect is superior to that in the prior art. The higher alcohol ester hindered phenol antioxidant disclosed by the invention is liquid, and compared with a solid product, the higher alcohol ester hindered phenol antioxidant has the advantage of being convenient to produce and use.

Owner:RIANLON +3

End socket gluing equipment for producing laminated veneer lumber

InactiveCN107442351ASave human effortSave time and costLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to end socket gluing equipment for producing laminated veneer lumber. The end socket gluing equipment comprises a pedestal, wherein a support is arranged above the pedestal; the end socket gluing equipment is characterized in that a gluing cylinder is arranged on the support; one end of the gluing cylinder is rotationally connected with the support; a rolling brush is arranged at the other end of the gluing cylinder; a glue fetching cylinder is further fixed to the support; the end part of the glue fetching cylinder is connected with the framework of the gluing cylinder via a connecting rod. The end socket gluing equipment has the beneficial effects of being automated in operation, low in time and, glue consumption, and high in labor protection for workers.

Owner:武汉昊宇明徽科技有限公司

Active positive-electrode material for lead-acid battery and preparation method thereof

The formula of active positive-electrode material consists of: lead sulfate 68-75 wt%, sulfuric acid 10-15 wt5, deionized water 6-12 wt%, short fiber 0.04-0.8 wt%, inorganic conducting additive 2-4 wt% and organic additive 1-2.5 wt%. The preparation process of the active positive-electrode material includes reaction sulfuric acid and lead powder to obtain lead sulfate powder, mixing lead sulfate powder with other material to obtain mixture paste. Utilizing lead sulfate, rather than lead powder, as positive electrode material results in high porosity, high active matter utilization, plate homogeneity, no environmental pollution, simple production process and low production cost.

Owner:江苏隆源双登电源有限公司

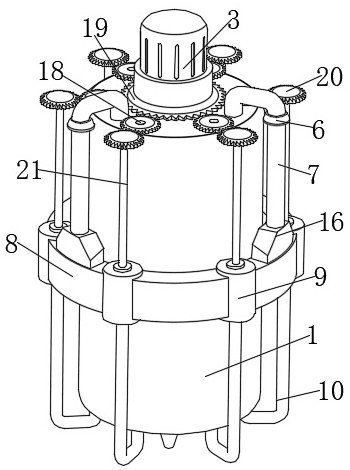

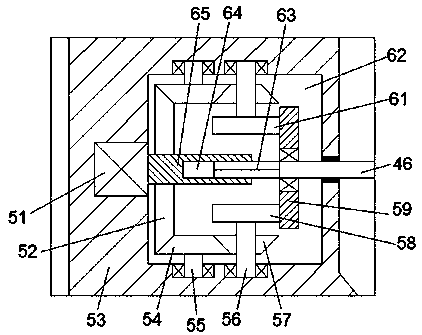

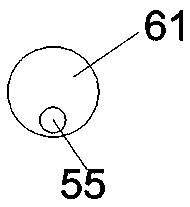

Stirring equipment for biological pharmacy

ActiveCN112791656ATo achieve the initial mixing effectTo achieve a mixed effectFlow mixersRotary stirring mixersBiotechnologyPharmacy

The invention relates to the technical field of biopharmacy, in particular to stirring equipment for biological pharmacy. The stirring equipment comprises a stirring cylinder; a squeezing and pushing disc is horizontally arranged in the stirring cylinder, the outer side of the squeezing and pushing disc is fixedly sleeved with a sealing ring, and the sealing ring is in sliding close contact with the inner wall of the stirring cylinder; a driving sleeve head is vertically and fixedly mounted in the middle of the extruding and pushing disc, a reciprocating screw rod matched with the driving sleeve head is inserted into the inner side of the driving sleeve head and is vertically and rotatably mounted between the two ends in the stirring barrel, and the top end of the reciprocating screw rod extends to the exterior of the stirring barrel to be connected with an output shaft of a driving motor; a plurality of limiting sliding rods are vertically connected between the two ends in the stirring barrel at equal intervals in the circumferential direction, and the extruding and pushing disc is arranged on the outer sides of the multiple limiting sliding rods in a sliding and sleeving mode. The invention has a dual-circulation mixing and stirring effect, the mixing and stirring time of multiple pharmaceutical liquid raw materials is effectively shortened, and the mixing and stirring uniformity of the multiple pharmaceutical liquid raw materials is improved.

Owner:广州加泰医药科技有限公司

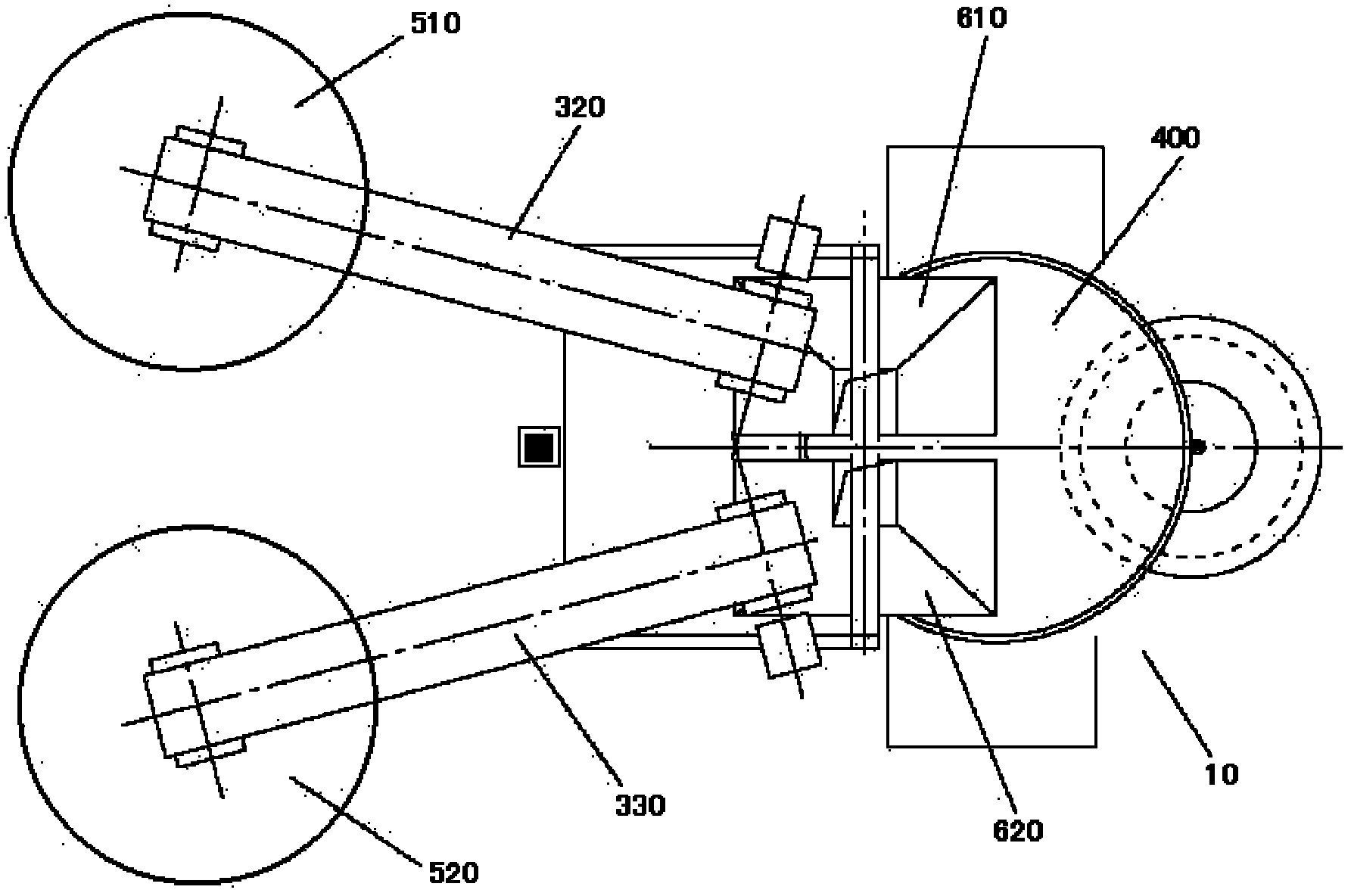

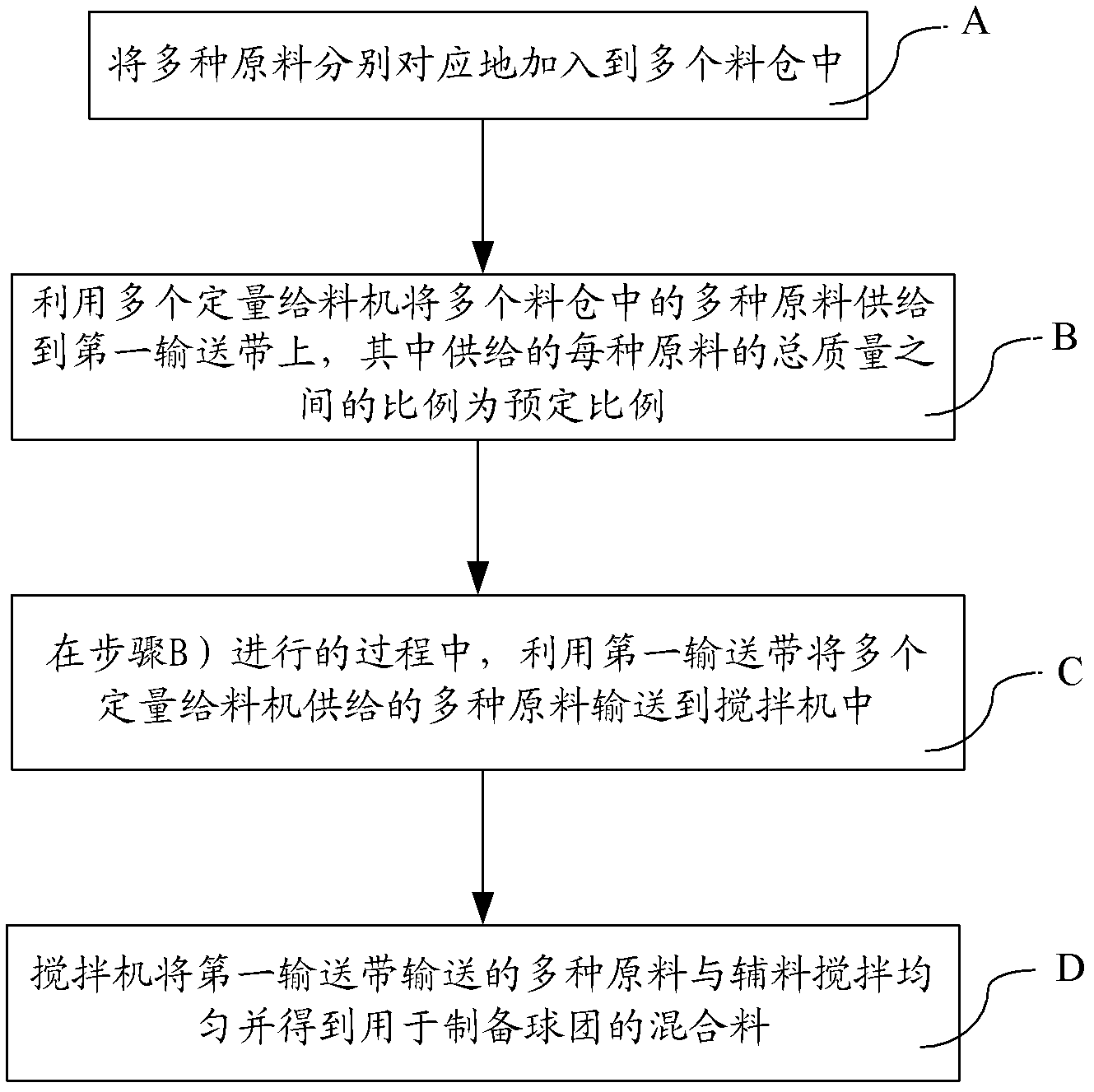

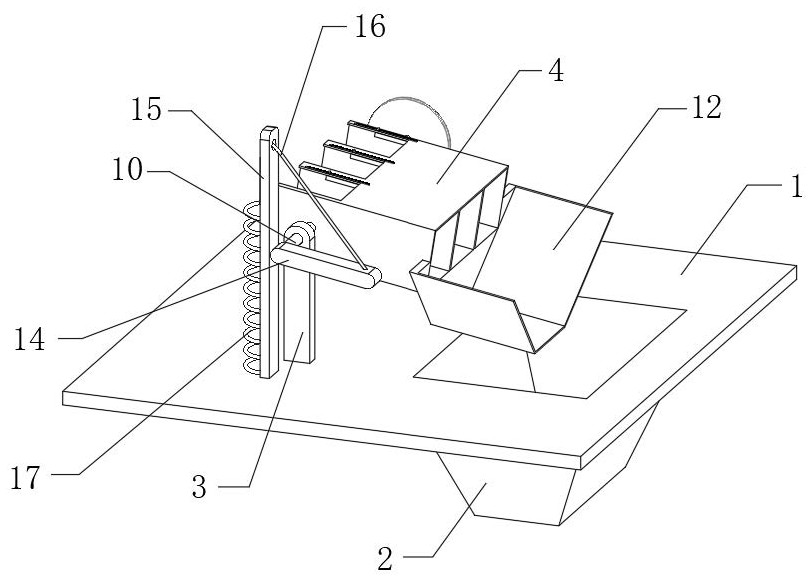

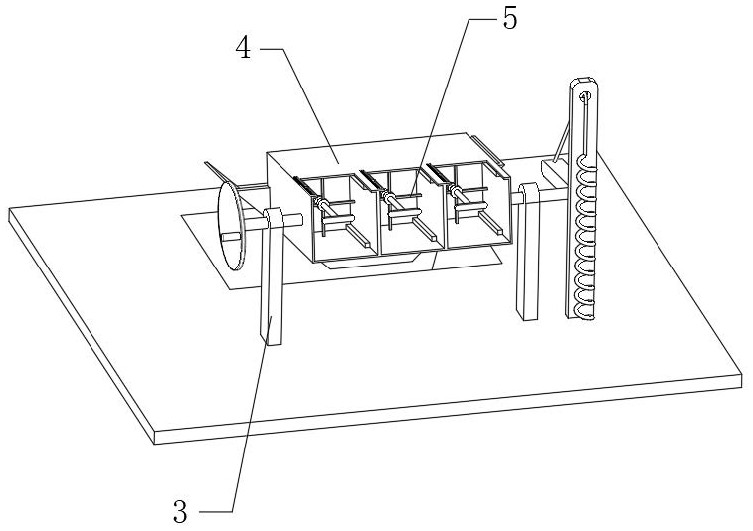

Pellet batching device and pellet batching method

Owner:YUNNAN JIANSHUI MANGANESE

Nutrient solution blending device for clinical nutrition department

The invention discloses a nutrient solution blending device for a clinical nutrition department, and relates to the field of the clinical nutrition department. The nutrient solution blending device for the clinical nutrition department comprises a tank outer shell, a raw material measuring box and a dumping reset mechanism, a feeding hopper is fixedly connected to the bottom of the tank outer shell, a rotary supporting assembly is arranged at the top of the tank outer shell, the dumping reset mechanism is arranged above the tank outer shell, and the dumping reset mechanism is arranged on the right side of the raw material measuring box. According to the nutrient solution blending device for the clinical nutrition department, before multiple groups of raw materials are mixed, the raw materials can be rapidly proportioned according to the corresponding volume, then the later mixing work is facilitated, a user does not need to repeatedly measure the raw materials of all the components, and the whole nutrient solution blending device is good in function. The volume adjusting mechanism is used for conveniently adjusting the corresponding volume of each inner cavity of the raw material measuring box body, so that multiple groups of raw materials can be conveniently and quantitatively proportioned through the raw material measuring box.

Owner:赵焕焕

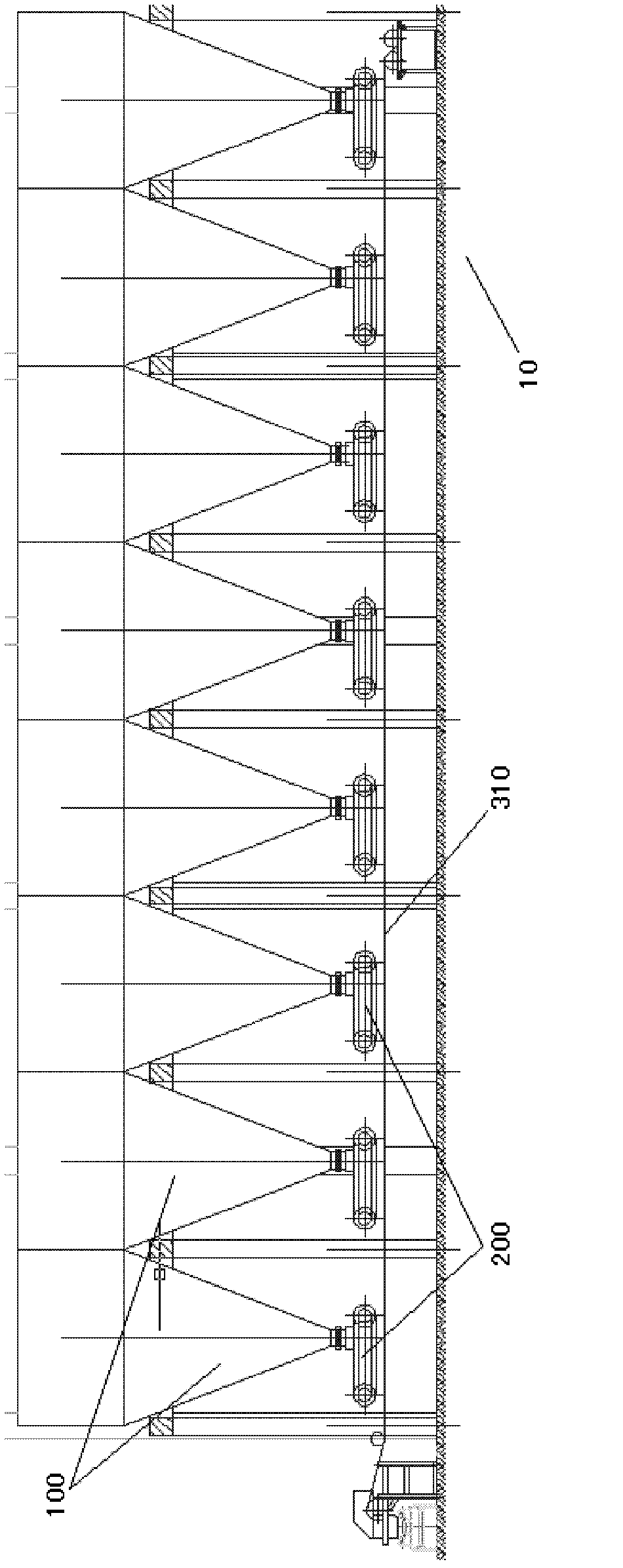

Integrated feed mixing and throwing machine for modern agricultural breeding

ActiveCN110250038AStir quicklySave mixing timeTransportation and packagingRotary stirring mixersPush pullAgricultural engineering

The invention discloses an integrated feed mixing and throwing machine for modern agricultural breeding. The machine comprises a base, a throwing frame rotatably arranged on the base and a mixing device fixedly arranged on the throwing frame, wherein a throwing cavity is formed in the right side end face of the throwing frame, a throwing plate is slidably arranged in the throwing cavity, the throwing plate is internally provided with a feed storage cavity with openings in the upper side and right side, the portion, at the left side of the throwing cavity, of the throwing frame is internally provided with a driving cavity, and a push-pull rod is slidably arranged between the driving cavity and the throwing cavity. The integrated feed mixing and throwing machine for modern agricultural breeding has the advantages that feed can be rapidly mixed and stirred, so that the mixing and stirring time is effectively saved, and the manpower is saved; the feed can be thrown out from different directions, which facilitates large-scale throwing of the feed, is conducive to poultry breeding, and is suitable for popularization and use.

Owner:安徽笑果农牧产业科技有限公司

Rare earth functional ceramic color material equipment

InactiveCN109200940AImprove mixing efficiencyImprove mixing uniformityShaking/oscillating/vibrating mixersTransportation and packagingRare earthMaterials science

The invention discloses rare earth functional ceramic color material equipment comprising a machine body, wherein a stirring chamber is arranged in the machine body, a stirring shaft is rotatably andcooperatively arranged in the stirring chamber, and a plurality of groups of first blocks are arranged on the outer circumference of the stirring shaft. The first blocks are hingedly connected with inner stirring blades, the inner stirring blades are slidably sleeved with outer stirring blades, the outer stirring blades are hingedly connected with second blocks, the circumferential inner wall of the stirring chamber is provided with a circular groove, a rotating ring is rotatably and cooperatively arranged in the circular groove, the second blocks are fixedly connected to the inner side of therotating ring, a first positioning regulating chamber is disposed in the machine body on the right side of the stirring chamber, the stirring shaft extends into the first positioning regulating chamber, and the end of the stirring shaft is rotatably and cooperatively provided with a positioning regulating block.

Owner:广州尚儒自控系统工程有限公司

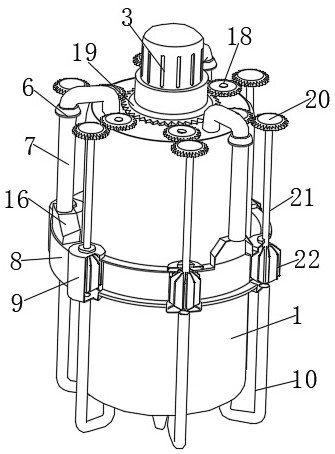

A water wheel type liquid circulation stirring device

ActiveCN107551893BImprove mixing uniformityImprove mixing efficiencyFlow mixersTransportation and packagingWater wheelPipe water

The invention discloses a water wheel type liquid circulation stirring device, which comprises a stirring tank; a liquid pushing cylinder, which includes a cylinder, a propeller and a driving mechanism, the cylinder is installed in the stirring tank, the diameter of the middle part of the cylinder is larger than that of the upper part and The diameter of the lower part, the propeller is installed on the upper part of the cylinder in a rotatable manner, and the driving mechanism is used to drive the propeller to rotate; the water wheel mechanism includes a runner, a fixed shaft and several blades, and the fixed shaft is installed in the middle of the cylinder , the runner is mounted on the fixed shaft in a rotatable manner, and several vanes are mounted on the runner; and a liquid delivery mechanism, which includes a water pump and a delivery pipeline, and the water pump can deliver the mixed liquid to the upper end of the cylinder through the delivery pipeline. The invention disturbs the flowing mixed liquid through the rotation of the blades, thereby changing the flow direction of the mixed liquid; the mixed liquid with different flow directions can be mixed again, thereby reducing the mixing and stirring time and improving the mixing efficiency.

Owner:TIANE HONGCHANG AGRI MACHINERY SPECIALIZED COOP

Experimental device and method for increasing yield of coalbed methane microorganisms based on different fracturing fluid environments

PendingCN114575815ASave mixing timeImprove accuracyTransportation and packagingRotary stirring mixersMicroorganismFracturing fluid

The invention discloses a coalbed methane microorganism yield increasing experiment device and method based on different fracturing fluid environments, and relates to the technical field of coalbed methane yield increasing experiments, the coalbed methane microorganism yield increasing experiment device comprises: a driving box which is preset on a to-be-extracted hole and is used for providing power for the device; the stirring assembly is mounted at the bottom of the driving box, and the stirring assembly and a hole to be extracted are coaxially arranged; the fracturing assembly is fixed to the end, away from the driving box, of the stirring assembly, multiple sets of fracturing holes are formed in the fracturing assembly at equal intervals, and the fracturing assembly is used for conducting fracturing collection on coal bed gas in the holes to be extracted; and the hole packer is fixed among the plurality of groups of fracturing holes and is used for carrying out segmented collection on the interior of the to-be-extracted hole.

Owner:纪国柱

A kind of processing method of cone and taper hole

The invention discloses a cone and cone hole machining method. The method comprises the steps that a taper rod and a taper sleeve which are same in taper are made, wherein the cone matching contact area reaches 95% or above; a first marking line is drawn on the portion, with the diameter equal to a standard diameter value of the big end of a preset propeller cone hole, of the taper rod, and a second marking line is drawn on the portion, with the diameter equal to the above-mentioned standard diameter, of the taper sleeve; a propeller cone hole and a screw shaft cone are made, wherein the length of the propeller cone hole is correspondingly smaller than the cone length of the taper rod, and the length of the screw shaft cone is correspondingly smaller than the cone hole length of the taper sleeve; and when the propeller cone hole and the screw shaft cone are machined, the taper rod and the taper sleeve are adopted for replacing the corresponding screw shaft cone and propeller cone hole to check the contact area of the taper rod and the propeller cone hole and the contact area of the taper sleeve and the screw shaft cone and the cone size. The invention provides an efficient propeller cone hole machining method. The method is high in machining precision, good in cone matching contact surface, easy to operate, good in interchangeability, capable of saving labor and low in manufacturing cost.

Owner:ZHUHAI HOLYFORT MARINE EQUIP CO LTD

Improved multi-color rubber making process

The invention discloses an improved multi-color rubber making process. An outer frame body is included, and is internally provided with a mixing and stirring cavity; a mixing and stirring shaft is installed in the mixing and stirring cavity in a normal running fit manner; a plurality of sets of first protruding corners are arranged on the periphery of the mixing and stirring shaft; an inner mixingand stirring paddle is connected to the first protruding corners in a hinged manner, and is sleeved in an outer mixing and stirring paddle in a sliding fit manner; a second protruding corner is connected to the outer mixing and stirring paddle in a hinged manner; an arc face cavity is formed in the inner wall of the mixing and stirring cavity in the circumferential direction; a rotating ring is installed in the arc face cavity in a normal running fit manner; the second protruding corner is fixedly connected with the inner side face of the rotating ring; a first distance adjusting cavity is arranged in the portion, on the right side of the mixing and stirring cavity, of the outer frame body; and the mixing and stirring shaft stretches into the first distance adjusting cavity and a distanceadjusting block is installed at the tail end in a normal funning fit manner.

Owner:广州佶兔工业设计有限公司

Preparation process of multicolor rubber

InactiveCN109291277AImprove mixing efficiencyImprove mixing uniformityEngineeringAerospace engineering

The invention discloses a preparation process of multicolor rubber. The preparation process of the multicolor rubber relates to an outer frame body. A mixing cavity is formed in the outer frame body.A mixing shaft is mounted in the mixing cavity in a running fit mode. A plurality of sets of first lugs are arranged on the outer circumference of the mixing shaft. Inner mixing blades are connected to the first lugs in a hinged mode. The inner mixing blades are sleeved with outer mixing blades in a sliding fit mode. Second lugs are connected to the outer mixing blades in a hinged mode. An arc cavity is formed in the circumferential inner wall of the mixing cavity. A rotary ring is mounted on the inner arc cavity in a running fit mode. The second lugs are fixedly connected with the inner sideface of the rotary ring. A first distance adjustment cavity is formed in the outer frame body and is located on the right side of the mixing cavity. The mixing shaft stretches into the first distanceadjustment cavity, and a distance adjustment block is mounted at the tail end of the mixing shaft in a running fit mode.

Owner:广州佶兔工业设计有限公司

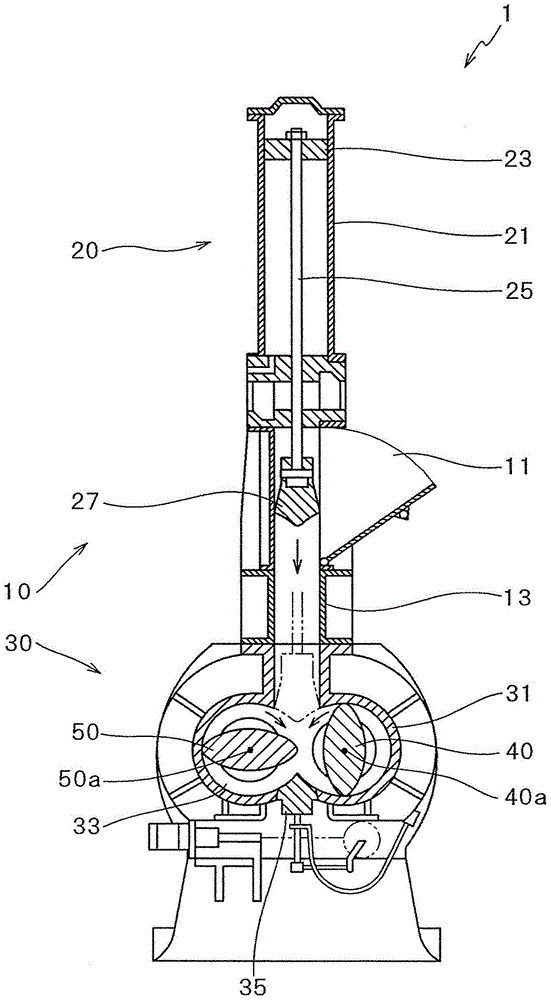

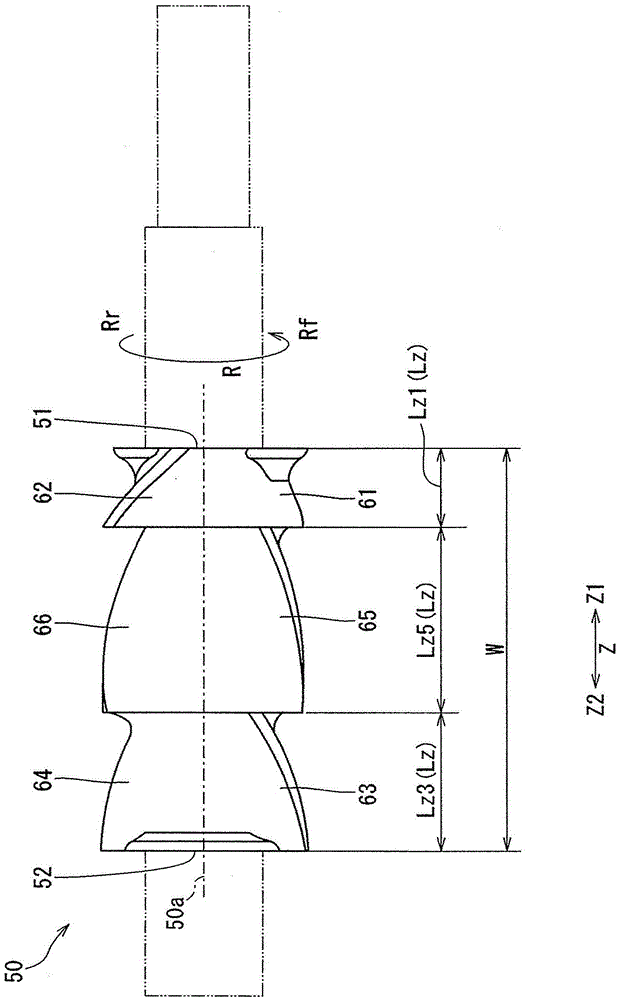

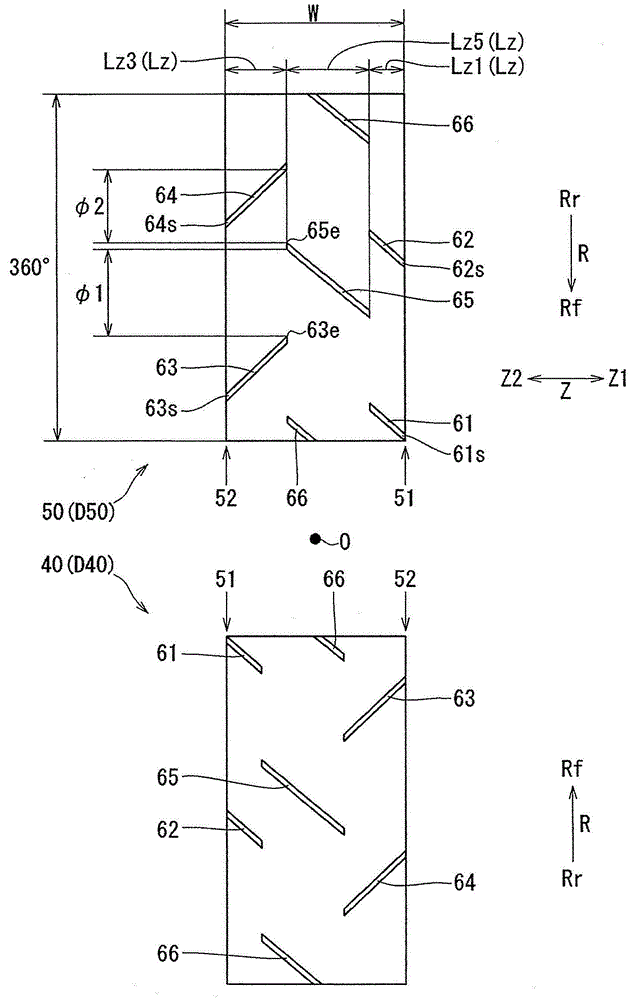

Sealed kneading machine

ActiveCN105473298AImprove productivityImprove the distribution effectRotary stirring mixersEngineeringMechanical engineering

The sealed kneading machine of the present invention is provided with a kneading chamber to which a material to be kneaded is supplied, and a rotor disposed in the kneading chamber so as to be able to rotate about a rotor shaft. The rotor is provided with a plurality of kneading blades for kneading the material to be kneaded, and the length of all the kneading blades in the rotor shaft direction of each thereof is 45% or less of the total length of the rotor in the rotor shaft direction.

Owner:KOBE STEEL LTD

A mixing device for biopharmaceuticals

ActiveCN112791656BTo achieve the initial mixing effectTo achieve a mixed effectFlow mixersRotary stirring mixersWire rodElectric machinery

The present invention relates to the technical field of biopharmaceuticals, in particular to a stirring device for biopharmaceuticals, comprising a mixing drum, a pushing plate is arranged horizontally inside the mixing drum, and a sealing ring is fixedly sleeved on the outside of the pushing plate , the sealing ring is in sliding close contact with the inner wall of the mixing drum, and the middle position of the pushing plate is vertically fixed with a drive sleeve, and the inside of the drive sleeve is inserted with a reciprocating screw rod matched with it, and the reciprocating wire The rod is vertically rotated and installed between the two ends of the mixing drum, and the top end extends to the outside of the mixing drum to connect with the output shaft of the drive motor. Position sliding rods, and the sliding sleeve of the pushing plate is arranged on the outside of a plurality of limiting sliding rods. The invention has double circulation mixing and stirring effects, effectively reduces the mixing and stirring time of various pharmaceutical liquid raw materials, and improves the mixing and stirring uniformity of various pharmaceutical liquid raw materials.

Owner:广州加泰医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com