Sealed kneading machine

一种混合搅拌、搅拌机的技术,应用在混合机、具有旋转搅拌装置的混合机、溶解等方向,能够解决混合搅拌时间变长、分布性能低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

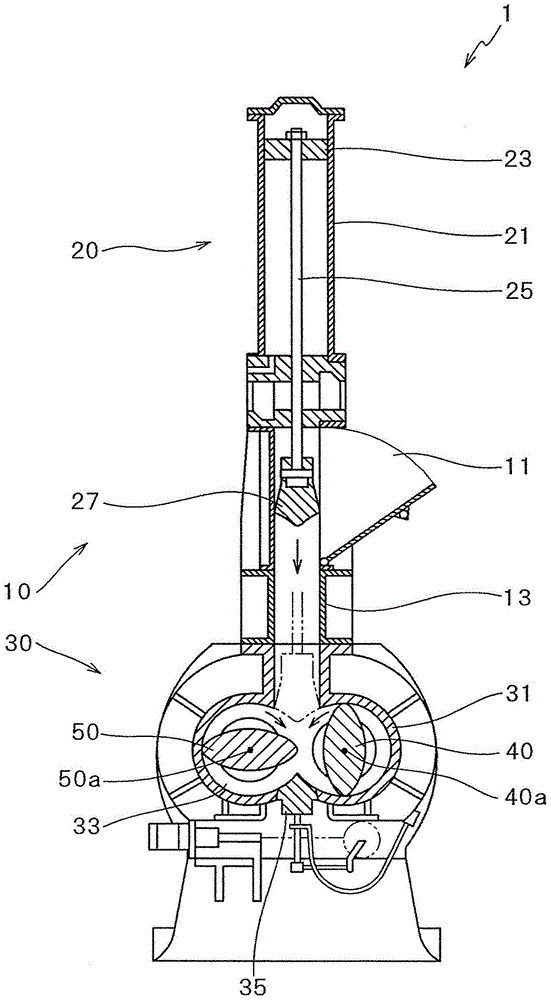

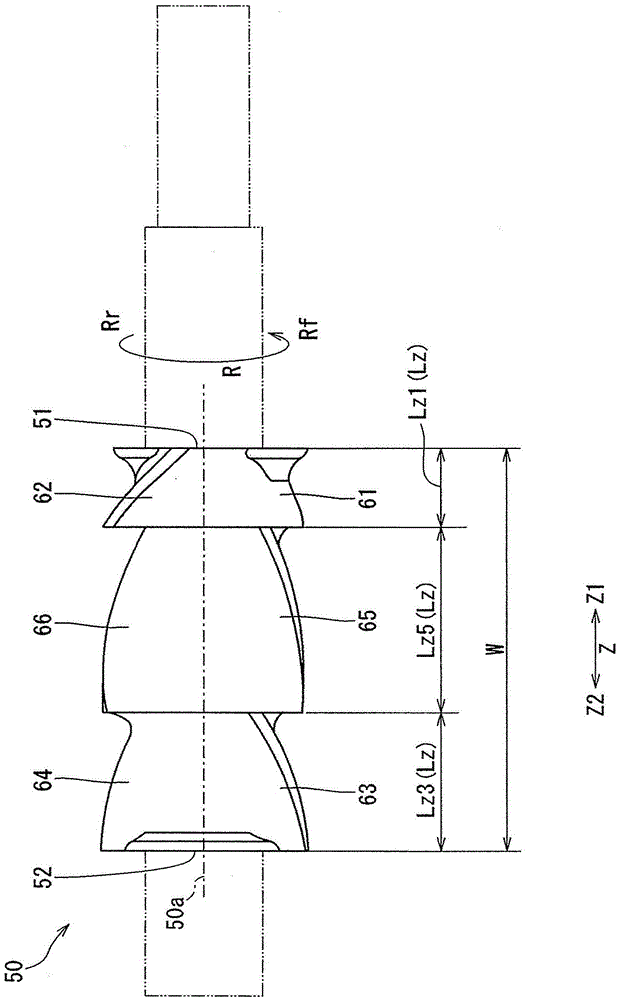

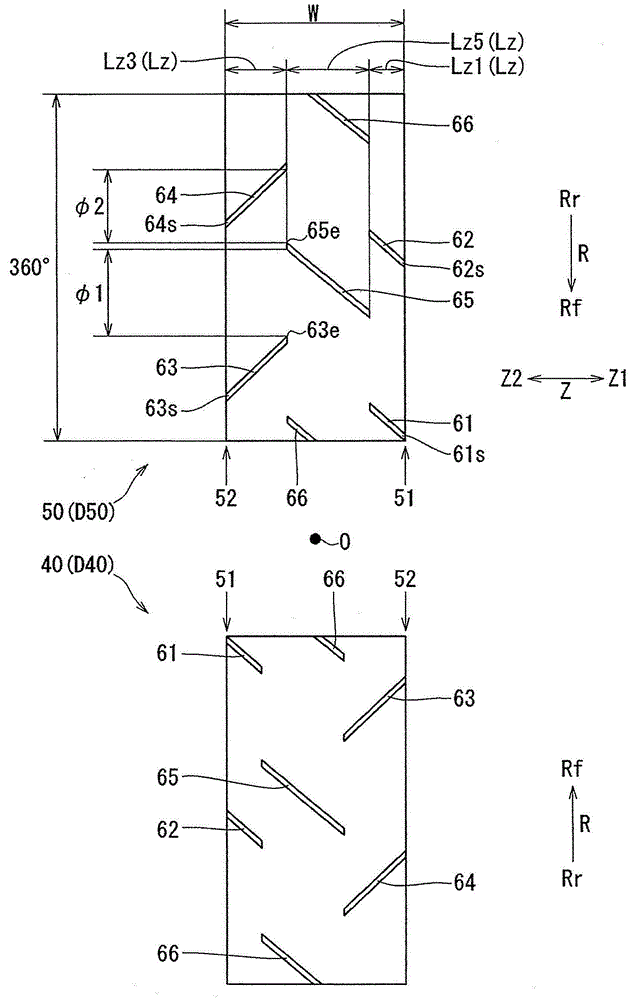

[0018] refer to Figure 1 to Figure 6 ,illustrate figure 1 The internal mixing mixer 1 shown.

[0019] The internal mixer 1 is a device for mixing and stirring the material to be mixed and stirred. The material to be mixed and stirred includes, for example, a polymer material. Examples of the polymer material include rubber and / or resin. The material to be kneaded is composed of, for example, rubber mixed with silica, a silane coupling agent, and the like. The internal mixer 1 is a batch mixer. The internal mixer 1 includes a supply unit 10 and a mixing unit 30 .

[0020] The supply unit 10 is a part that supplies the material to be kneaded to the kneading unit 30 . The supply unit 10 includes a hopper 11 , a material supply cylinder 13 , and a cylinder device 20 .

[0021] The material to be kneaded is thrown into the hopper 11 from the outside of the internal mixer 1 .

[0022] The material supply cylinder 13 is a cylinder through which the material to be kneaded ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com