Exterior wall external heat insulation protecting mortar

An external thermal insulation and mortar technology for external walls, applied in the field of protective mortar, can solve problems such as insufficient strength, poor quality, and unstable quality, so as to improve production efficiency and construction efficiency, save mixing time, and stabilize mortar quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

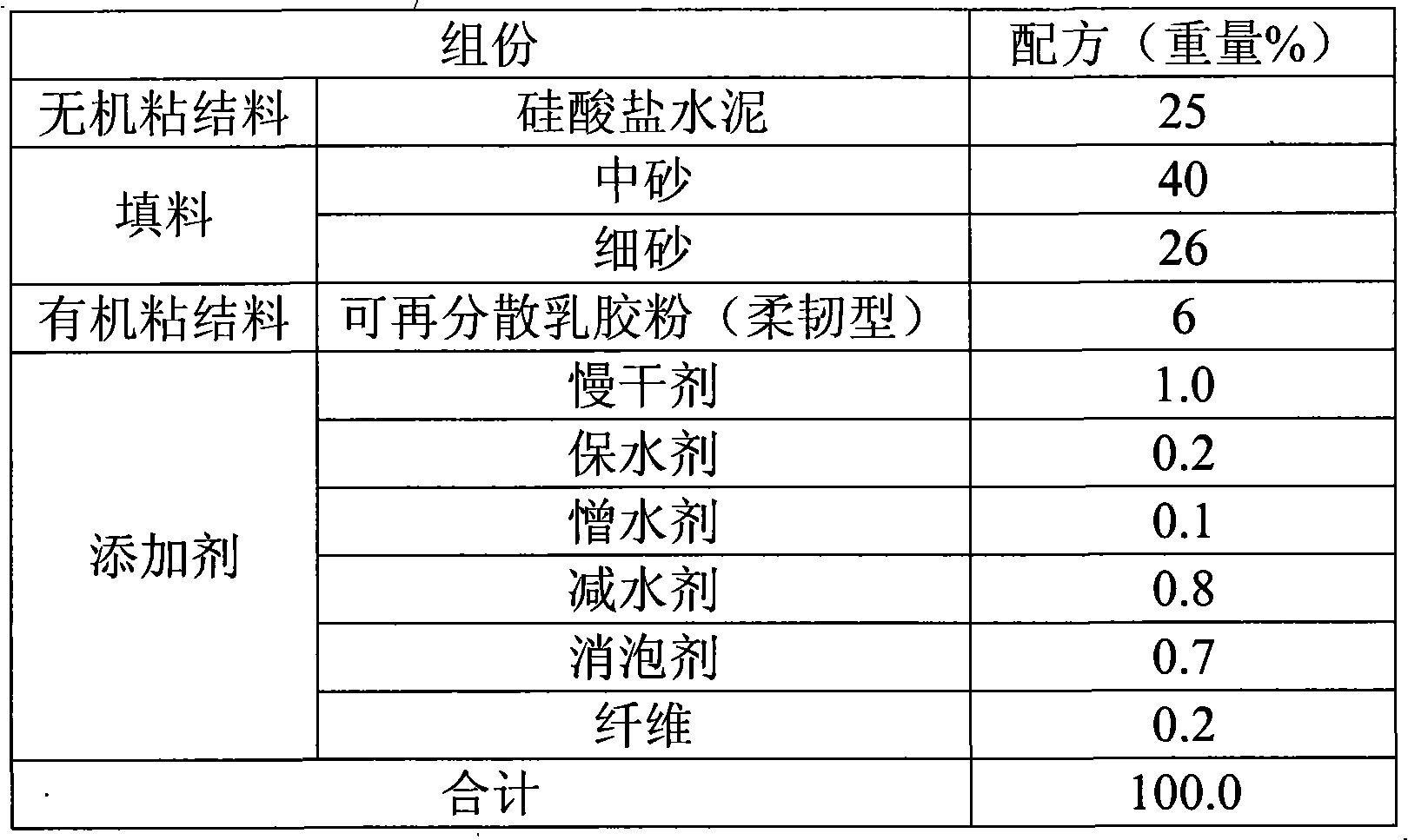

[0033] Components and formula one of the external wall thermal insulation protective mortar of the present invention:

[0034]

[0035] The production and construction methods are:

[0036] Add the stuffing to the blender and start blending;

[0037] Add the inorganic binder and the organic binder into the mixer;

[0038] Add additives to the blender;

[0039] Stir well and pack into bags or store.

[0040] During construction, according to a certain water-cement ratio of 11:100, add water and mix, stir well before construction.

Embodiment 2

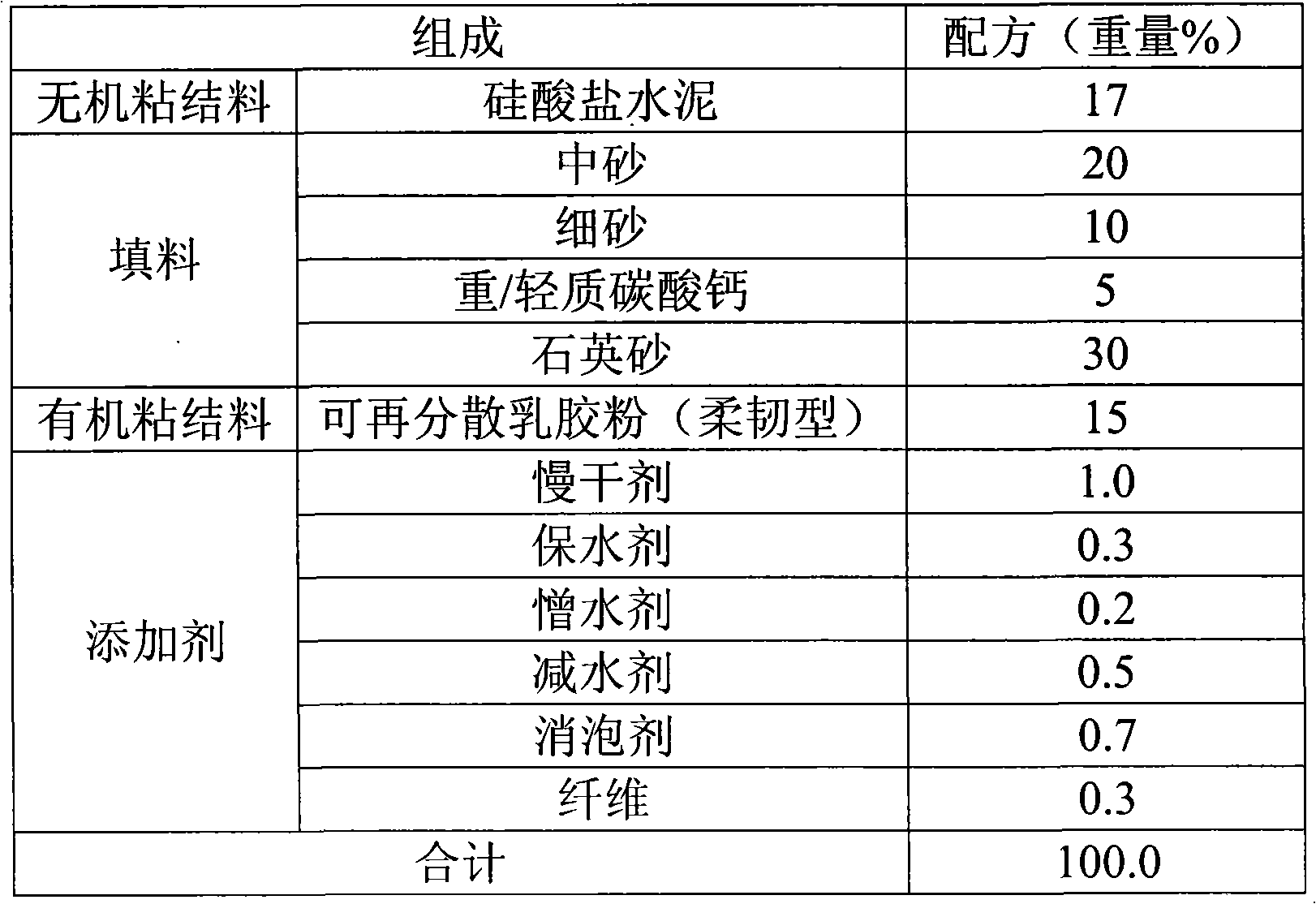

[0042] Components and formula two of the external wall thermal insulation protective mortar of the present invention:

[0043]

[0044] The production and construction method of product of the present invention are:

[0045] Add the stuffing to the blender and start blending;

[0046] Add the inorganic binder and the organic binder into the mixer;

[0047] Add additives to the blender;

[0048] Stir well and pack into bags or store.

[0049] During construction, according to a certain water-cement ratio of 16:100, add water and mix, stir evenly before construction.

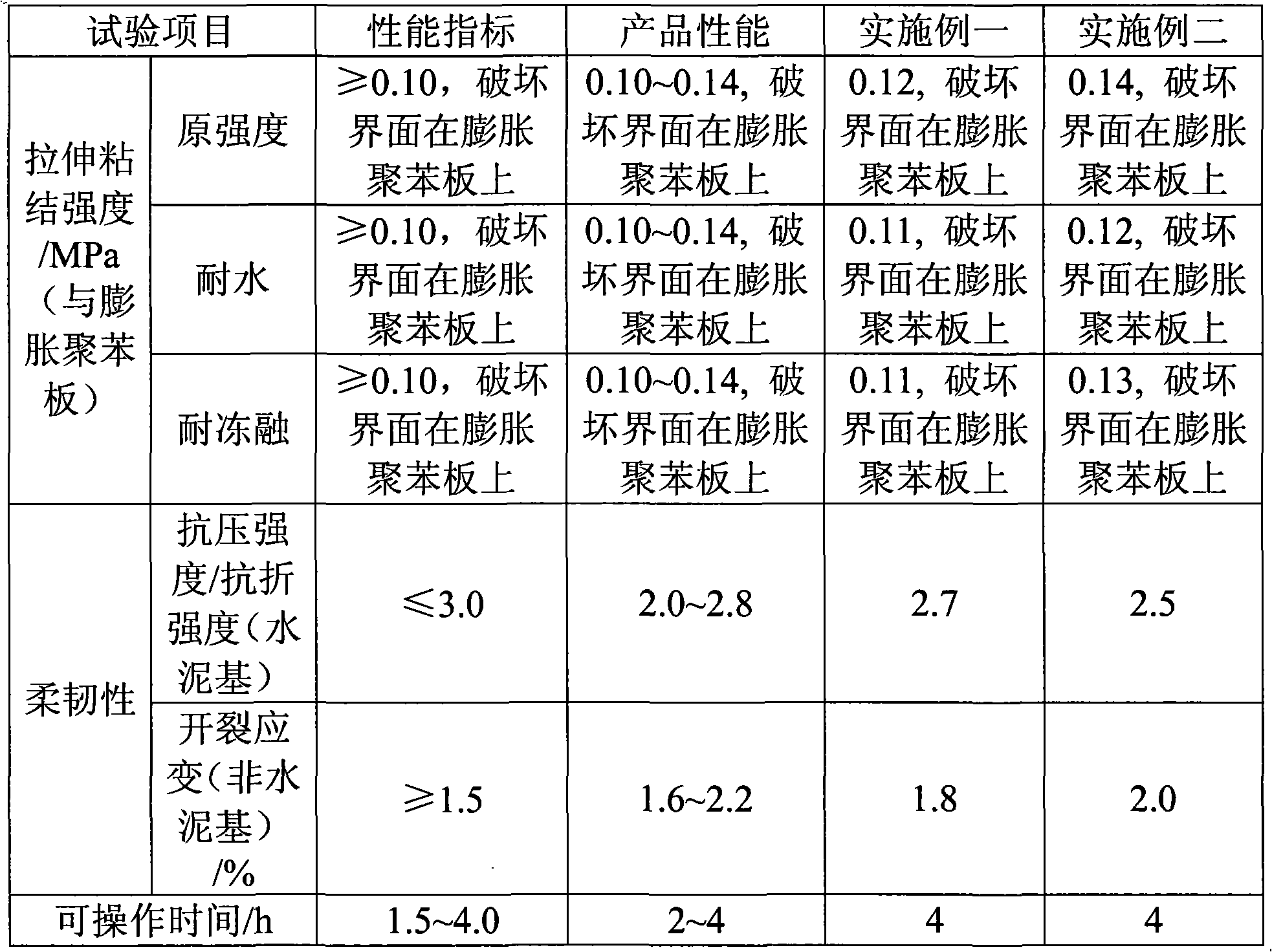

[0050] The main technical performance of the product of the present invention is as follows:

[0051]

[0052] The product of the present invention needs to pay attention to during concrete construction:

[0053] Finish the wall surface, apply the bonding mortar to the wall surface according to the construction technology, and stick the expanded polystyrene board on the bonding mortar.

[0054] The surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com