Improved multi-color rubber making process

A multi-color rubber and manufacturing process technology, applied in the field of multi-color rubber preparation, can solve the problems of inconvenient quantitative discharge and low mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

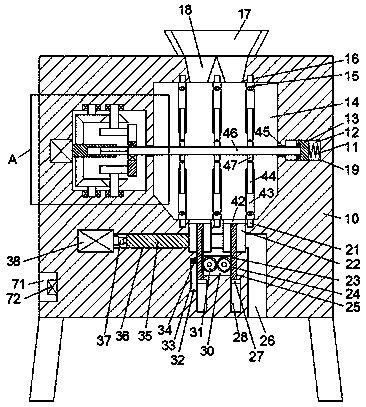

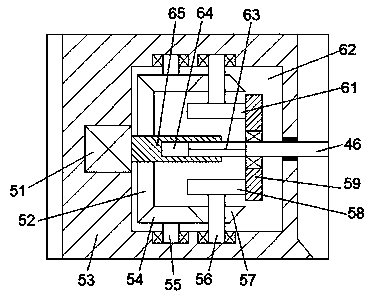

[0016] Combine below Figure 1-4 The present invention will be described in detail.

[0017] refer to Figure 1-4 , according to an embodiment of the present invention, an improved multi-color rubber manufacturing process includes an outer frame body 10, a mixing chamber 14 is provided inside the outer frame body 10, and a rotating fitting is installed in the mixing chamber 14 A mixing shaft 46, the outer periphery of the mixing shaft 46 is provided with multiple groups of first lobes 47, the first lobes 47 are hingedly connected with an inner mixing paddle 44, and the inner mixing paddle 44 is slidably fitted on the outer mixing paddle In the mixing chamber 43, the outer mixing chamber 43 is hingedly connected with a second lobe 15, and the inner wall of the mixing chamber 14 is provided with an arc-shaped cavity 16, and the inner wall of the arc-shaped cavity 16 is equipped with a rotating circle. 21. The second lobe 15 is fixedly connected to the inner surface of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com