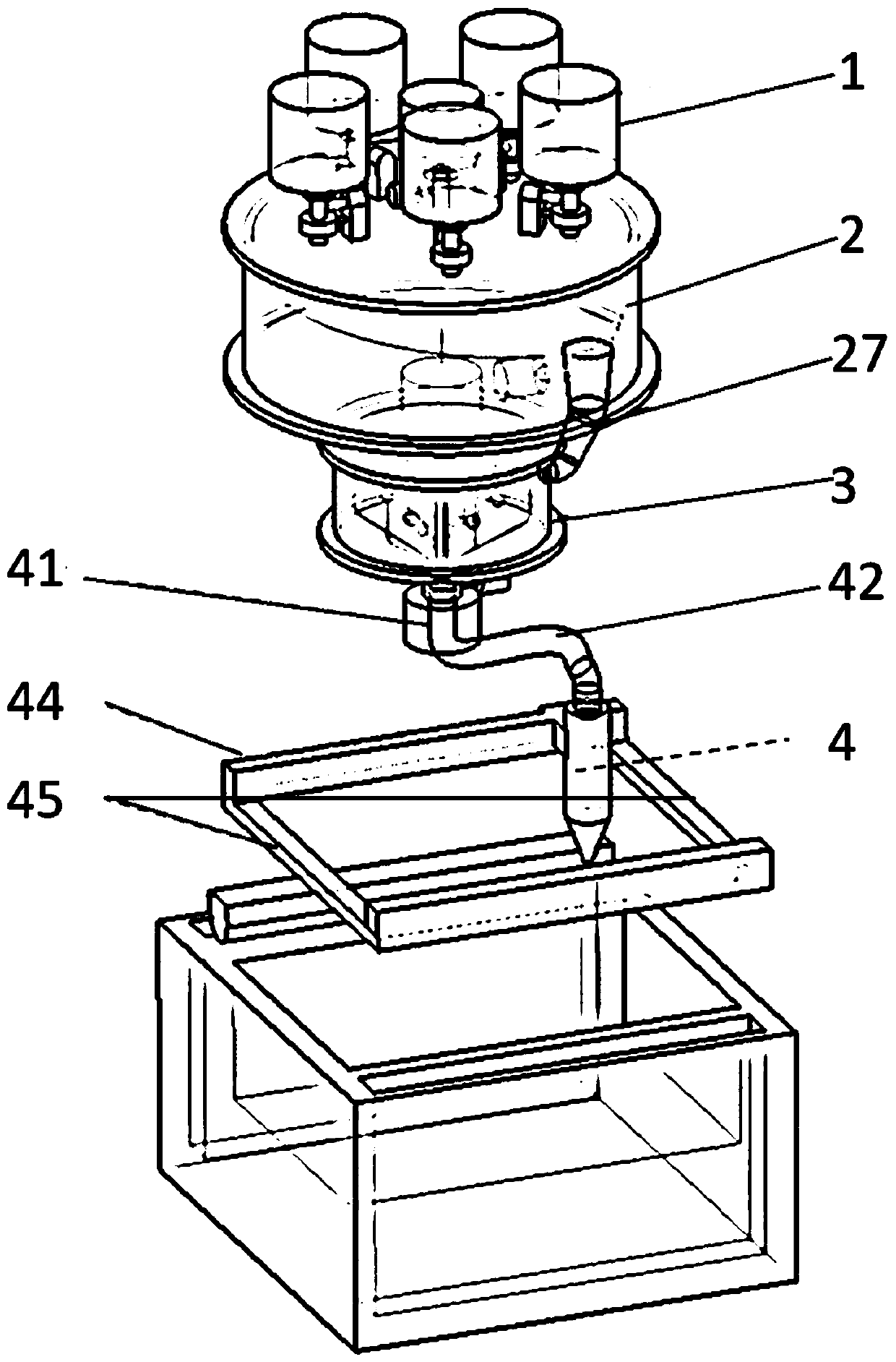

Multi-material powder supplying and laying device for powder bed melting and control method of multi-material powder supplying and laying device

A powder spreading device, multi-material technology, applied in the directions of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problem that it is difficult to directly and efficiently form continuous gradient materials, it is difficult to realize the change of longitudinal powder gradient, and it is difficult to realize continuous gradient. materials and other issues, to save the mixing time, reduce the mixing time, and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: The tungsten (W) particle reinforced CoCrFeMnNi selective laser melting additive manufacturing forming method using the above-mentioned device:

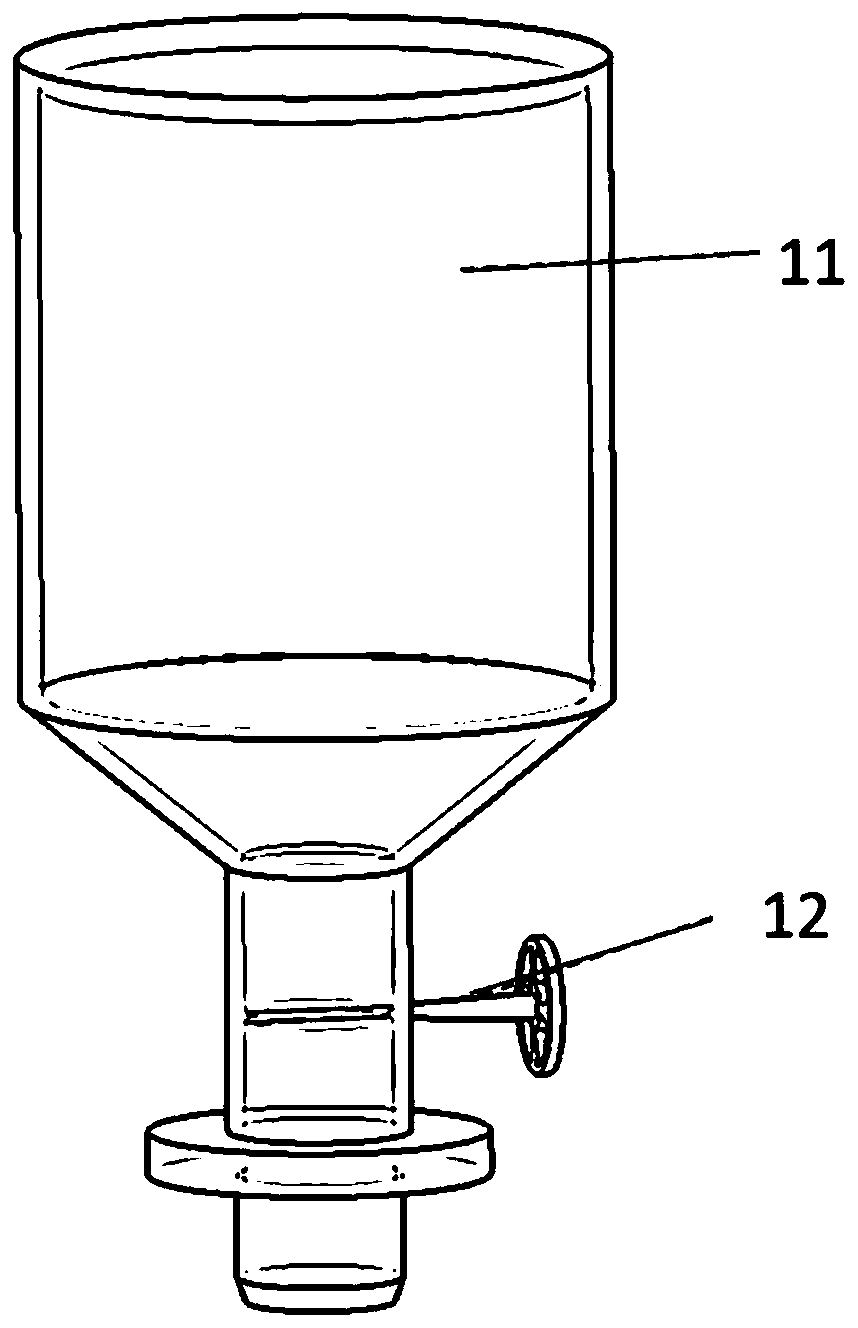

[0042] Step 1: Fill enough Co, Cr, Fe, Mn, Ni and W powders into the 6 sub-powder storage tanks 1 respectively, install them on the main powder storage tank 2 respectively, and open the valve of sub-powder storage tank 1 12;

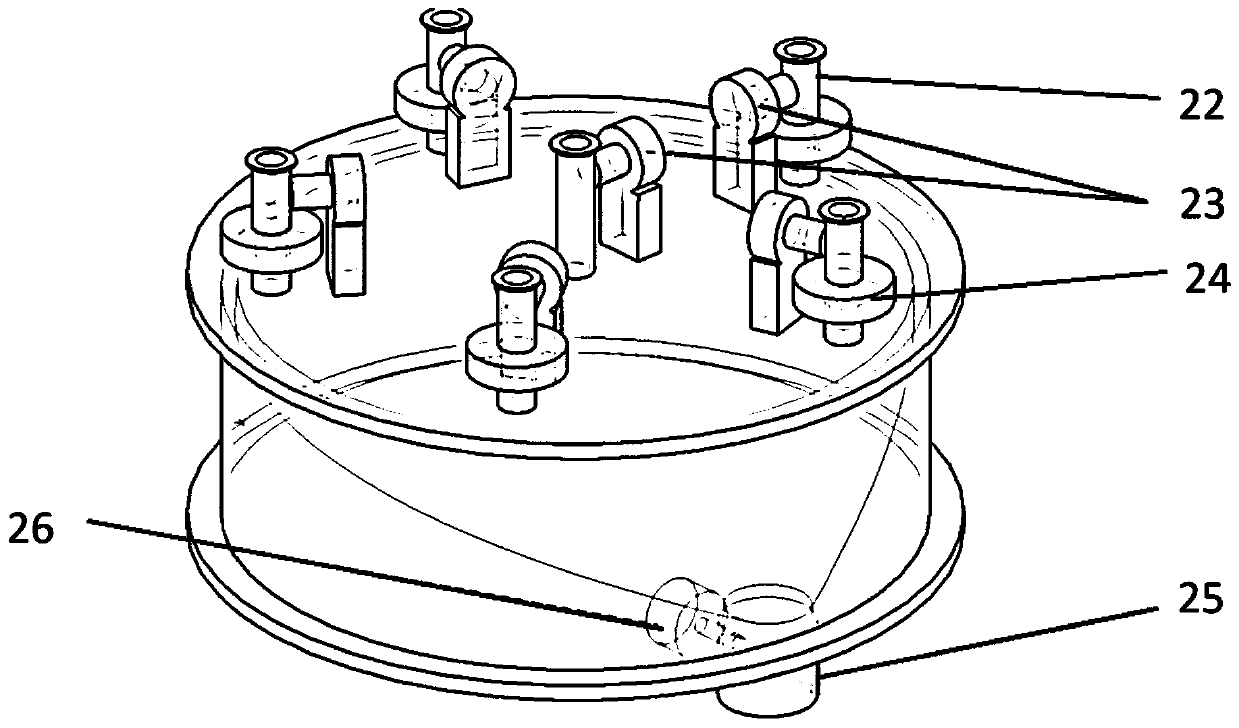

[0043] Step 2: Open the powder inlet 22 through the first flow motor 23 of the main powder storage tank 2, and the powder in the sub-powder storage tank 1 flows into the main powder storage tank 2 according to the set ratio, and the weight ratio of the six powders is Co: Cr: Fe: Mn: Ni: W = 19.3: 17.8: 18.9: 17.4: 17.4: 9.1;

[0044] Step 3: Turn off the first flow motor 23, turn on the second flow motor 26, the premixed powder in the main powder storage tank 2 flows into the powder mixing tank 31, stir and mix through the powder mixer 32, and close the second flow motor after the feeding ...

Embodiment 2

[0048] Embodiment 2: adopt the Mo-Cu continuous gradient material selective electron beam forming method of above-mentioned device, comprise the following steps:

[0049] Step 1: Fill Mo powder and Cu powder in the two sub-powder storage tanks 1 respectively, install them on the main powder storage tank 2, and open the valve 12 of the sub-powder storage tank 1;

[0050] Step 2: Open the powder inlet 22 through the first flow motor 23 of the main powder storage tank 2, and the powder in the sub-powder storage tank 1 flows into the main powder storage tank 2 according to the set ratio;

[0051] The third step: turn off the first flow motor 23, turn on the second flow motor 26, the premixed powder in the main powder storage tank 2 flows into the powder mixing tank 31 through the first powder conduit 41, and is stirred and mixed by the powder mixer 32, Close the second motor 25 after the feeding is completed;

[0052] Step 4: After the powder mixing is completed, turn on the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com