Pellet batching device and pellet batching method

A batching equipment and pelletizing technology, applied in the field of metallurgy, can solve the problems of difficult mixing of various raw materials and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

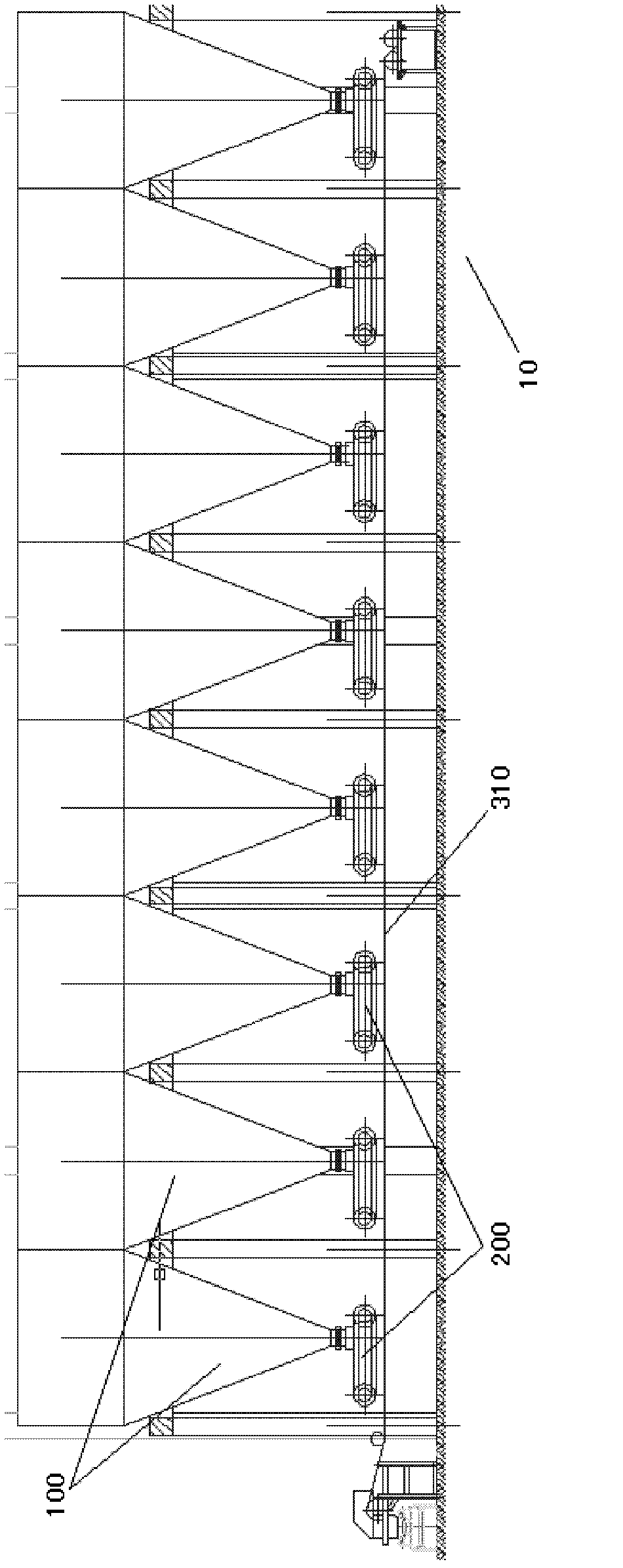

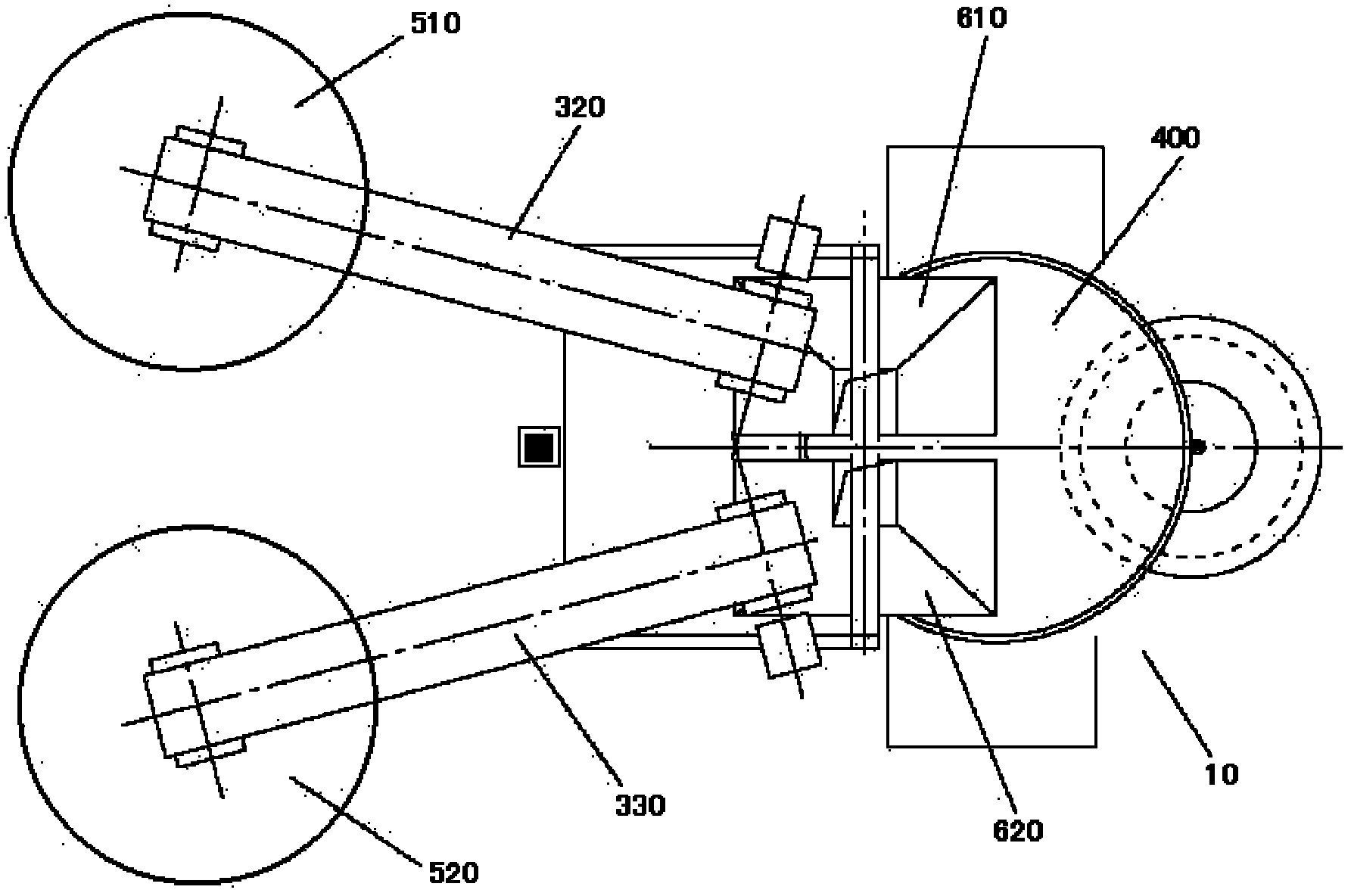

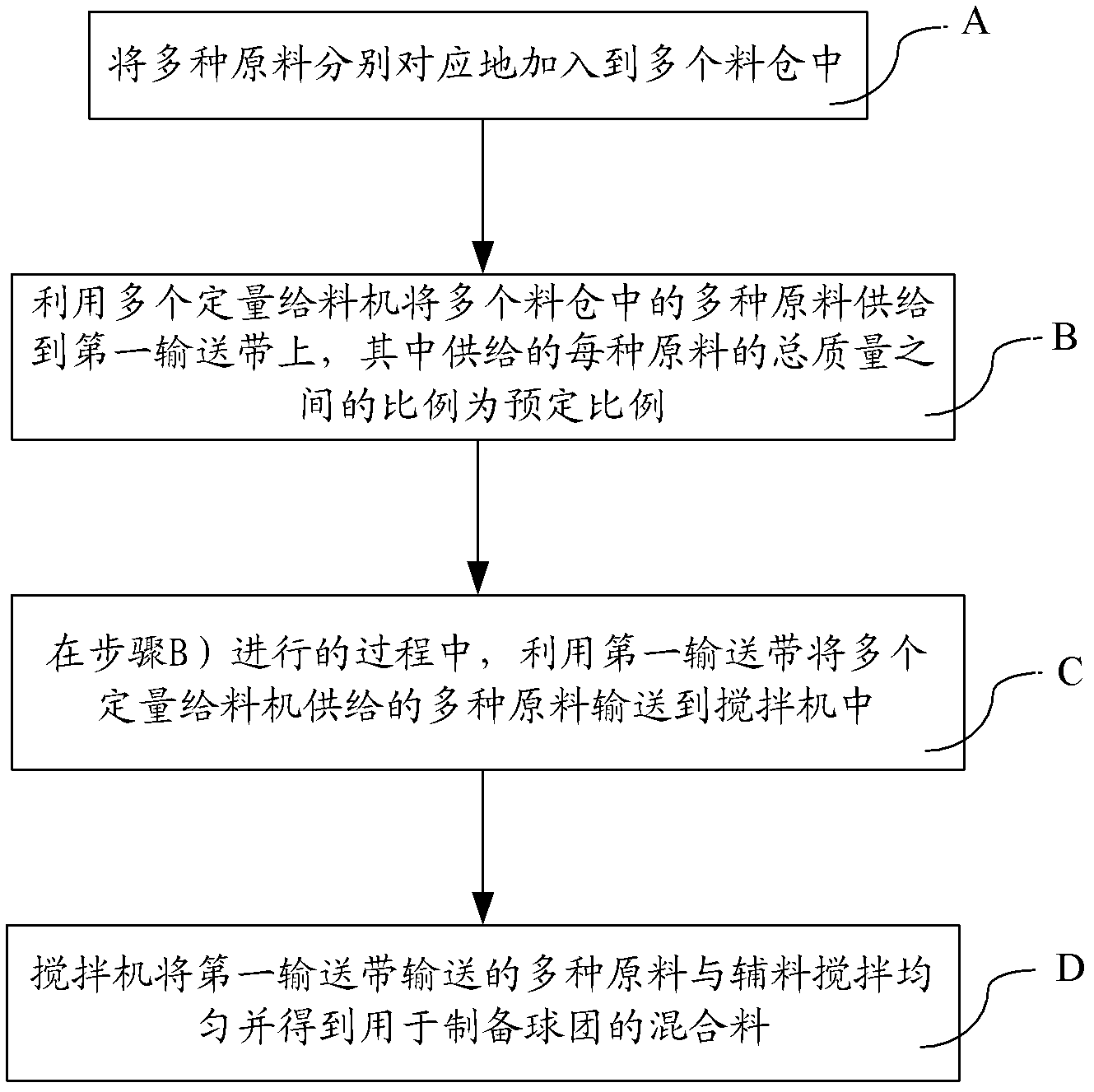

[0067] Batching was carried out according to the pellet raw material formula shown in Table 1. The 7 kinds of raw materials, concentrate 1, concentrate 2, raw ore powder 1, raw ore powder 2, auxiliary raw material 1, auxiliary raw material 2 and auxiliary raw material 3, are added to the 7 feed bins 100 respectively. Then, using 7 quantitative feeders 200 (DEL061 quantitative feeder, Chengdu Guanghua Electric Manufacturing Co., Ltd.), the above 7 kinds of raw materials are supplied to the first conveyor according to the weight ratio of 30:45:40:42:35:26:32. On the belt 310, the first conveyor belt 310 transports the raw materials supplied by the seven quantitative feeders 200 to the mixer 400 (LNX planetary roller mixer, Nanjing Xinghuo Machine Tool Co., Ltd.). Wherein, the total weight of each raw material supplied by the seven quantitative feeders 200 is shown in Table 1. Finally, the 7 kinds of raw materials and 120 kg of binder are stirred evenly by using a mixer 400 .

...

Embodiment 2

[0082] The batching was carried out according to the pellet raw material formula shown in Table 1, wherein the auxiliary raw material No. 3 was a high-ash raw material, and the rest were low-ash raw materials. Six kinds of low-ash raw materials, i.e. concentrated ore 1, concentrate 2, raw ore powder 1, raw ore powder 2, auxiliary raw material 1 and auxiliary raw material 2, are added to the 6 feed bins 100 respectively. Then utilize 6 quantitative feeders 200 to supply the above-mentioned 6 kinds of raw materials on the first conveyor belt 310 according to the weight ratio of 30:45:40:42:35:26, and the first conveyor belt 310 feeds the 6 quantitative feeders The raw materials supplied by 200 are delivered to the first buffer bin 510. Wherein, the total weight of each raw material supplied by the six quantitative feeders 200 is shown in Table 1.

[0083] Add 320kg of auxiliary raw material three (high ash raw material) into the second buffer bin 520 . Utilize the second conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com