Sand mixer

A sand mixing machine and yarn mixing technology, which is applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problems of long sand mixing time, large volume and floor space, and low sand mixing efficiency and other problems, to achieve the effect of saving yarn mixing time, saving production cost, and ensuring the effect of yarn mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

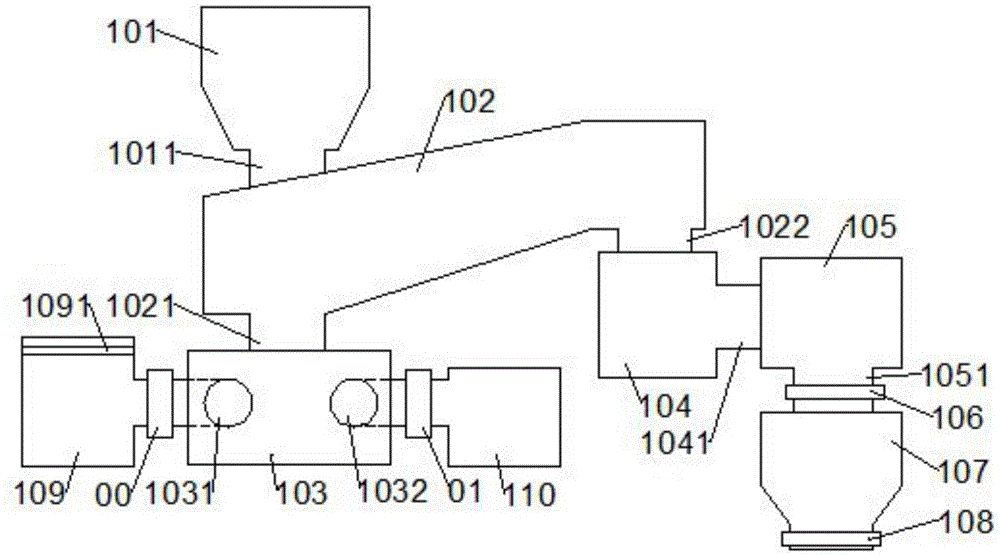

[0015] figure 1 It is a schematic structural view of the sand mixer provided by Embodiment 1 of the present invention; as shown in the figure, the sand mixer provided by Embodiment 1 of the present invention includes: a yarn storehouse 101 for storing raw yarns, and a discharge port at the bottom of the yarn storehouse 101 1011 communicates with a boom conveying mechanism 102 for conveying materials, the inlet 1021 at the bottom end of the boom conveying mechanism 102 communicates with a storage tank 103 for storing resin and curing agent, and the output port 1022 of the boom conveying mechanism 102 communicates with a The forearm slewing mechanism 104 for conveying materials, the outlet 1041 of the forearm slewing mechanism 104 is connected to a yarn mixing and stirring cage 105 for yarn mixing, and the outlet 1051 of the yarn mixing and stirring cage 105 is connected to a discharge tank through a sand outlet valve 106 107, a discharge valve 108 is provided at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com