Adjustable energy-saving catalytic auxiliary heating chamber with low main air pressure drop

An adjustable, main air technology, used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of large pressure drop of main air supply air, large energy loss of catalytic main fan, and increase the main air power of catalytic system. Consumption and other problems, to achieve the effect of increasing the cross-sectional area of the runner, ensuring the heat utilization efficiency, and avoiding high-frequency vibration accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

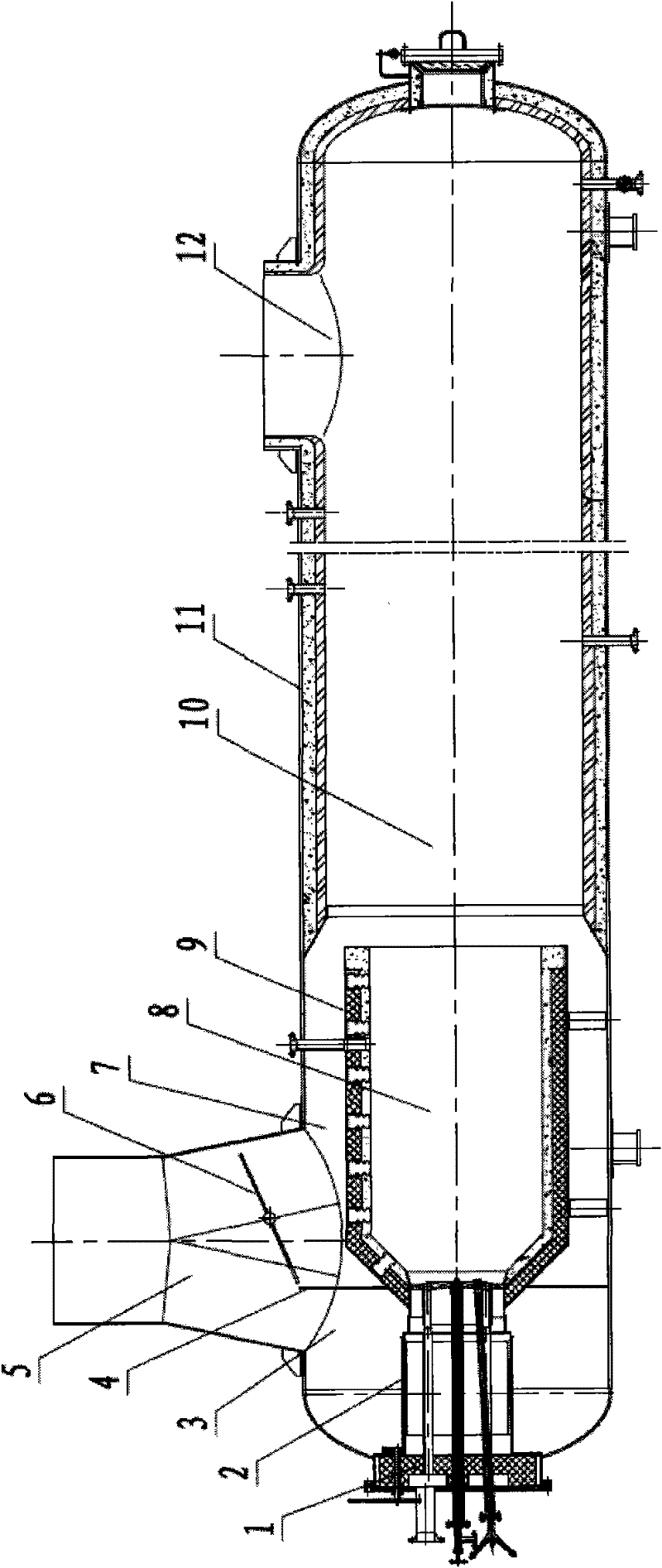

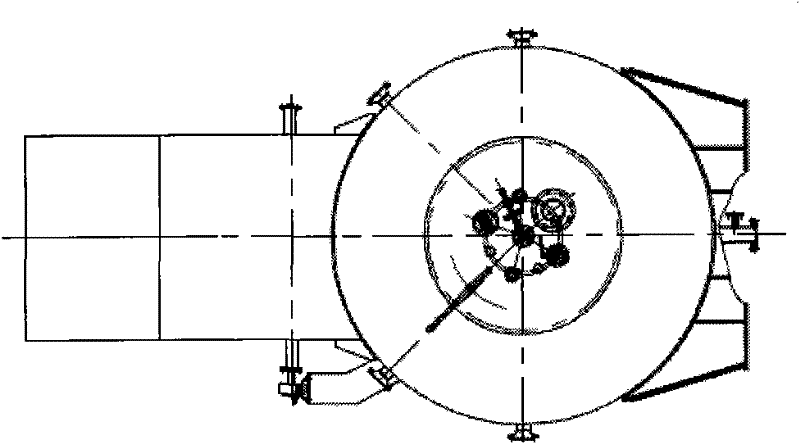

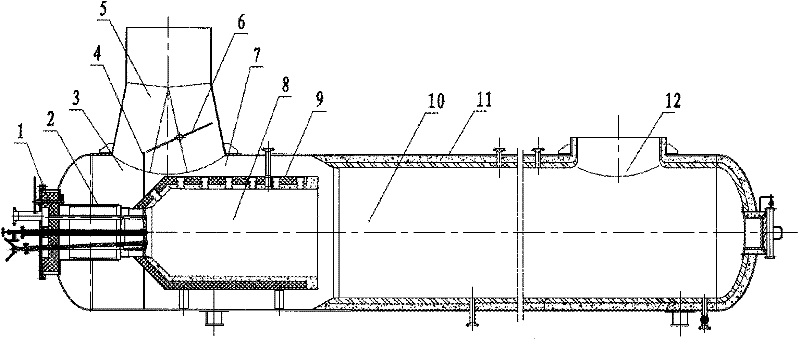

[0030] The present invention is described in conjunction with accompanying drawing and embodiment:

[0031] Such as figure 1 , figure 2 As shown, an adjustable low pressure drop catalytic main air auxiliary heating chamber has a burner 1, a combustion chamber 8, a heating chamber 10 and a main air inlet pipe 5; the burner 1 communicates with the combustion chamber 8; the combustion chamber It consists of a combustion chamber cylinder lined with high-temperature refractory materials; the heating chamber 10 communicates with the combustion chamber 8, and the heating chamber 10 is located at the rear of the combustion chamber 8; the main air inlet pipe 5 is located at the upper part of the combustion chamber and is perpendicular to the combustion chamber Cylinder 9; the upper part of the main air inlet pipe is circular, and its lower part is an expanded oblate cone; the lower part of the main air inlet pipe is divided into the combustion primary air flow channel 3 and the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com