Patents

Literature

173results about "Baking sheets/boards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

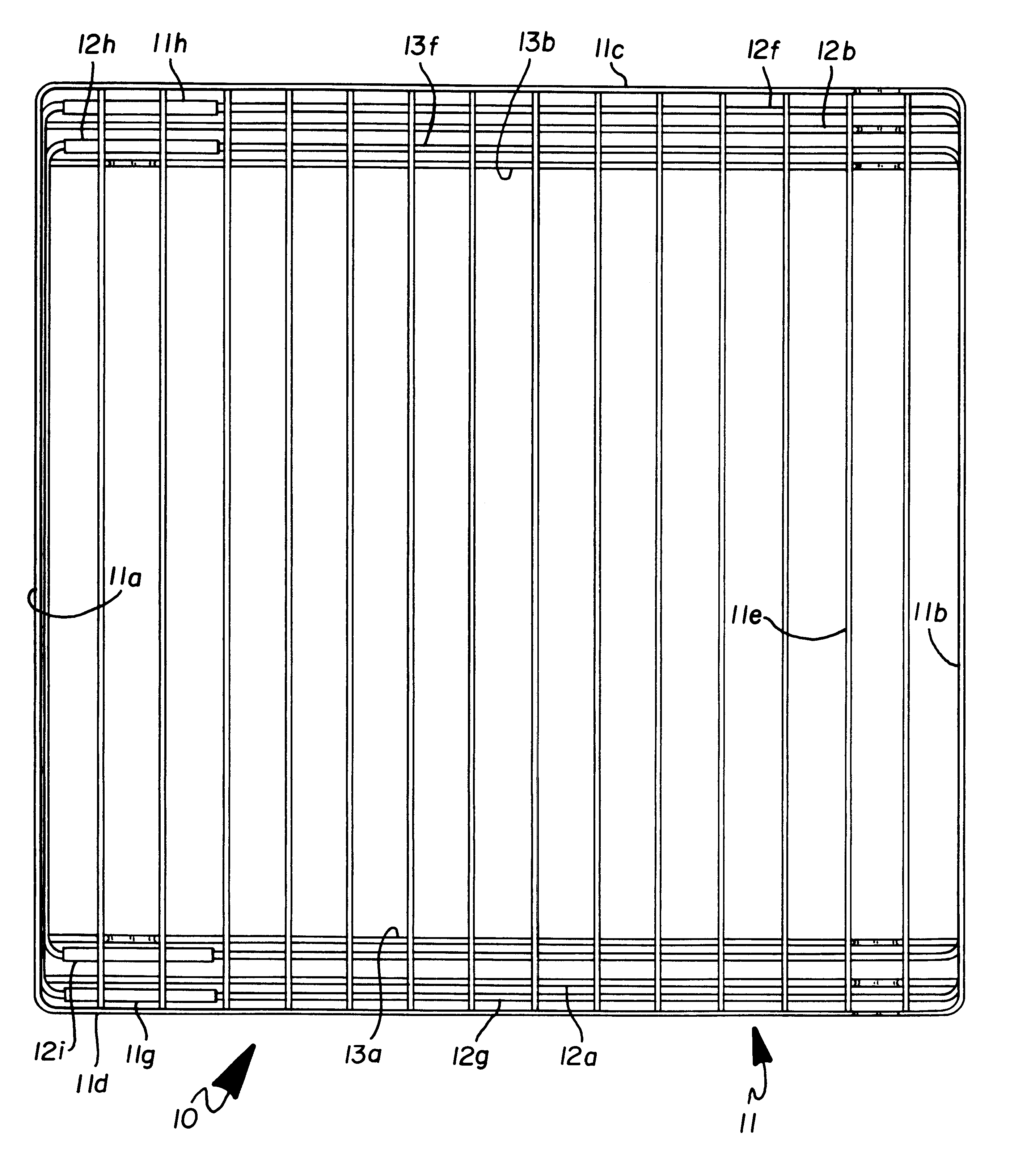

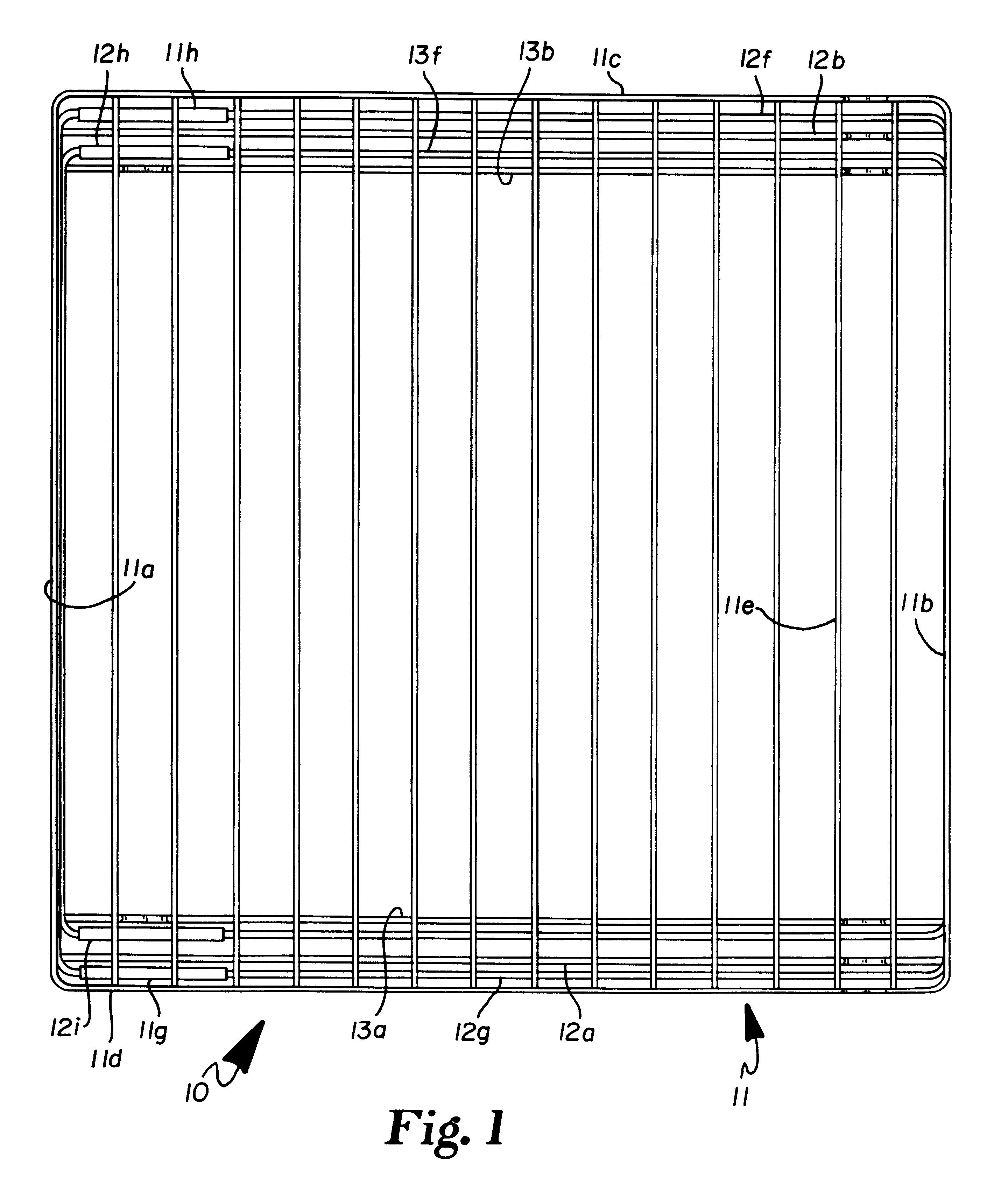

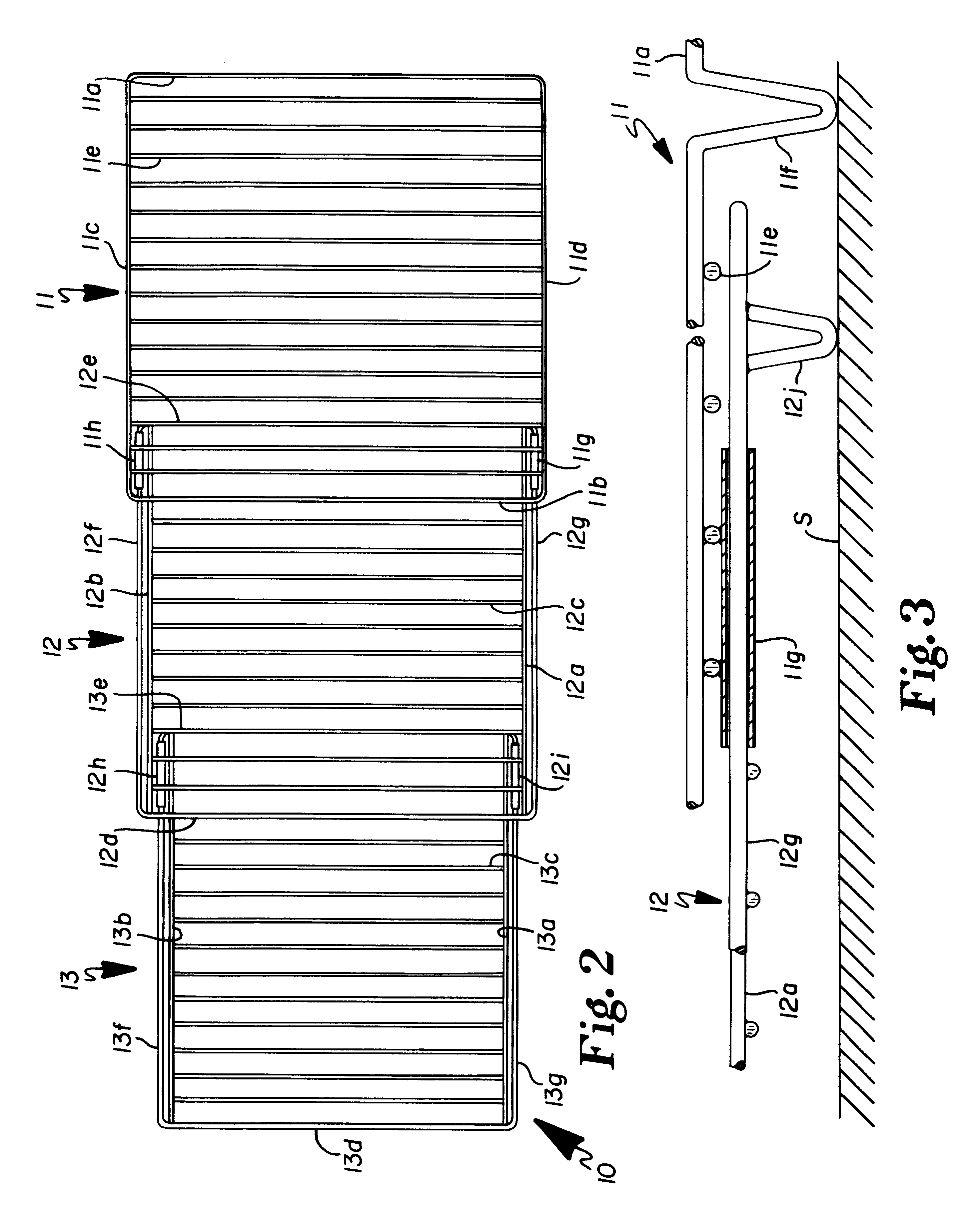

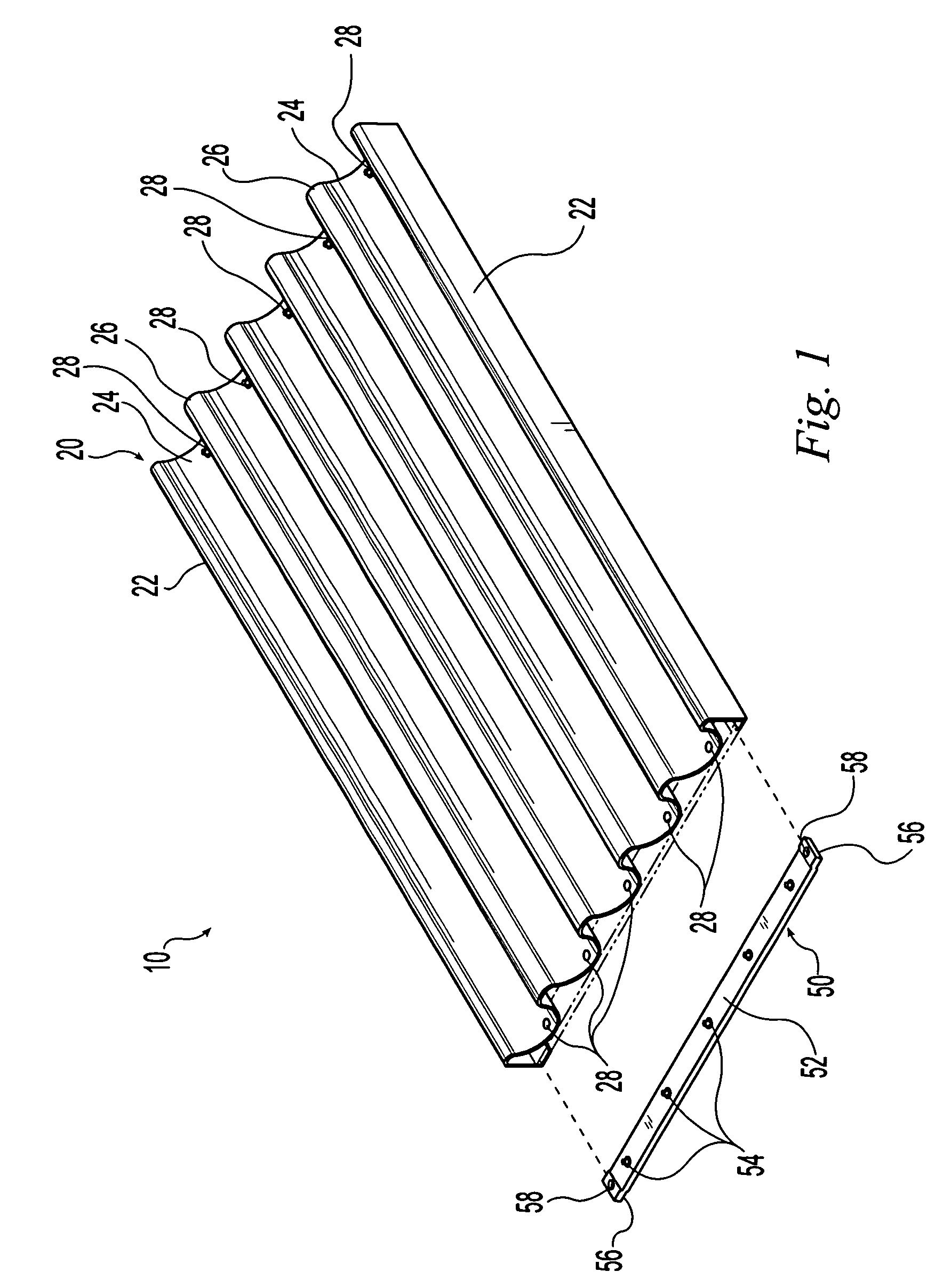

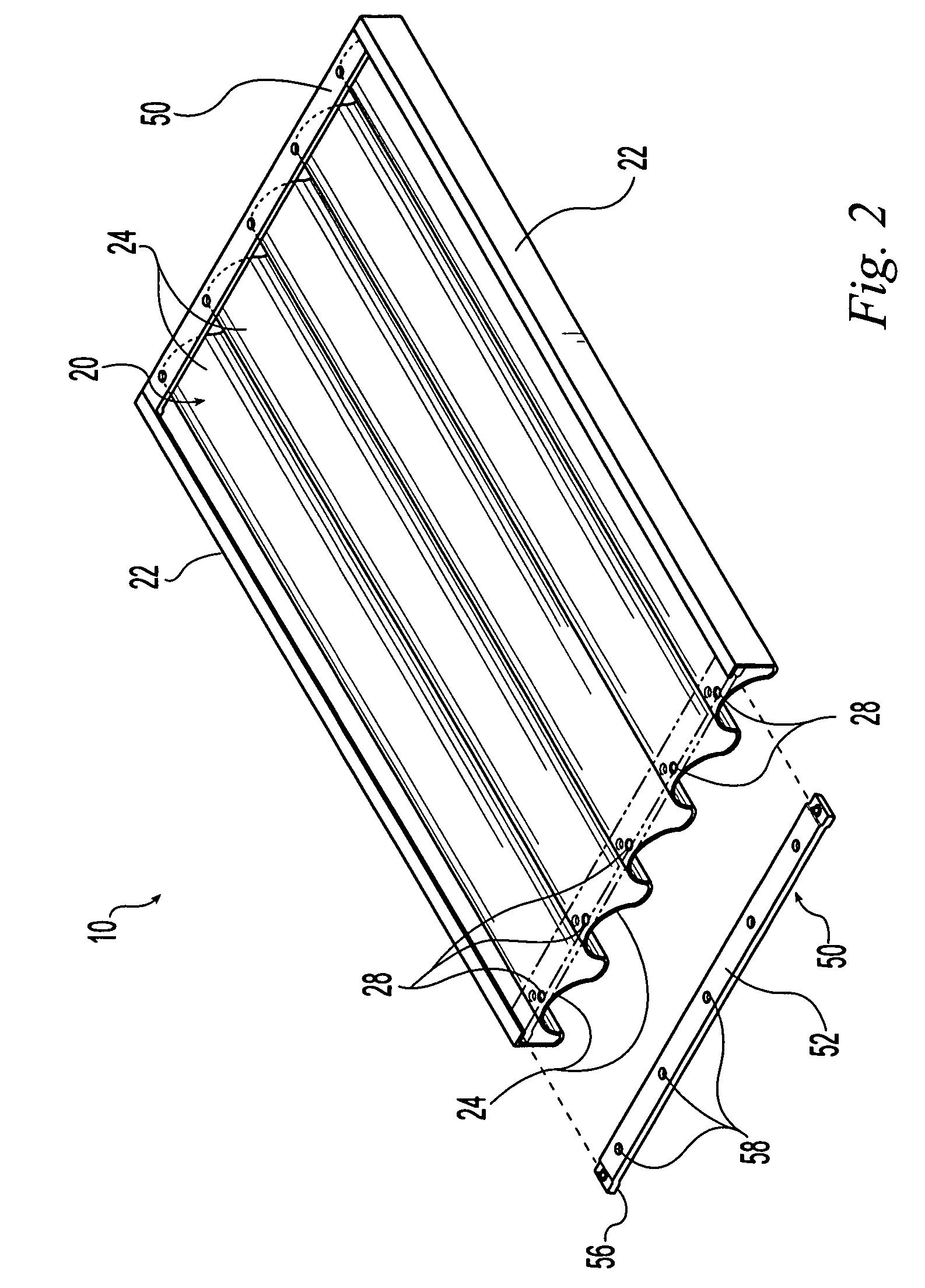

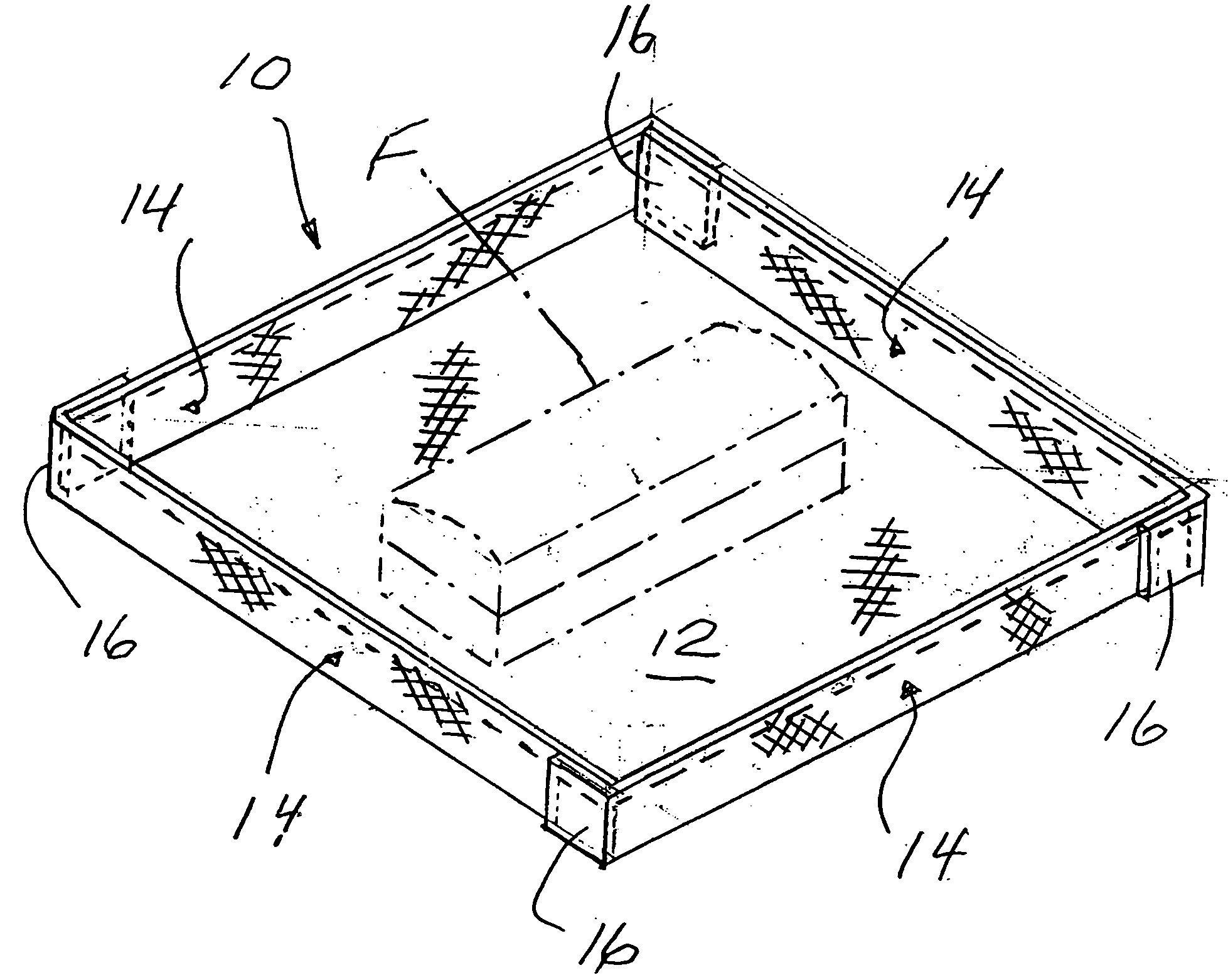

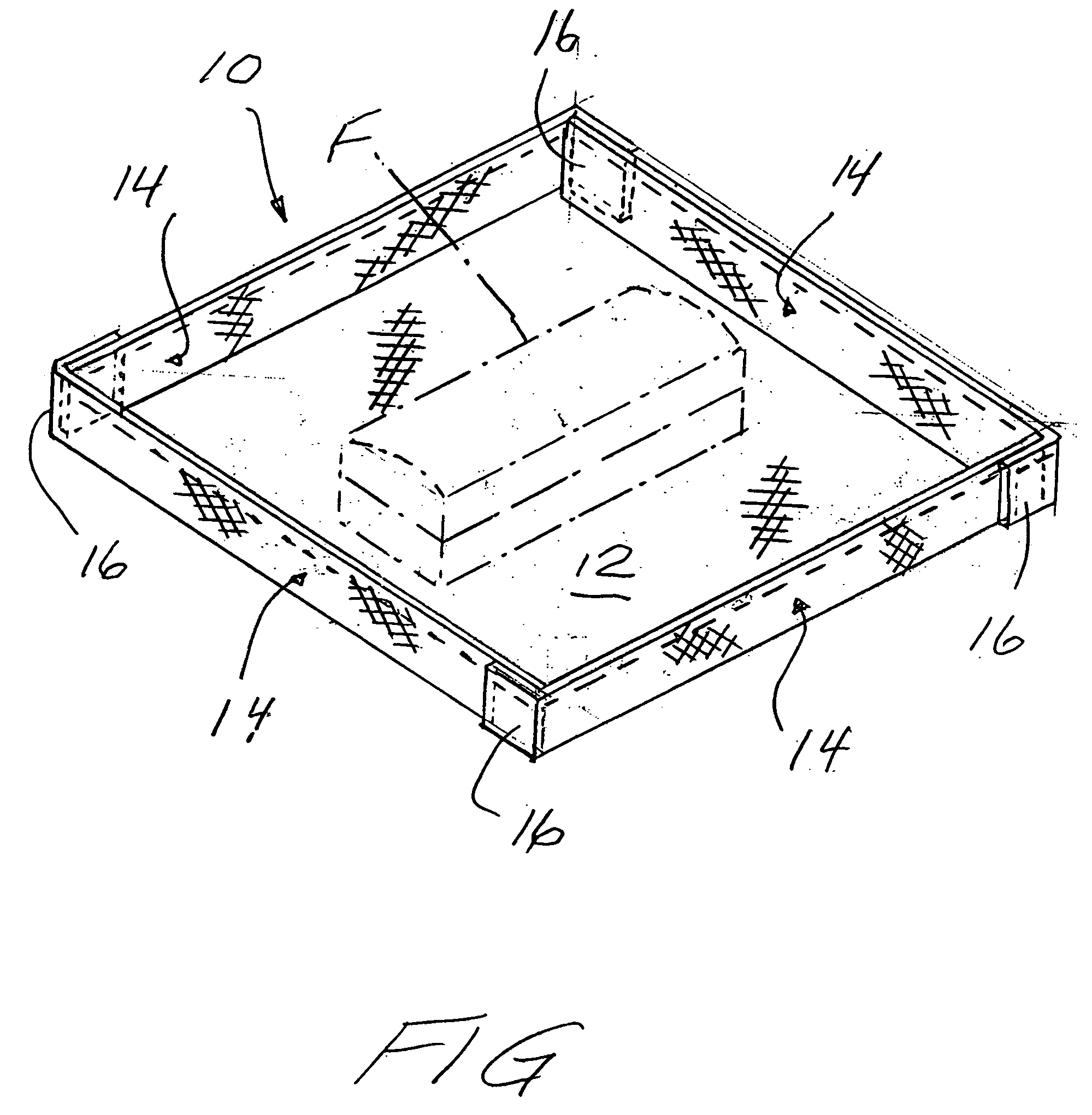

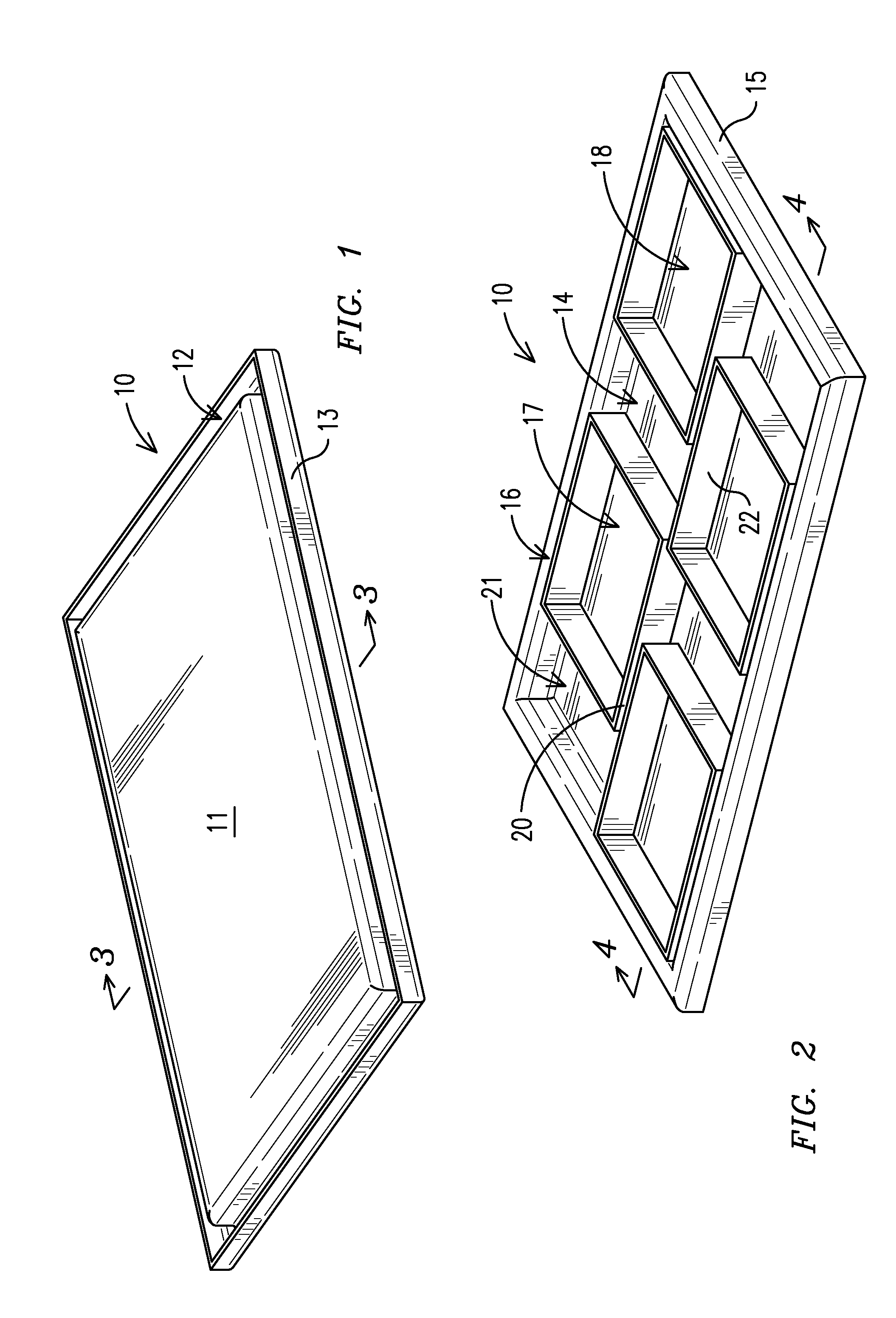

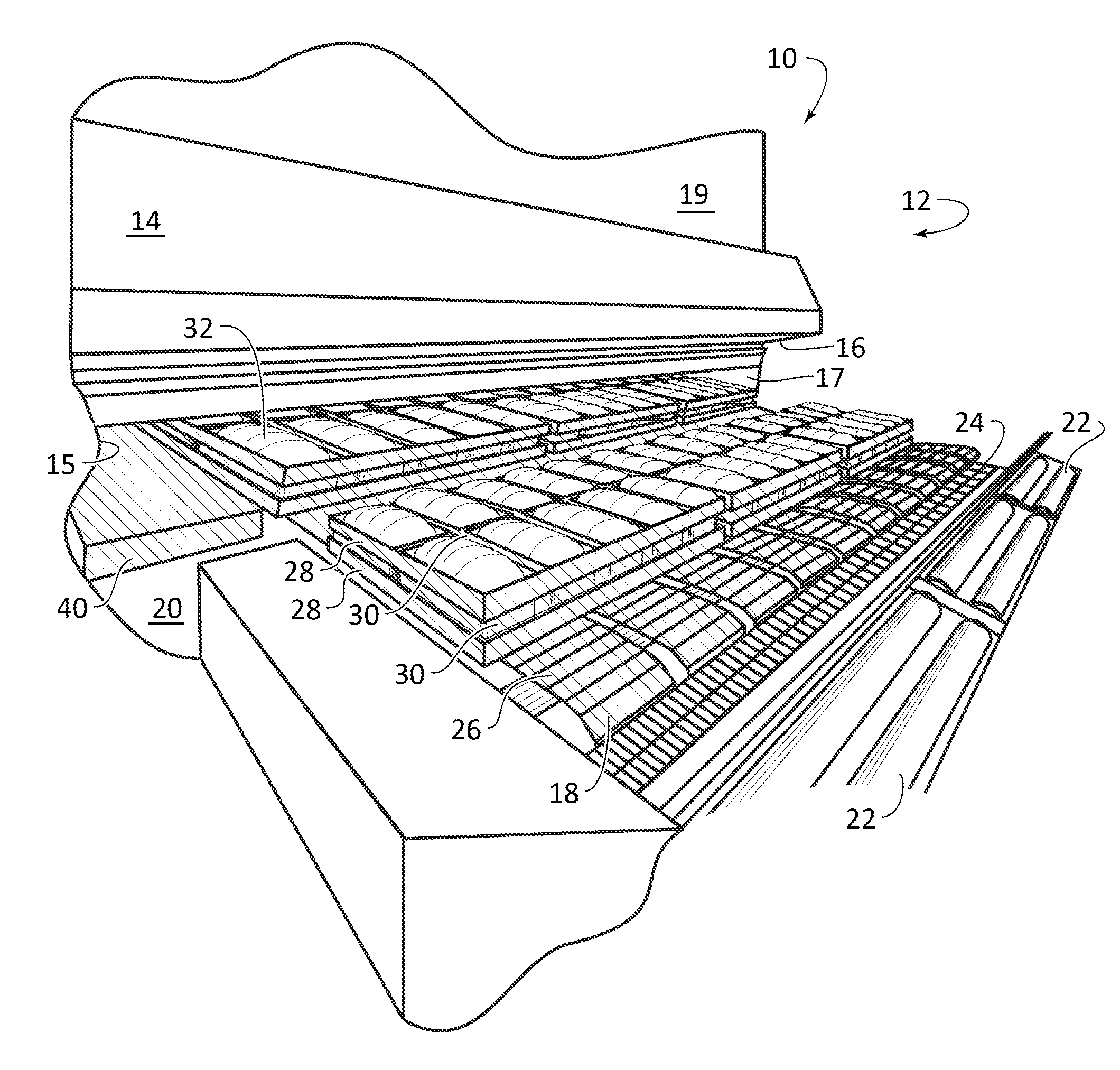

Expandable cooling rack for foodstuffs

InactiveUS6279467B1Simple methodClosely arrangedStoves/ranges shelves or racksMeat processingReduced sizeEngineering

An expandable rack for foodstuffs or other articles for temporary use after baking or cooking to allow the foodstuff to cool. The expandable rack consists of a plurality of tiers or layers which are slidably arranged with respect to one another such that the entire rack may be slid together to form a compact size for storage. A first layer or tier consists of a plurality of spaced, longitudinally extending rods surrounded by a continuous, formed member, to substantially provide a rectangular shape and having downwardly depending legs to elevate the same above a support surface. Each of the additional layers employs the same construction but is of reduced size to permit all layers to be slid together in underlying relation to the first layer. The structure for retaining the tiers or layers to one another and allow sliding therebetween is incorporated into each of the tiers and each tier has support legs.

Owner:NIFTY HOME PROD

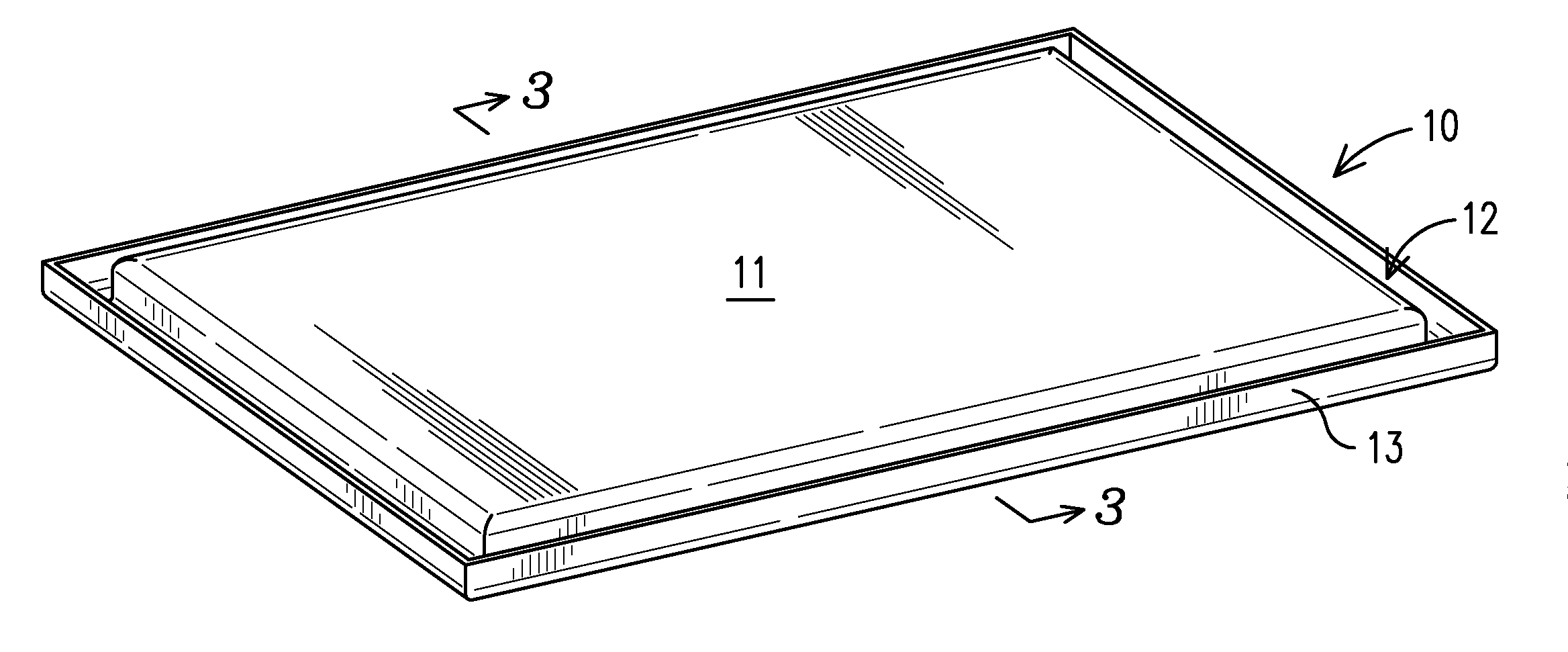

Baking tray

Owner:AMERICAN PAN

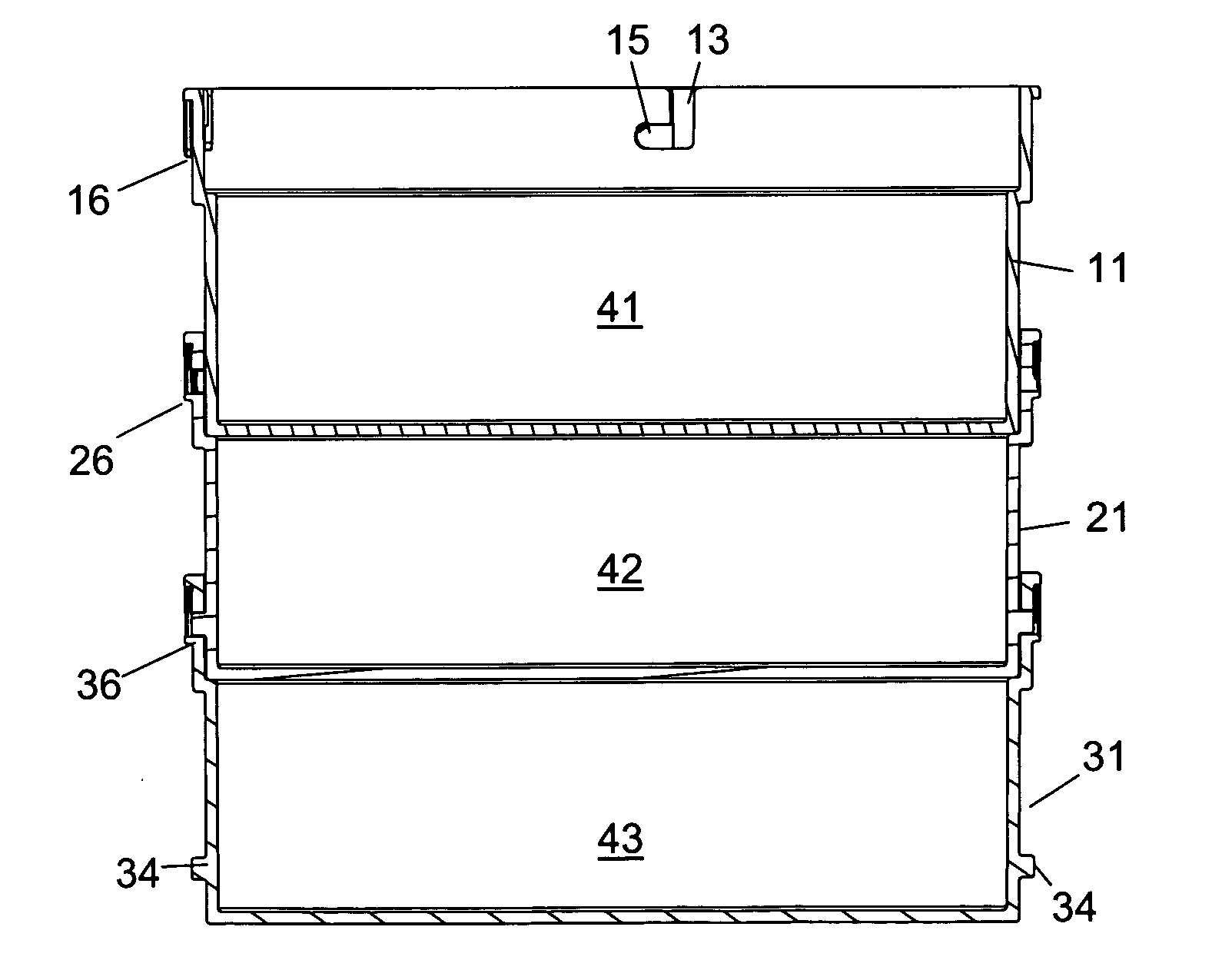

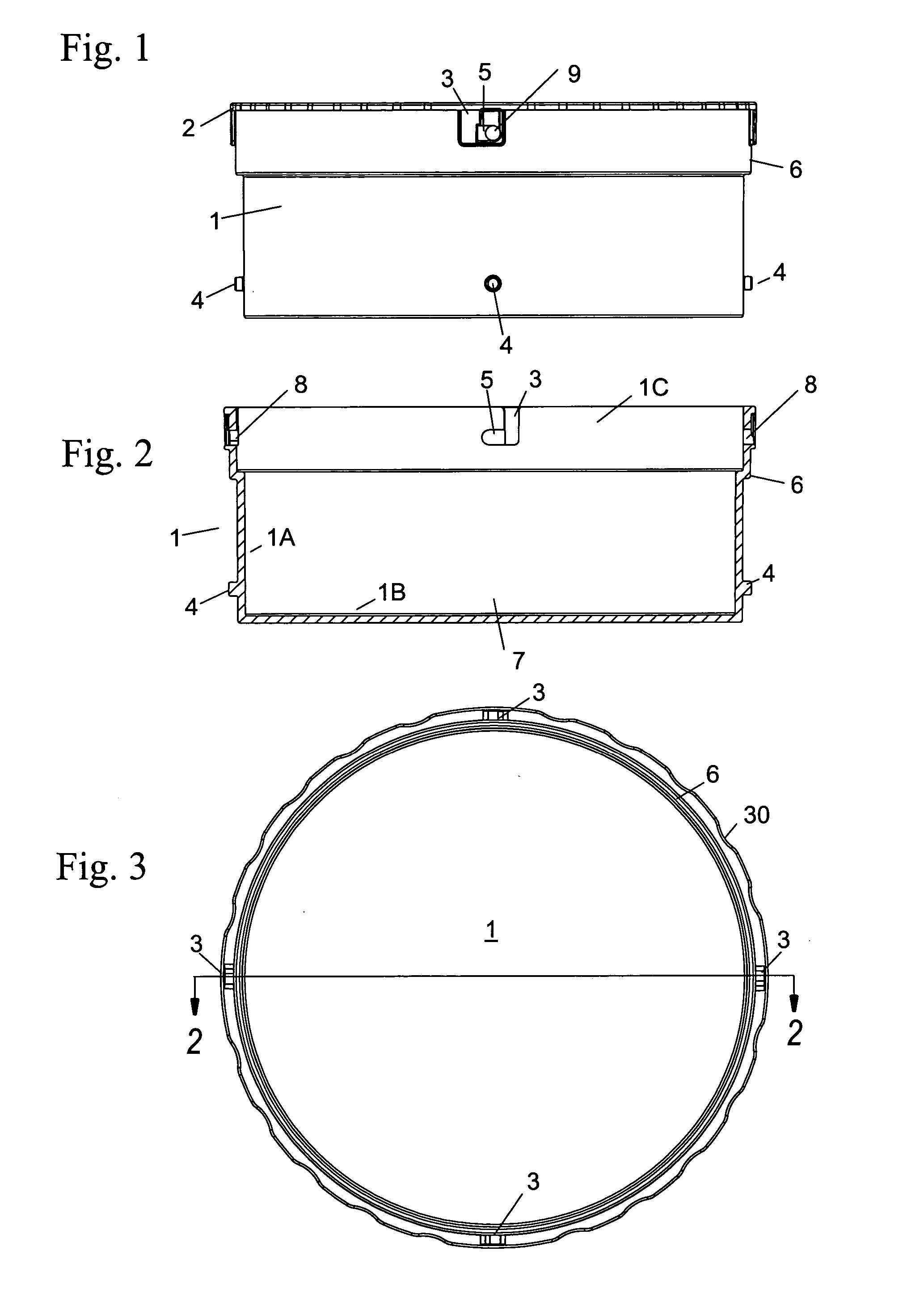

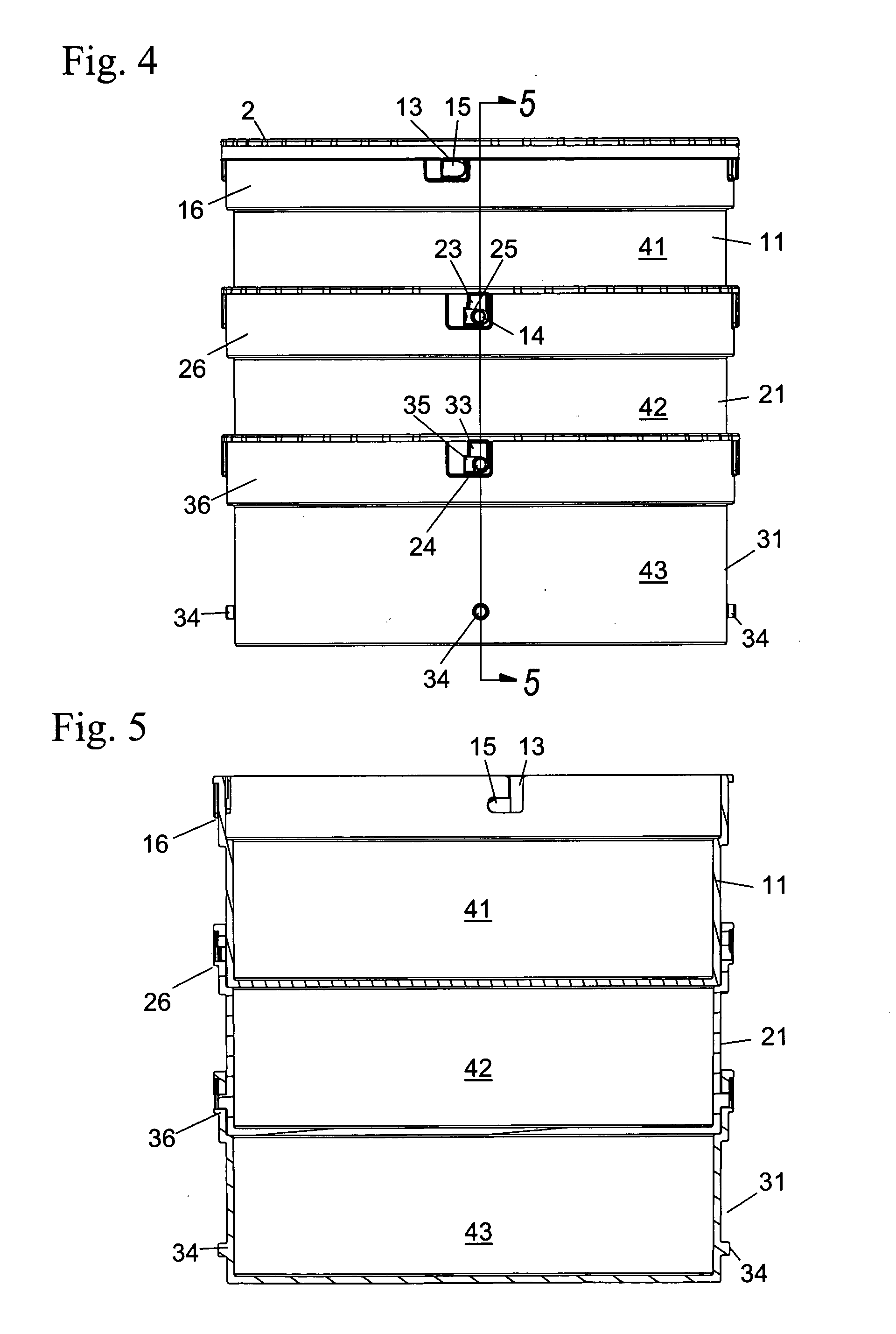

Dough storage container system

InactiveUS20050109774A1Less spaceResistant to topplingRigid containersDough processingEngineeringMechanical engineering

A stackable dough storage containment system uses nesting stackable interlocking pan bodies having a locking system for connecting the bodies, such that a pan body in a stack can be locked to pan bodies stacked above and below it. The locking system includes locking members positioned on the outside of each pan body near its base, forming locking connections with locking interfaces located on the outside of each pan body near its top. In the preferred embodiments, the locking members are radial pins and the locking member interfaces are bayonet joints. This allows each pan body to be dropped into position in the open top of the pan body below and rotated slightly to form a secure connection. Vents in each pan body release gases generated during the rising process.

Owner:ORIOLES RICHARD TIMOTHY

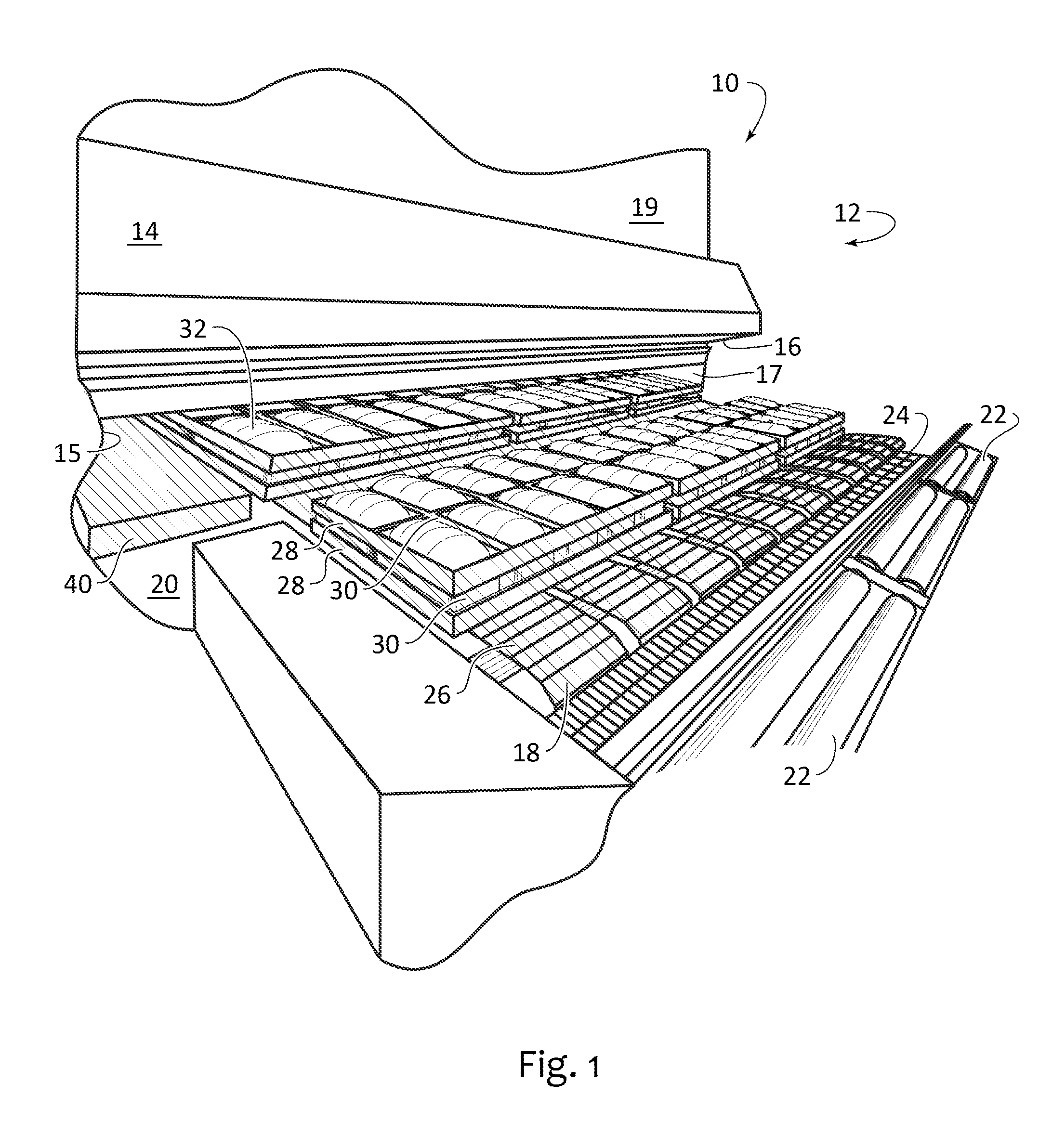

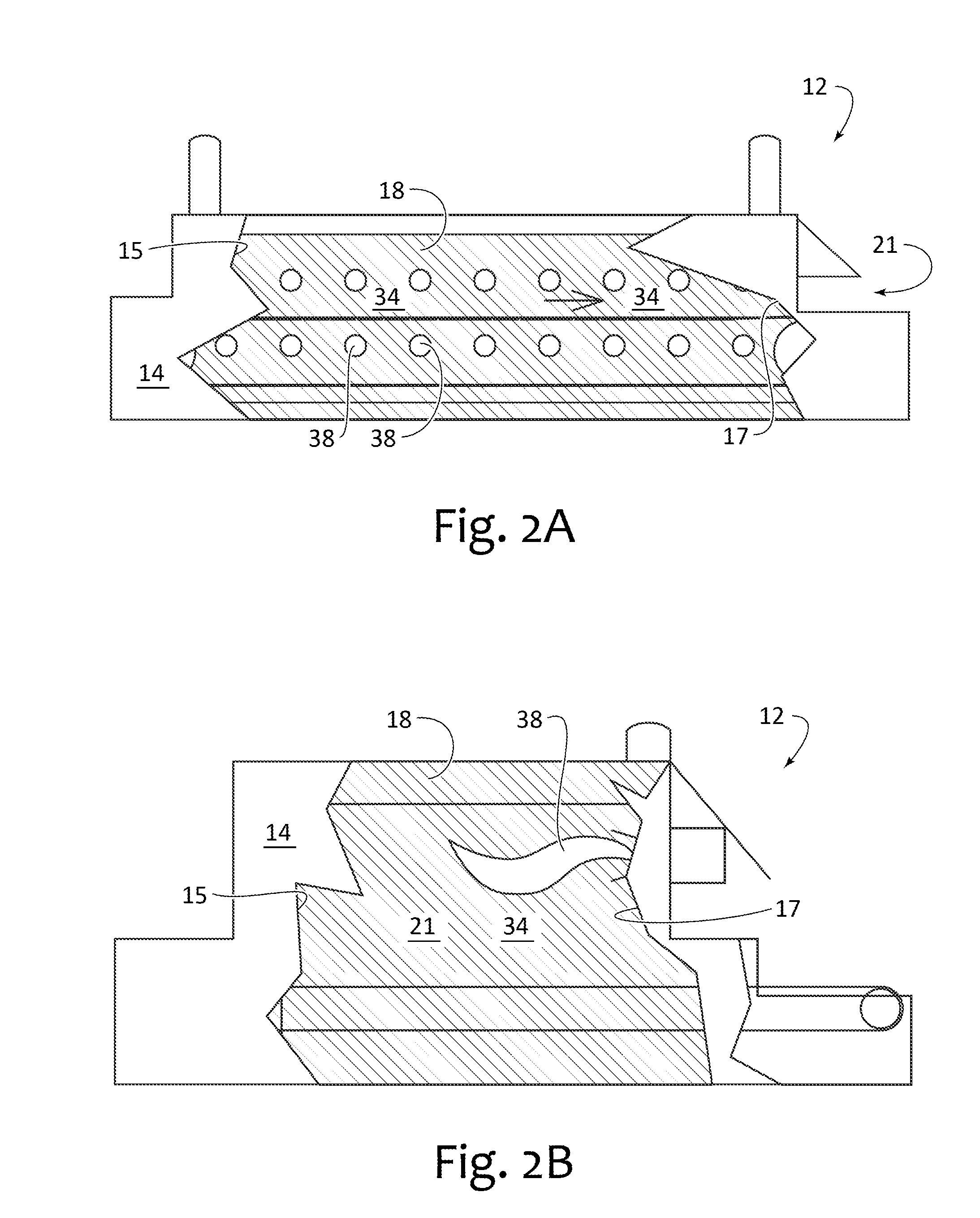

Cooking tray for rapid cook oven

A cooking tray (optionally interstices-defining, microwave-transparent and providing an appropriate view factor) has a one-piece, integral, unitary construction formed of a food-grade, non-stick material suitable for use in a rapid cook oven which cooks by a combination of at least two heat transfer mechanisms selected from the group consisting of radiant heat transfer, convection heat transfer and microwave energy transfer. The construction defines a base and an upstanding peripheral sidewall about the base for the collection of solid debris created during cooking. Preferably the material is food-grade fiberglass with a non-stick coating.

Owner:TURBOCHEF TECH INC

Griddle plate for a gas grill

Owner:HAMLIN EDWARD W

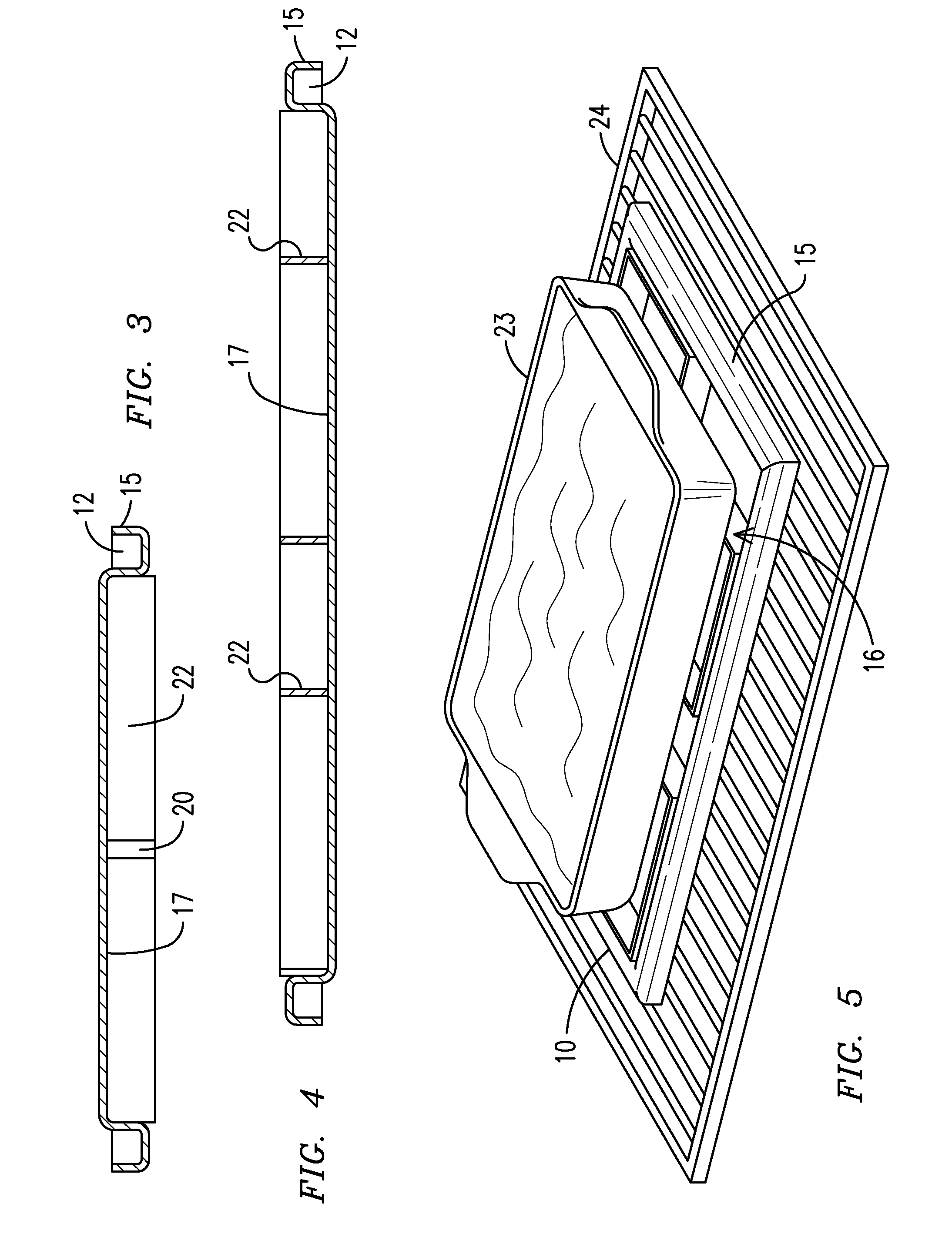

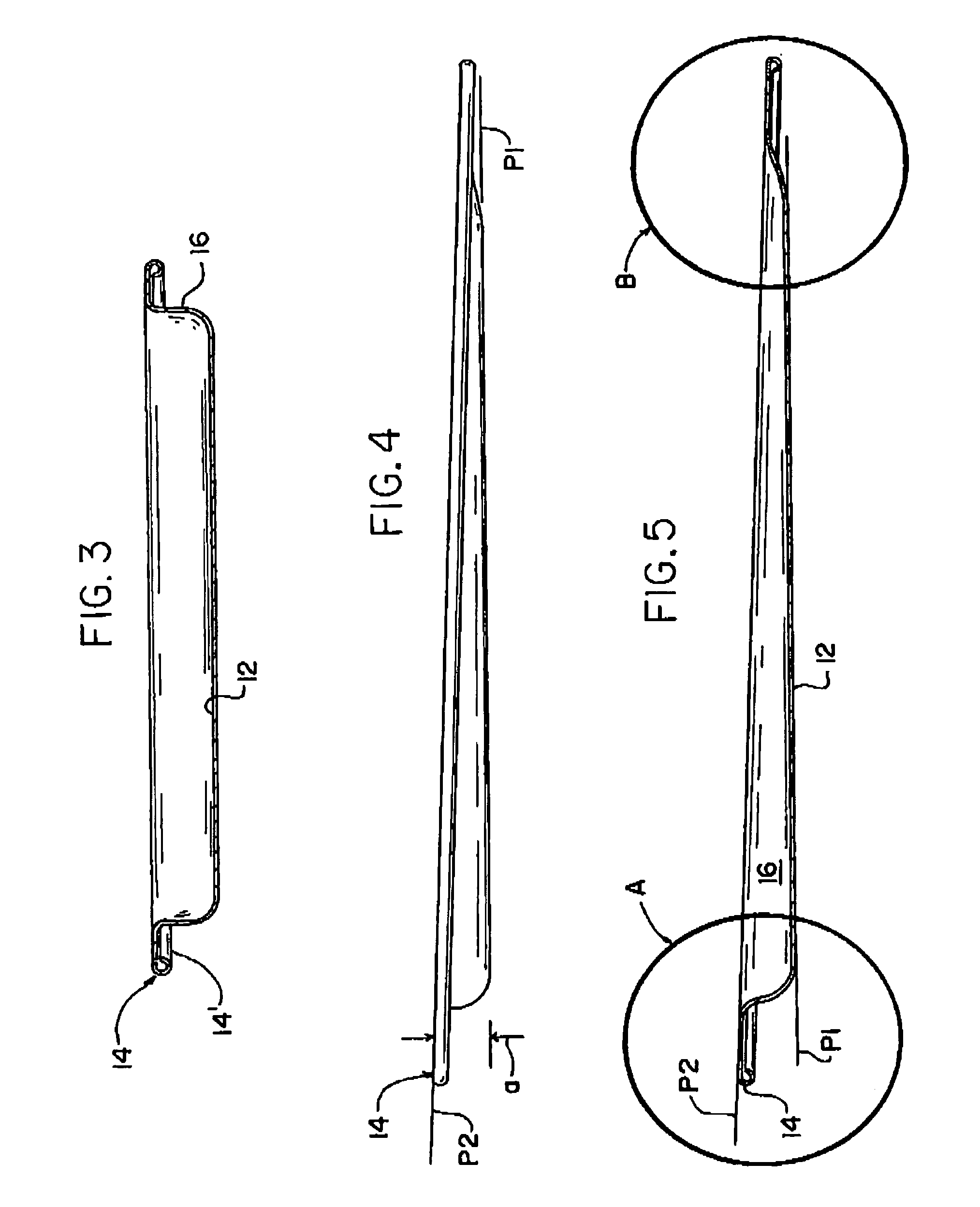

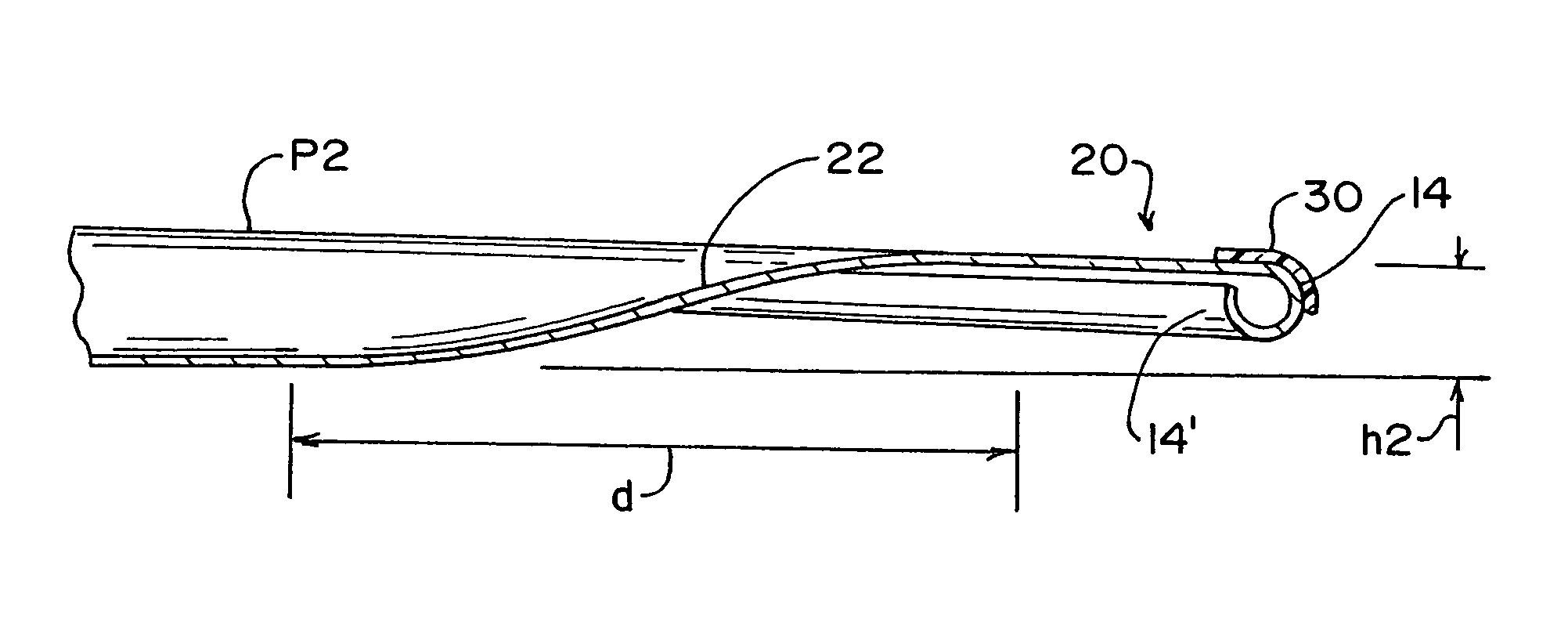

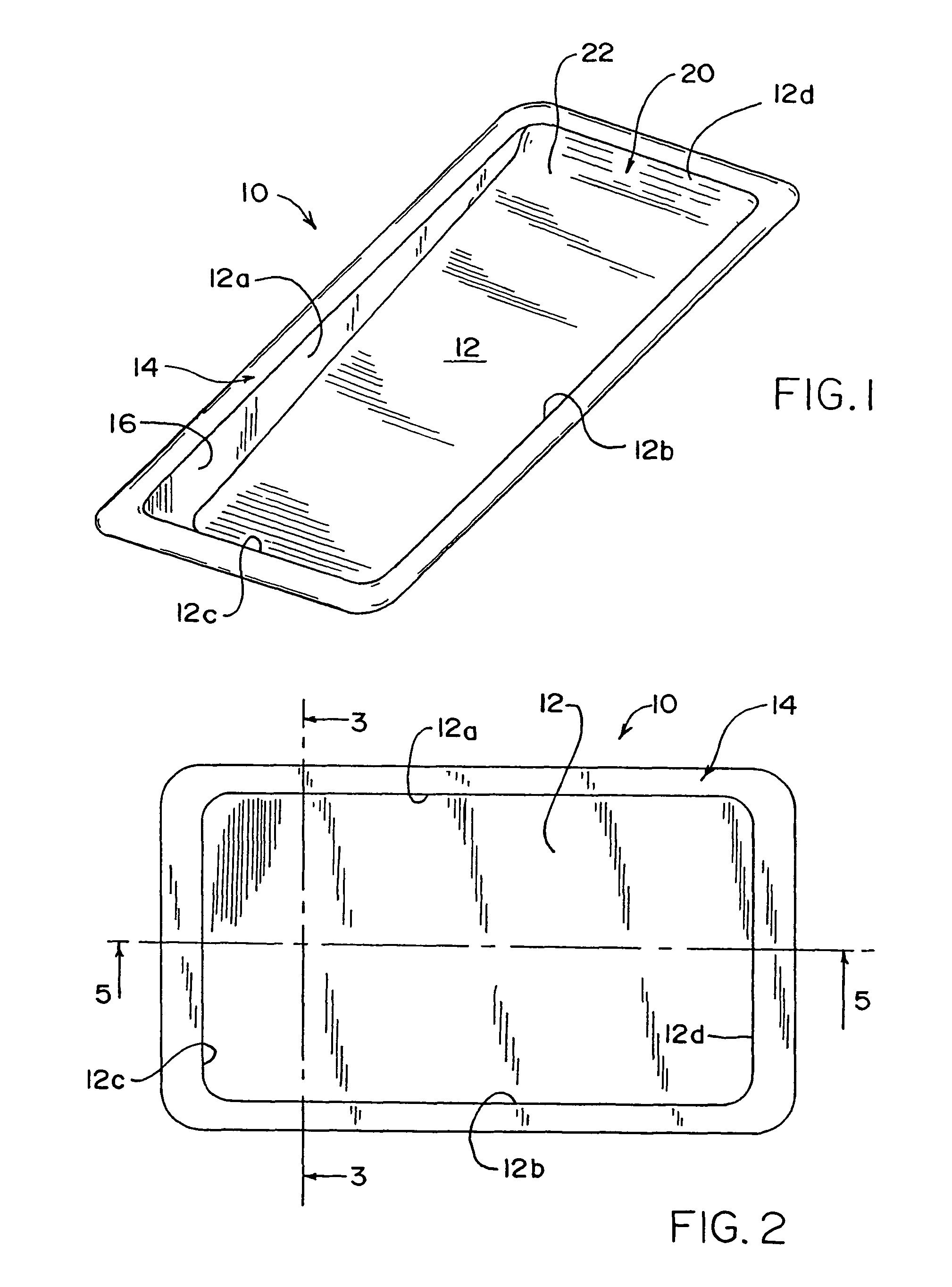

Cookie baking sheet with cookie slide-off ramp

A cookie baking sheet is formed of substantially flat heat-resistant material including a baking surface in a first plane and defining a rolled peripheral edge and a baking area within the peripheral edge. A generally upright wall is integrally formed with the sheet material and extends along only a first portion of the periphery. This wall defines an upper edge contained within a second plane that is inclined relative to and meeting the first plane substantially along a second portion of the periphery. The upright wall is provided with a variable vertical height from a maximum predetermined height to a minimum predetermined height relative to said first plane. This variable height wall substantially encloses the baking area along the first portion of the peripheral edge. In the disclosed embodiment the baking sheet is rectangular and the upright wall extends along three of the sides while the fourth side is not founded by a wall. Baked cookies can only be slid off or pushed off into a receptacle without lifting the cookies along this second peripheral portion or fourth side, which serves as a slide-off chute or ramp.

Owner:LIFETIME BRANDS

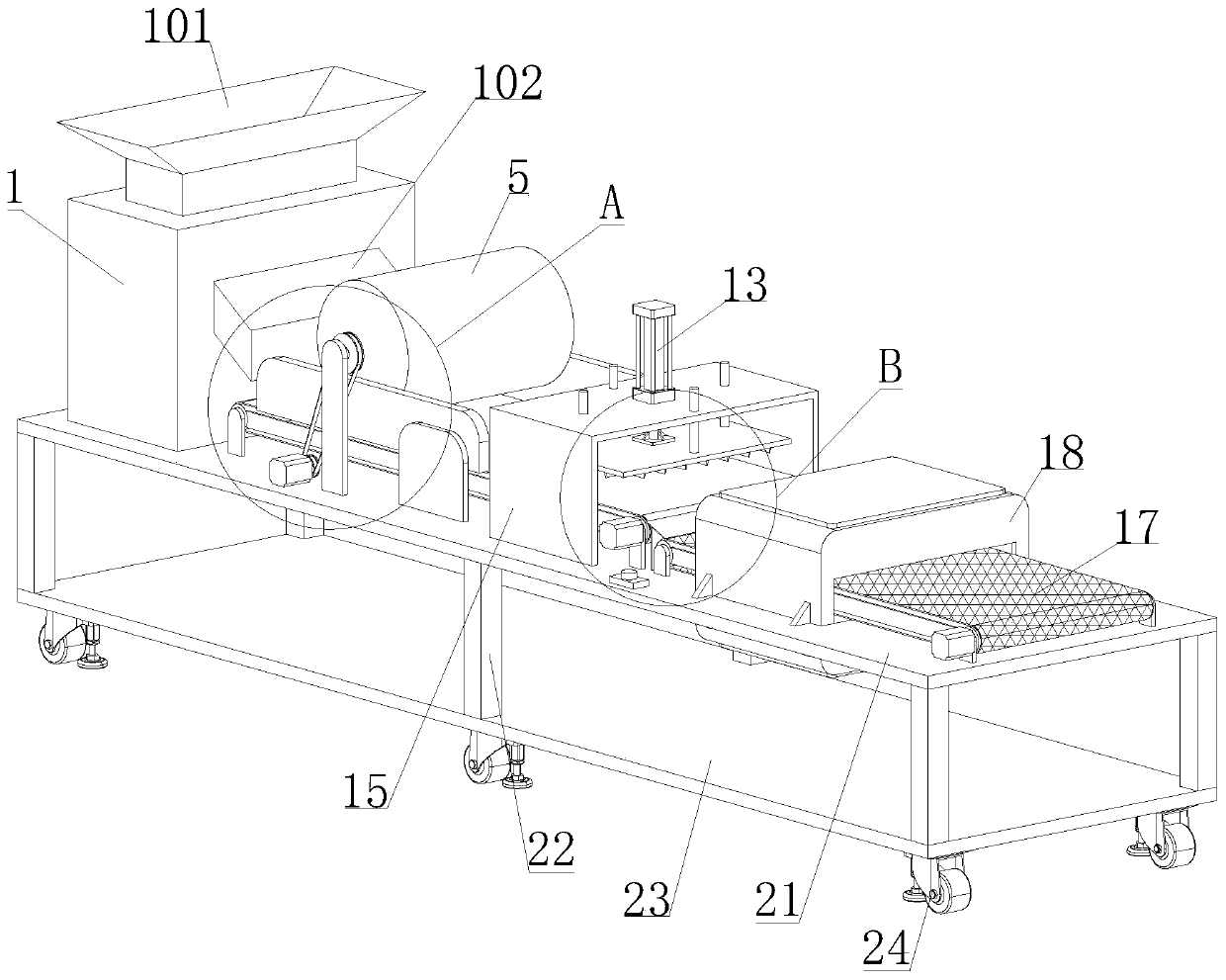

Leavened cake production device and preparation method thereof

InactiveCN110973179AImprove production efficiencyFully bakedDough-sheeters/rolling-machines/rolling-pinsDough dividingEngineeringControl switch

The invention discloses a leavened cake production device and a preparation method thereof. The leavened cake production device comprises a conveying belt conveying mechanism, baffles, a connecting plate, a dough rolling roller, a forming grid plate, a first mounting plate, a supporting frame, a mesh belt conveying mechanism, a baking cover, a baking device, a processing table, supporting legs anda control switch. The two baffles are located at the top of a conveying belt, arranged side by side in the longitudinal direction and connected with the connecting plate. The connecting plate is arranged on the processing table; a driving mechanism for driving the dough rolling roller to rotate is arranged on the processing table; the forming grid plate is arranged at the bottom of the first mounting plate; the supporting frame is arranged on the processing table, and an electric push rod used for driving the first mounting plate to move in the vertical direction is arranged on the supportingframe; the baking cover is arranged on the processing table; the baking device is arranged on the baking cover; the control switch is in respective control connection with the conveying belt conveying mechanism, the mesh belt conveying mechanism, the driving mechanism, the electric push rod and the baking device. According to the invention, automatic production can be achieved, and the leavened cake production efficiency is improved.

Owner:九江市金樱食品发展有限公司

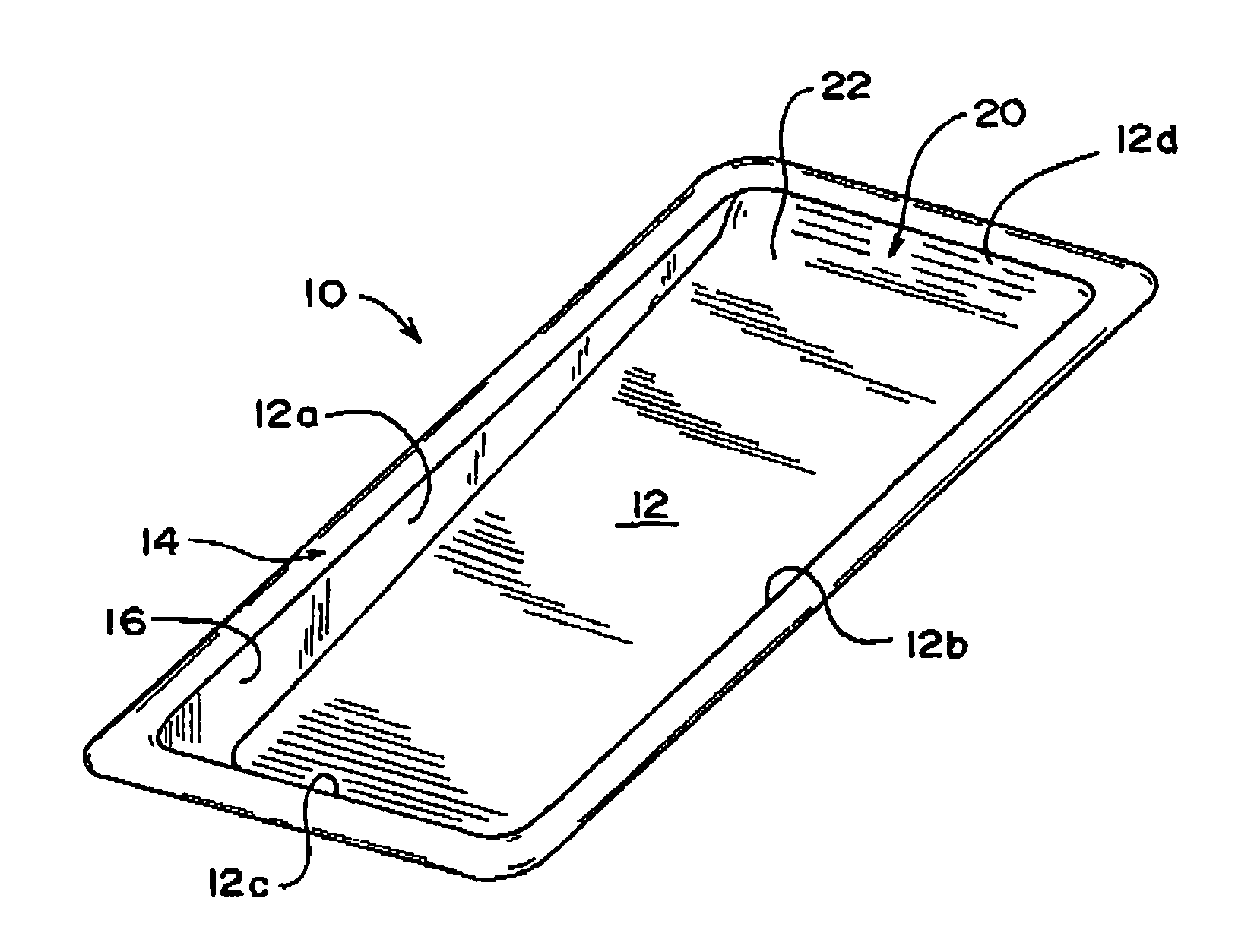

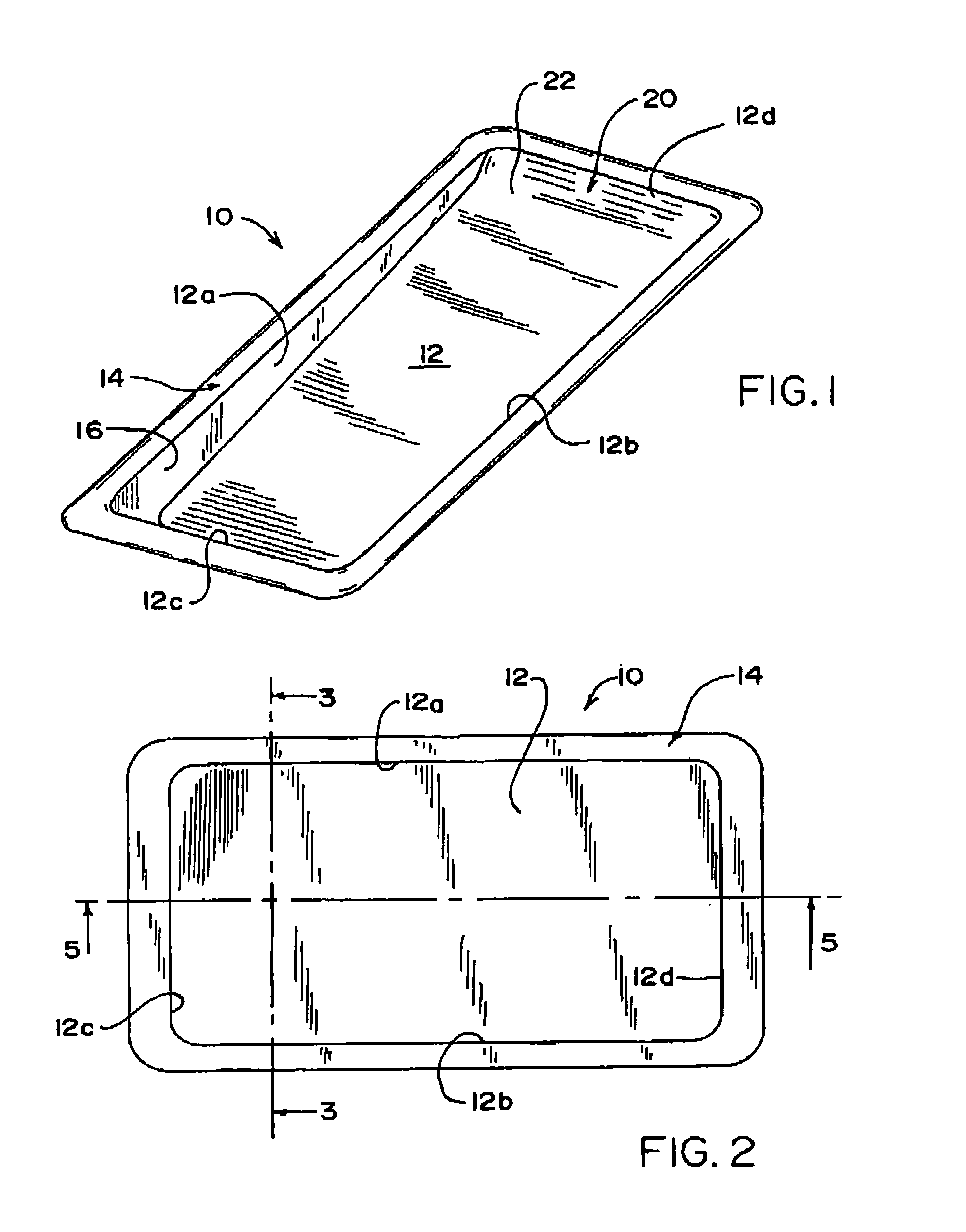

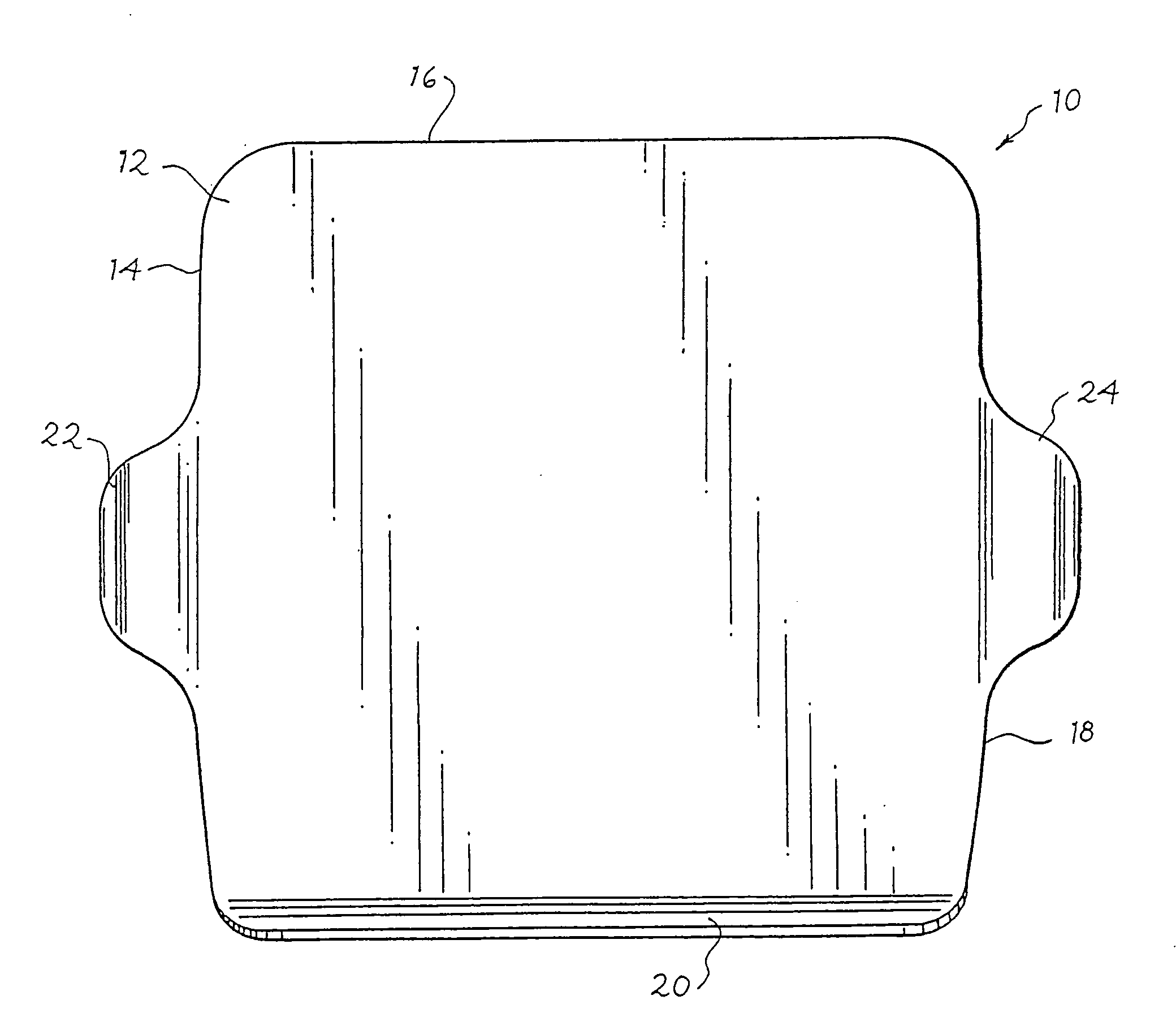

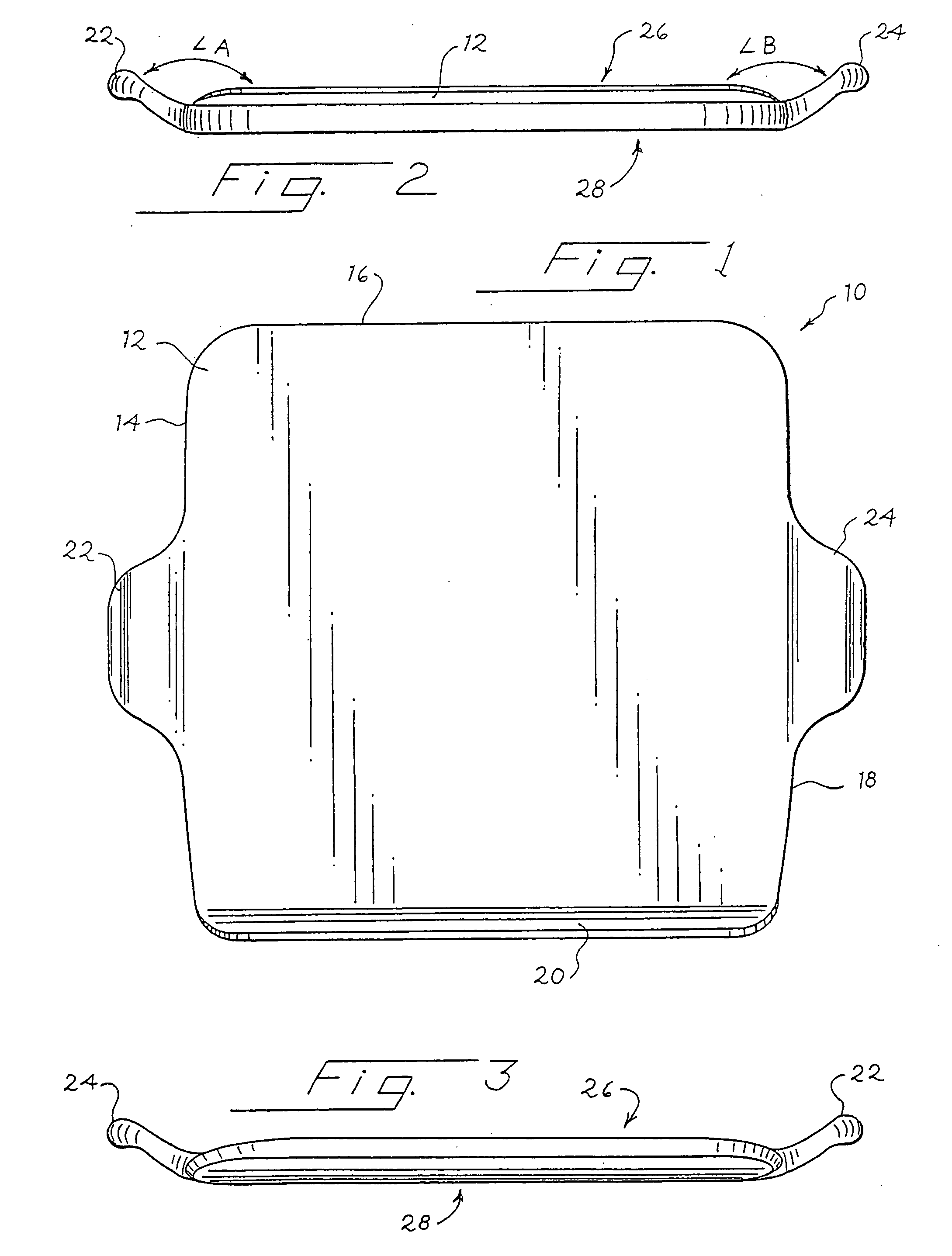

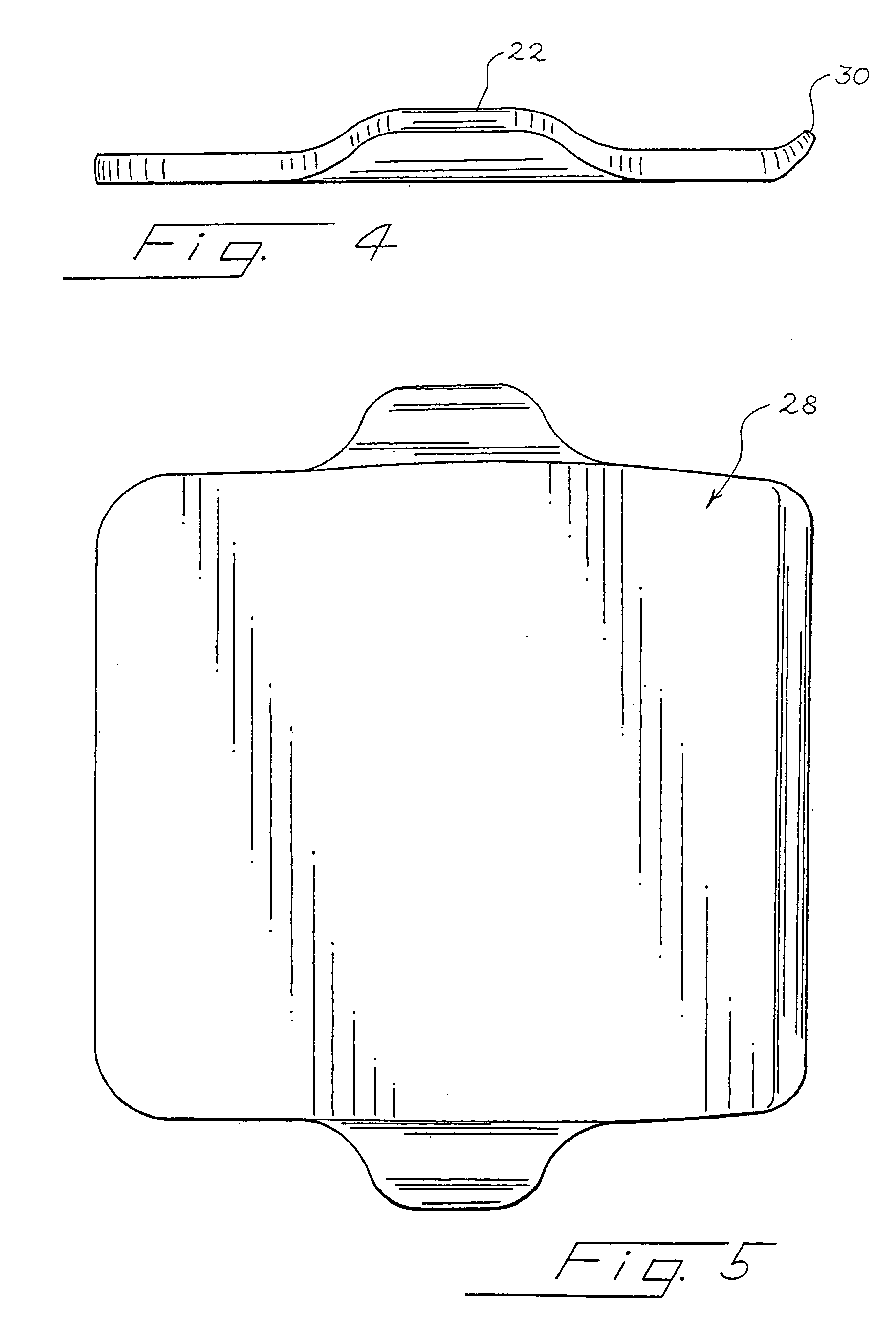

Handled baking dish

InactiveUS20100018409A1Reduce the possibilityEase of transportationCooking vesselsBaking sheets/boardsMetallic materialsEngineering

Owner:HAEGER INDS

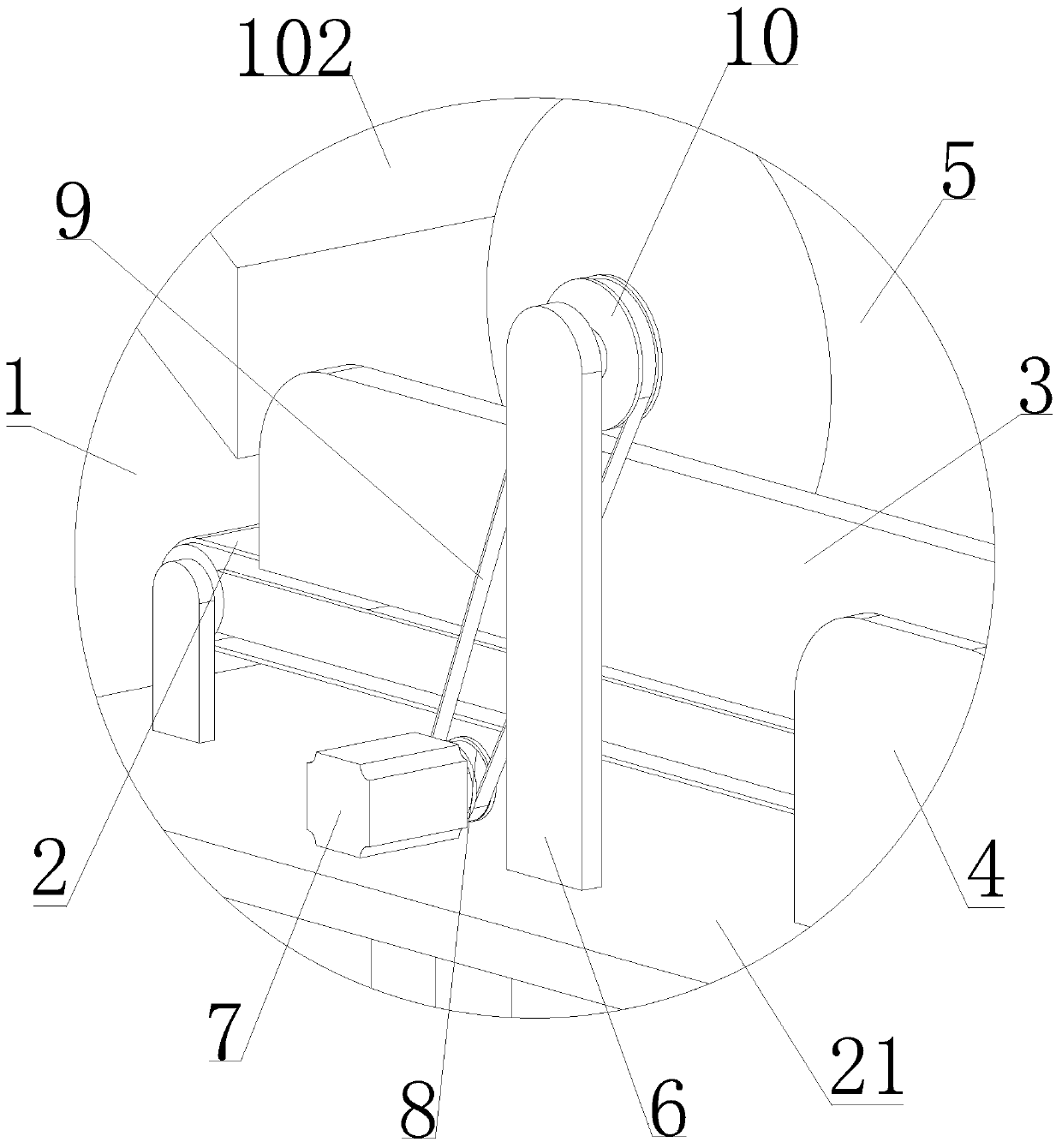

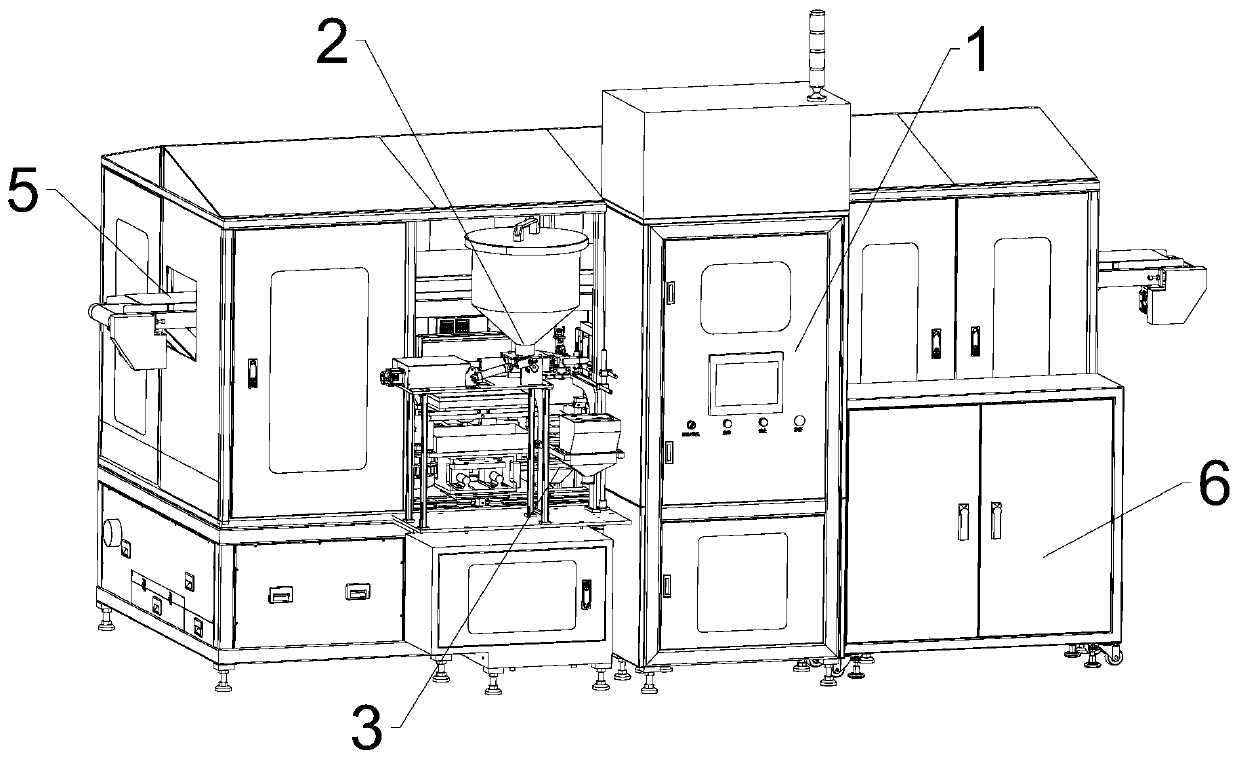

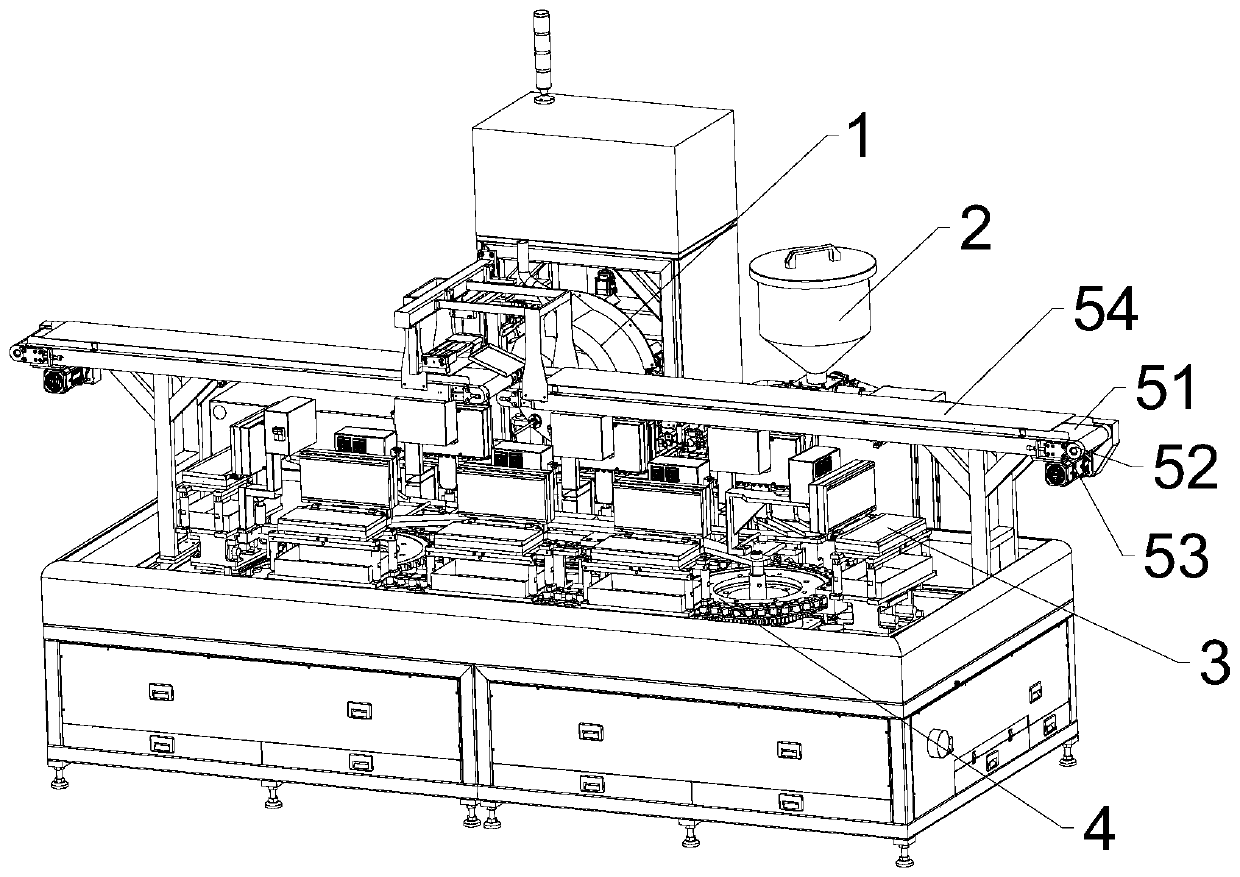

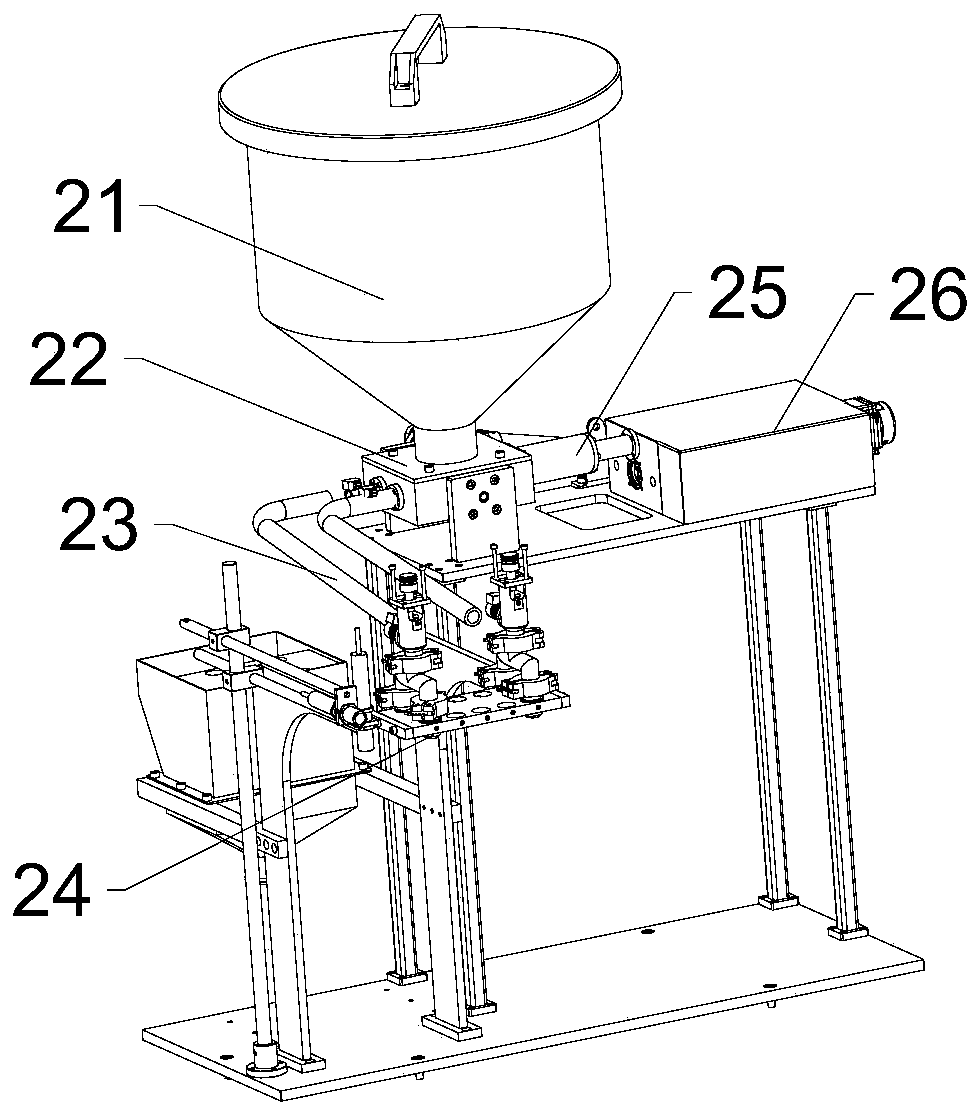

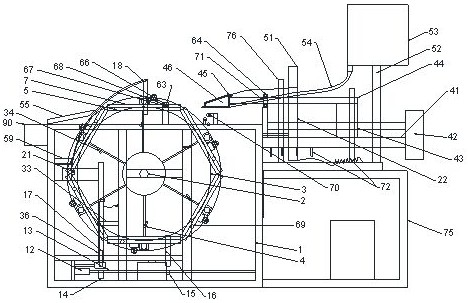

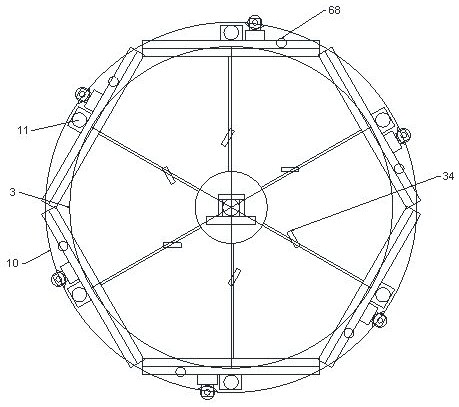

Egg roll processing equipment

PendingCN111150008ARealize automatic productionIncrease productivityOil/fat bakingPancakes bakingBiotechnologyMechanical engineering

The invention discloses egg roll processing equipment. The egg roll processing equipment comprises a baking plate mechanism, a baking plate circulating mechanism and an egg roll forming mechanism, wherein the baking plate mechanism comprises a plurality of baking plates which are provided with grouting positions and rolling positions and used for making egg roll wrappers from a slurry dripping onto the baking plates by a grouting mechanism; the plurality of the baking plates are fixedly arranged on the baking plate circulating mechanism; the baking plate circulating mechanism drives the bakingplates to circularly rotate and controls the baking plates to be opened and closed; and the egg roll forming mechanism is arranged at the rolling positions and used for rolling egg roll wrapper on the baking plates to form egg rolls. The egg roll processing equipment provided by the invention comprises the grouting mechanism, the baking plate mechanism, the baking plate circulating mechanism, theegg roll forming mechanism and a discharging mechanism; automatic production of egg rolls is achieved; and the production efficiency is greatly improved. The baking plate mechanism is fixedly arranged on the baking plate circulating mechanism; opening and closing of the baking plates are achieved under driving of the baking plate circulating mechanism; the baking plate mechanism is matched with the grouting mechanism to make the egg roll wrappers; and the consistency of the egg roll wrappers is effectively improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Baking sheet with slide-off ramp

Owner:LIFETIME BRANDS

Food product and method and apparatus for baking

ActiveUS20120074122A1Less timeLess energyEnvelopes/bags making machineryCharge supportsColloidal silicaCooking & baking

Provide an oven and optional cooking accessories having a high emissivity thermal protective layer on a substrate surface which comprises a metal or ceramic. The layer comprises from about 5% to 30% of an inorganic adhesive, from about 45% to 92% of at least one filler, and from about 1% to 25% of one or more emissivity agents; or from about 5% to 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to 79% of at least one filler, and from about 1% to 25% of one or more emissivity agents.

Owner:EMISSHIELD +1

Silica gel ovenware and its preparing process

The invention discloses gel silica baking pot and its preparation methods. The gel silica baking pot the invention is formed by adopting combination molding pressing or ejecting and sulfurizing of multi-component, and its composition are silicone rubber, thermal conductivity agent, vulcanizing agent. Gel silica baking pot using the technology program of the invention, under the same conditions, the cake or bread using the present product has better sallow effects than that using traditional gel silica baking pot, and in particular, makes shape, color and taste of the baked cake have the same desired effect as that of the traditional metal baking pot.

Owner:张进德

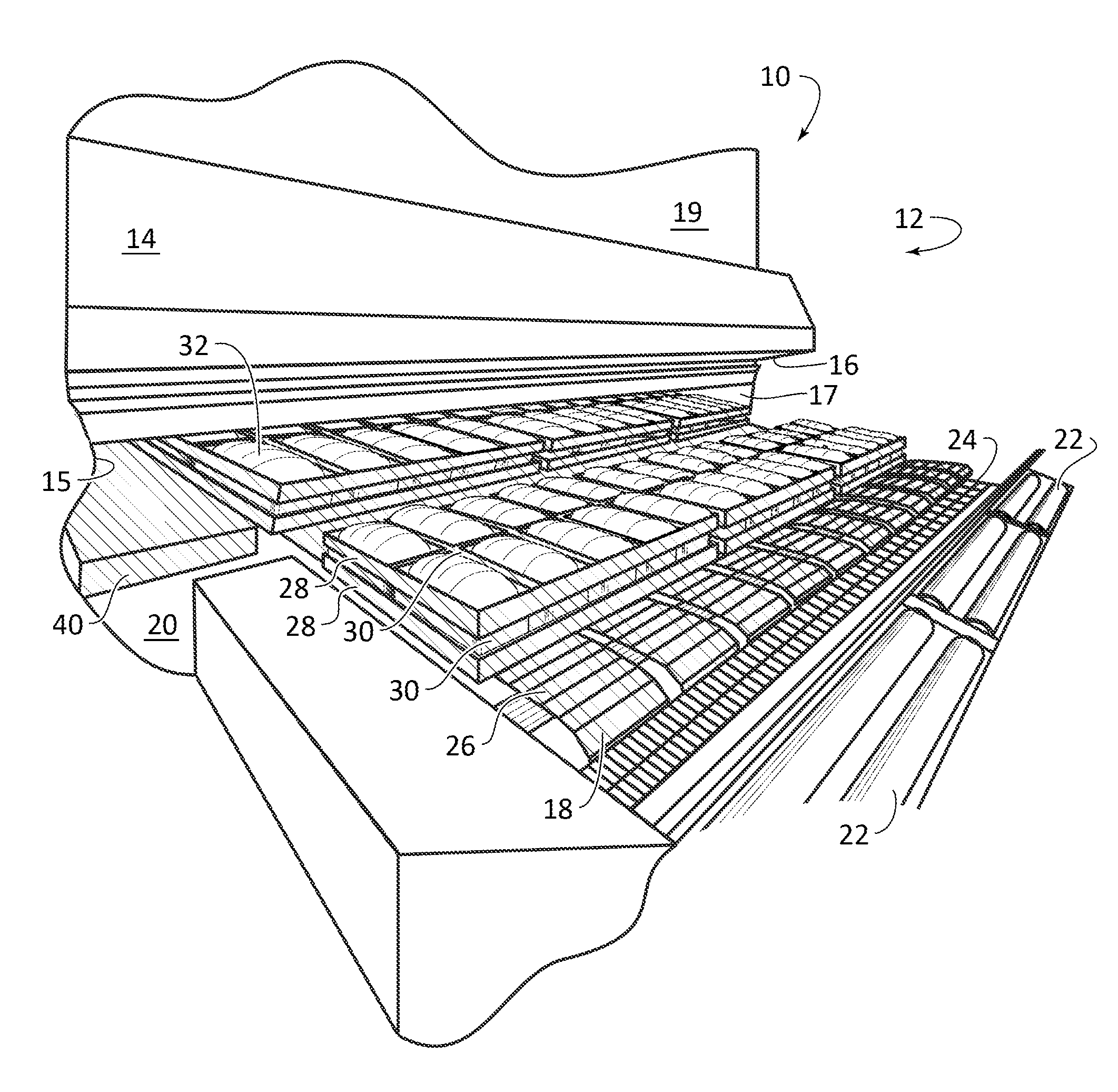

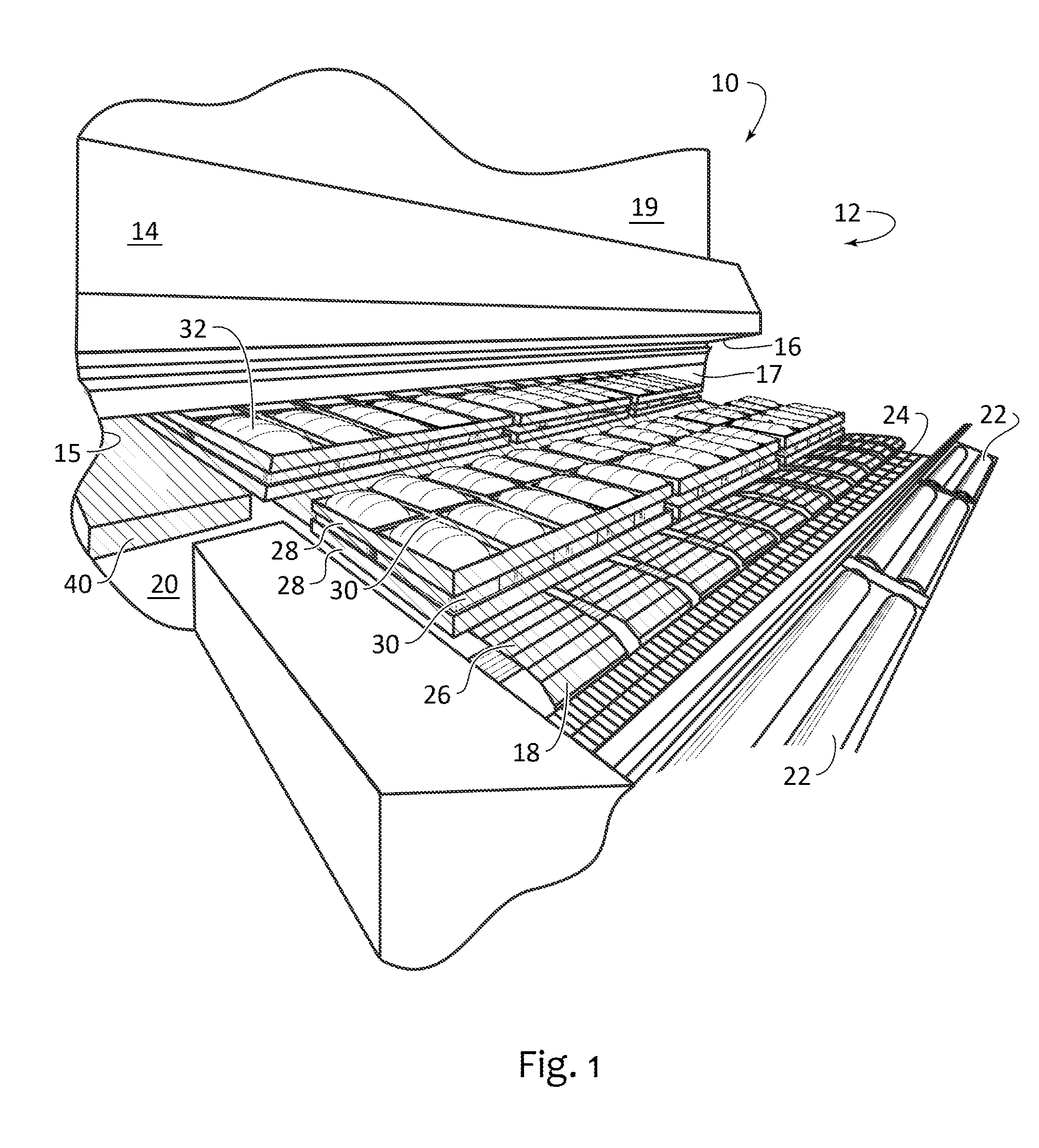

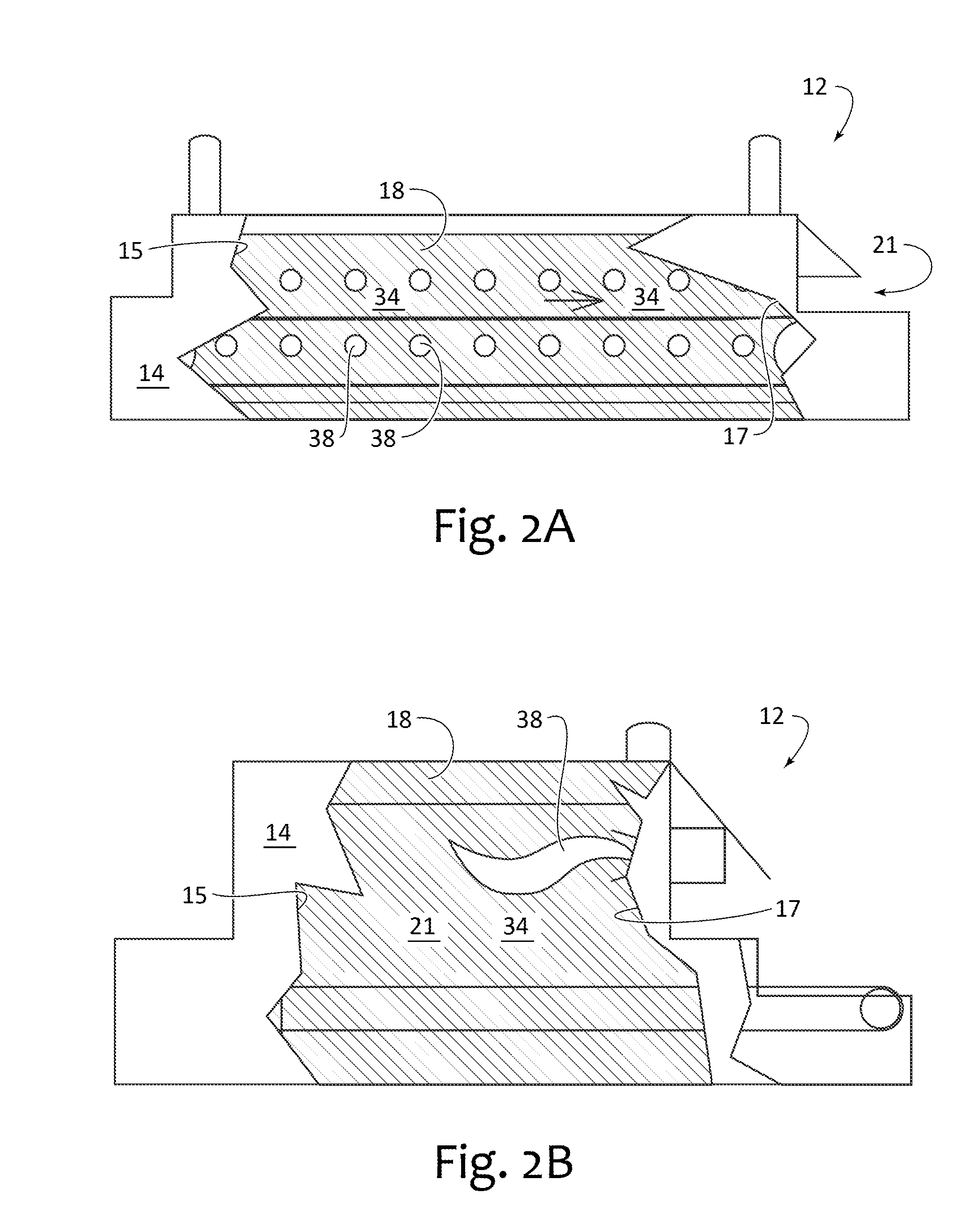

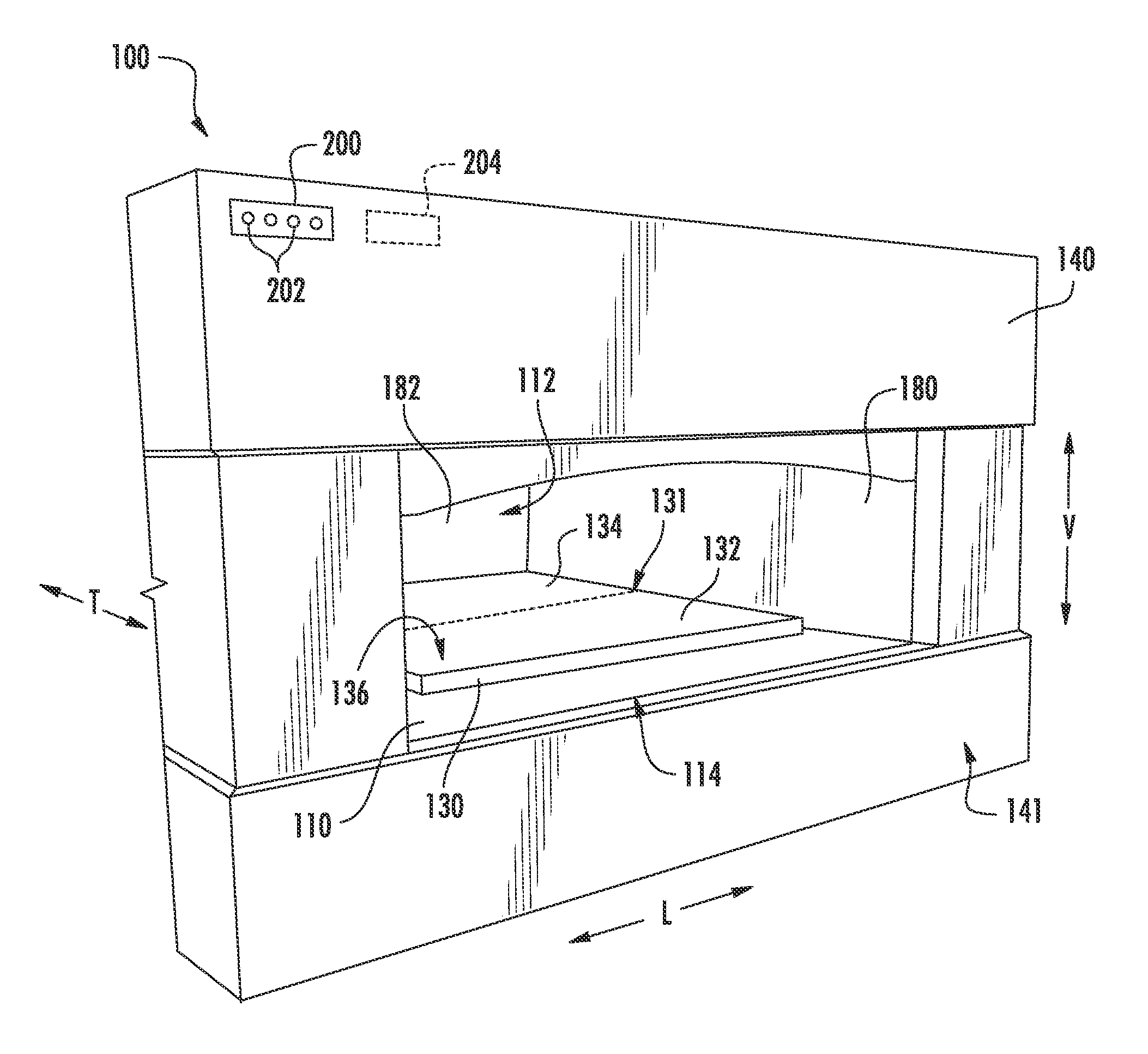

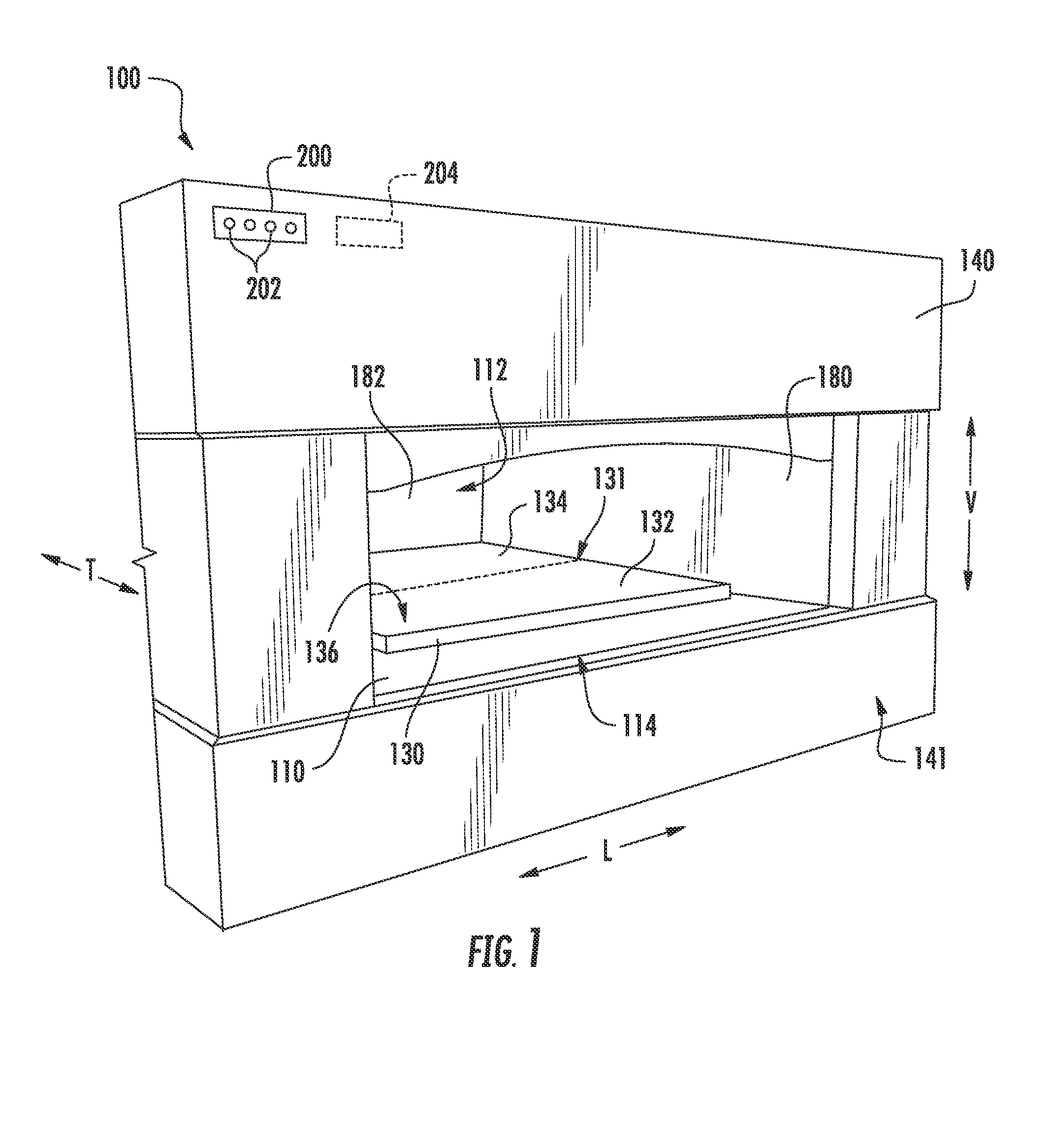

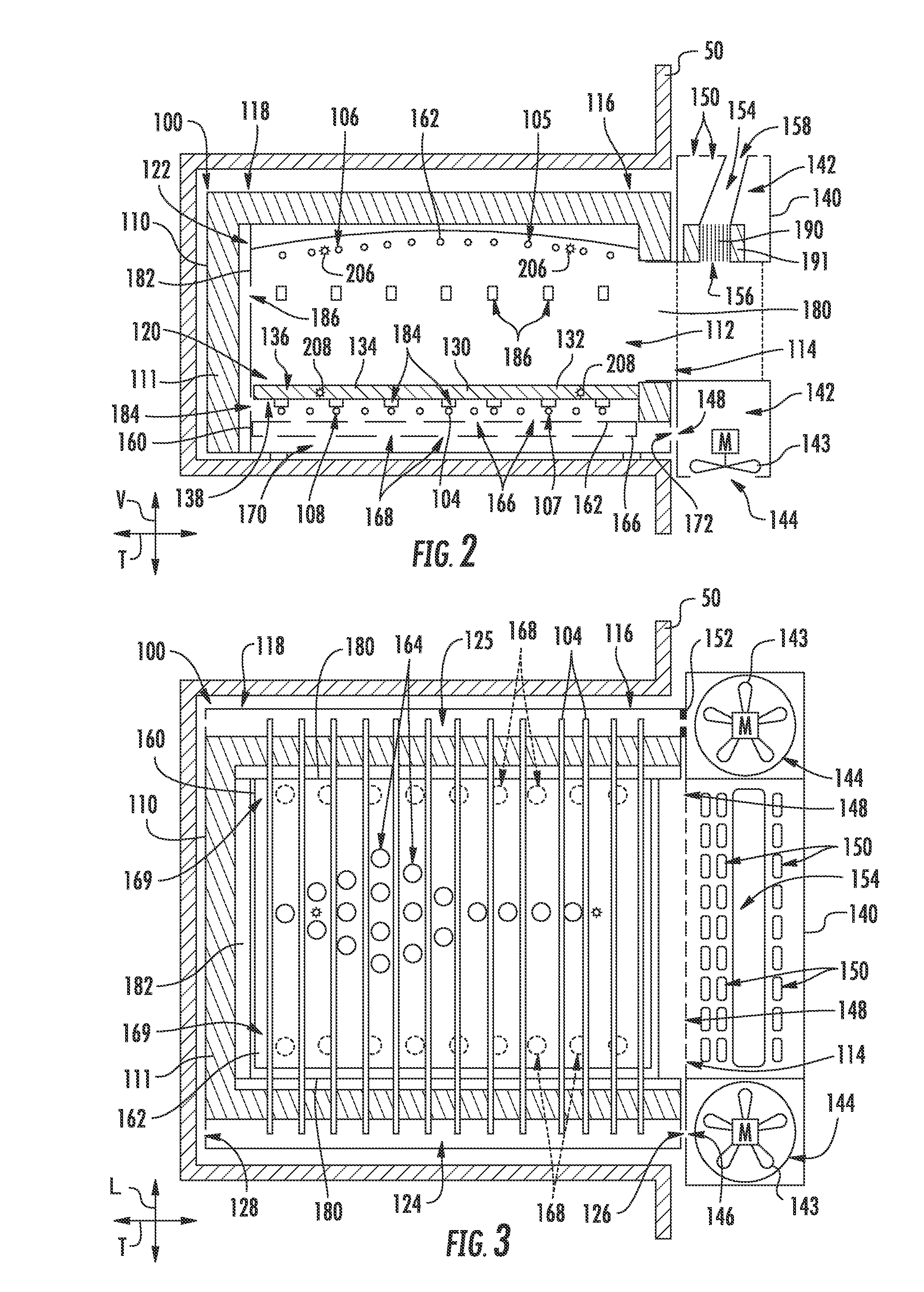

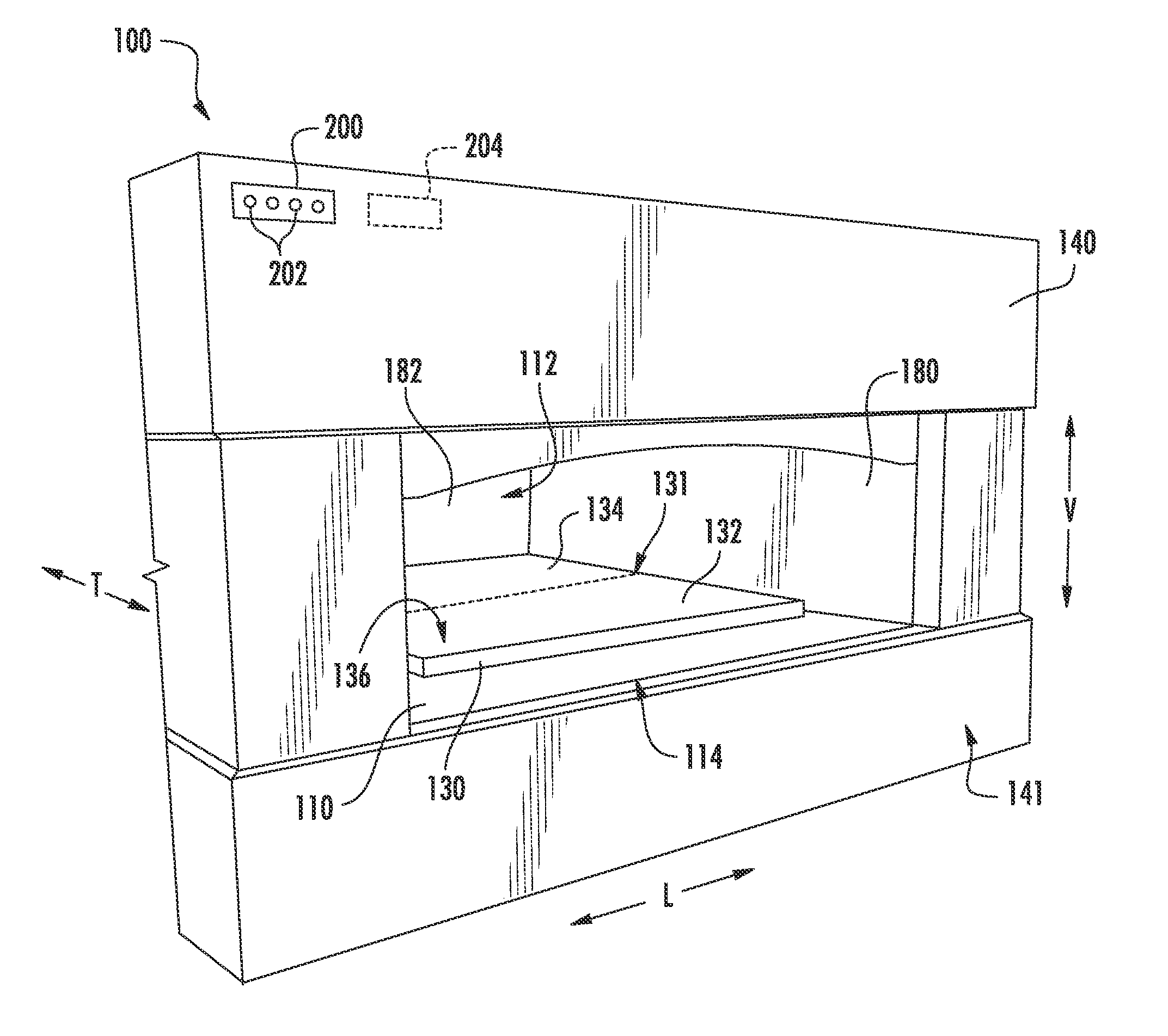

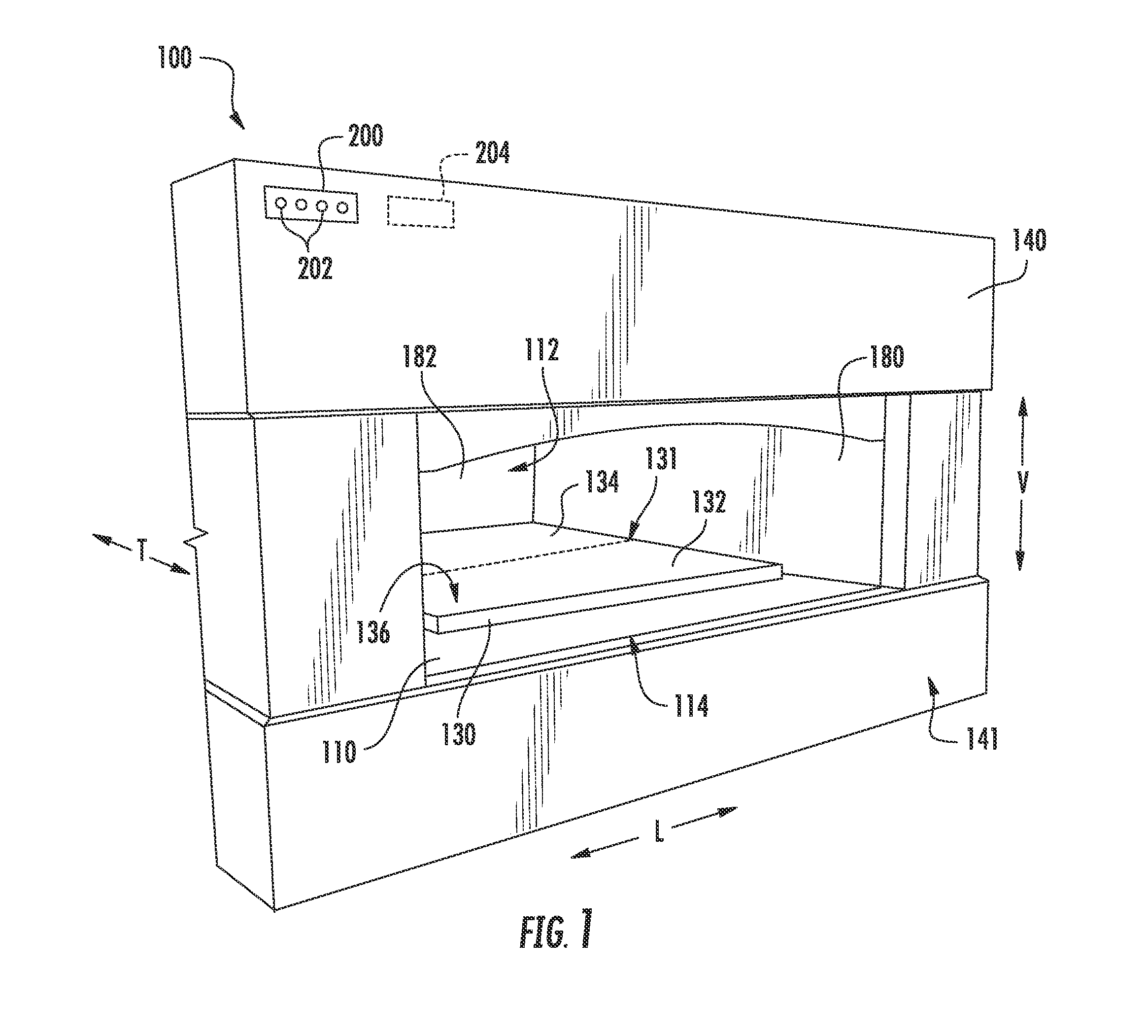

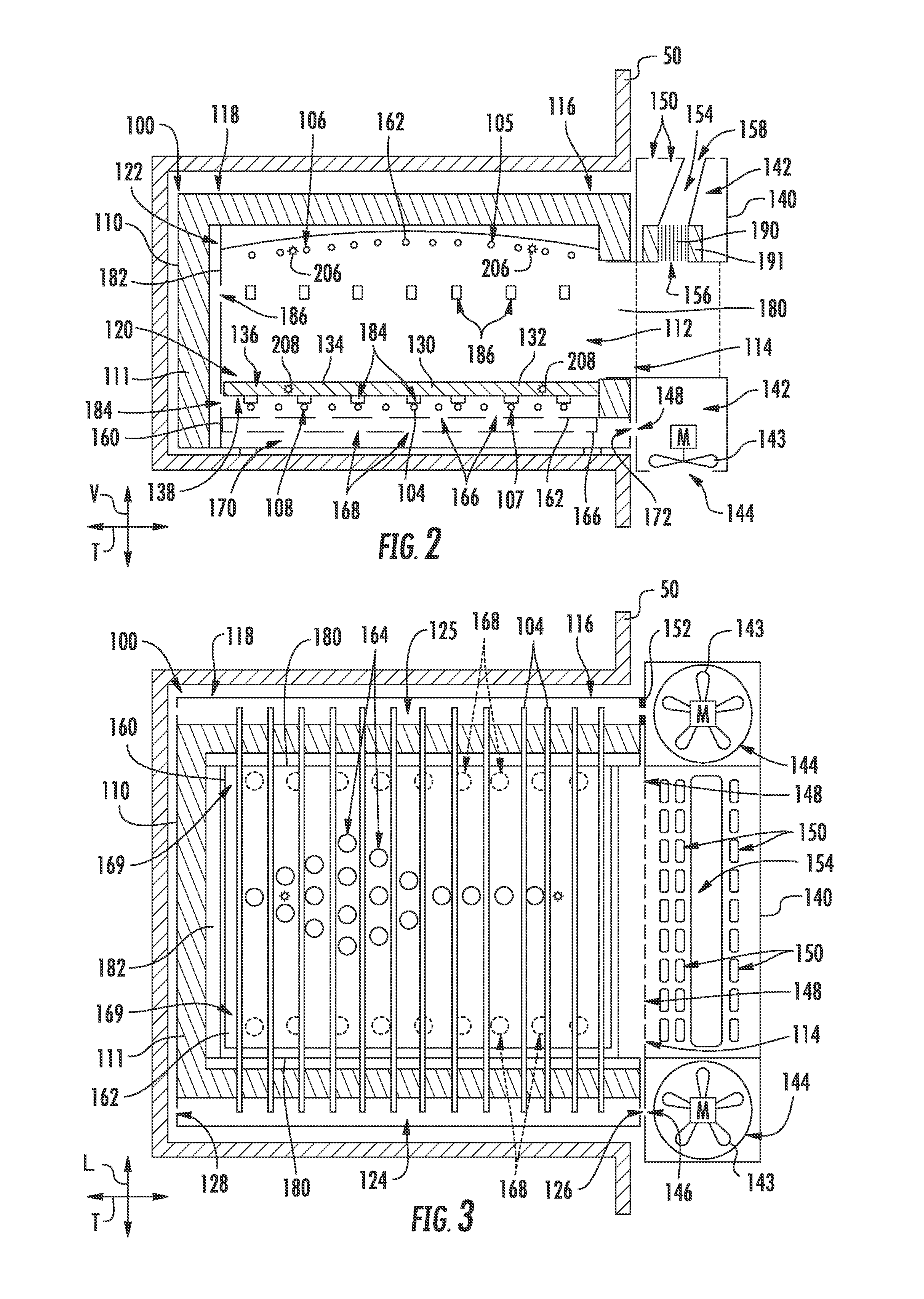

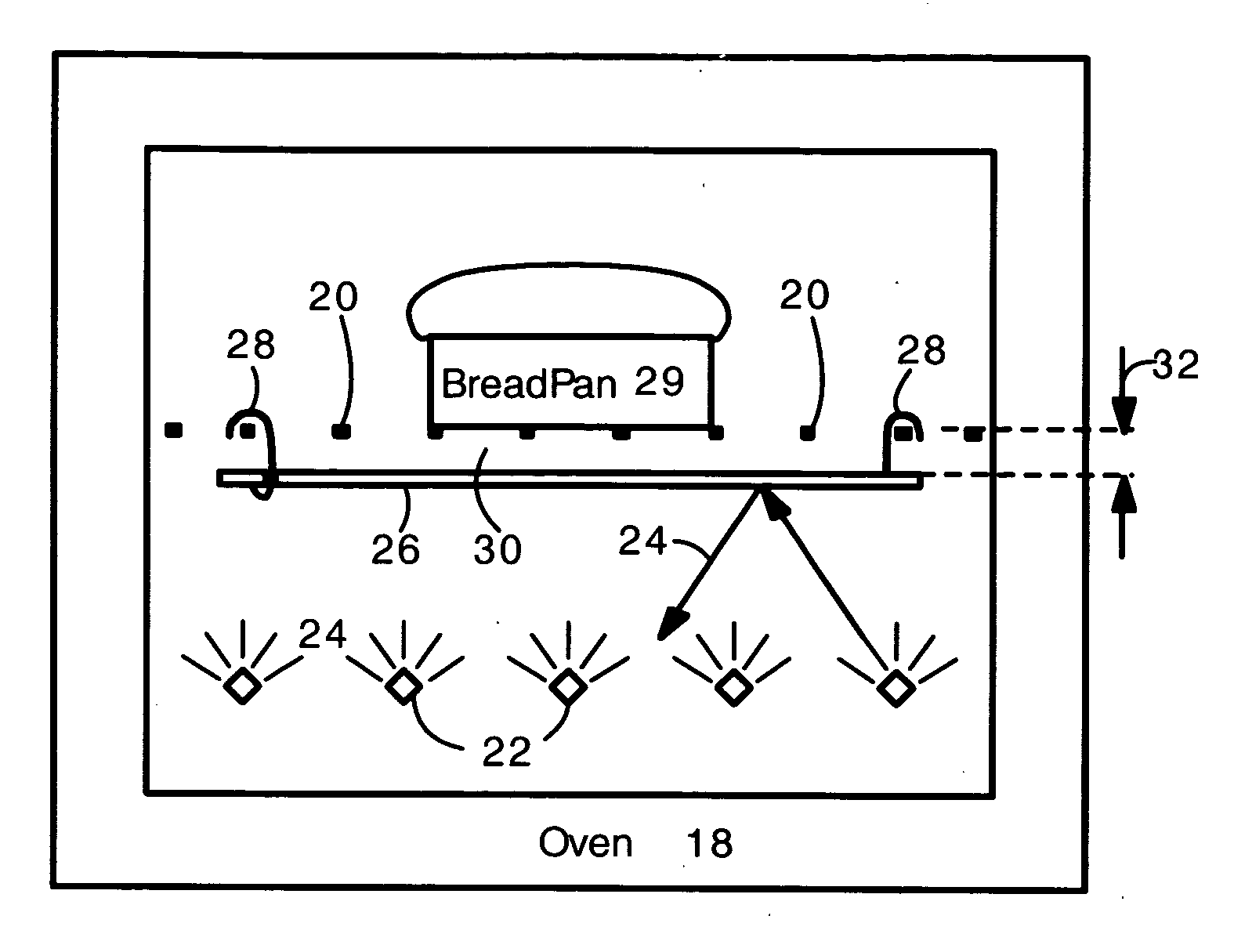

Oven appliance

ActiveUS20170055535A1Domestic stoves or rangesLighting and heating apparatusEngineeringHeating element

An oven appliance includes a baking stone positioned within a housing at a bottom portion of a cooking chamber. A baffle is positioned within the housing below a lower heating element array. The baffle includes an upper plate and a lower plate. Holes of the upper plate are offset from holes of the lower plate. The holes of the lower plate are contiguous with a regulating air duct of the housing such that a flow of air enters the baffle through the holes of the lower plate. Regulating air exits the holes of the upper plate and is impinged onto a bottom surface of the baking stone in a pattern to regulate baking stone temperature.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Oven appliance

An oven appliance includes a baking stone positioned within a housing at a bottom portion of a cooking chamber. A controller is in operative communication with an upper heating element array, a lower heating element array, a pair of upper temperature sensors and a pair lower temperature sensors. The controller is configured for independently operating each of a first zone of the upper heating element array, a second zone of the upper heating element array, a first zone of the lower heating element array and a second zone of the lower heating element array.

Owner:HAIER US APPLIANCE SOLUTIONS INC

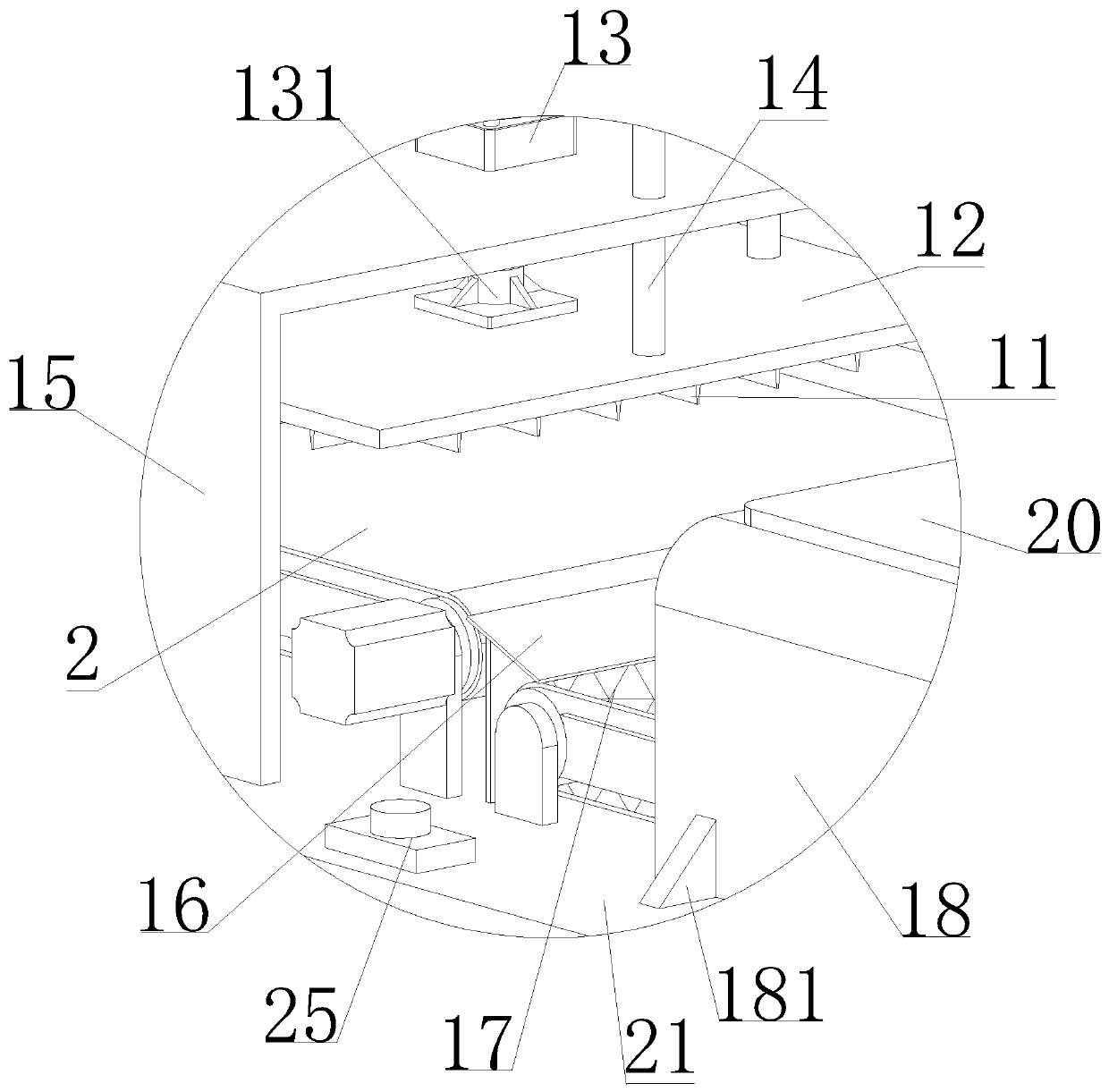

Full-automatic egg roll making machine

PendingCN112120048AImprove processing efficiencySimple structureOil/fat bakingPancakes bakingElectric machineryMachine

The invention belongs to the technical field of egg roll processing equipment, and particularly discloses a full-automatic egg roll making machine. The full-automatic egg roll making machine comprisesa mounting frame, wherein a rotary drum is connected to the mounting frame through a bearing, six reinforcing rods are symmetrically arranged at the front end of the rotary drum, six lower dies are evenly arranged on the rotary drum, an upper die is mounted on the lower dies through connecting shafts, and a pin is arranged on the upper die. The pin is mounted on the upper die through a first spring, a circular ring is arranged at the front end of the rotary drum, pin holes are correspondingly formed in the circular ring, a first motor is arranged on one side of the bottom end of the mountingframe, and a first cam and a second cam are arranged on a driving roller of the first motor; a first driving device and a second driving device are arranged on the mounting frame at the upper end of the first motor; and a sliding table is arranged on one side of the mounting frame, a pulley is arranged on one sides of the pin through a connecting rod, a rivet mechanism is arranged at the bottom end of the sliding table, and a feeding-discharging device is arranged on the right side of the mounting frame. The full-automatic egg roll making machine can automatically charge and discharge for eggroll processing and manufacturing, improves the egg roll processing efficiency, and is high in practicability.

Owner:上海尚记智能科技有限公司

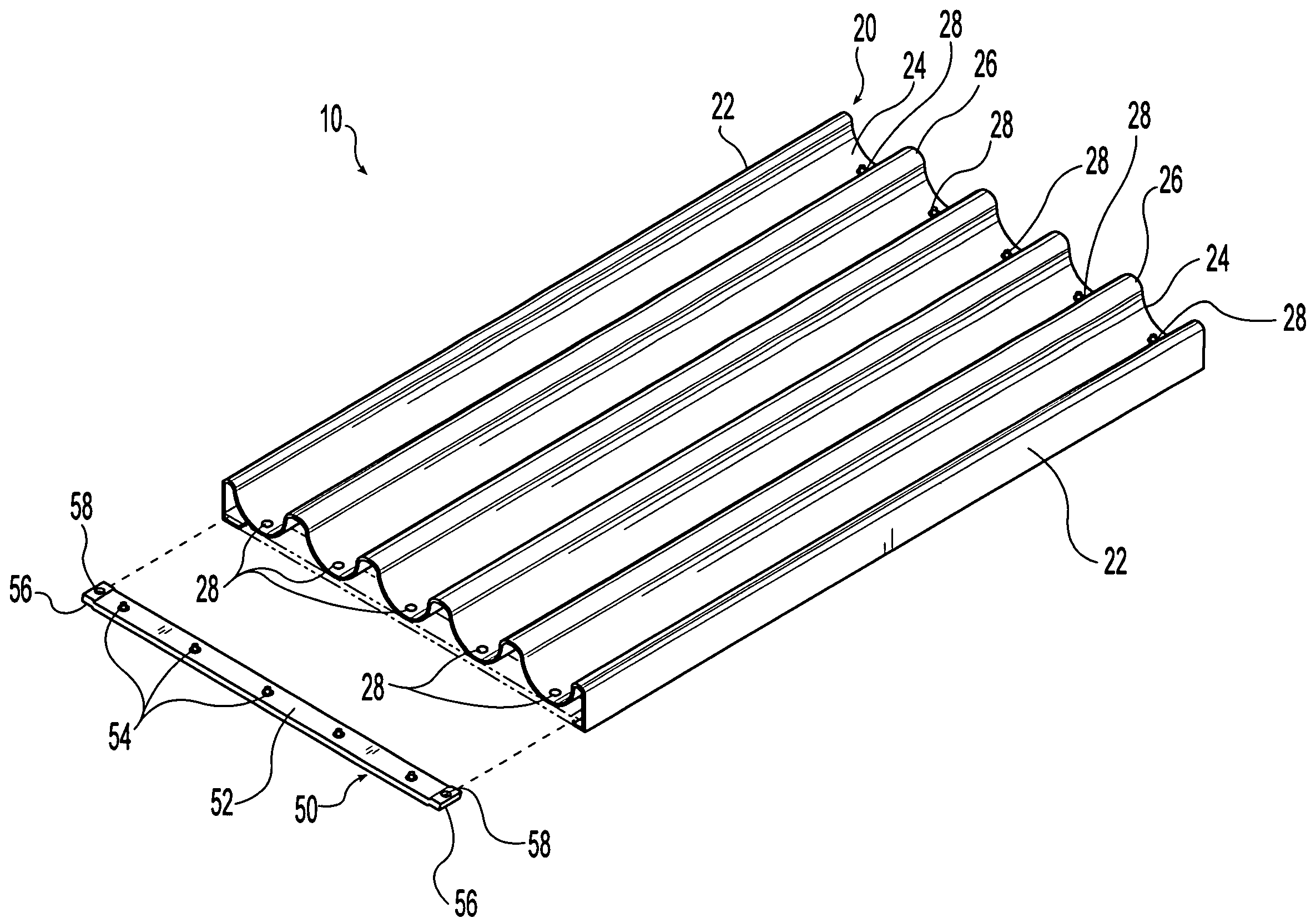

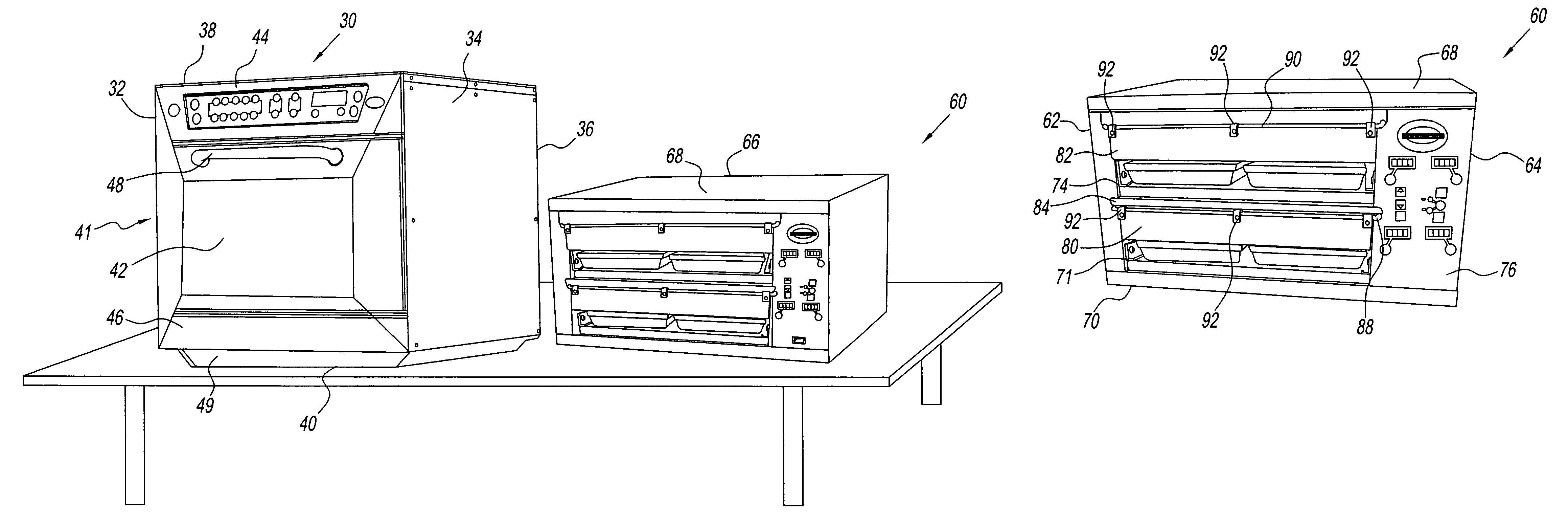

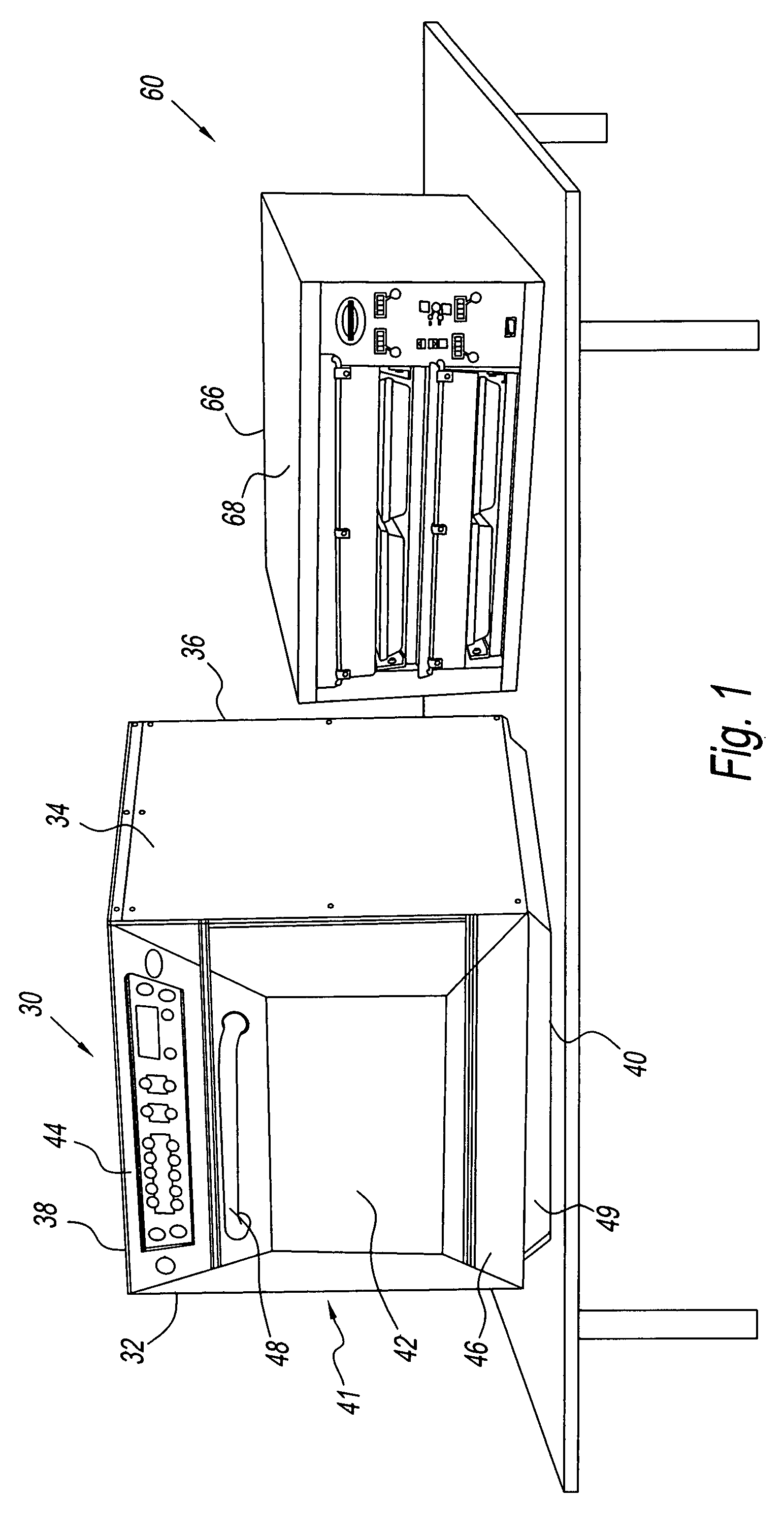

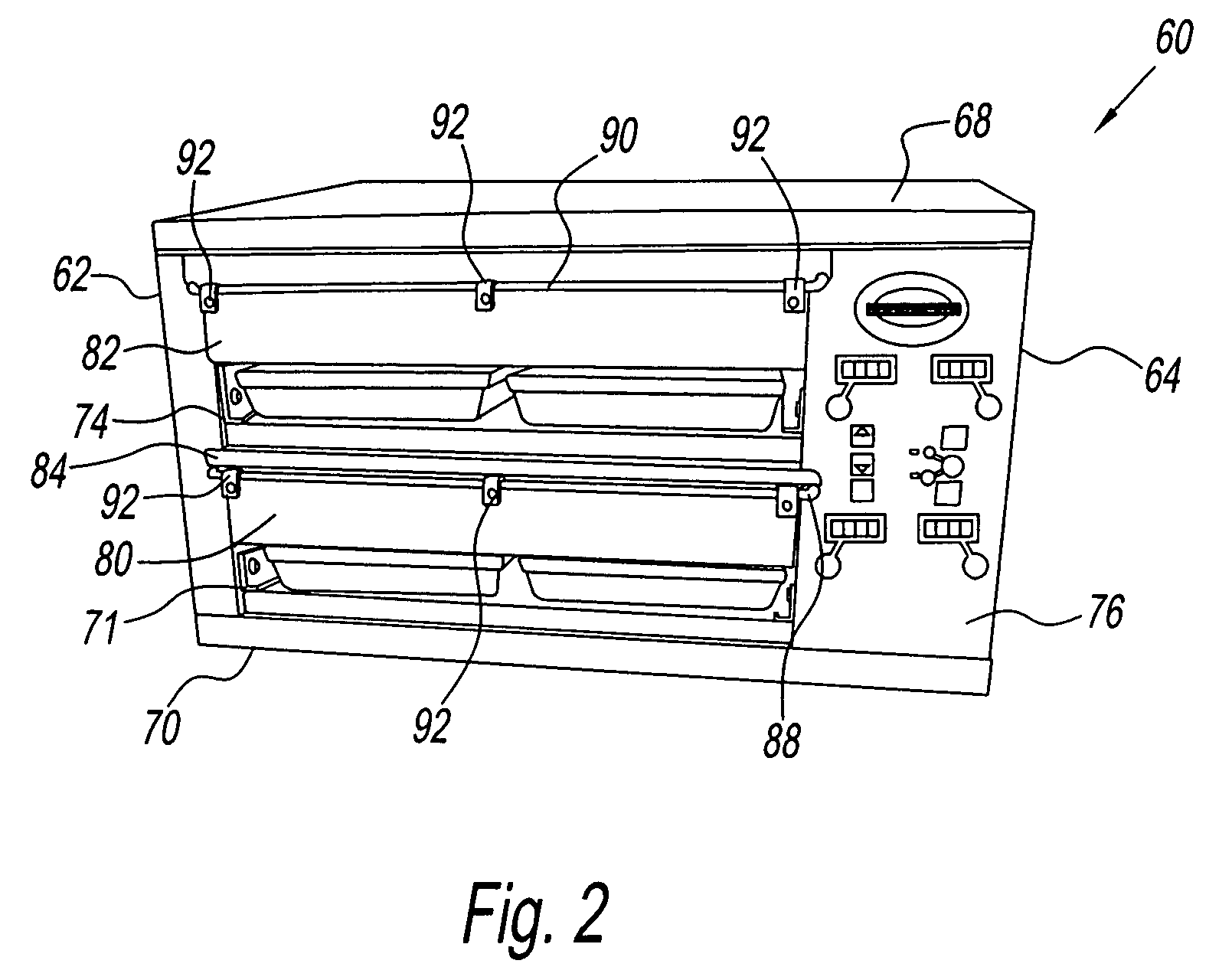

Cook and hold system and method with ribbed tray

A cook and hold system having an oven, a food warmer and a metallic food tray. The metallic food tray is used in the oven to hold the food products during cooking and then is rapidly transferred to the food warmer for holding. The food warmer has doors that cover the food warmer inlets so as to retain moisture and heat so that the food products are moist and warm when removed from the food warmer. The food tray has a bottom with parallel ribs that provide grill markings on the food products and a trapping of cook byproducts, such as moisture, grease and particles in the bottom spaces along side the ribs. These byproducts help to preserve heat and moisture when the food tray is transferred from the quick cook oven to the food warmer.

Owner:MERCOSAVORY

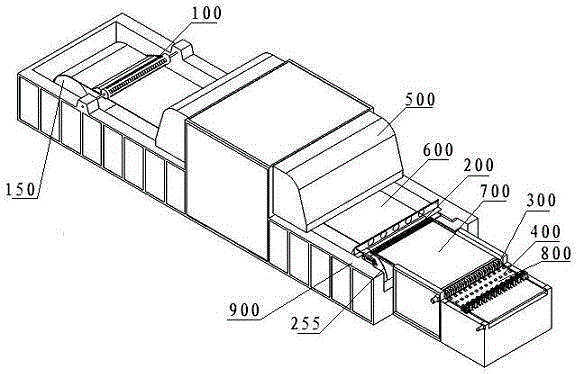

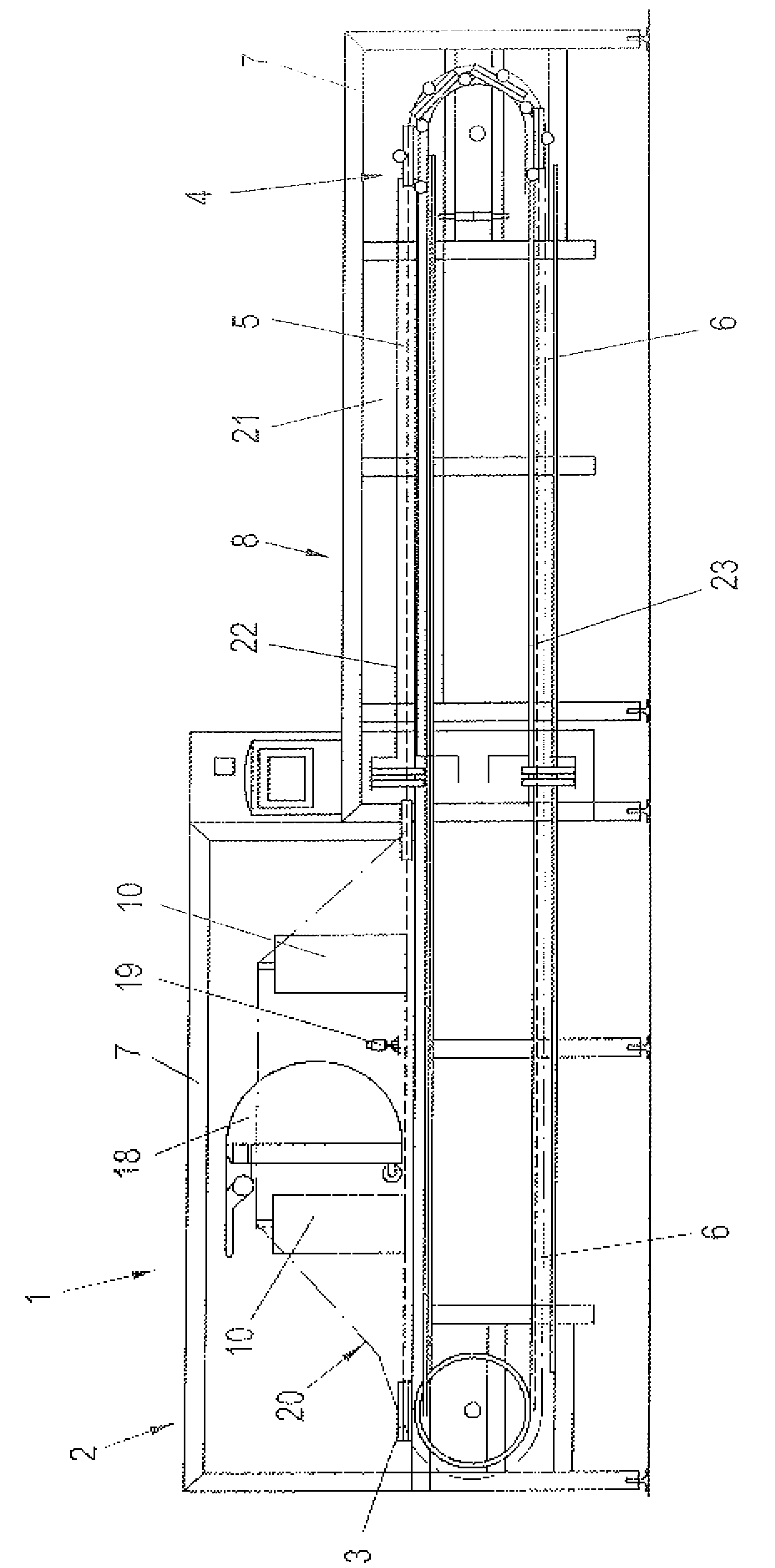

Tunneling-type food baking equipment

ActiveCN104381350ARealize switchingEasy to controlOven air-treatment devicesFood processingCooking & bakingEngineering

The present invention discloses a tunneling-type food baking equipment. In the baking chamber, there set up at least two sets of air outlets located on different side walls and the intake channel is divided into at least two sub-channels which are connected with corresponding air outlets in each group. The hot air flows into the concerted sub-channels from the intake channels through air ducting and into the baking chamber through the connected air outlets. Air outlets in each group are set up in columns and each column has vertically and parallel arranged multiple air outlets. Each air outlet stretches from side wall into the inside of the baking chamber with a gradual decreased interior diameter; at least one baking vehicle is set up in the baking chamber and the baking vehicle has vertically and parallel arranged multiple baking plates. The baking plates and the air outlets are vertically arranged in a dislocation to evenly bake the food on each baking plate.

Owner:DUOLUFA ENVIRONMENTAL PURIFY TECH FUJIAN

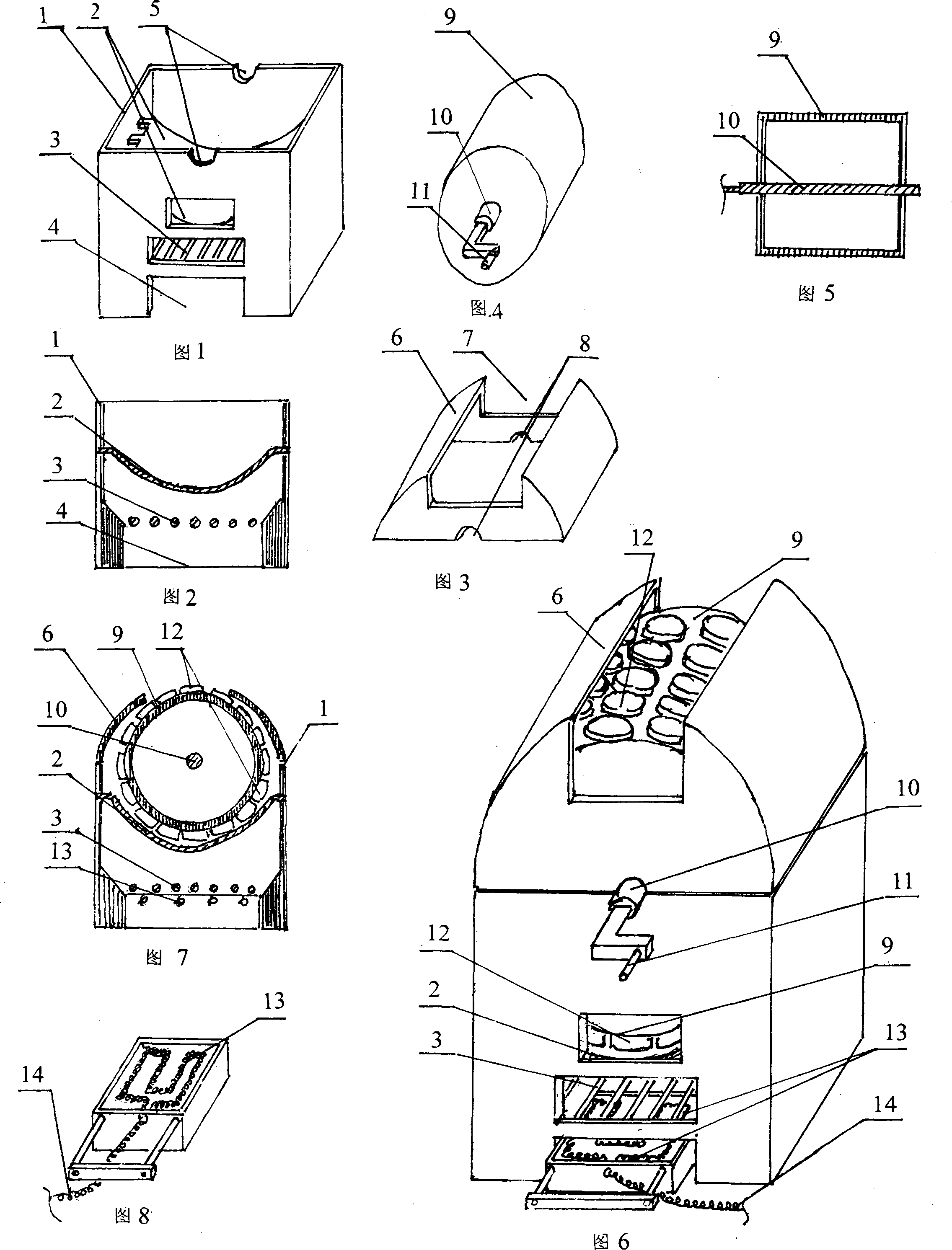

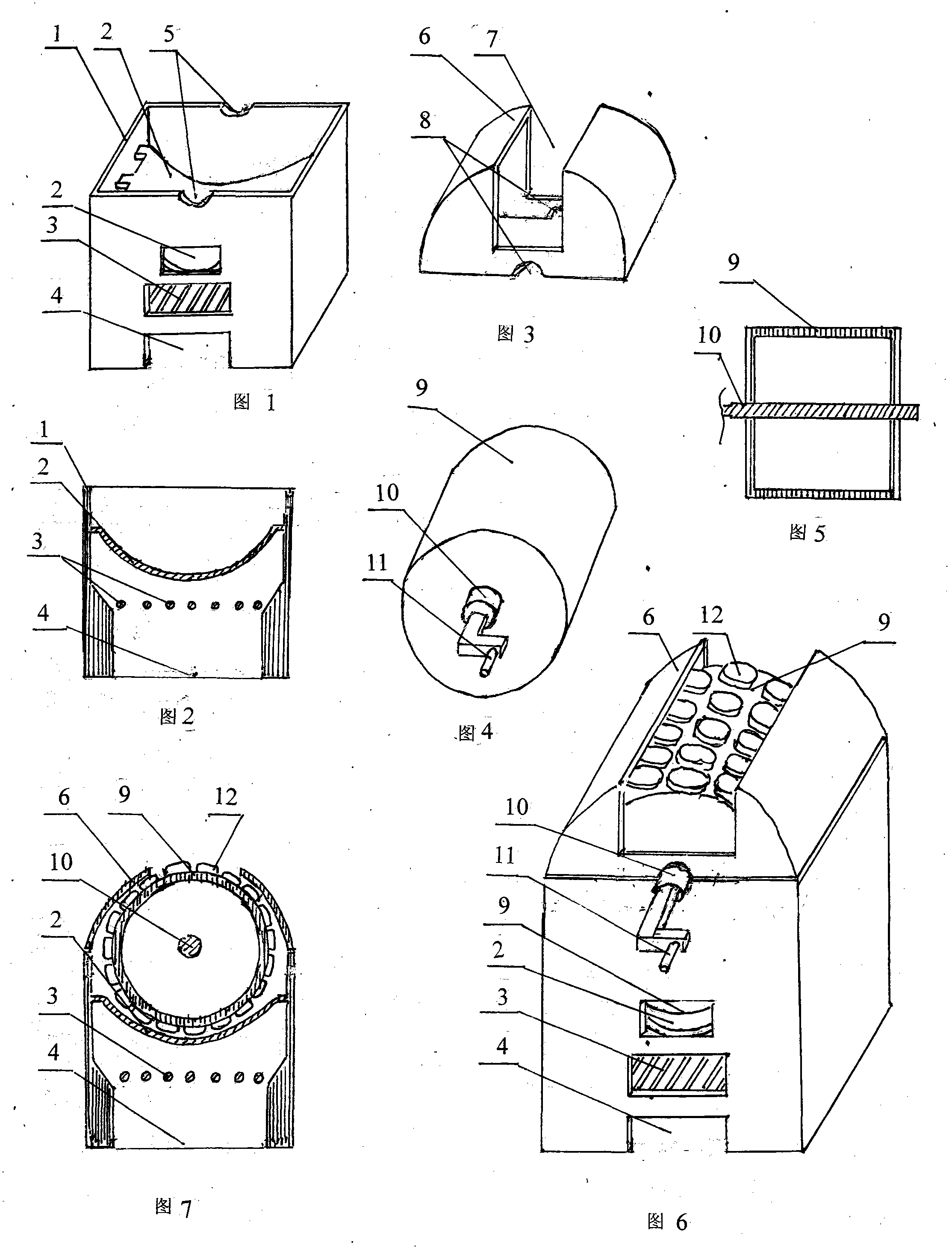

Sesame seed cake stove assisted by electric stove and provide with rotary shaft

The invention discloses a sesame seed cake stove assisted by an electric stove and provided with a rotary shaft. The sesame seed cake stove comprises a ceramic stove body, a ceramic hood and a ceramic baking and clinging shaft. The baking and clinging shaft is arranged on a hearth at an upper opening of the stove body, the hood covers a large portion of the baking and clinging shaft, and only a part of a baking and clinging surface of the baking and clinging shaft is exposed at a U-shaped notch in the hood, so that sesame seed cakes can be baked on the part of the baking and clinging surface of the baking and clinging shaft in a clinging manner. The sesame seed cake stove has the advantages that the labor intensity of operators can be greatly relieved; the heat-insulation performance of the stove body can be improved, burning charcoal can be controlled via the electric stove according to real-time requirements, accordingly, consumption of the charcoal can be greatly reduced, and the sesame seed cakes can keep unique flavor of sesame seed cakes baked by an urn type charcoal-burning stove.

Owner:QIDONG QINGQING VEGETABLE & FRUIT RURAL LAND STOCK PROFESSIONAL COOP

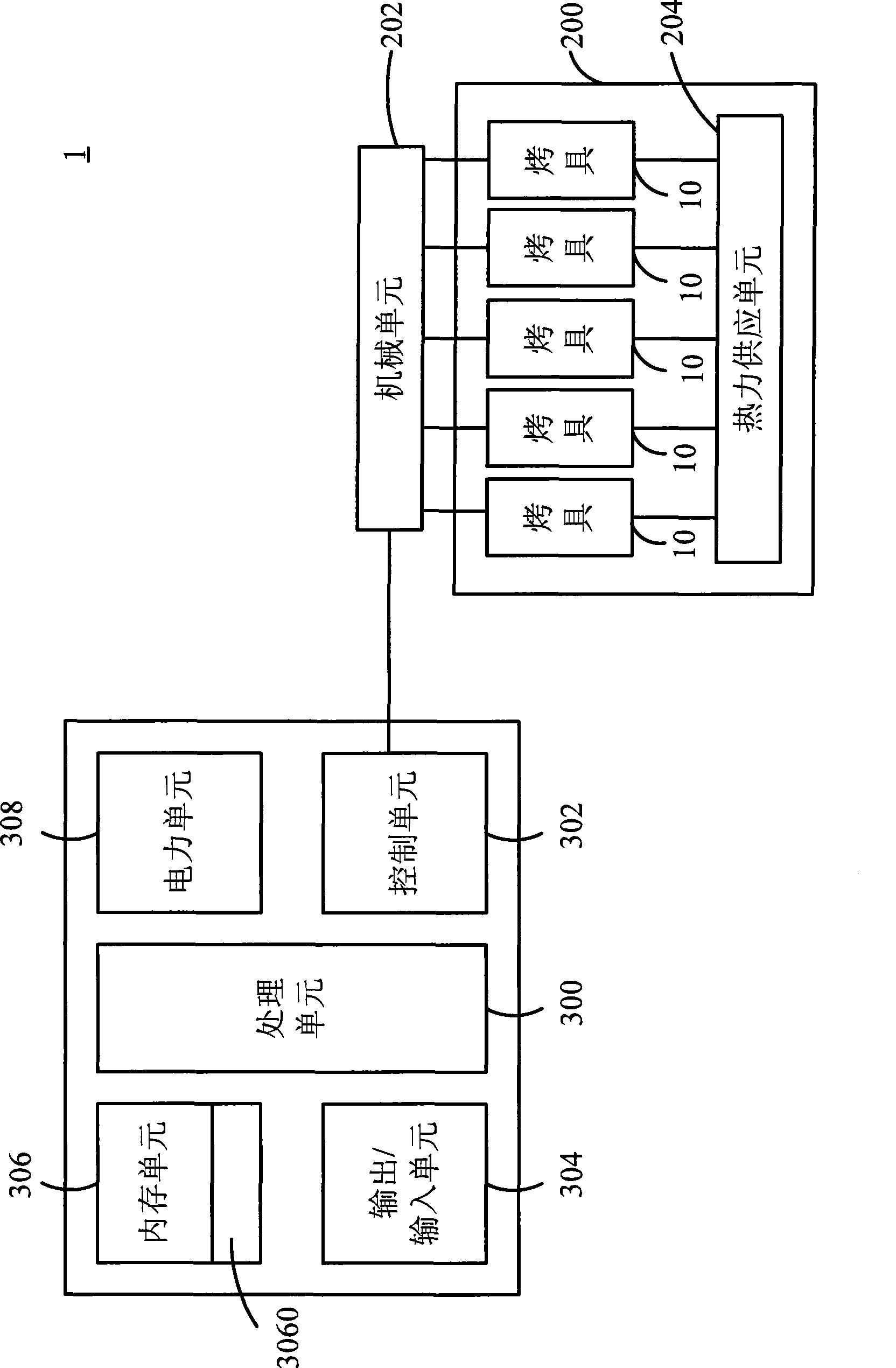

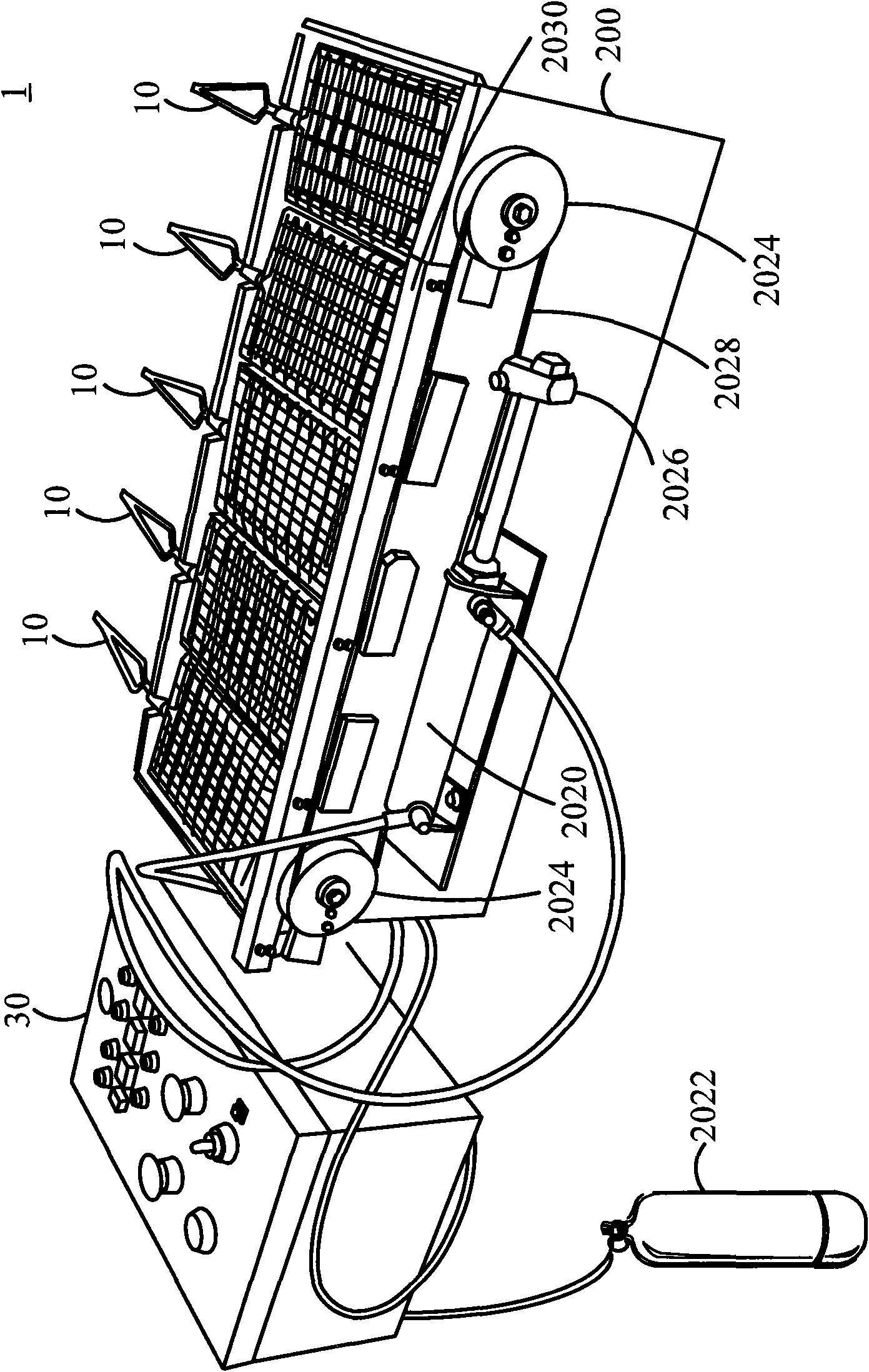

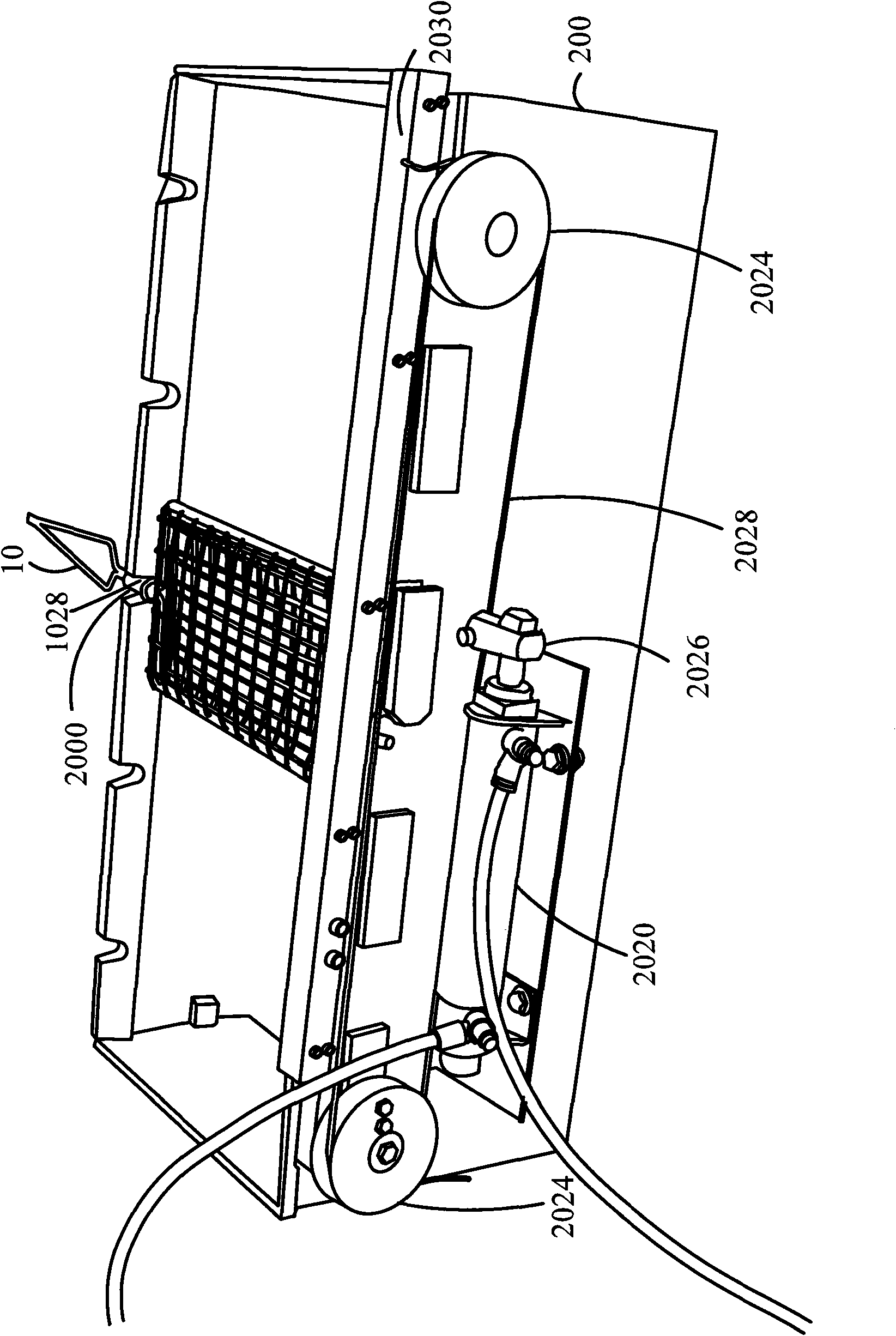

Electric barbecue system and executing method thereof and baking tool suitable for electric barbecue system

The invention provides an electric barbecue system and an executing method thereof and a baking tool suitable for the electric barbecue system. The electric barbecue system comprises at least one baking tool, a baking frame body used for bearing the baking tool, at least one mechanical unit, a processing unit, a control unit and an output / input unit, wherein the control unit is used for controlling the mechanical unit; the output / input unit is used for presetting control information; and the processing unit is used for controlling the action of the mechanical unit through the control unit according to the control information preset by the output / input unit to ensure that the mechanical unit drives the baking unit to rotate.

Owner:李建佑

Cooking Appliance With Baking Plate Having Embedded Heating Element

In a cooking appliance and method for baking a food product, the appliance has a generally solid plate member, a first heating element disposed above the solid plate member in spaced relationship therewith and a second heating element embedded in the solid plate member.

Owner:RAYOVAC CORP

Rotating-shaft-type baked wheat cake furnace

A rotating-shaft-type baked wheat cake furnace is composed of a ceramic furnace body, a ceramic furnace cover and a ceramic baking and pasting shaft. The ceramic baking and pasting shaft is arranged on a furnace hearth at an upper opening of the furnace body and mostly covered by the furnace cover, and a part of baking and pasting face is exposed only at a U-shaped notch of the furnace cover for pasting and baking operation of baked wheat cakes, so that labor intensity of practitioners can be reduced substantially; heat-insulating performance of the furnace body is improved, so that charcoal consumption can be remarkably reduced, and products can be enabled to maintain unique flavor of the baked wheat cakes produced by a vat-type charcoal burning furnace.

Owner:NANTONG ZHONGYI BOILER EQUIP

Food product and method and apparatus for baking

ActiveUS8840942B2Less timeLess energyEnvelopes/bags making machineryDough treatmentColloidal silicaCooking & baking

Provide an oven and optional cooking accessories having a high emissivity thermal protective layer on a substrate surface which comprises a metal or ceramic. The layer comprises from about 5% to 30% of an inorganic adhesive, from about 45% to 92% of at least one filler, and from about 1% to 25% of one or more emissivity agents; or from about 5% to 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to 79% of at least one filler, and from about 1% to 25% of one or more emissivity agents.

Owner:EMISSHIELD +1

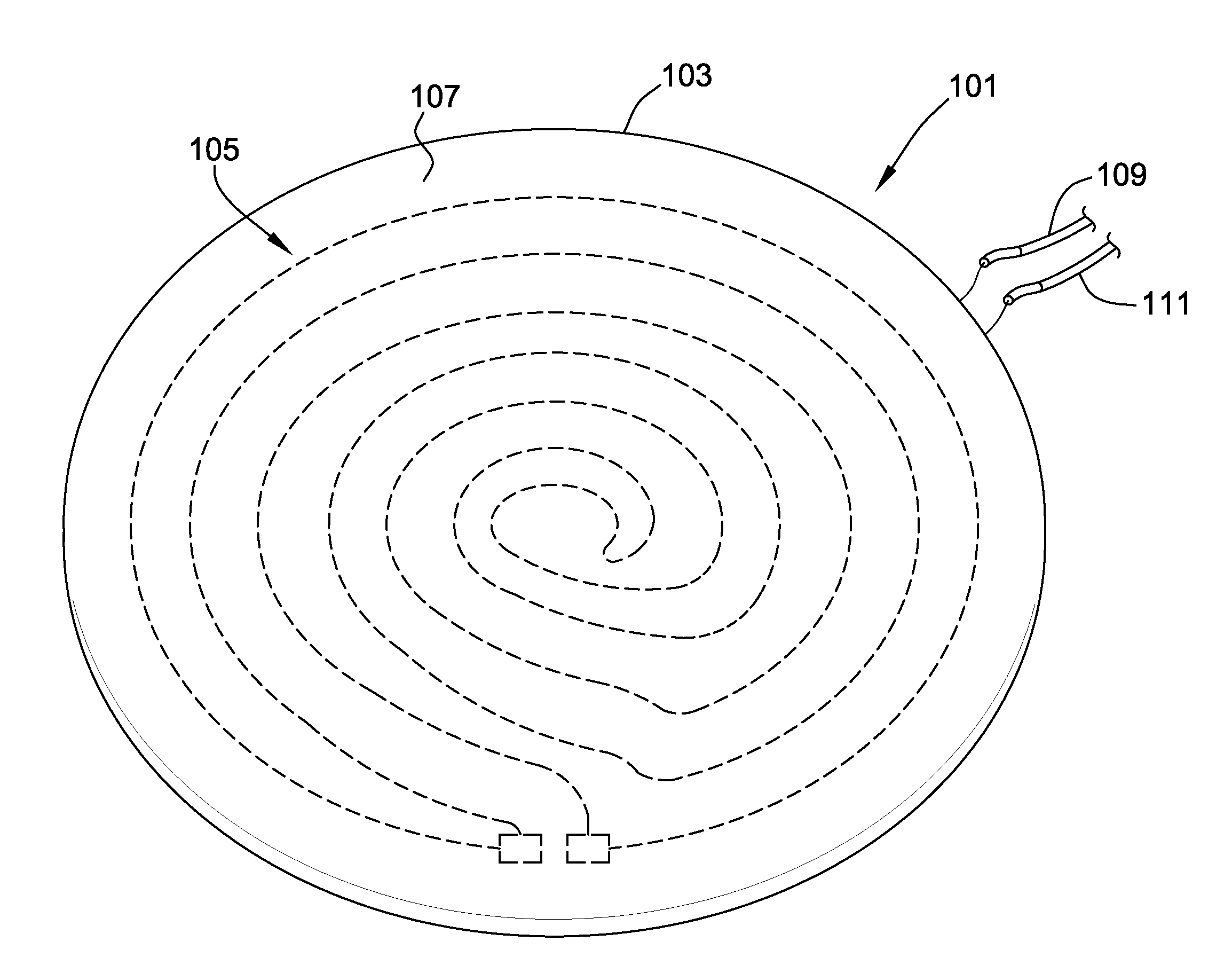

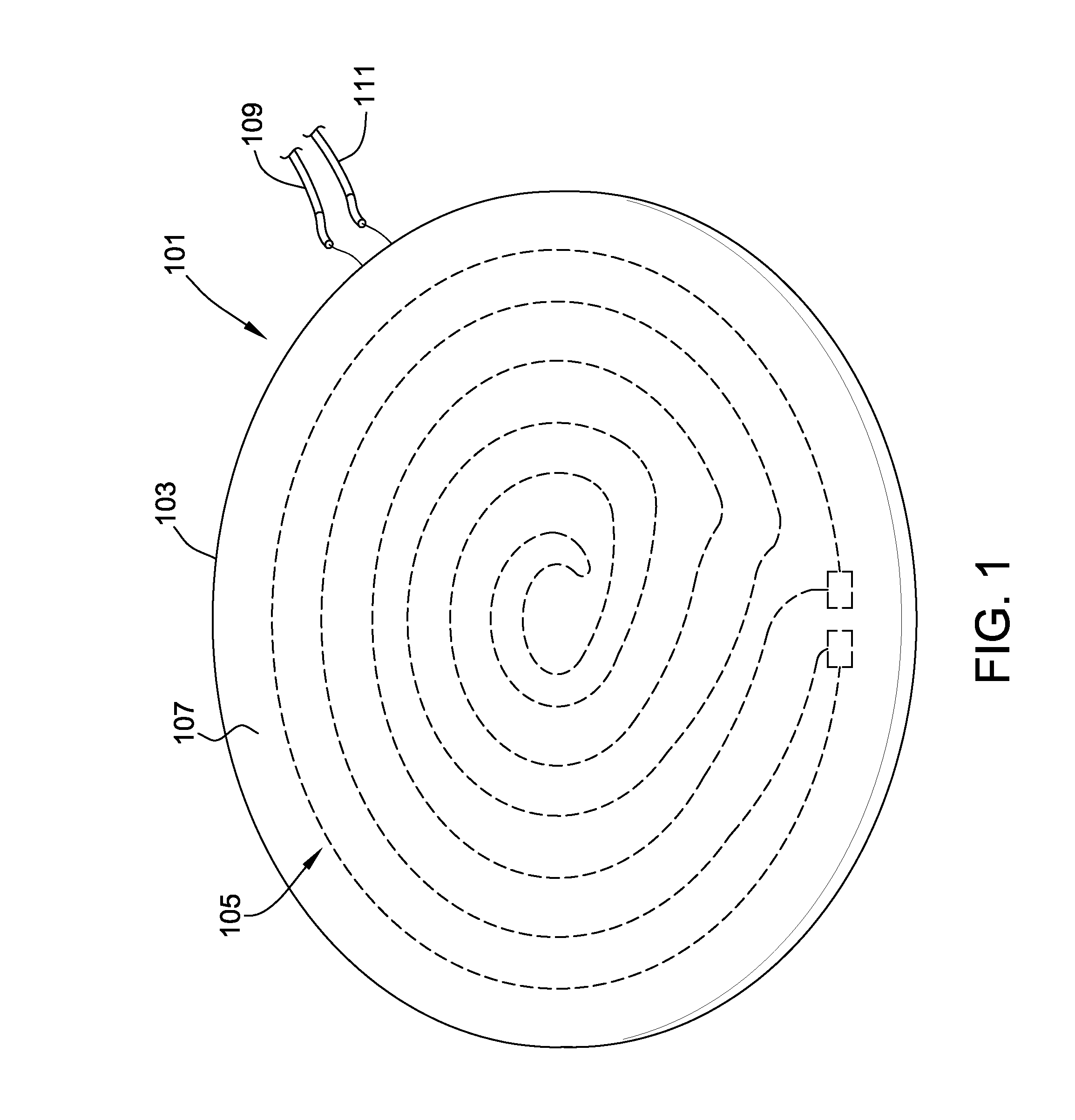

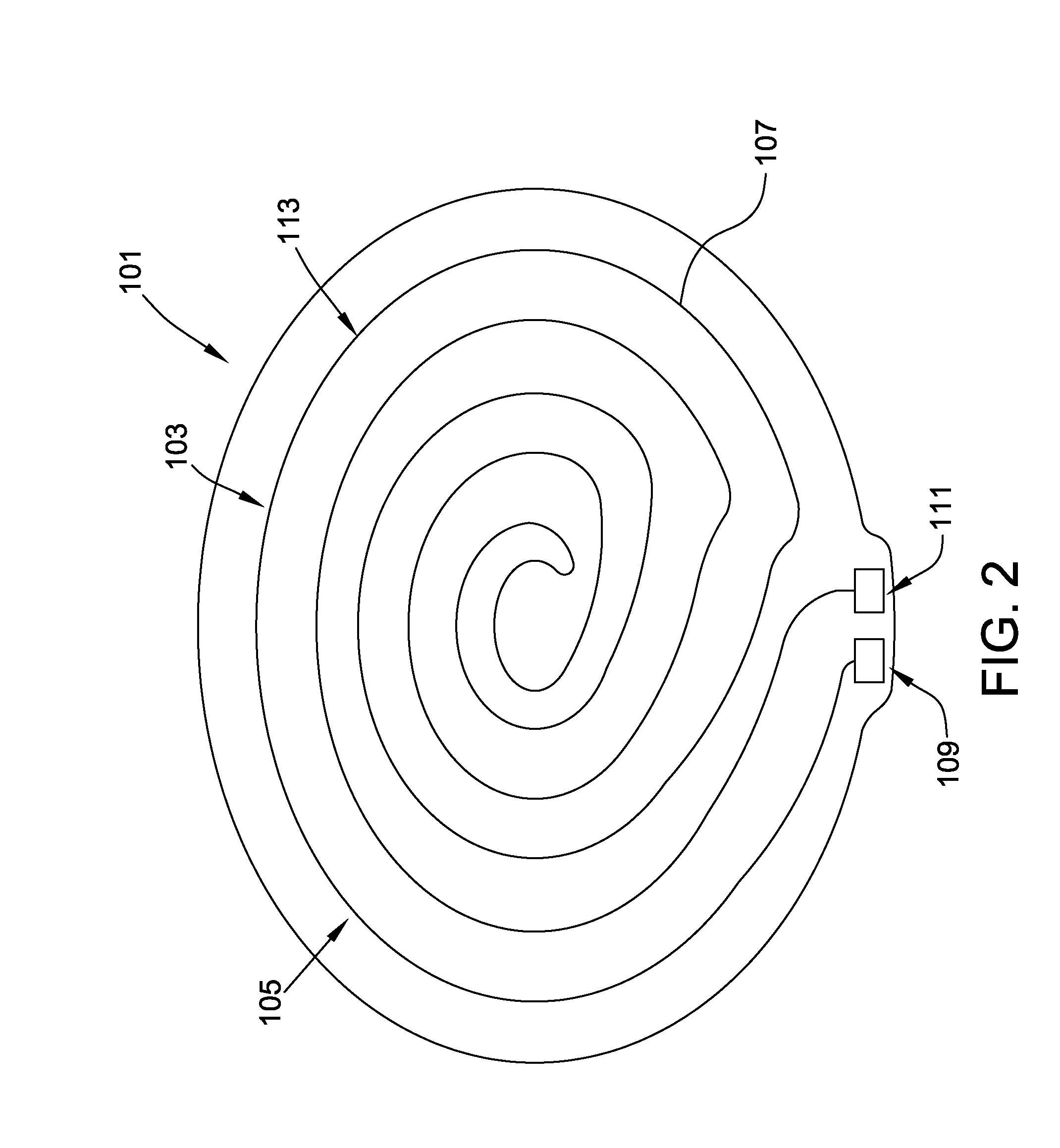

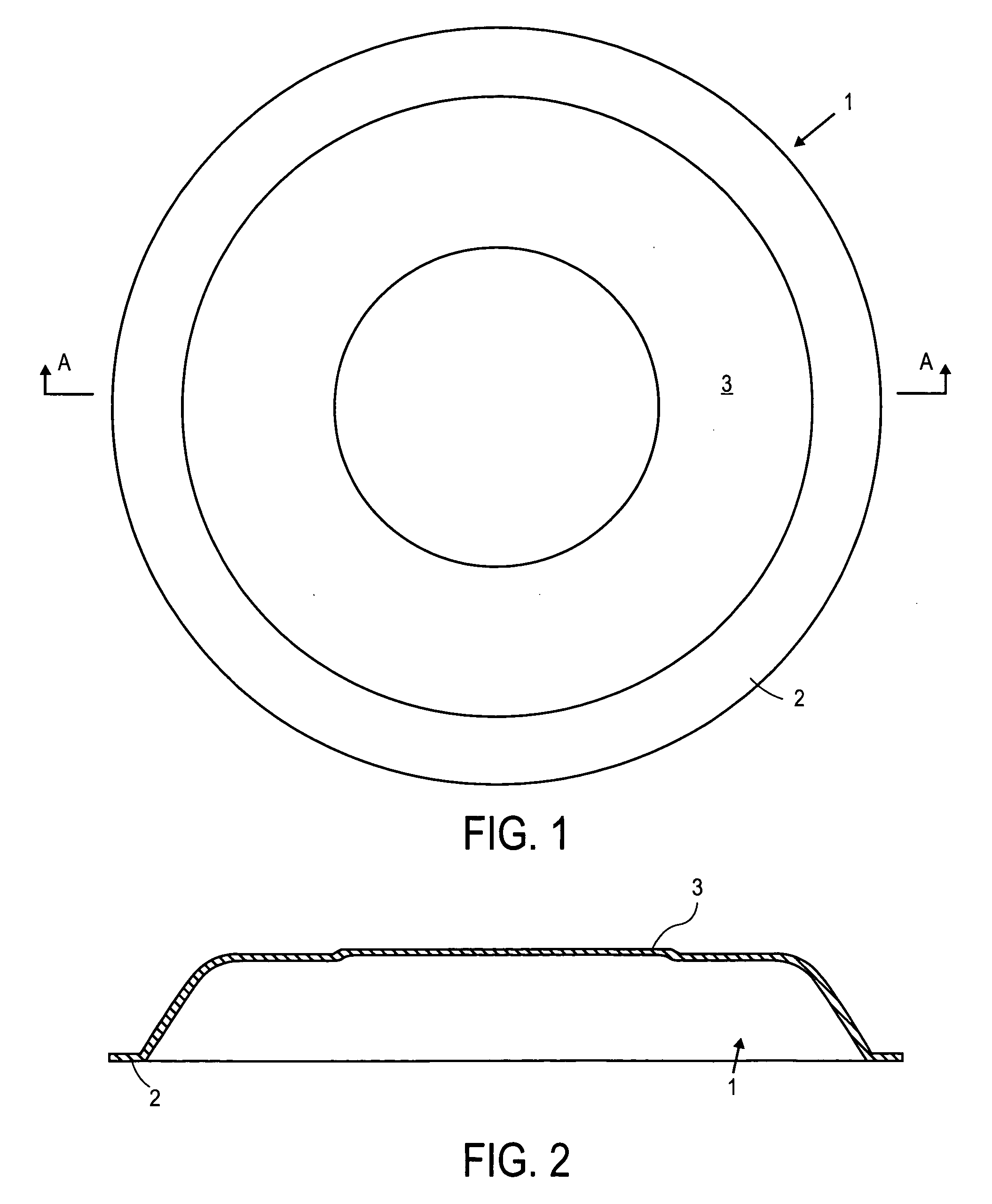

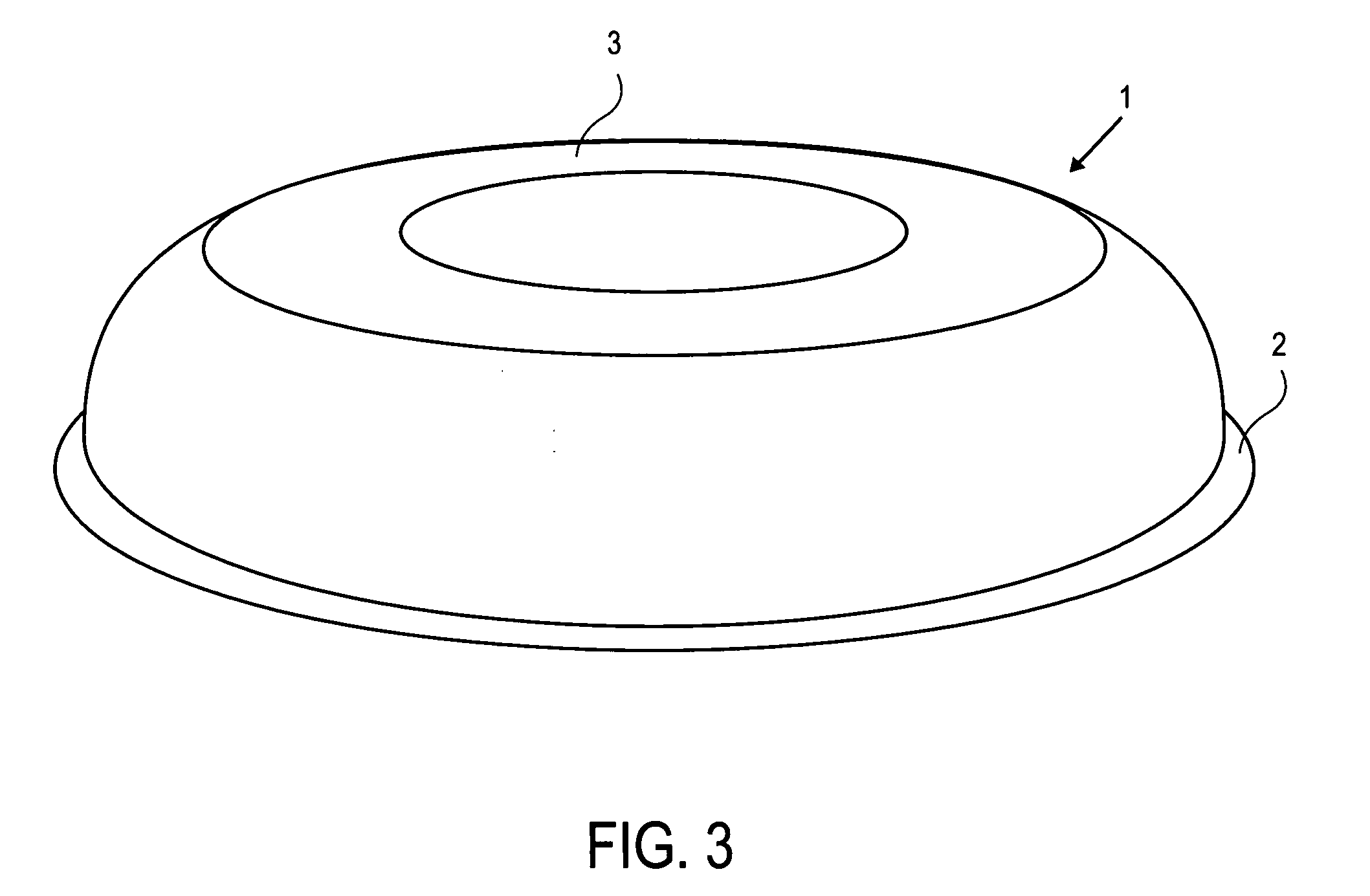

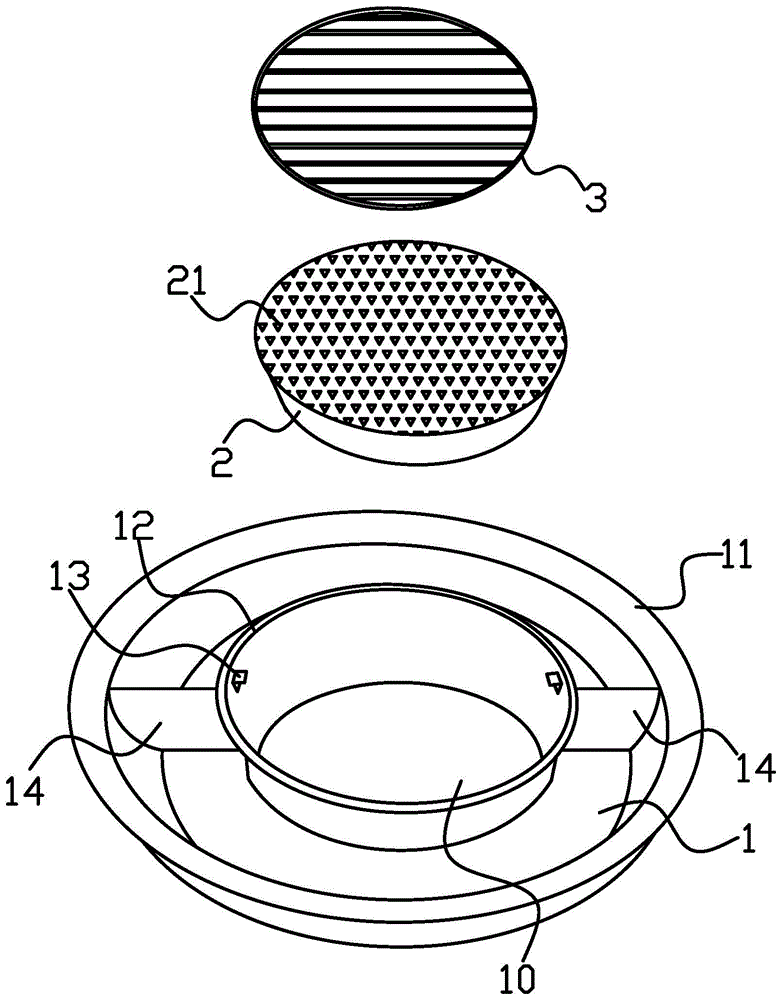

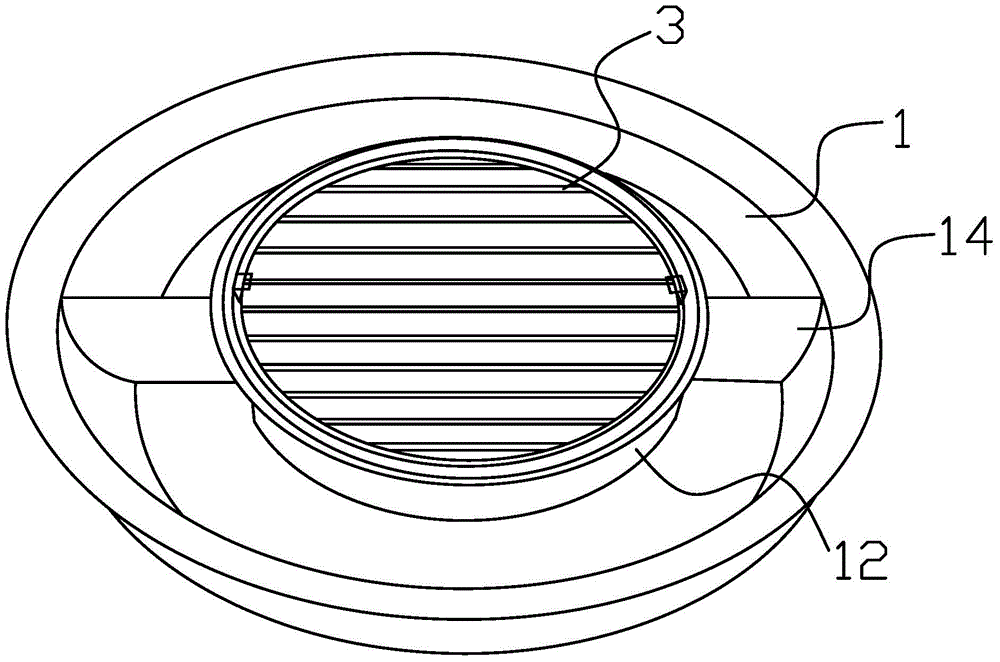

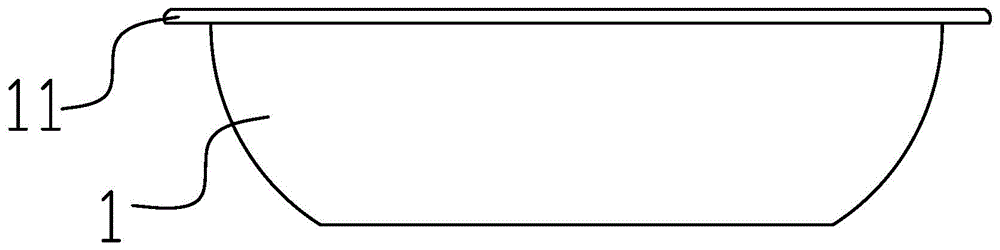

Method and apparatus for cooking a pizza

InactiveUS20050175753A1Increase heatCook evenlyDough treatmentBaking vesselsEngineeringCooking process

The method of cooking a pizza comprising placing a pizza in an oven with at least the central region of the pizza resting upon a pizza supporting device having an upper supporting surface such that the central portion of the pizza is raised above the level of the peripheral region of the pizza during cooking by means of the upper supporting surface. A device 1 for performing the method comprises an upper supporting surface 3 for supporting at least a central region of a pizza such that said central region is raised above the level of the peripheral region of the pizza during cooking.

Owner:SMITH RAYMOND

Cooking aid

A cooking aid comprising a sheet of flexible burn resistant material and a composition disposed on one face of the sheet, the composition comprising a mixture of vegetable or animal oil with a melting point below 20° C., vegetable or animal fat with a melting point above 20° C., and one or more herbs, spices and flavour enhancers.

Owner:SOC DES PROD NESTLE SA

Multifunctional kitchenware

InactiveCN104433837AReduce heat transfer area lossGreat tasteRoasters/grillsBaking sheets/boardsEngineeringSoldering

The invention discloses multifunctional kitchenware. The multifunctional kitchenware comprises a pot body with a barbecuing hole in the bottom, a baffle plate connected with the edge of the barbecuing hole, and an air draft device, wherein a cavity for accommodating a soup is formed between the baffle plate and the inner chamber of the pot body; the baffle plate is arranged in an inclined way, so that the area of a zone defined by the upper side edge of the baffle plate is greater than that of the barbecuing hole; the pot body and the baffle plate are made of a copper material; the pot body and the baffle plate form an integral structure or are connected through lead-free soldering; the air draft device comprises an air draft opening formed above the pot body, an air draft pipeline connected with the air draft opening, and an exhaust fan connected with the air draft pipeline and provided with a fan silencer. The multifunctional kitchenware integrates instant-boiling and barbecuing functions and has the advantages of health, environment friendliness, high convenience for use and wide adaptability and the like.

Owner:FOSHAN SHUNDE BAOTONG METAL TECH

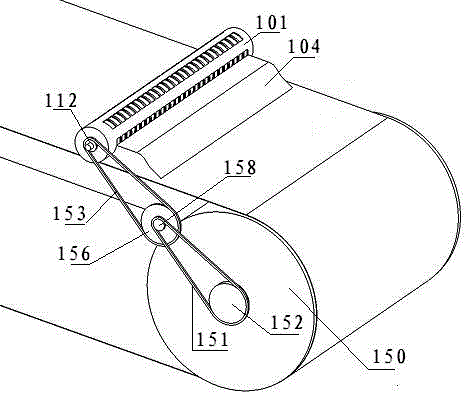

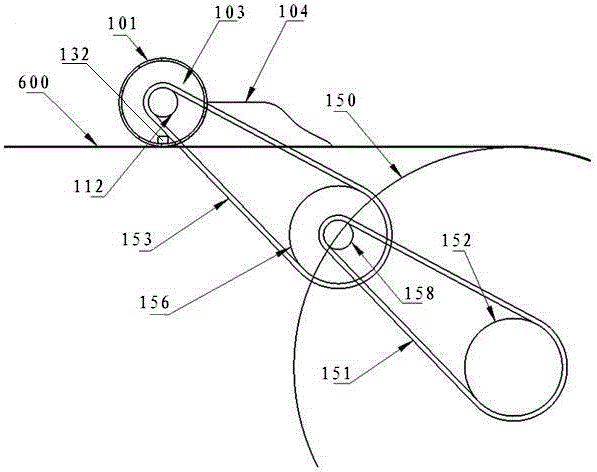

Full-automatic thin pancake producing device

ActiveCN106259586ANo sticking to roll stamping diesSimple structureOil/fat bakingPancakes bakingMechanical engineeringMechanical abrasion

The invention relates to the technical field of food baking machines, and provides a full-automatic thin pancake producing device which comprises a steel band, a fixed machine frame and a roll mark forming device. The roll mark forming device comprises a roll mark mold located on the steel band of the full-automatic thin pancake producing device and provided with a central containing cavity, a mold driving part and a plurality of forming grooves, a roll mark inner barrel contained in the central containing cavity and provided with a central pin shaft located at one end and a demolding groove axially located in the circumference, and a mold driving mechanism connected with the mold driving part. The mold driving mechanism is arranged in the mode that the mold driving part can drive the roll mark mold to rotate so that the linear speed of the outer edge, attached to the steel band, on the roll mark mold can be the same as the linear speed of the steel band. A central hole is formed in the mold driving part so that the central pin shaft can penetrate through the central hole. The roll mark inner barrel is fixed to the fixed machine frame of the full-automatic thin pancake producing device through the central pin shaft and installed in the mode that the demolding groove covers the tangent line of the roll mark mold and the steel band. The full-automatic thin pancake producing device is simple in structure, convenient to detach and wash, free of mechanical abrasion, beneficial to demolding and free of adhesion.

Owner:SHANGHAI MAIKE FOOD MACHINERY CO LTD

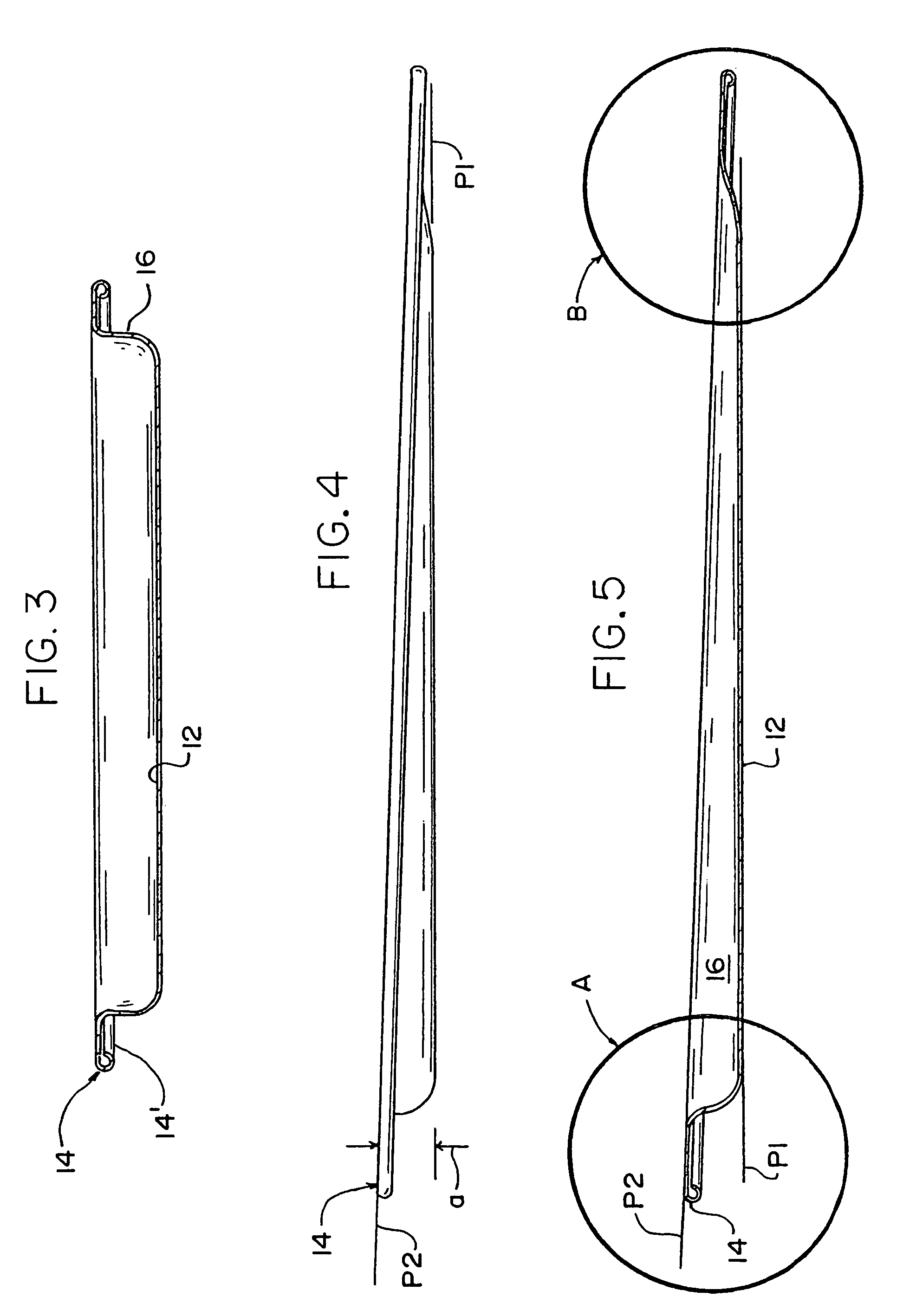

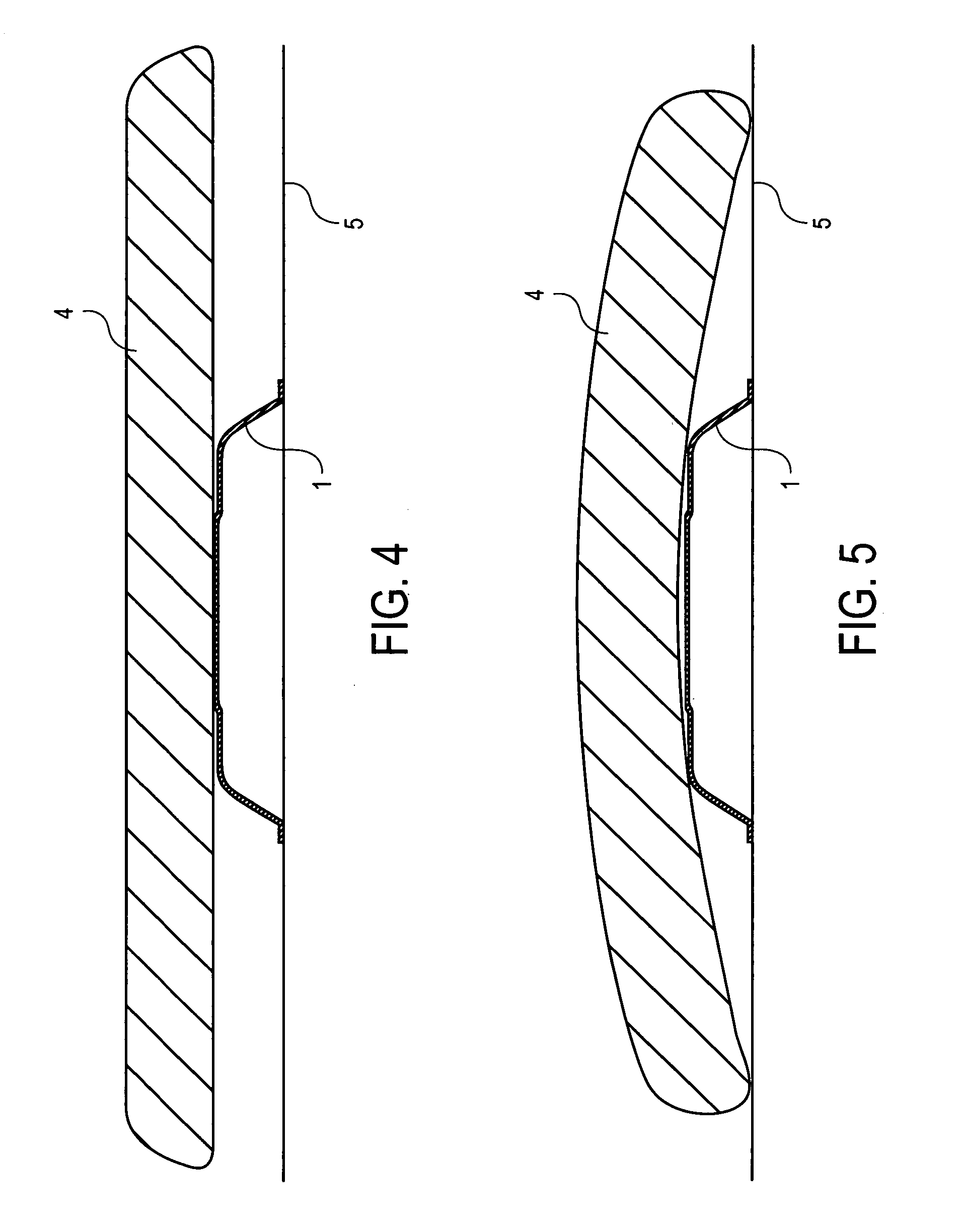

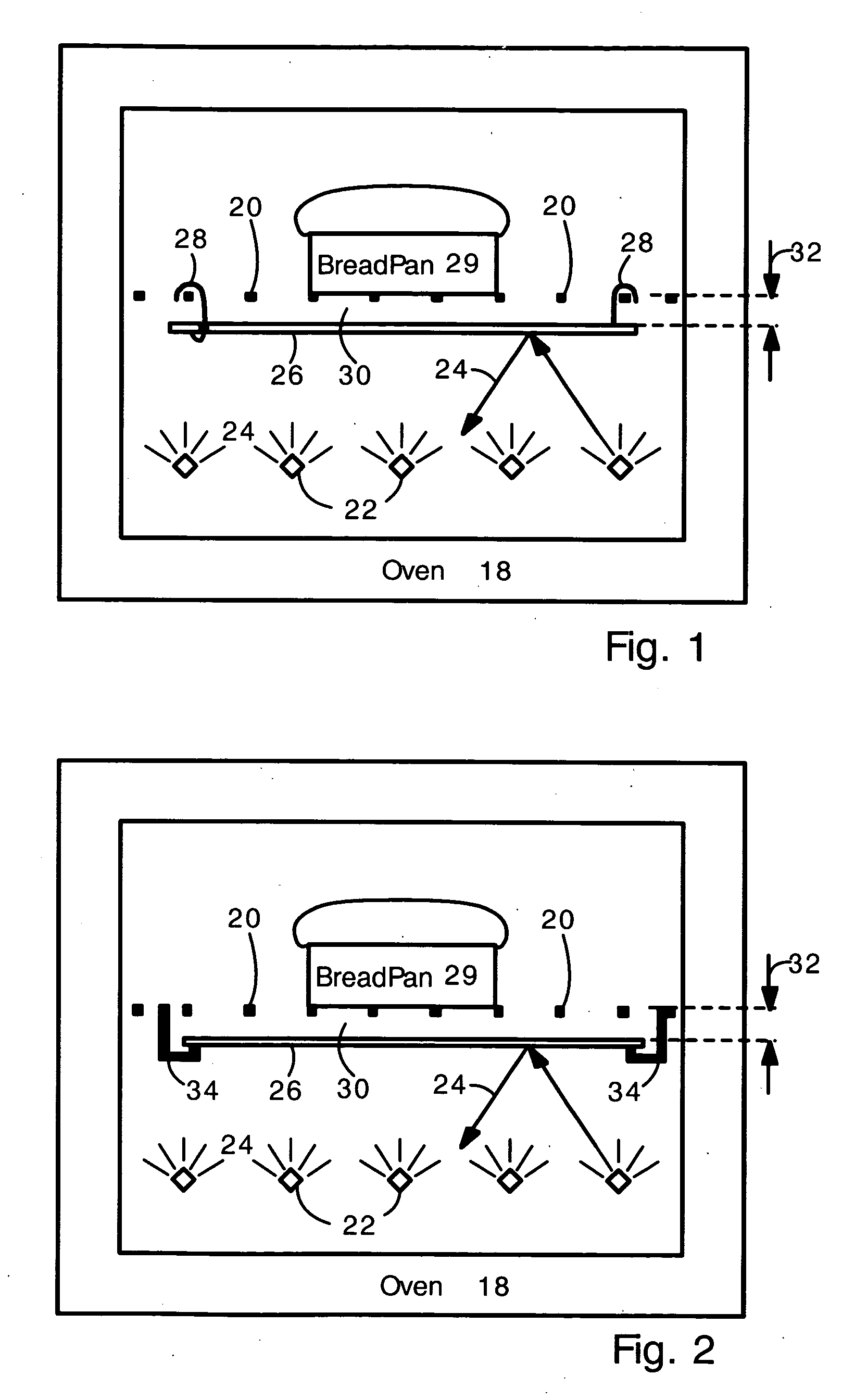

Heat shield for preventing bottom surface burning of baked foods

InactiveUS20060112952A1Preventing bottom surface burningPrevent surfaceDomestic stoves or rangesStoves/ranges shelves or racksCooking & bakingInfrared

Baked goods are often burned by exposure to heat radiation (infrared rays) from heating coils in an electric baking oven. The infrared rays strike the bottom surface of bakeware and heat the surface to the point of burning. The present invention provides a heat shield that protects the bakeware from infrared rays and burning. The present invention comprises a metal sheet having corrugations or bumps. Bakeware is disposed on the bumps. The bumps make point contact with the bakeware, thereby limiting heat transfer to the bakeware. The bumps provide an insulating air gap between the heat shield and bakeware. Also included is a sheet disposed under a wire baking rack. The sheet blocks infrared rays. The sheet can be suspended by hooks or brackets, for example.

Owner:STEINBERG DAN A

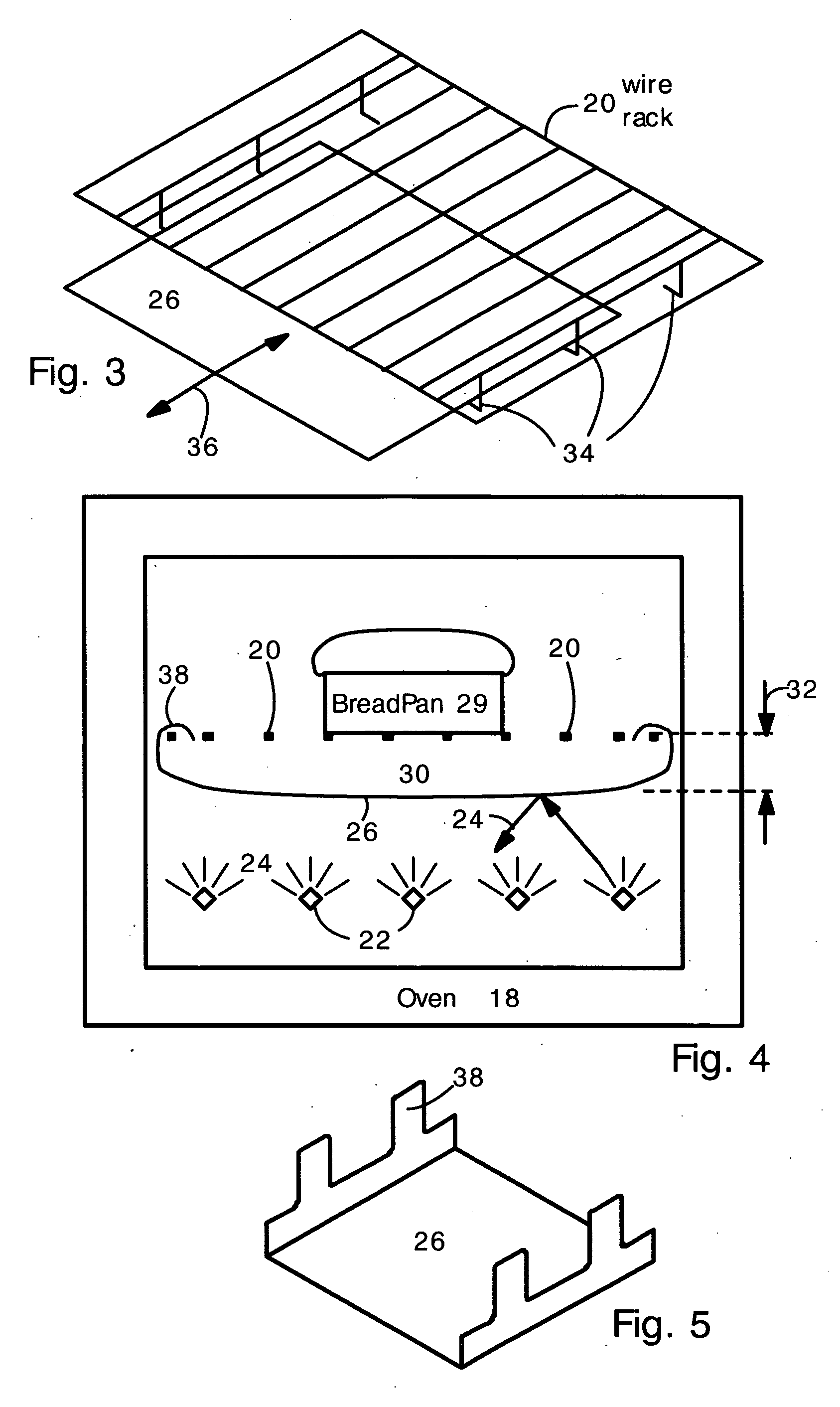

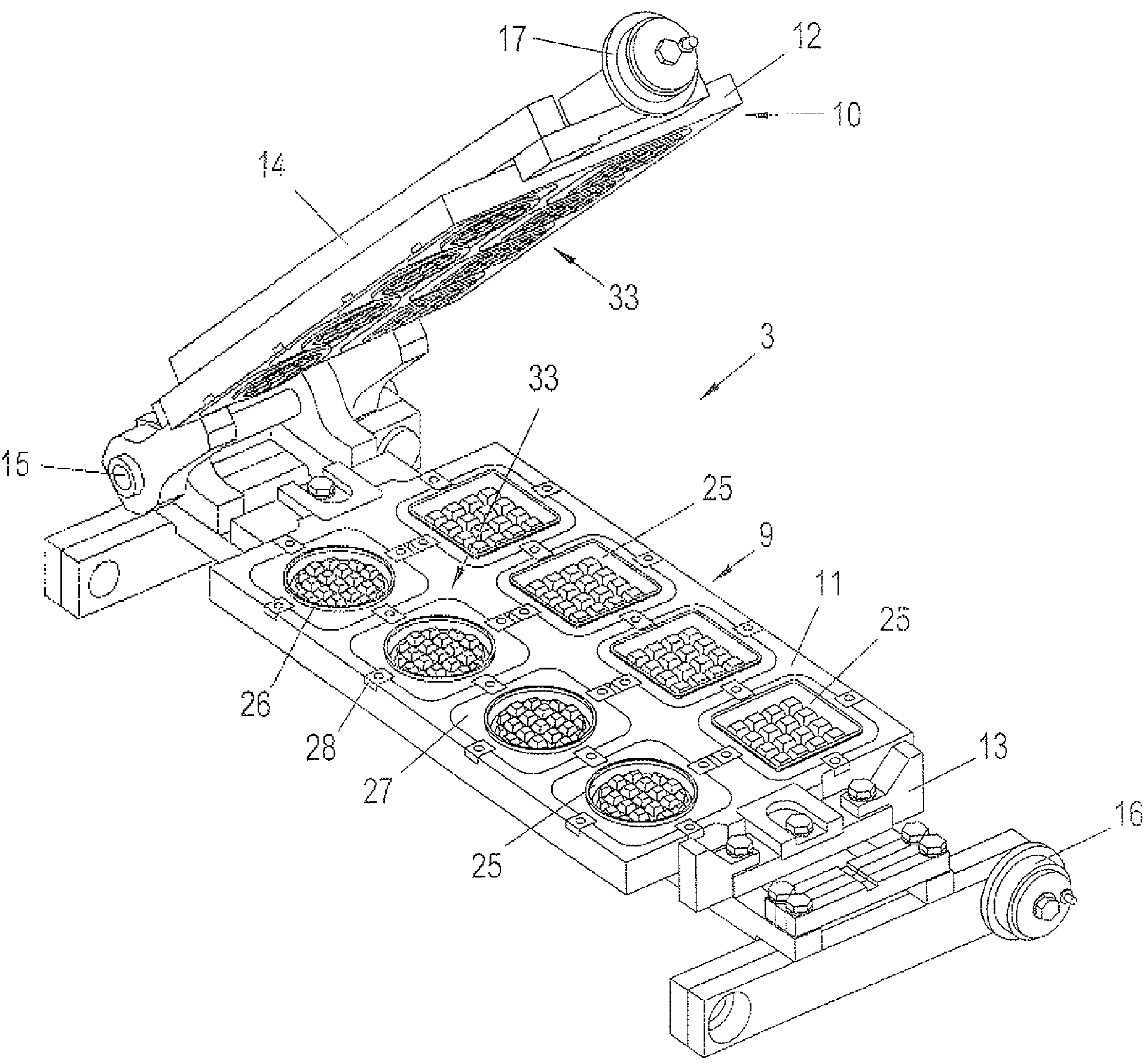

Baking plate for baking ovens

The invention relates to a baking plate for baking ovens for producing baked goods, such as soft waffles, crisp waffles, pancakes, and the like, characterized in that the baking plate (9, 10) has a carrier plate (11, 12) and one or more baking inserts (25) arranged on the carrier plate, the baking inserts being designed to accommodate the dough to be baked, and that the baking inserts (25) are made of sintered ceramic having high toughness and low thermal expansion.

Owner:HAAS FOOD EQUIP

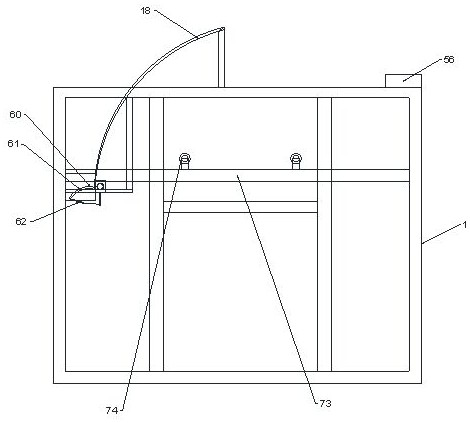

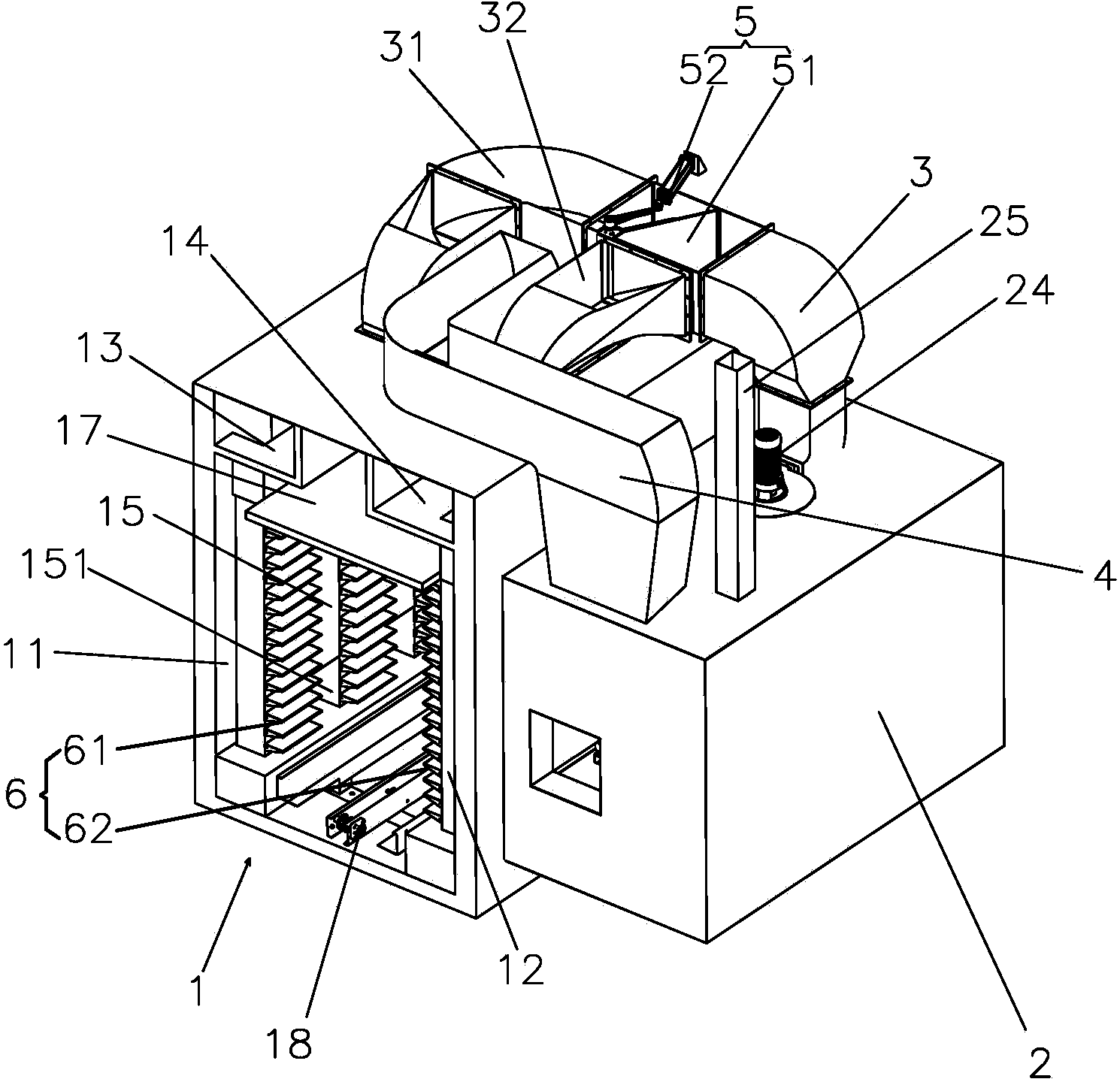

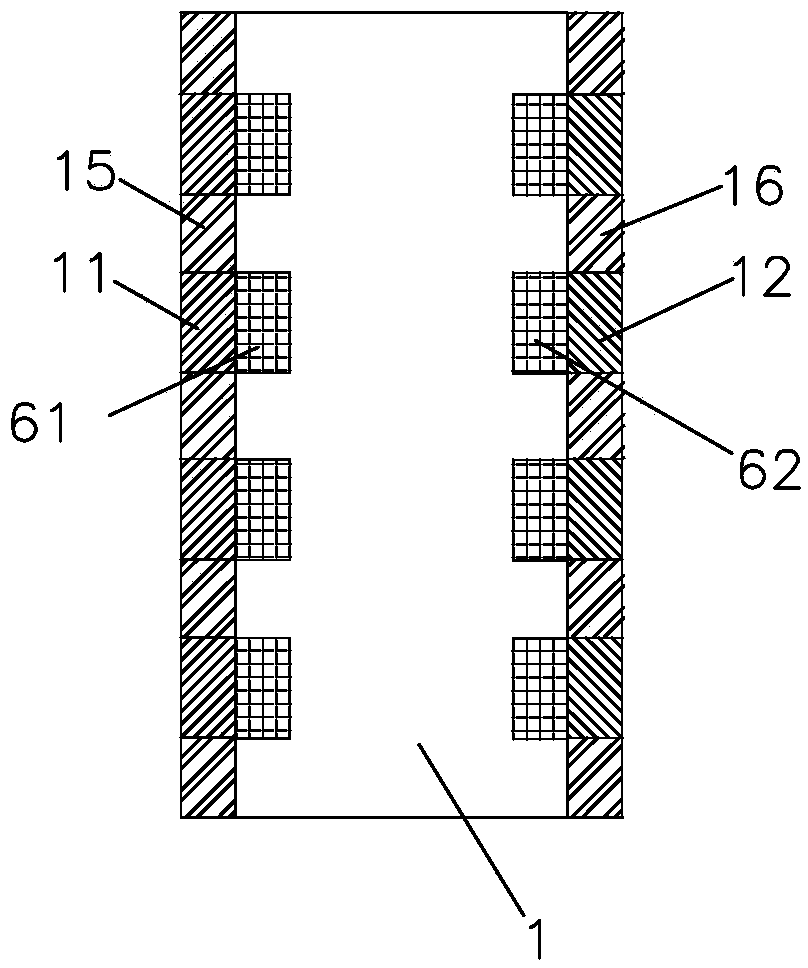

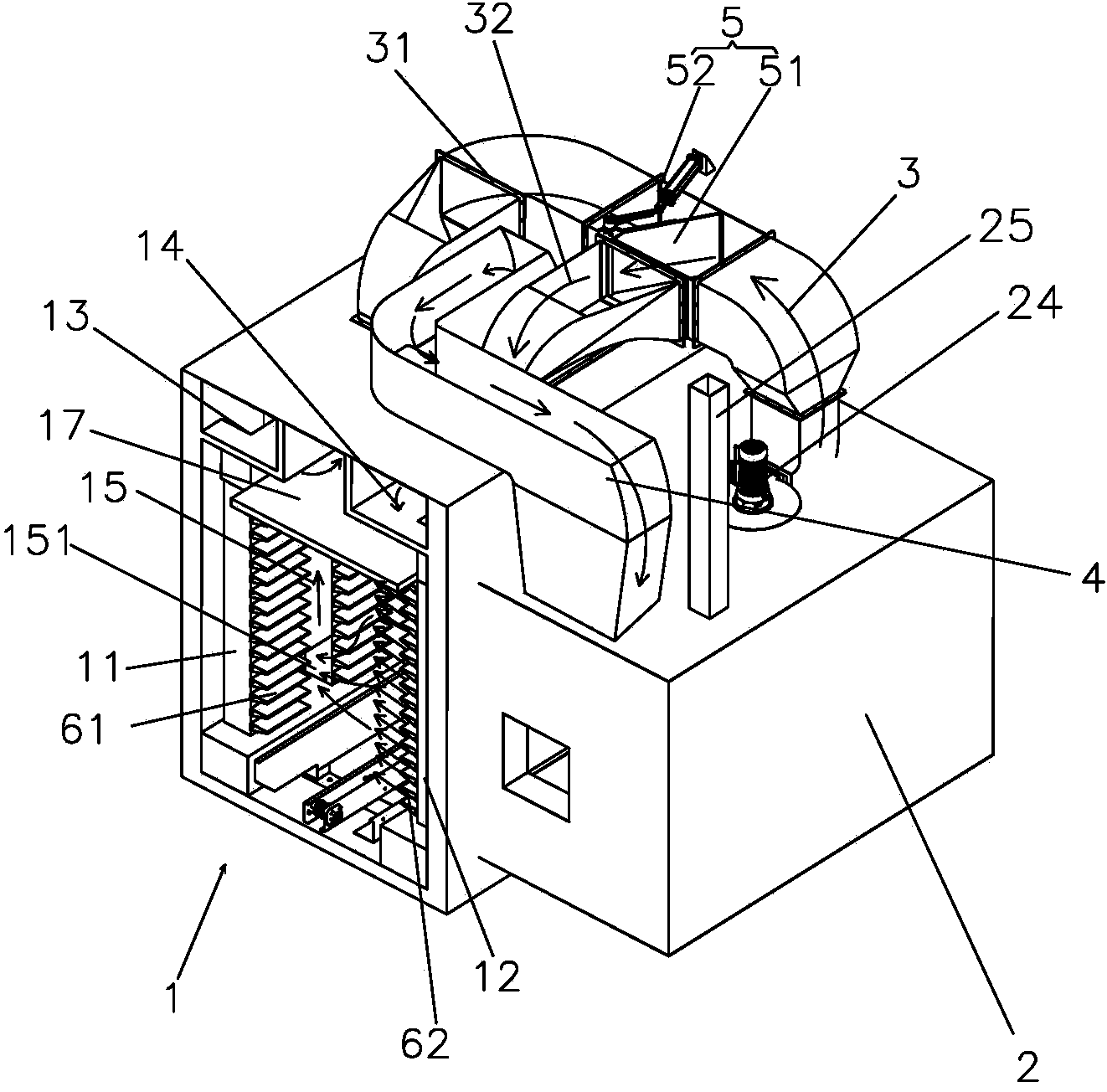

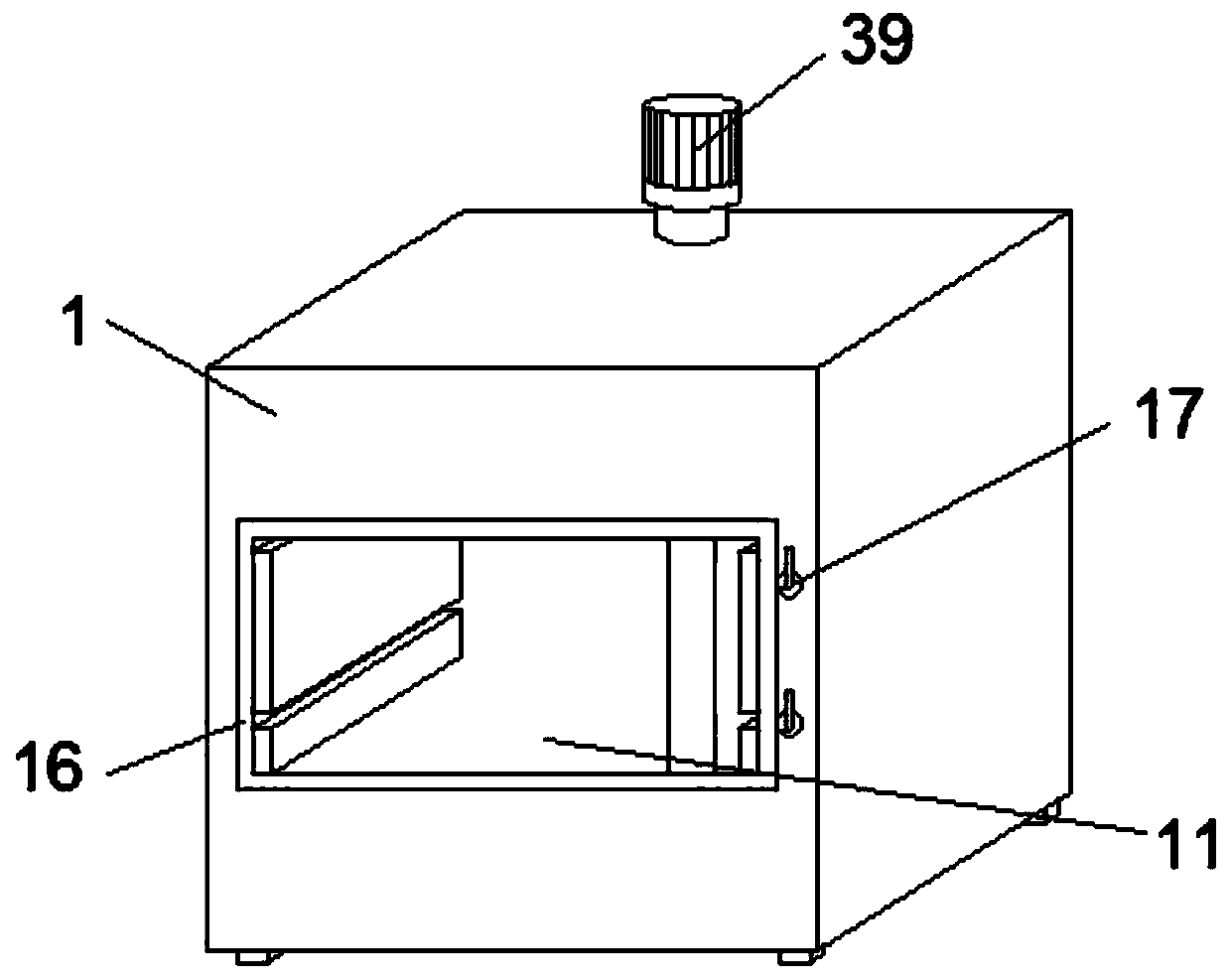

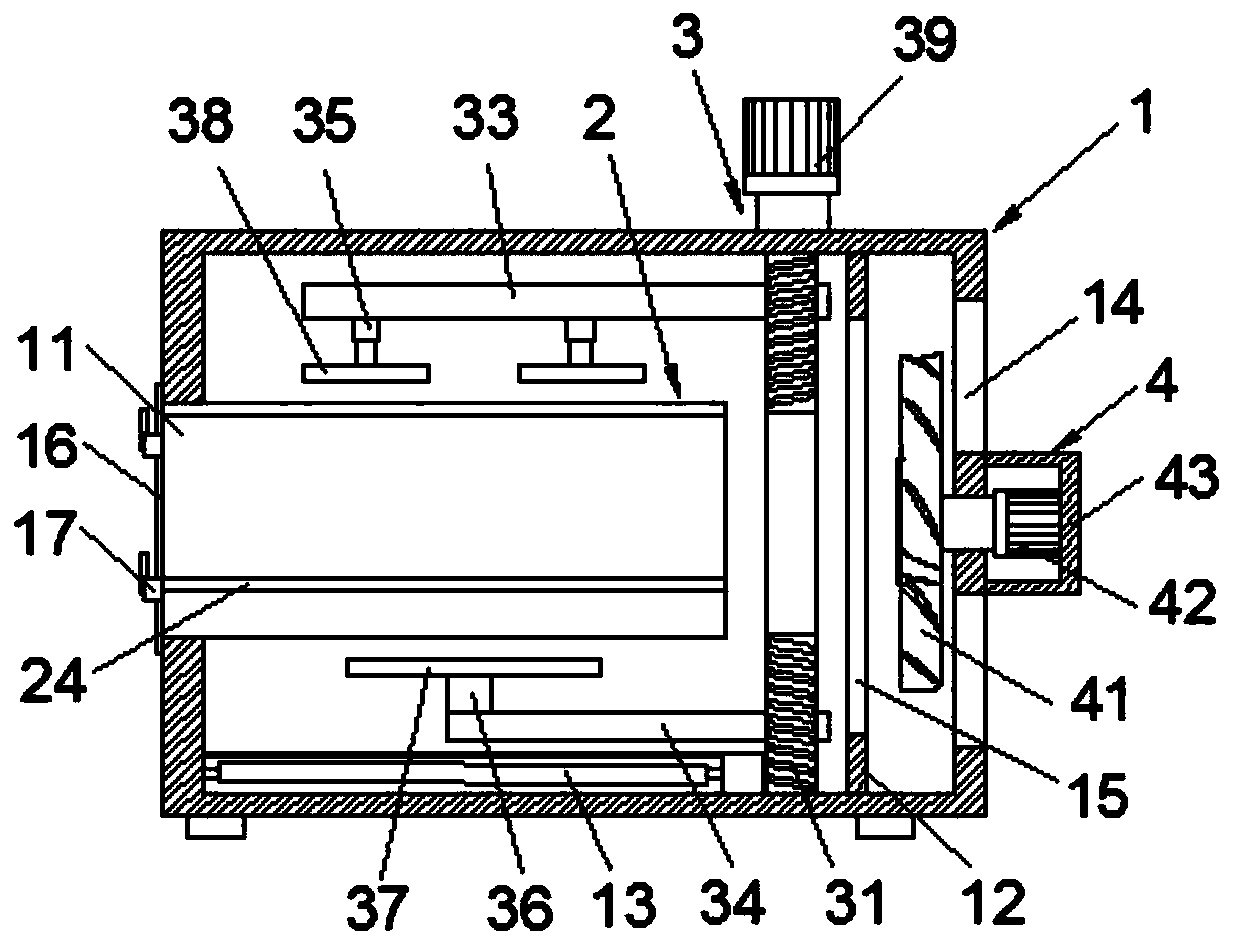

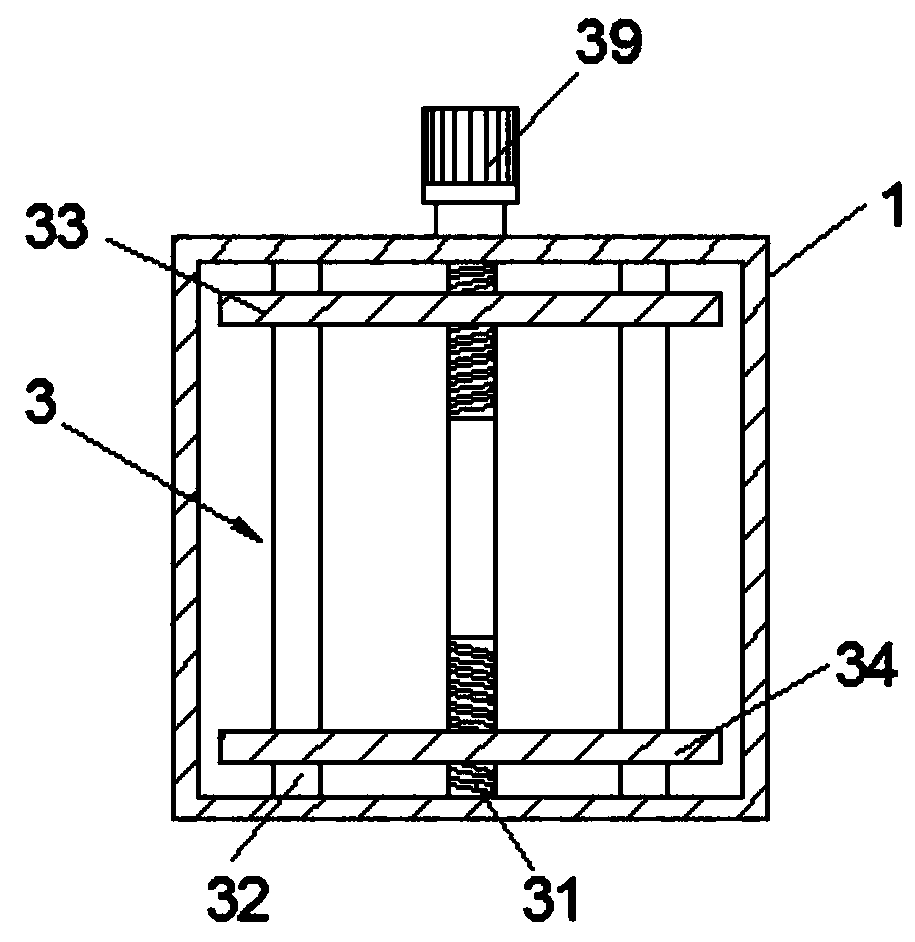

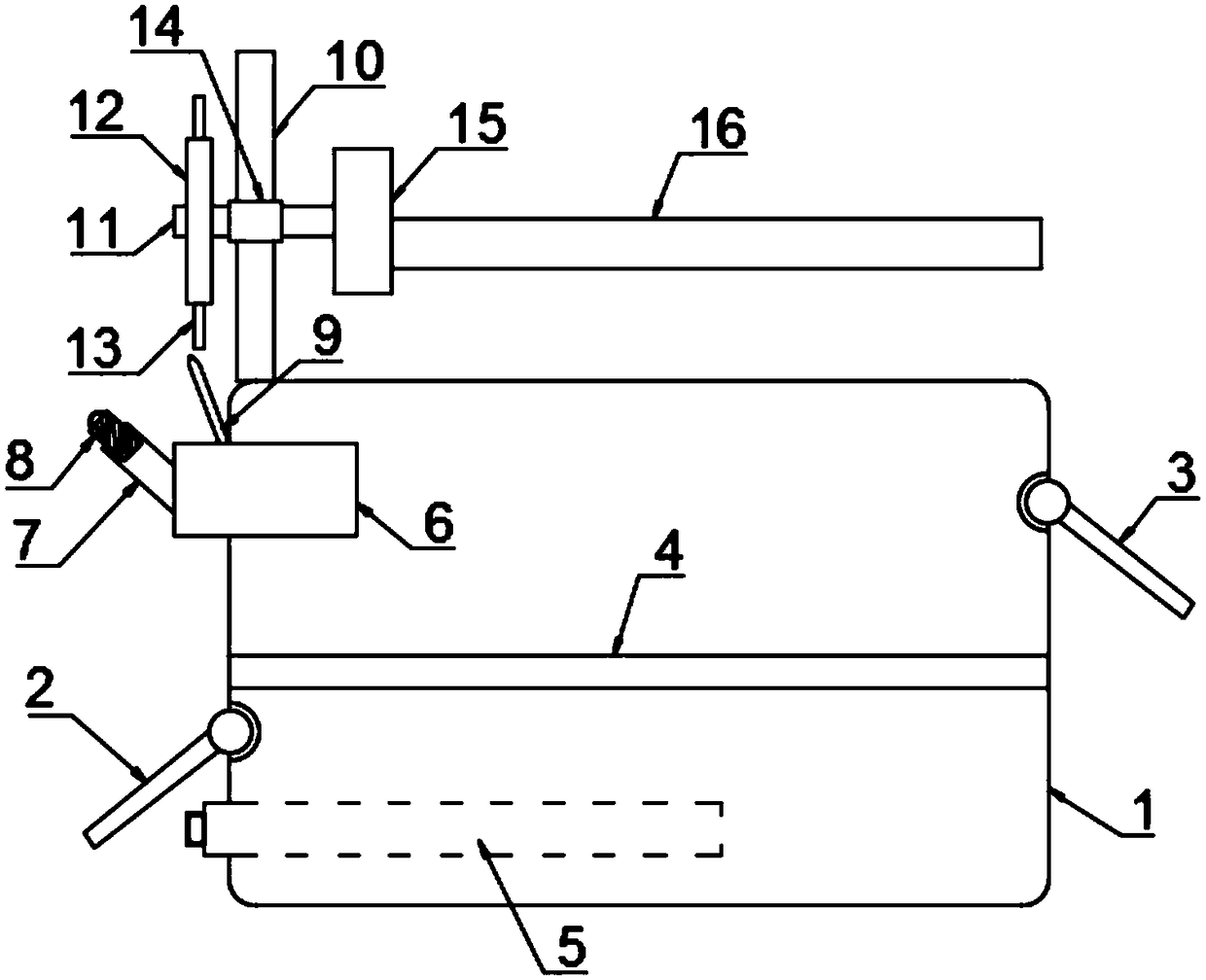

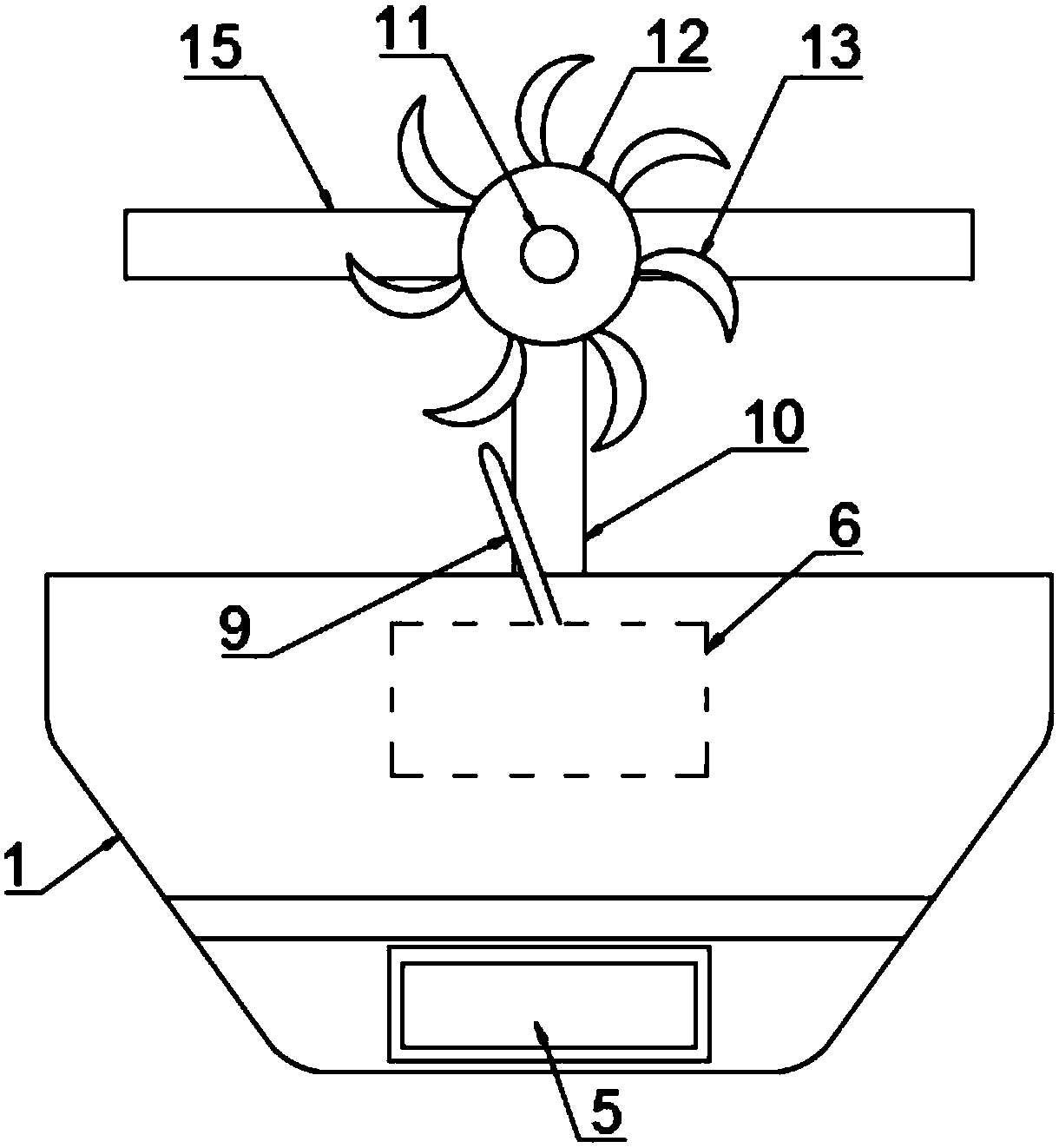

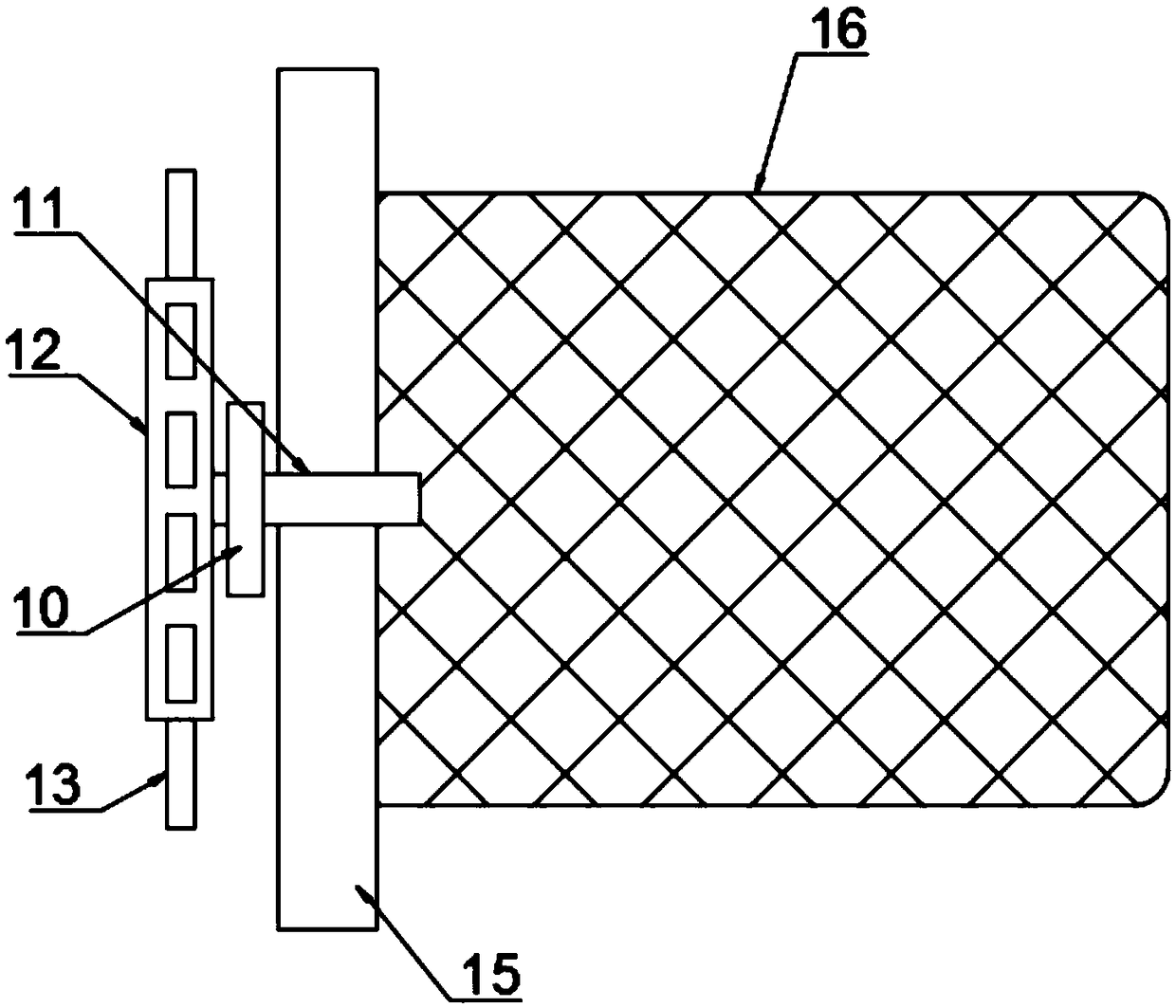

Processing device and processing method used for double-layer tiger cake

ActiveCN111513090AImprove baking efficiencyImprove processing efficiencySpecial goods bakingBaking sheets/boardsMechanical engineeringThreaded rod

The invention discloses a processing device and a processing method used for a double-layer tiger cake. The processing device comprises a box body, a grill component, a lifting and lowering mechanismand a heat dissipation mechanism, wherein the front side wall of the box body is provided with an opening; the grill component is arranged in the opening; the heat dissipation mechanism is positionedon the rear end of the box body; the lifting and lowering mechanism is positioned between the grill component and the heat dissipation mechanism; in addition, a partitioning board is arranged betweenthe lifting and lowering mechanism and the heat dissipation mechanism; a heating pipe is installed below the grill component and is fixedly connected on a lower end in the box body; the rear side wallof the box body is provided with a ventilation opening; and the heat dissipation mechanism is installed on two sides of the ventilation opening. The processing device is provided with a cake grill and a tiger grill, so that the cake and the grill can be simultaneously processed and baked, and tiger cake processing efficiency is improved. A threaded rod and a spacing rod are arranged, so that a down-pressing board and a supporting board can be controlled to vertically move. When the cake and the tiger finish being baked, a baffle board can be directly pulled out, and the cake is pressed to thetiger through the down-pressing board to directly finish a tiger cake processing and shaping process.

Owner:安徽青松食品大健康研究院

Self-rotating barbecue grill

The invention discloses a self-rotating barbecue grill. The self-rotating barbecue grill comprises an grill body; a first opening is formed on an outer wall of the grill body; a first cover plate is in rotating connection with an outer side of the first opening; a collection box is inserted in the first opening; a combustion net is fixedly connected onto an inner wall of the grill body, and is located above the collection box; a second opening is further formed on an outer wall of the grill body; a second cover plate is in rotating connection with an outer side of the second opening; the second opening is located above the combustion net; and a vertically arranged fixing plate is fixedly connected with an upper side wall of the grill body. The self-rotating barbecue grill disclosed by theinvention has the following advantages: water in a water storage box is heated by utilizing heat emitted by charcoal during use process of the barbecue grill so as to produce steam flow, so that, fanblades are driven to rotate under the action of the steam flow; and thus, rotation of roasting net is allowed so as to avoid rotation by manpower or electrically driven force. Therefore, manpower or electricity is saved with performance of barbecuing on foods facilitated.

Owner:佛山市粤创五金制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com