Tunneling-type food baking equipment

A food baking device and tunnel-type technology are applied in food ovens, baking, oven air handling devices, etc. Reasonable and efficient use of flow path, efficient automatic production, uniform baking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

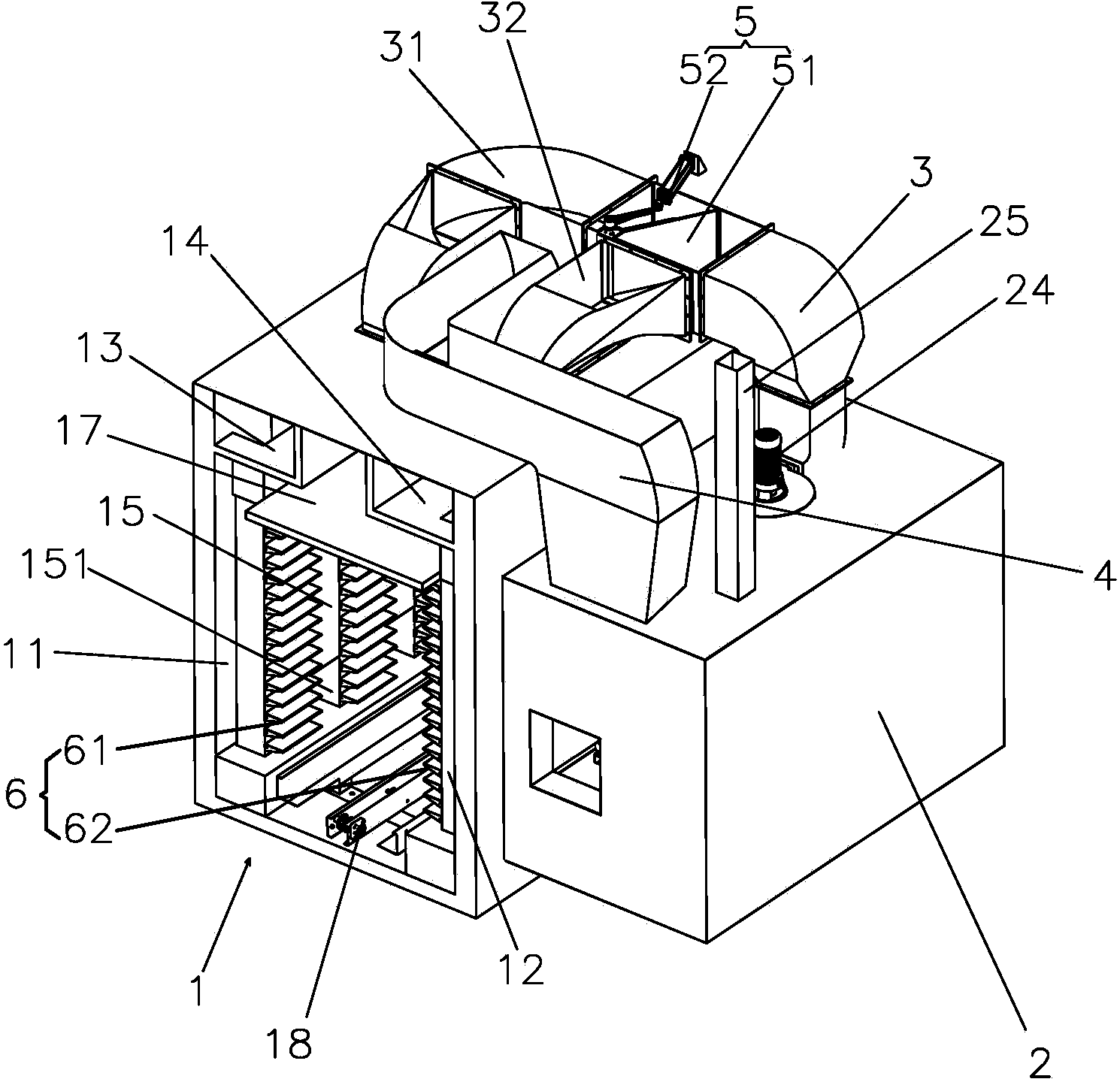

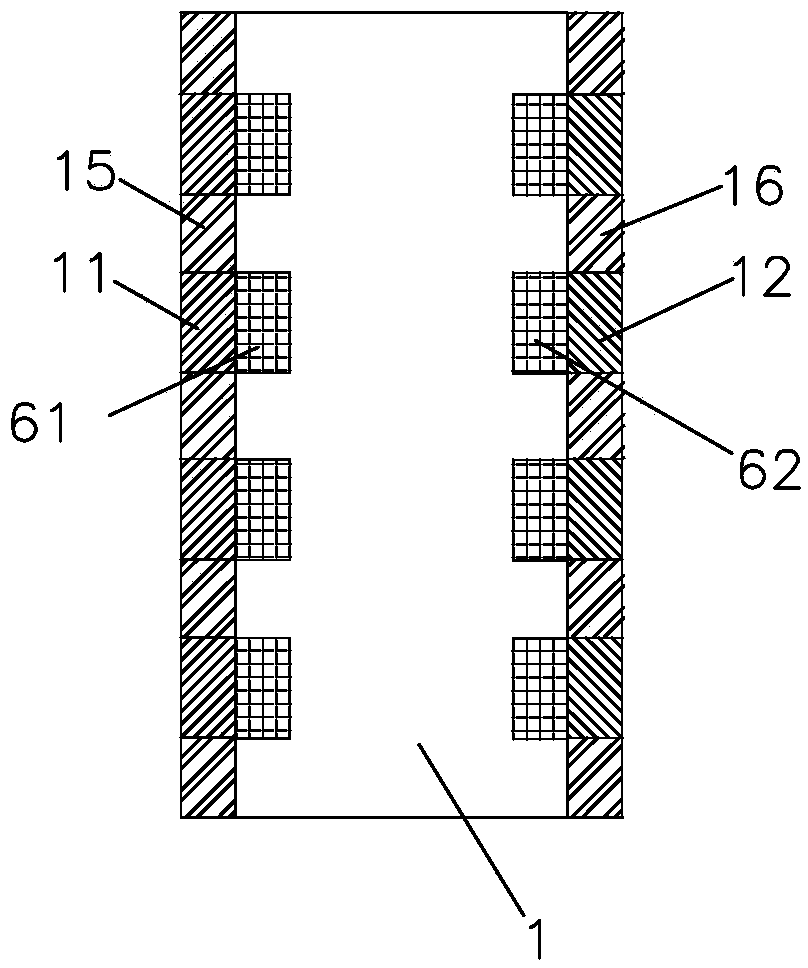

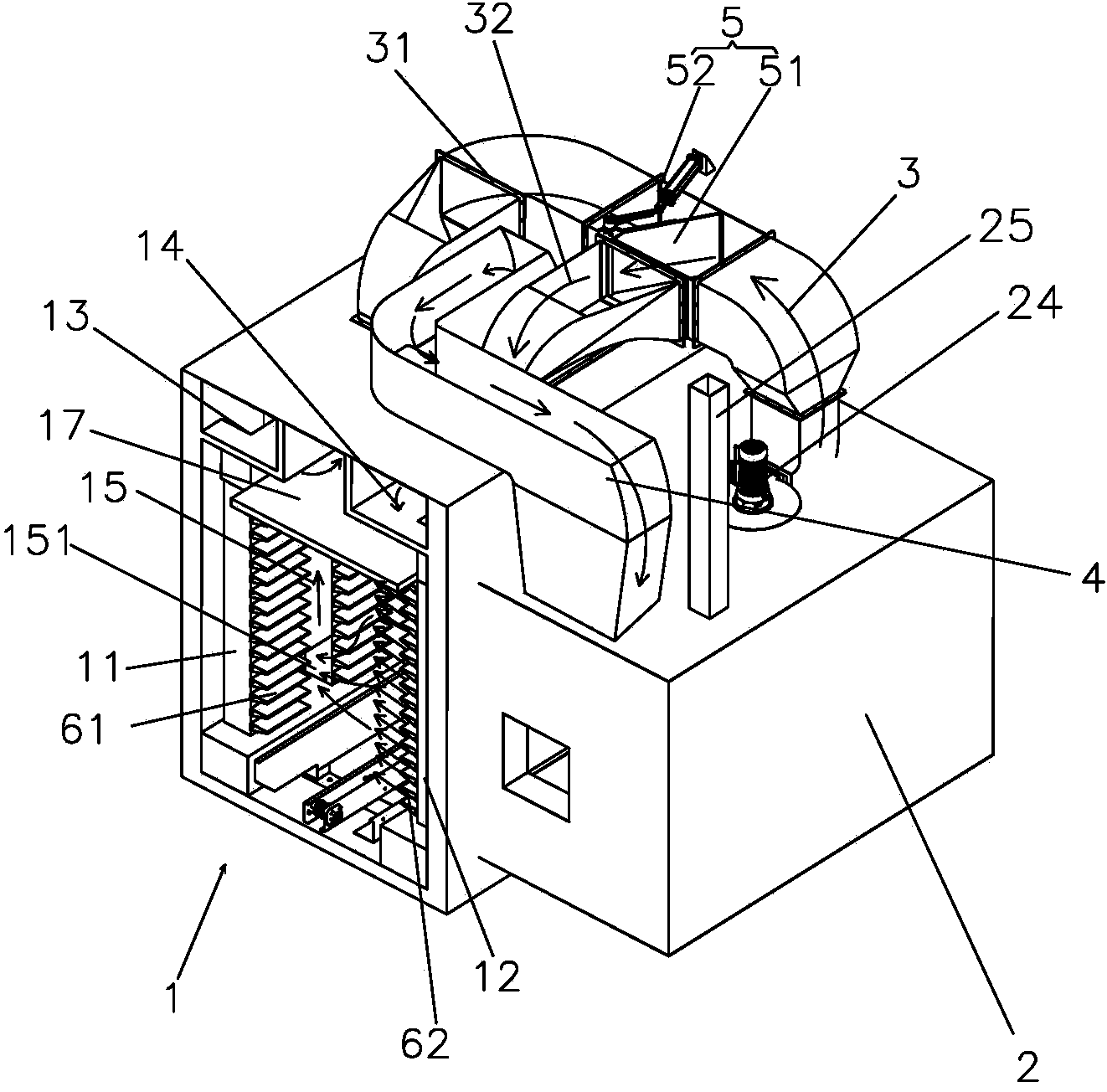

[0032] Examples, see figure 1 and figure 2 , a tunnel type food baking device, including a baking chamber 1, a combustion chamber 2, an air inlet channel 3, a return air channel 4, an air guiding device 5 and an air outlet 6. The air inlet channel 3 and the return air channel 4 communicate with the baking chamber 1 and the combustion chamber 2 respectively, and the air guiding device 5 is arranged on the air inlet channel 3 . The air outlet 6 includes a first group of air outlets and a second group of air outlets arranged on the opposite side walls of the baking chamber 1, wherein the first group of air outlets includes a plurality of first air outlets 61, and the second group of air outlets includes A plurality of second air outlets 62 . Specifically, a plurality of first air inlet cavities 11 and second air inlet cavities 12 are arranged in parallel on the opposite side walls of the baking chamber 1, and each first air inlet cavity 11 is provided with a row of The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com