Full-automatic thin pancake producing device

A kind of production equipment and fully automatic technology, which is applied in the direction of baking pancakes, baking, oil/fat baking, etc., can solve the problems of unrealizable, error-prone, synchronous detachment, etc., and achieve simple design structure, convenient adjustment, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

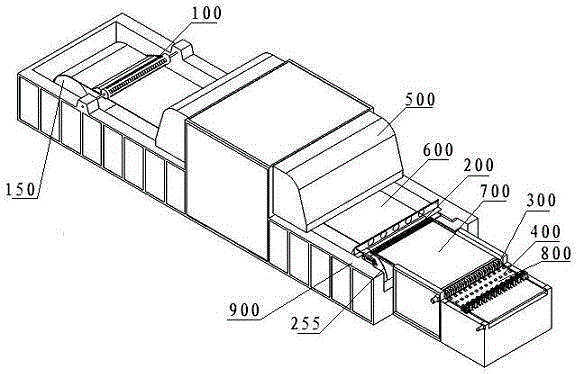

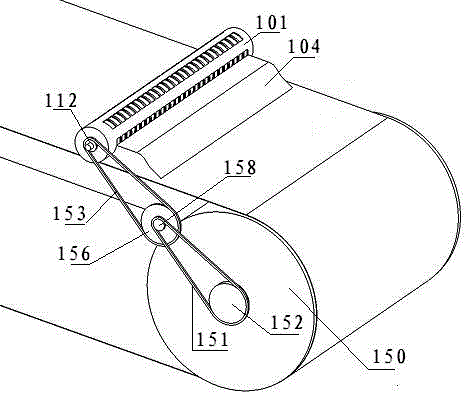

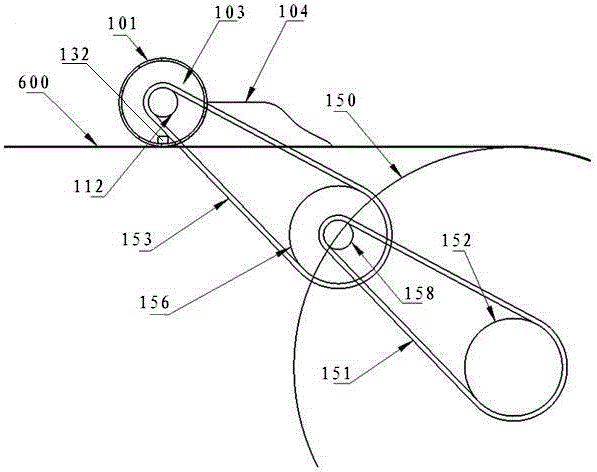

[0062] figure 1 It schematically shows a perspective view of a fully automatic pancake production device according to a specific embodiment of the present invention. Such as figure 1 As shown, in this embodiment, the fully automatic pancake production equipment includes a roll printing forming device 100, a demoulding device 200, an interval turning device 300, a steel belt 600, a first conveyor belt 700, and a second conveyor belt 800 And fixed frame 900. A tunnel type steel belt oven 500 is also arranged between the roll printing forming device 100 and the stripping device 200 . The roll printing forming device 100 synchronously follows the forming pancakes, and then the pancakes enter the tunnel-type steel belt oven 500. The baked pancakes are stripped by the demoulding device 200 and sent to the first section of the conveyor belt 700 from the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com