Ignition type biomass forming fuel

A biomass fuel and briquette fuel technology, which is applied in the directions of biofuel and waste fuel, can solve the problems of short burning time, thick forming thickness and low heat, so as to reduce energy waste, reduce the probability of black smoke generation, and protect the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

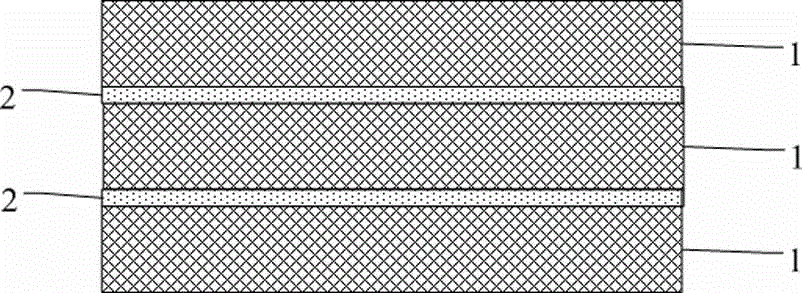

[0024] Such as figure 1 As shown, Example 1 is an ignition-type biomass briquette fuel with a five-layer structure, including three-layer laminated biomass fuel substrates 1, and an ignition device is arranged between two adjacent biomass fuel substrates 1. Adhesive layer 2, described ignition adhesive layer 2 is the mixture of fibrous adhesive, polyester polyol and diisocyanate, the mass ratio of described polyester polyol, diisocyanate is described fiber adhesive 1% of the mixture of polyester polyol and diisocyanate, the molar ratio of polyester polyol and diisocyanate is 1:4, and the polyester polyol is poly(alkylene alkanedioate) glycol and Poly(hydroxycaproyl) glycol. The material of the biomass fuel substrate 1 is agricultural waste, and the agricultural waste includes one or a mixture of straw, corn cob, bagasse, algae and water hyacinth. The thickness ratio of the ignition adhesive layer 2 to the biomass fuel substrate 1 is 1:50. During the preparation process of t...

Embodiment 2

[0026] Example 2 is an ignition-type biomass briquette fuel with a two-layer structure, including two laminated biomass fuel substrates, an ignition adhesive layer is provided between the two adjacent biomass fuel substrates, and the The ignition bonding layer is a mixture of fiber-based adhesive, polyester polyol and diisocyanate, and the mass ratio of the polyester polyol and diisocyanate is that of the fiber-based adhesive, polyester polyol and diisocyanate. 5% of the mixture. The molar ratio of the polyester polyol and diisocyanate is 1:6, and the polyester polyol is poly(alkylene alkanedioate) glycol. The biomass fuel substrate includes biomass scrap raw materials , the biomass chip raw material includes lignin, and the lignin includes one or a mixture of wood blocks, wood chips and bark. The fibrous binder is waste paper pulp and / or hydrolyzed fiber. The thickness ratio of the ignition adhesive layer to the biomass fuel substrate is 1:30. During the preparation proces...

Embodiment 3

[0028] Embodiment 3 is an ignition-type biomass briquette fuel with a five-layer structure, including three laminated biomass fuel substrates, and an ignition adhesive layer is provided between two adjacent biomass fuel substrates, so The ignition bonding layer is a mixture of fiber adhesive, polyester polyol and diisocyanate, and the mass ratio of the polyester polyol and diisocyanate is the fiber adhesive, polyester polyol and diisocyanate 3% of the mixture. The molar ratio of the polyester polyol and diisocyanate is 1:5, and the polyester polyol is poly(alkylene alkanedioate) diol and poly(hydroxycaproyl) diol. The biomass fuel substrate includes biomass scrap raw material, and the biomass scrap raw material is oil crop waste. The oil crop waste includes one or a mixture of cottonseed, hempseed and tung tree. The fibrous binder is waste paper pulp and / or hydrolyzed fiber. The thickness ratio of the ignition adhesive layer to the biomass fuel substrate is 1:70. During th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| combustion efficiency | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com