Patents

Literature

34results about How to "Guarantee the quality of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

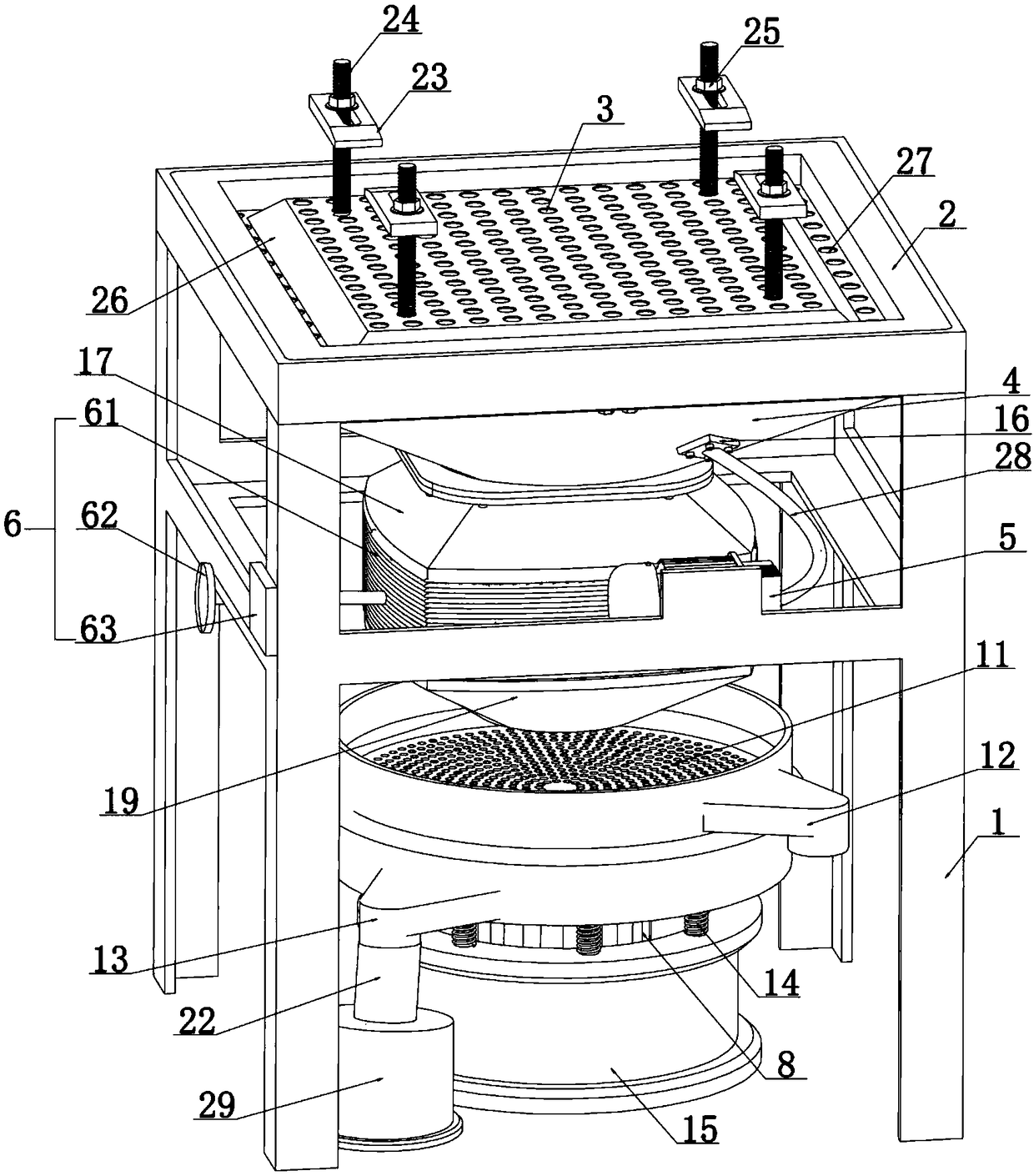

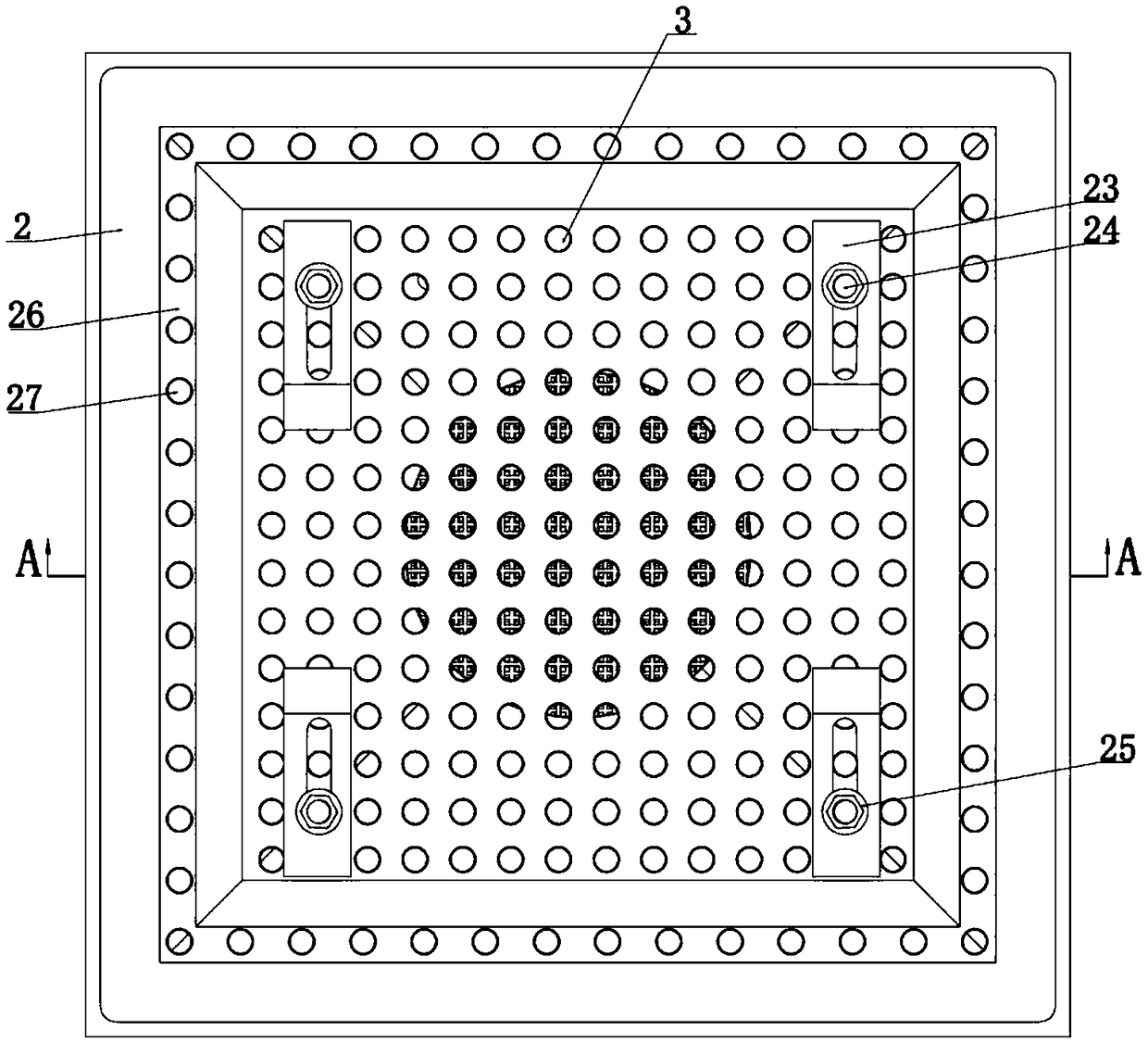

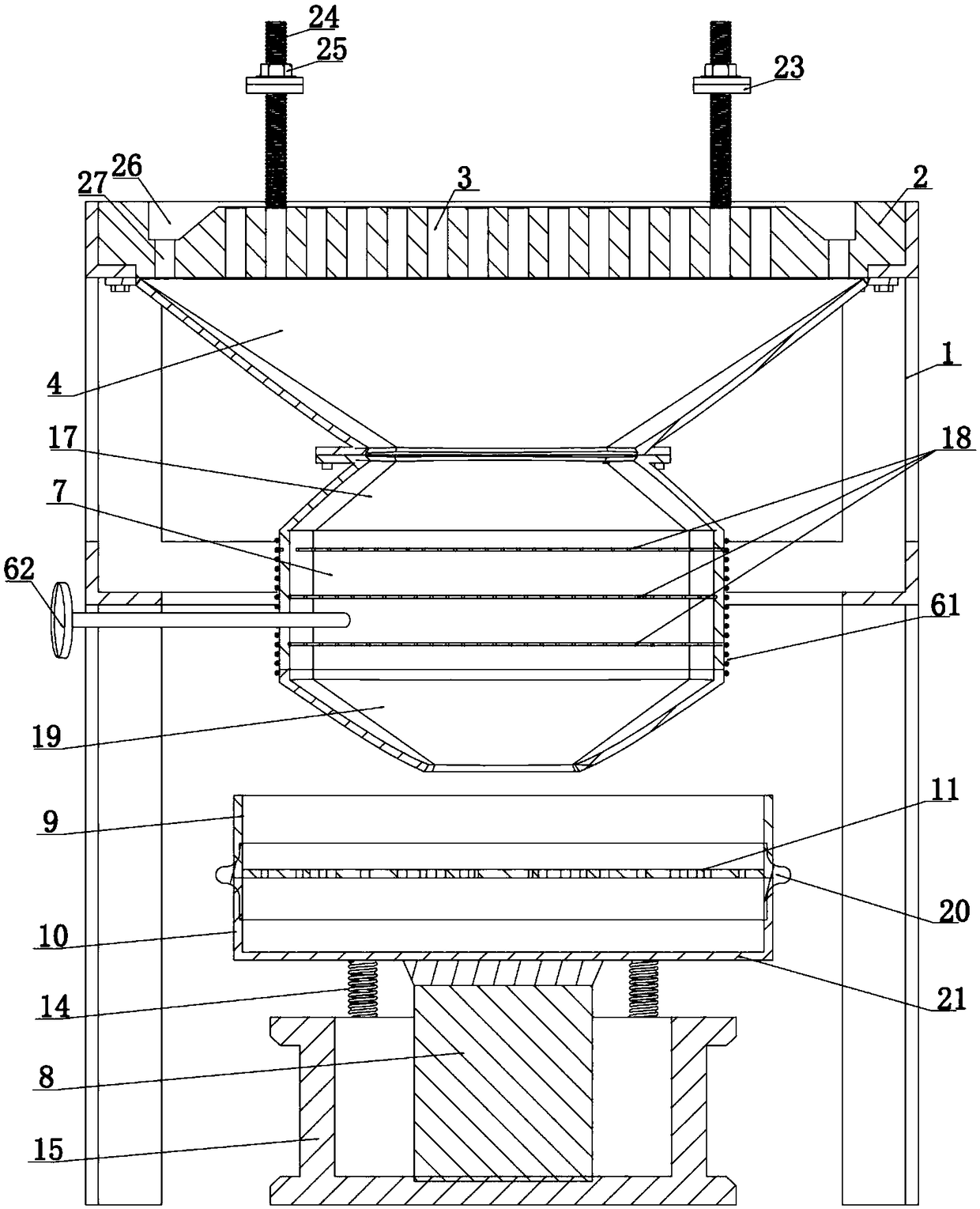

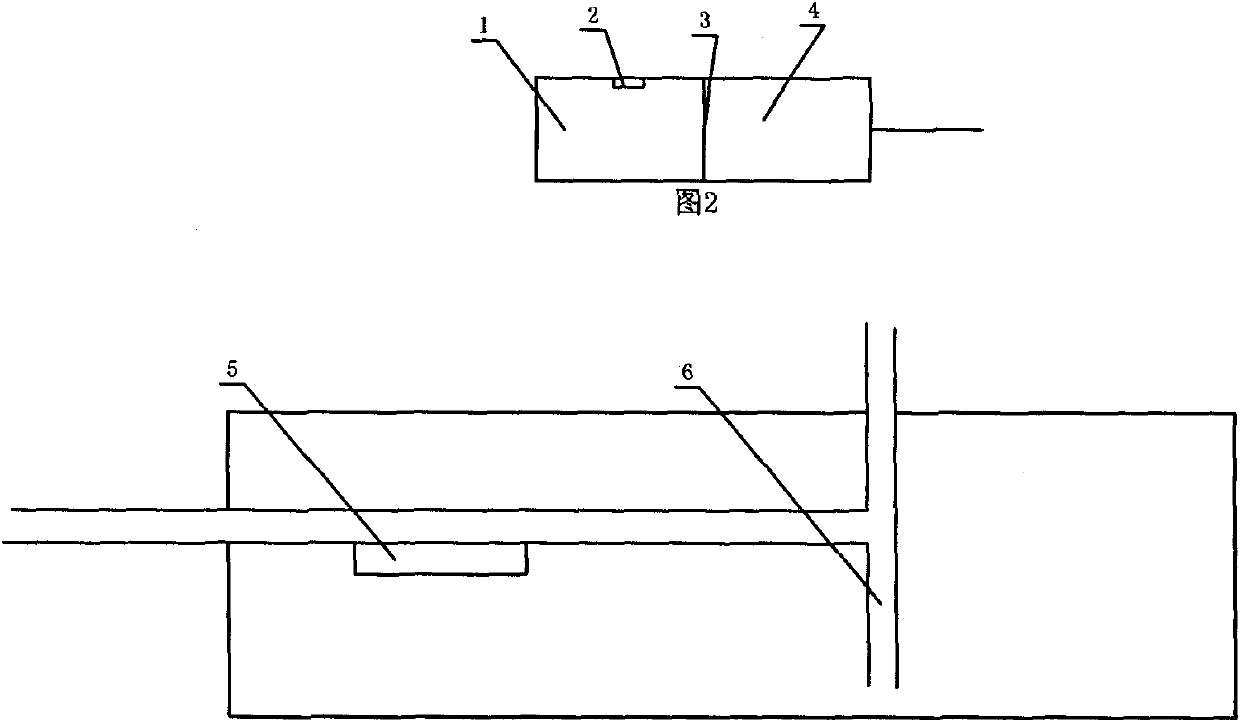

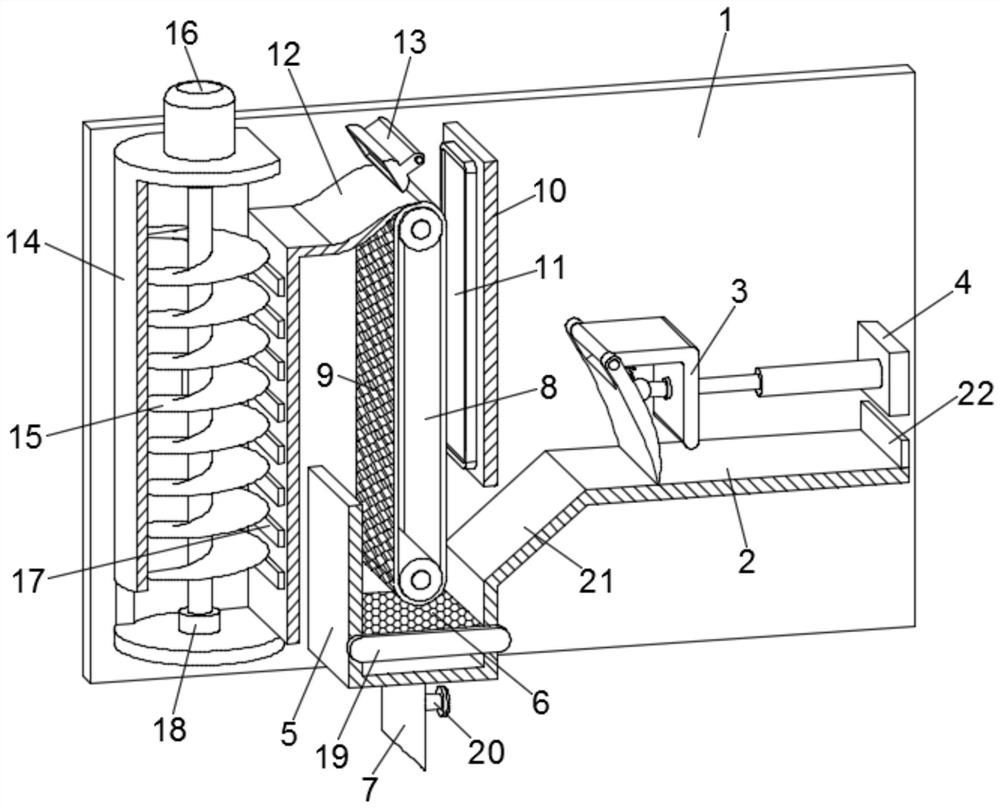

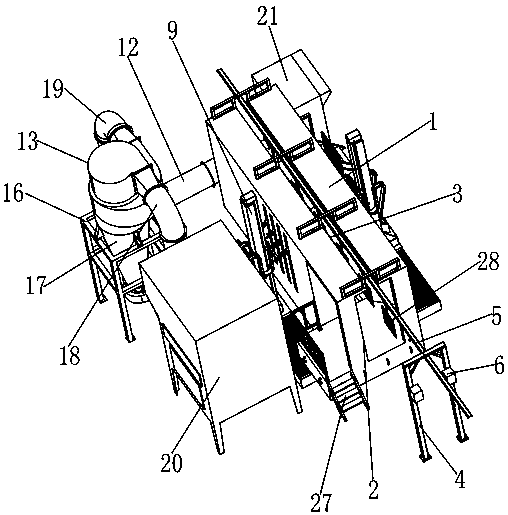

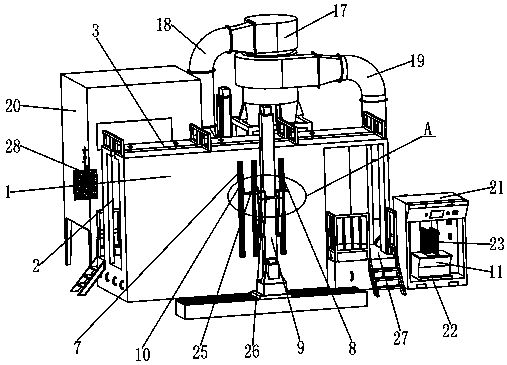

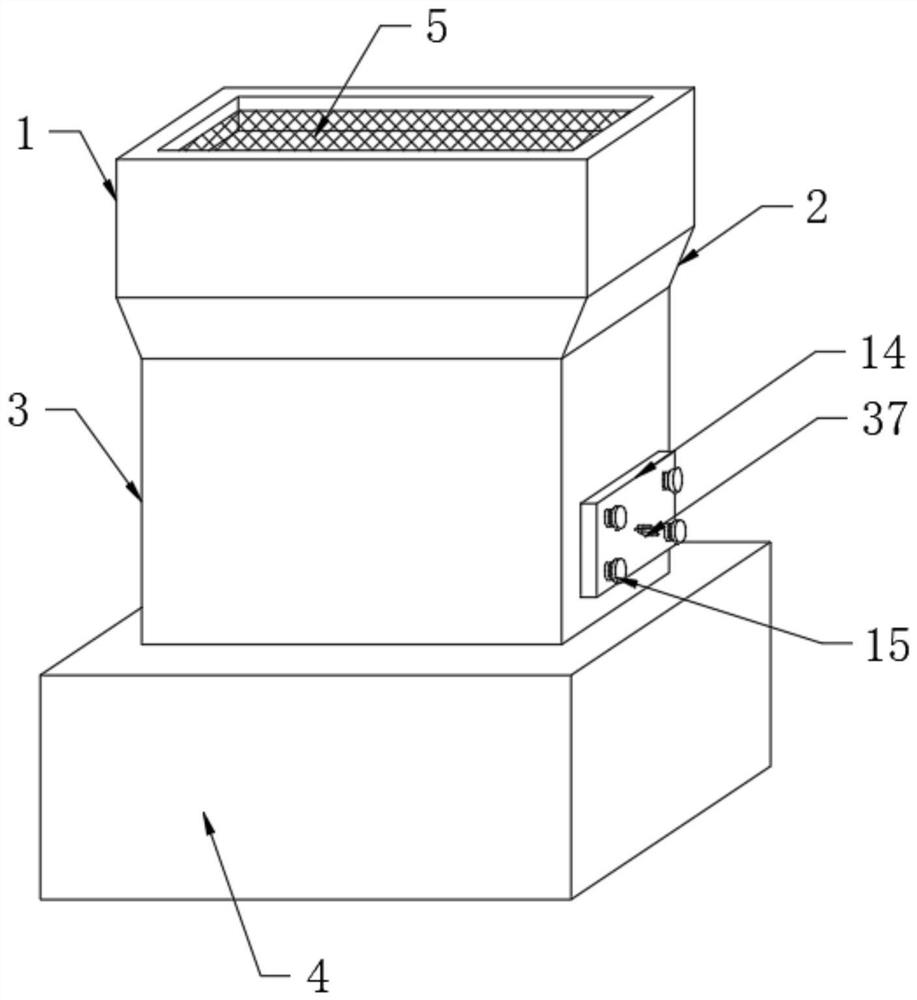

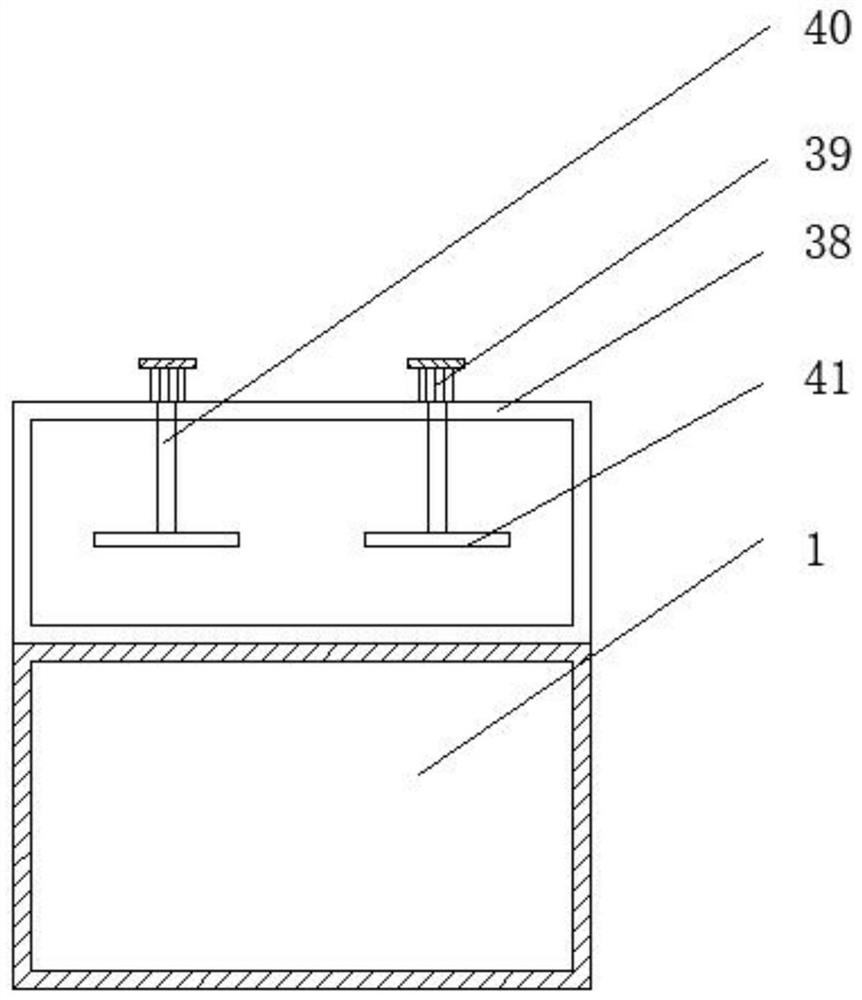

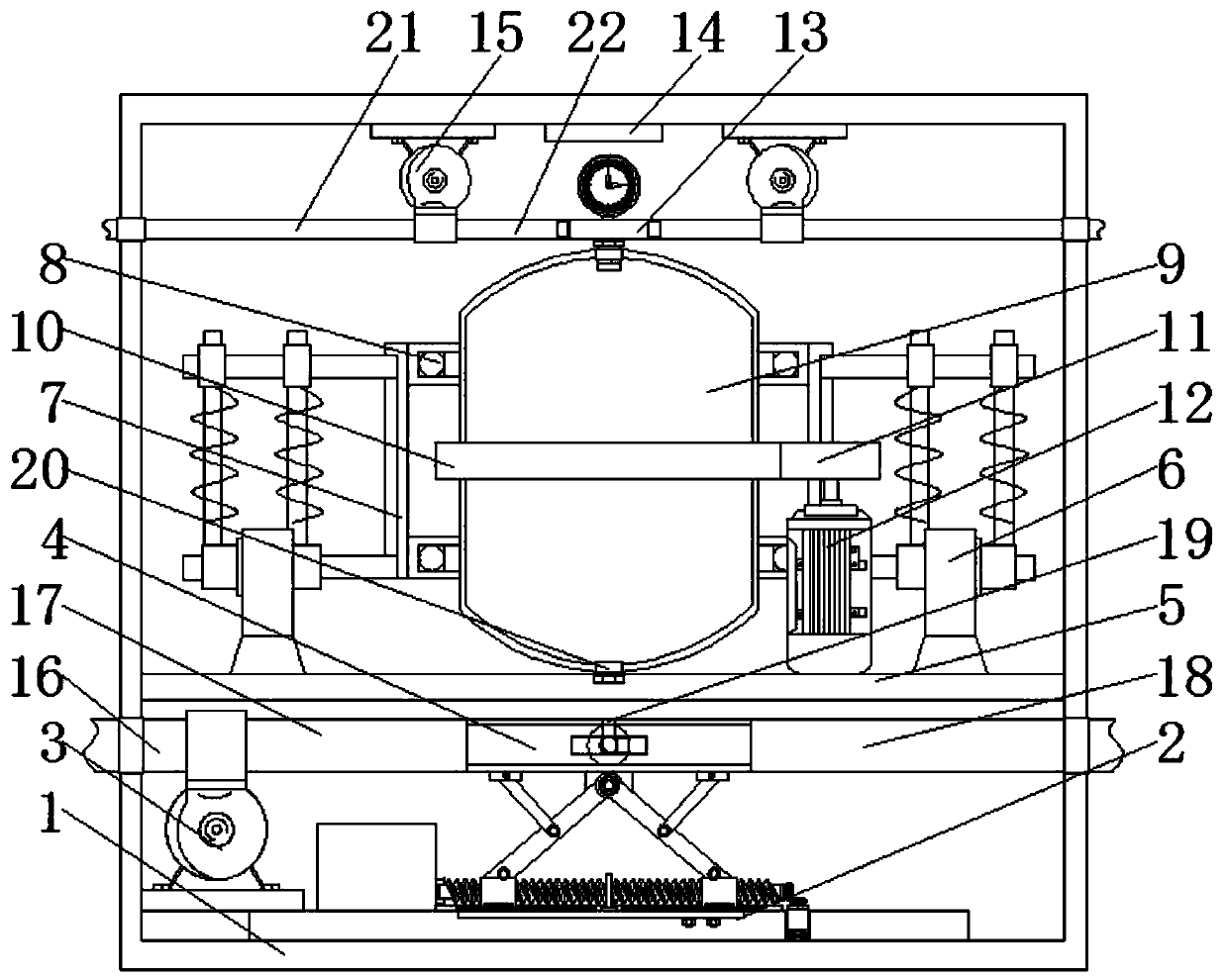

Powder recovery workbench used for metal 3D printing molding

PendingCN109304468AImprove recycling efficiencyImprove recycling ratesAdditive manufacturing apparatusIncreasing energy efficiencyImpurityMetal

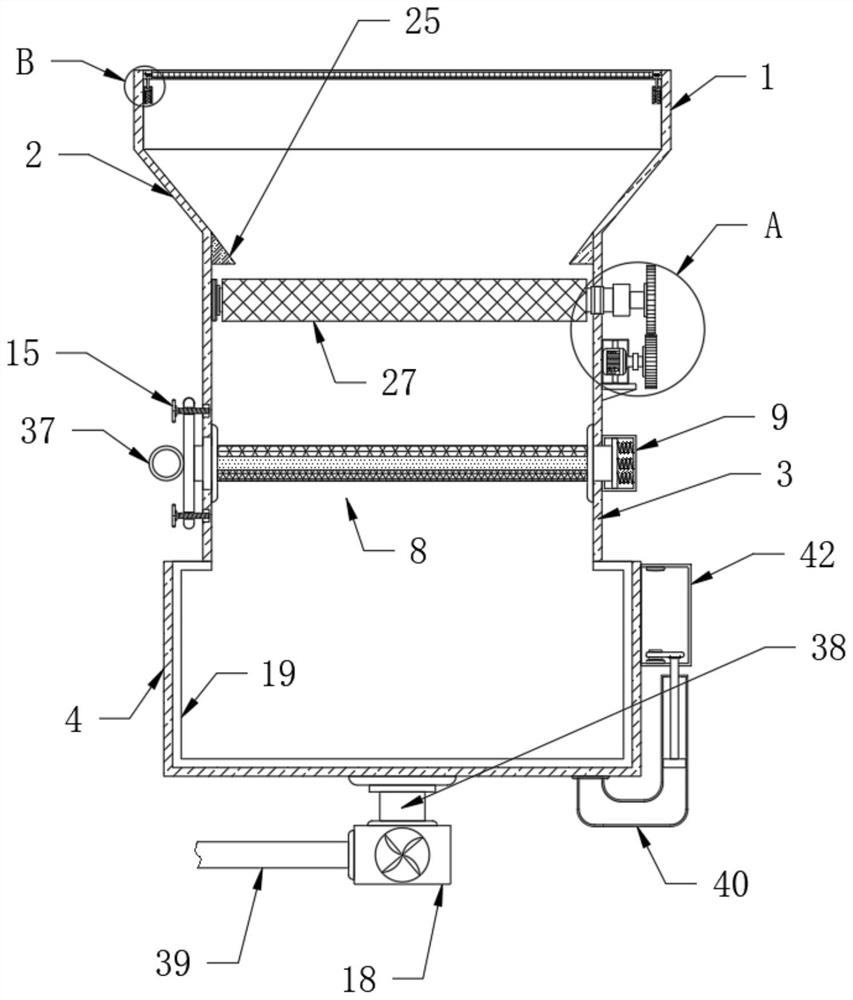

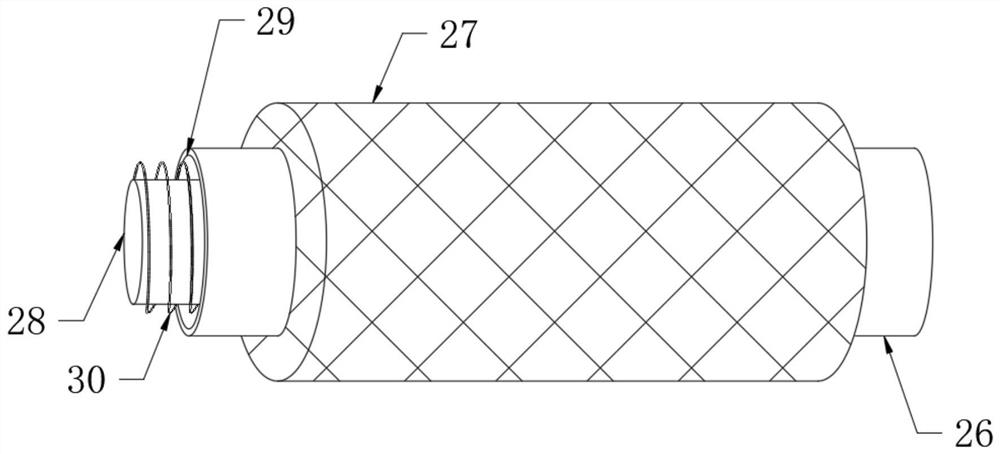

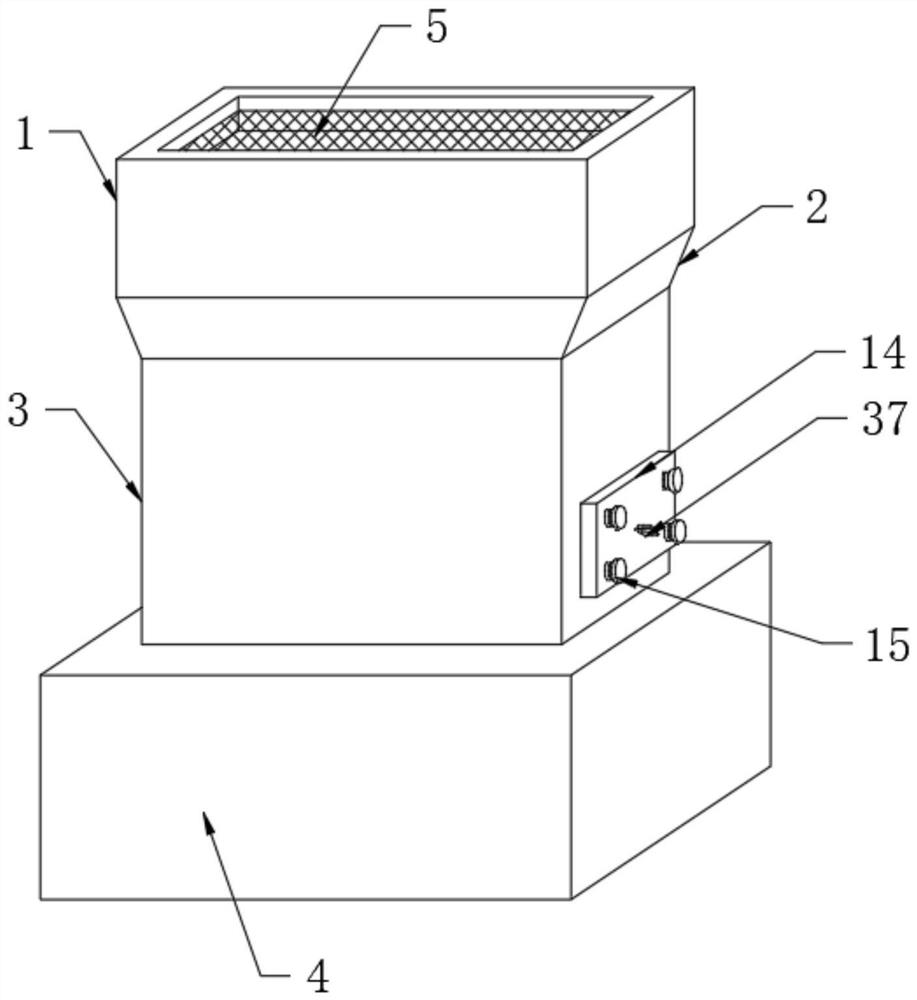

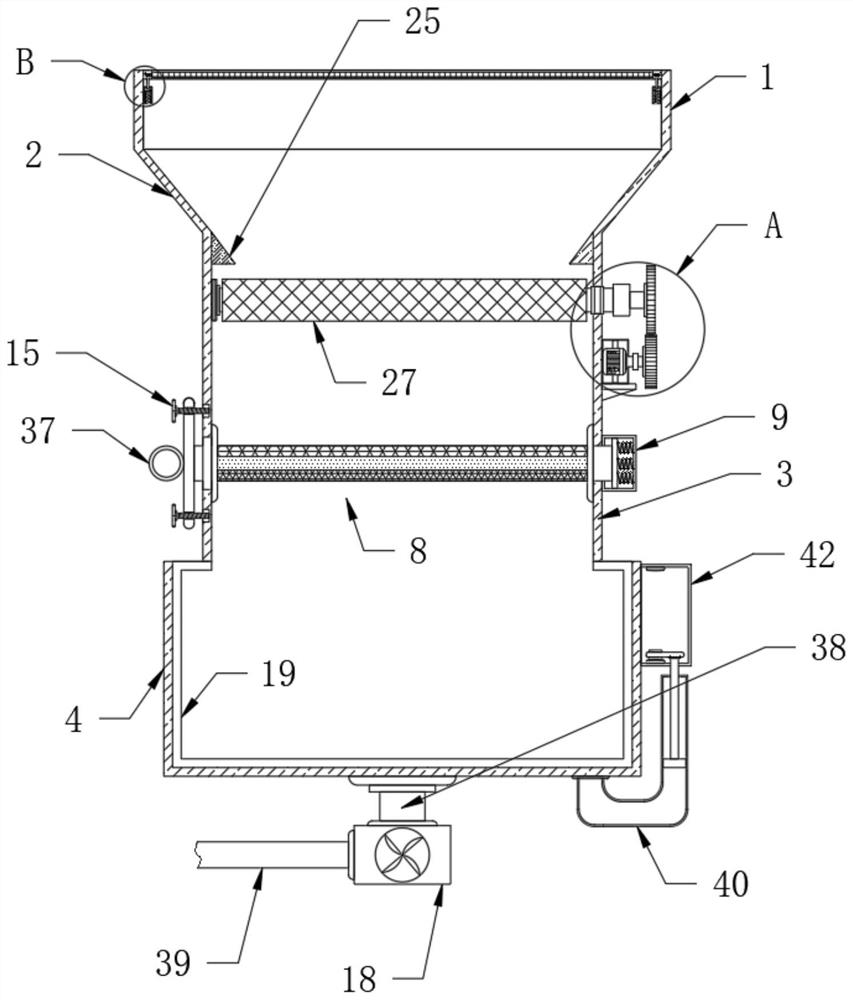

The invention discloses a powder recovery workbench used for metal 3D printing molding. The powder recovery workbench comprises a workbench panel, a powder recovery mechanism, a powder drying mechanism, a powder screening mechanism and a powder recovery bin. Locating holes are evenly formed in the workbench panel. The powder recovery mechanism comprises a powder collection funnel and a negative-pressure powder absorption mechanism. The powder drying mechanism comprises a powder drying bin and a heater. The powder screening mechanism comprises a screening frame, a screening net, a base and a power mechanism used for driving the screening frame to act. An impurity discharge opening and a powder recovery opening are formed in the screening frame, and the powder recovery opening communicates with the powder recovery bin through a powder recovery pipe. A matrix used for laser cladding molding or 3D printing molding can be directly mounted on the powder recovery workbench, powder which is not molten by lasers can be directly recycled through the powder recovery workbench, transfer is not needed, little manual participation is needed, and the labor intensity is small; and the powder recovery efficiency is high, and the powder recovery and utilization rate is increased.

Owner:山东泰利先进制造研究院有限公司

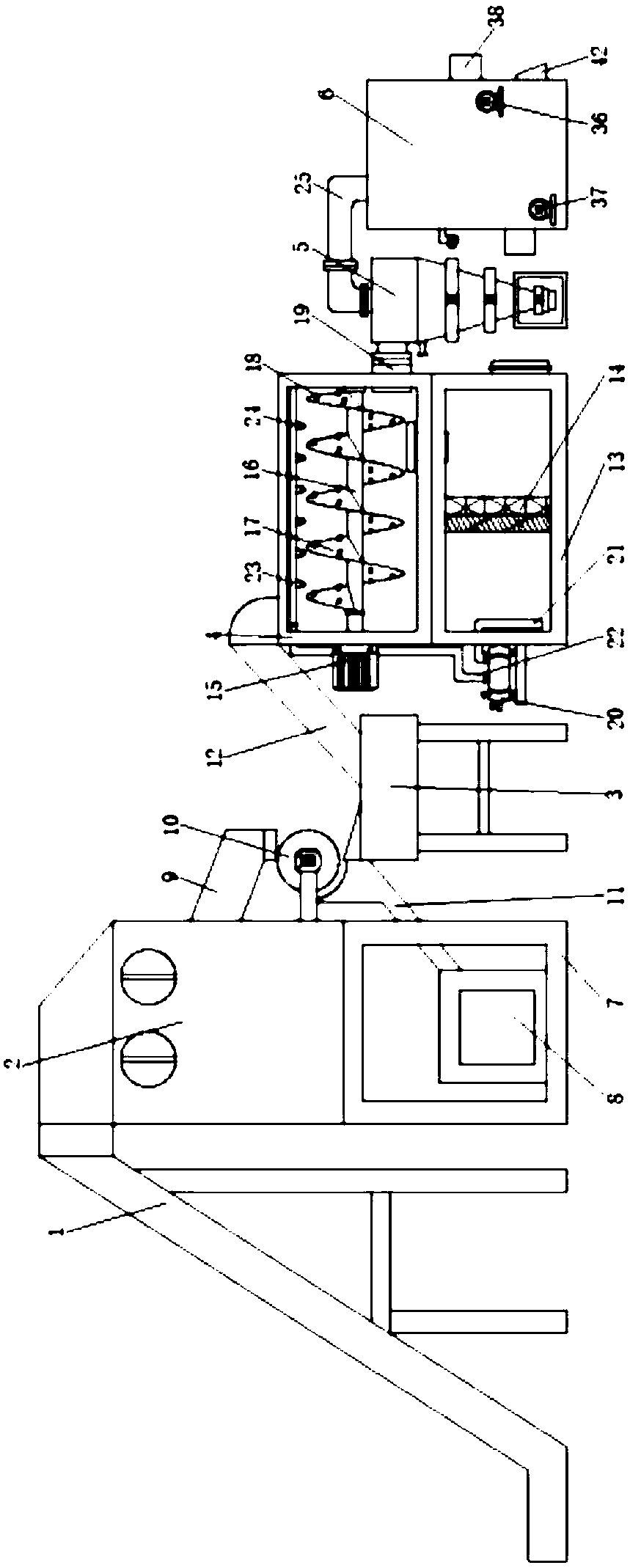

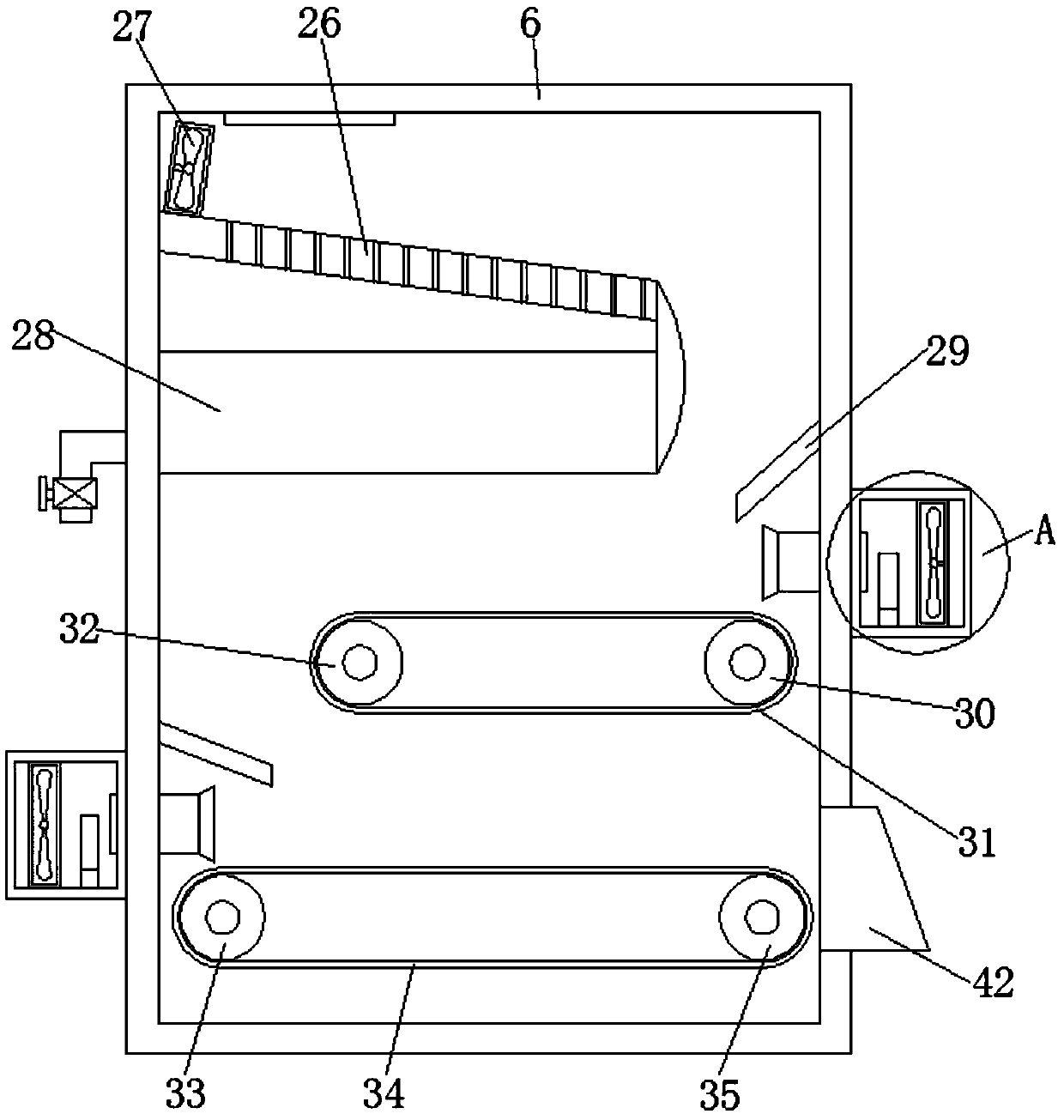

Swirling flow type waste plastic crushing sorting cleaning system

InactiveCN109551664AQuality improvementReduce metal magnetic impuritiesPlastic recyclingMechanical material recoveryWater resourcesPlastic recycling

The invention provides a swirling flow type waste plastic crushing sorting cleaning system. The swirling flow type waste plastic crushing sorting cleaning system includes a first transfer machine, a crushing machine, a transfer box, a cleaning device, a swirler, a box body and a fixing frame, and the top of the fixing frame is fixed to the bottom of the crushing machine. According to the swirlingflow type waste plastic crushing sorting cleaning system, metal magnetic impurities in waste plastic are reduced, the quality of waste plastic recycling is improved, meanwhile, the waste metal magnetic impurities are collected, post-processing and production of processing are convenient, multi-angle cleaning is realized, cleaning is more even, the efficiency and quality of cleaning are ensured, thus the recycling efficiency of the waste plastic is improved, reuse of water resources is improved, the cleanliness degree of the cleaning process is increased, thus the recycling quality of the wasteplastic is ensured, the water content of waste plastic recycling is decreased, and the quality of production is ensured, so that secondary processing is avoided.

Owner:开平市源成达塑胶制品有限公司

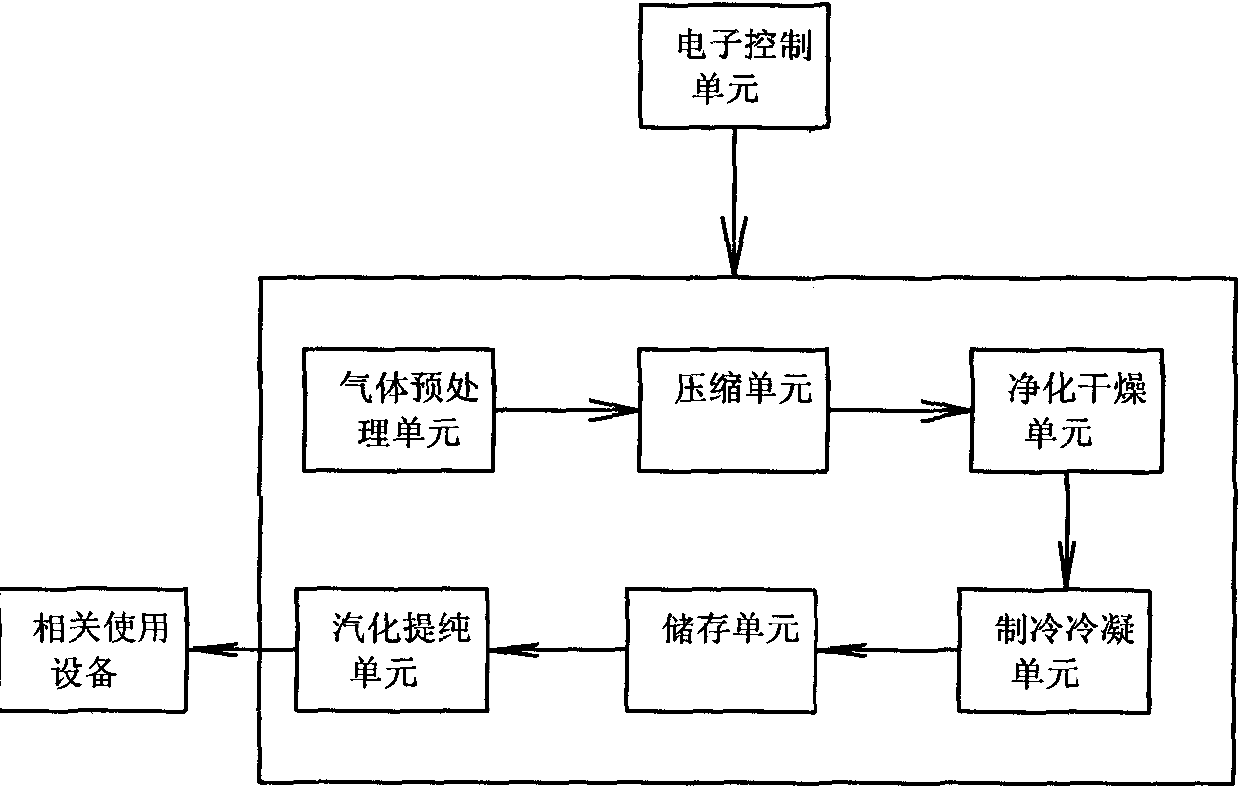

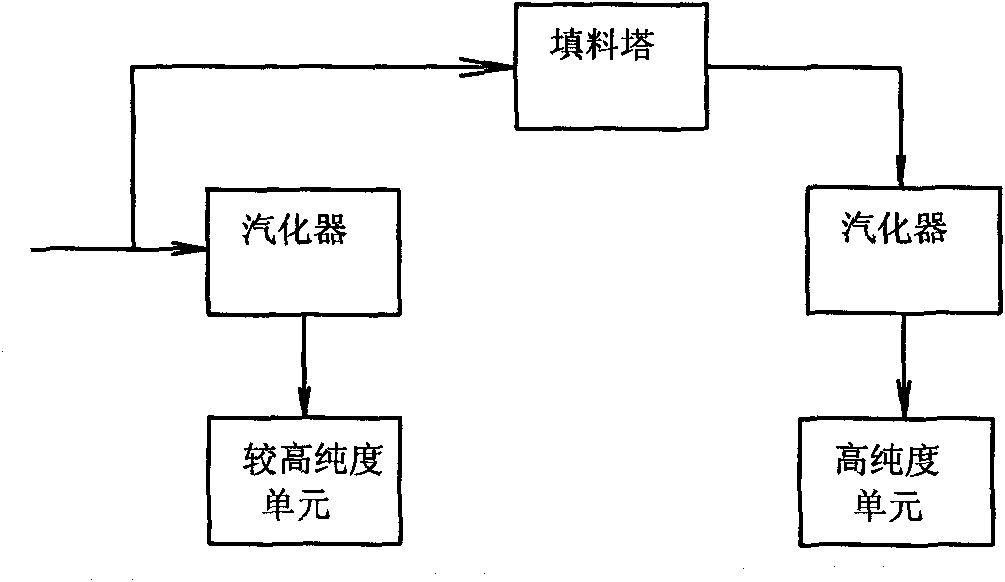

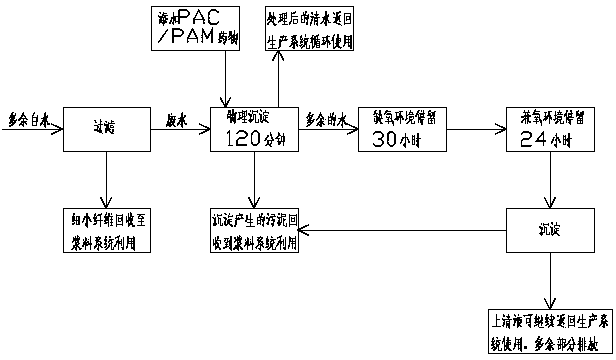

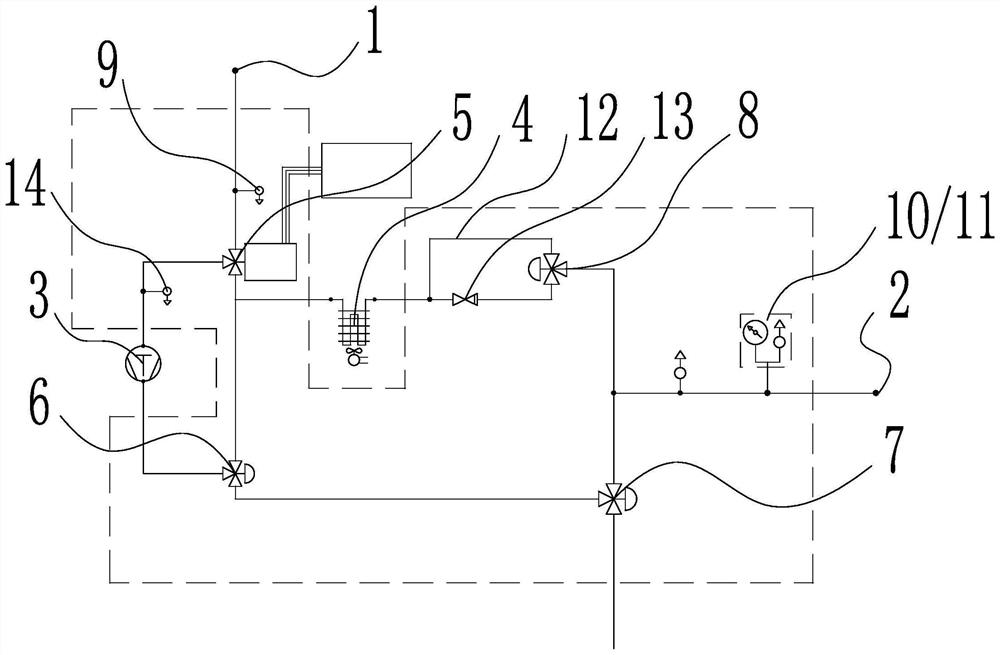

Carbon dioxide recovery system

InactiveCN102198939AGuarantee the quality of recyclingReduce consumptionProductsReagentsLiquid stateProcess engineering

The invention discloses a carbon dioxide recovery system, and relates to the recovery and purification of carbon dioxide gas in fermentation gas in a winery. The system comprises a gas pretreatment unit, a compression unit, a purifying and drying unit, a refrigerating and condensing unit, a storage unit, a vaporizing and purifying unit and an electronic control unit which are connected in turn, wherein a foam detection sensor is arranged in a demister; a valve is arranged between the demister and an air sac; a heating device is arranged in the storage unit; the top of the storage unit is provided with a pipeline for making liquid carbon dioxide flow to the bottom of the storage unit; the vaporizing and purifying unit is divided into a relatively high purity unit and a high purity unit; and one part of coarse liquid carbon dioxide in the storage unit enters the relatively high purity unit through a vaporizer, and the other part of the coarse liquid carbon dioxide is purified under the action of a purifying filler and enters the high purity unit through the vaporizer. The recovery system ensures high purity of the recovered carbon dioxide and has low energy consumption.

Owner:YANGZHOU XIANYE GRP

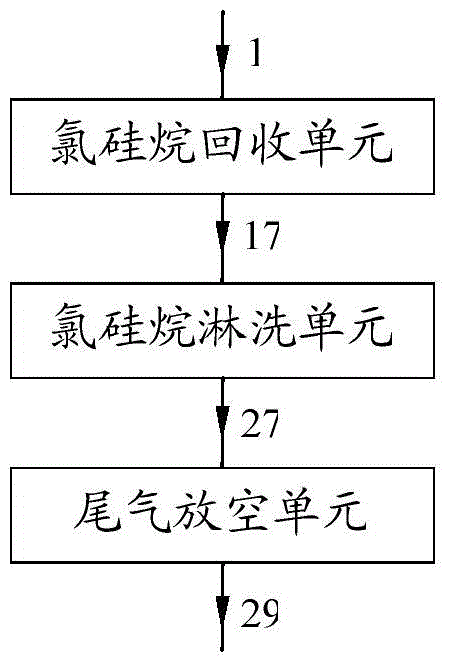

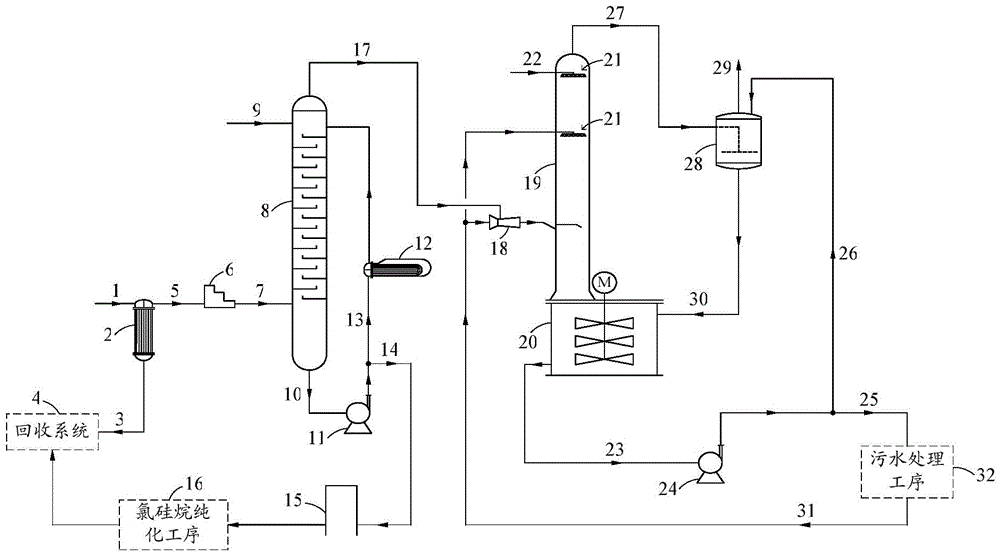

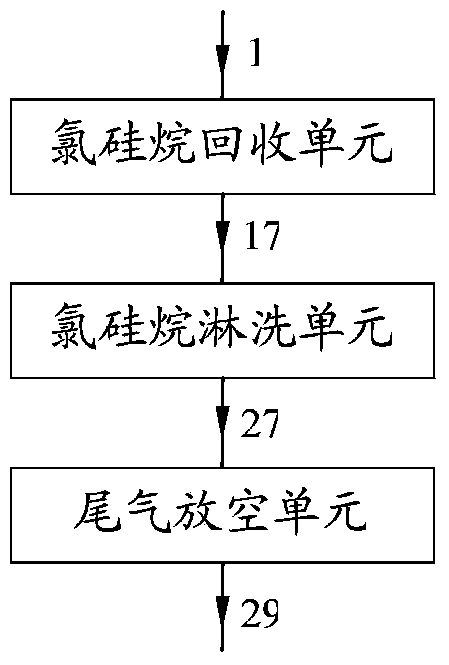

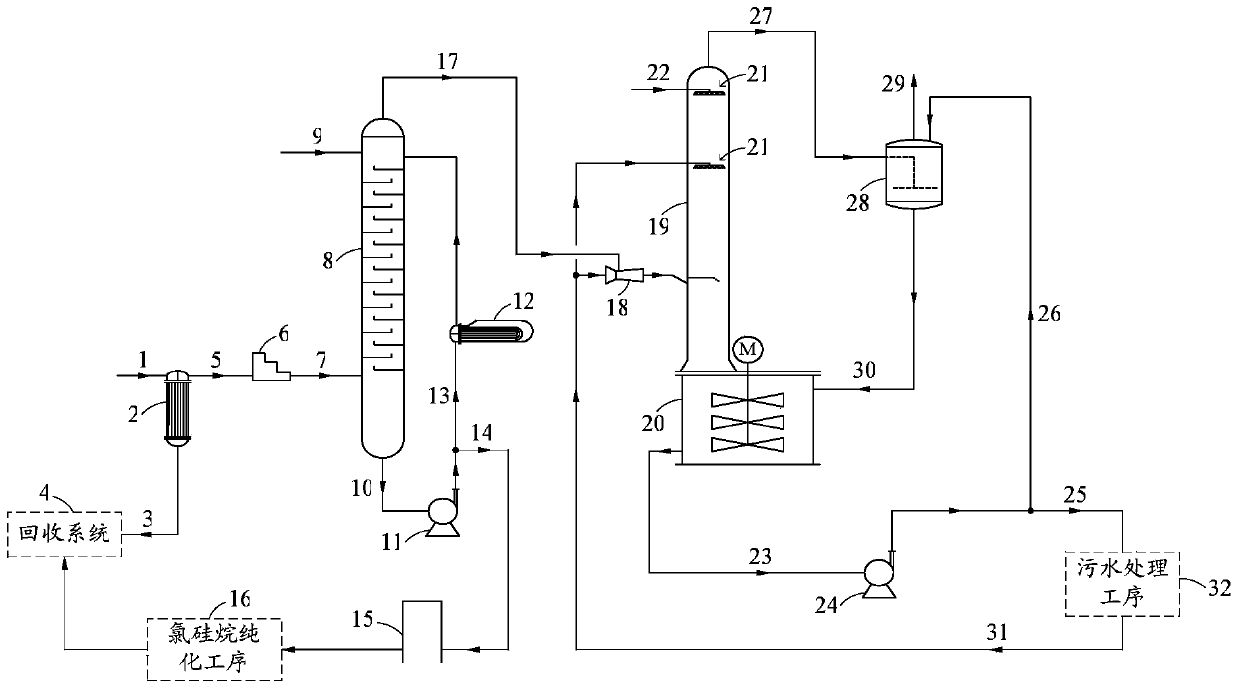

Chlorosilane-containing waste gas recovery treatment apparatus

ActiveCN105084369AReduce dosageReduce productionSolidificationLiquefactionEnvironmental engineeringHydrogen chloride

The present invention provides a chlorosilane-containing waste gas recovery treatment apparatus, which comprises a chlorosilane recovery unit, a chlorosilane leaching unit and a tail gas emptying unit, wherein the chlorosilane recovery unit is connected with the chlorosilane leaching unit and is used for recovering partial chlorosilane gas in chlorosilane-containing waste gas and conveying the remaining waste gas to the chlorosilane leaching unit, the chlorosilane leaching unit is connected with the tail gas emptying unit and is used for leaching out the remaining chlorosilane gas and hydrogen chloride gas in the remaining waste gas so as to clear the chlorosilane gas and the hydrogen chloride gas in the remaining waste gas, and conveying the chlorosilane gas and hydrogen chloride gas-clearing remaining waste gas to the tail gas emptying unit, and the tail gas emptying unit is used for emptying the chlorosilane gas and hydrogen chloride gas-clearing remaining waste gas. With the recovery treatment apparatus of the present invention, the chlorosilane resource in the recovered waste gas can be completely recovered, and the pollution-free treatment can be performed on the chlorosilane incapable of being recovered in the waste gas.

Owner:XINTE ENERGY

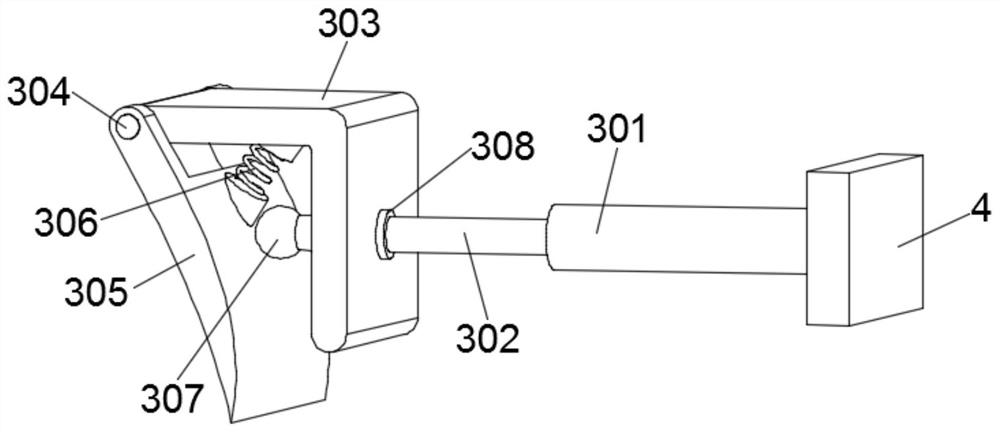

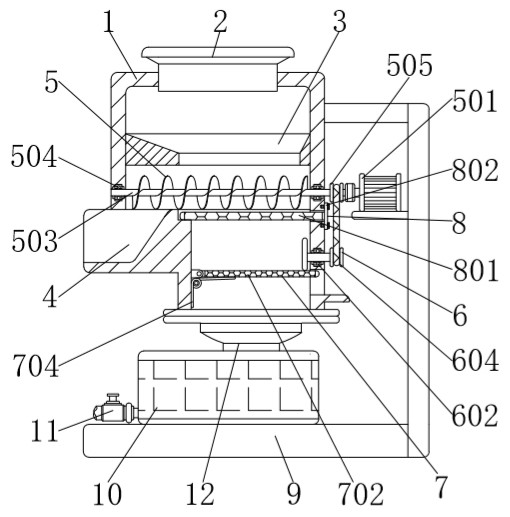

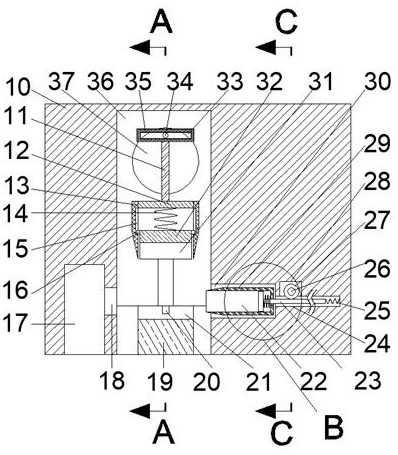

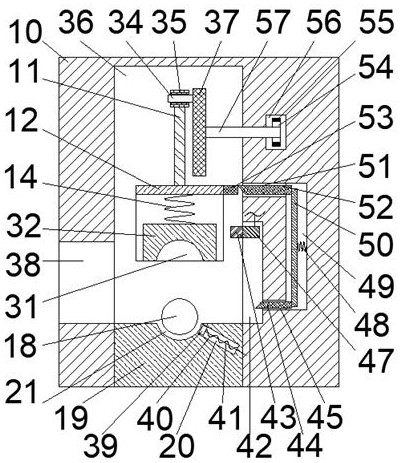

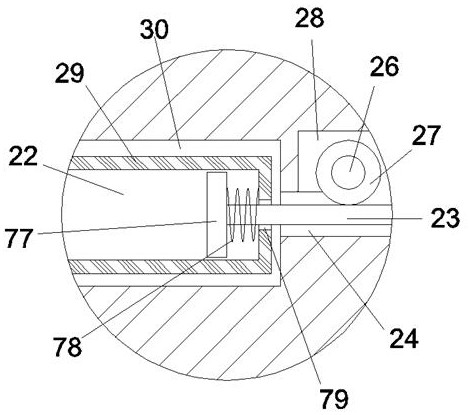

Chip recovery device for machine tool machining

InactiveCN112338620AAvoid bringing backKeep dryMaintainance and safety accessoriesStationary filtering element filtersHelical bladeAir blower

The invention discloses a chip recovery device for machine tool machining. The chip recovery device comprises a back plate and a platform, wherein a material pushing mechanism is arranged above the platform; a chip collecting groove is formed in one end of the platform, a filter screen is installed in the chip collecting groove, a conveying belt is arranged above the chip collecting groove, an electromagnet is laid on the conveying belt, a partition plate is arranged between the conveying belt and the material pushing mechanism, and a dehumidifier is installed on the partition plate; and a scraping plate is arranged at the upper end of the conveying belt, an air blower is arranged above the scraping plate, a shell is arranged at the end, far away from the partition plate, of the scraping plate, a spiral blade is rotationally installed in the shell, and a plurality of drying plates are vertically arranged on the inner wall of the shell. According to the chip recovery device for machinetool machining, chips are pushed into the chip collecting groove through the material pushing mechanism, then iron chips are adsorbed through the electromagnet on the conveying belt, and dehumidification treatment is carried out on the iron chips through the dehumidifier; and the chips on the conveying belt are scraped off through the scraping plate at the upper end, the chips are blown into the shell through the air blower, water on the surfaces of the chips is removed again through the drying plates, so that the chips are prevented from being rusted, and the recovery quality is guaranteed.

Owner:王军

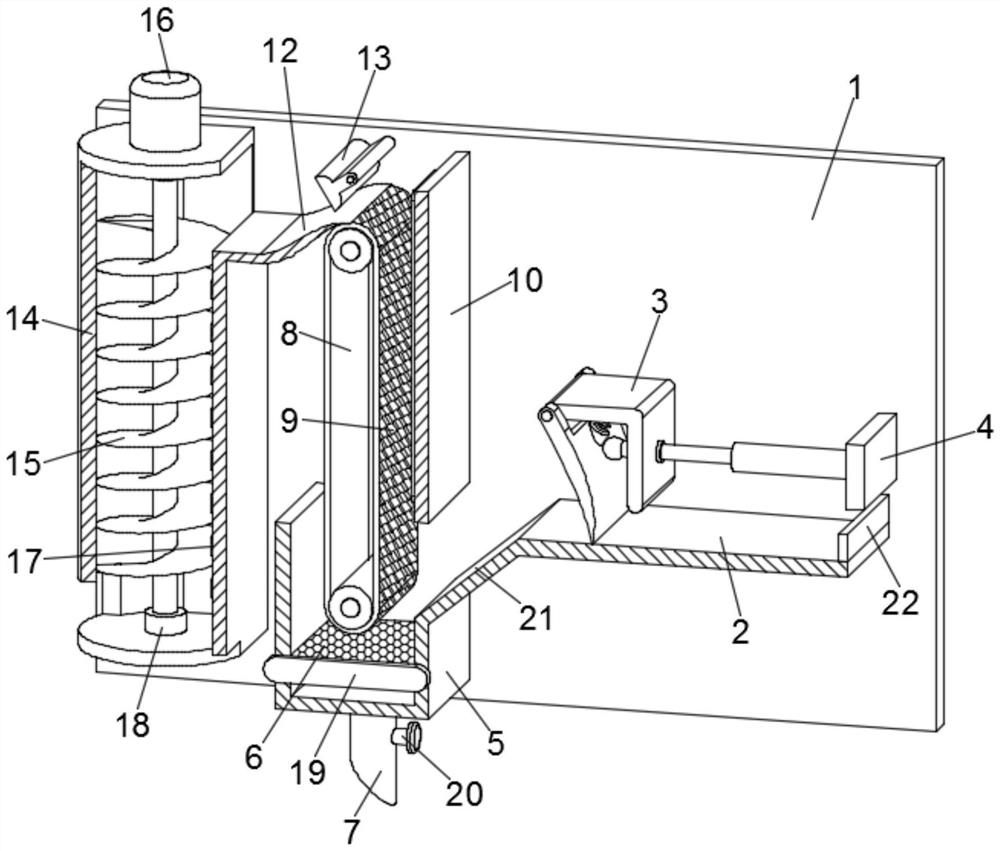

Method and system for realizing zero emission of papermaking pulp residue and sludge

InactiveCN103726386AGuarantee the quality of recyclingFast separationMachine wet endMultistage water/sewage treatmentSludgeWastewater

The invention belongs to the field of papermaking and relates to a method and a system for realizing zero emission of papermaking pulp residue and sludge. Waste water generated in papermaking is processed by steps of filtering, physical sedimentation, biochemical treatment and sedimentation, in other words, pulp residue and sludge in waste water are recovered at multiple levels and stages and then are supplied to a slurry system for production, so that pulp residue and sludge in the waste water are recovered completely and zero emission thereof is achieved. In the system, by the aid of filtering and purifying facilities such as a grid machine and an inclined screen for filter, an efficient purifying tower for settling, an anaerobic tank and an aerobic tank for performing biochemical treatment and a secondary sedimentation tank and tertiary sedimentation tank for performing re-sedimentation, the pulp residue and sludge of the waste water are separated completely and then delivered to papermaking workshops to be recovered, and thus, zero emission of the pulp residue and sludge in papermaking is realized.

Owner:吕建荣

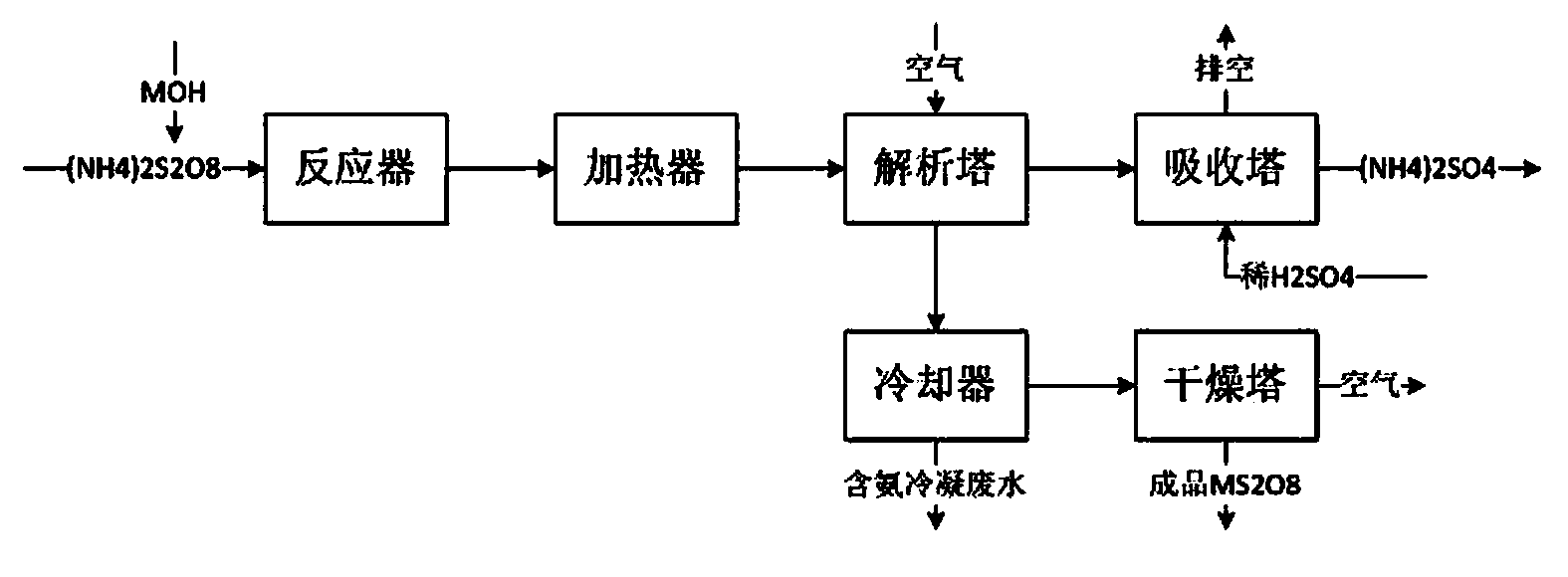

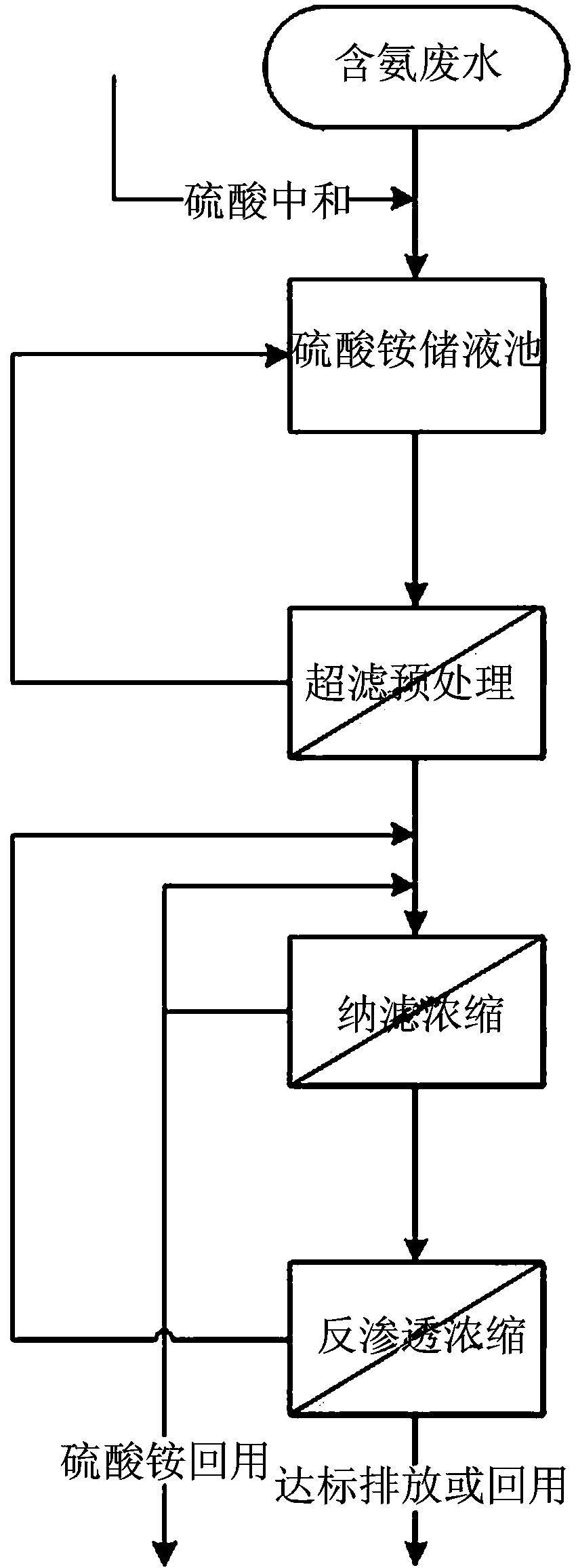

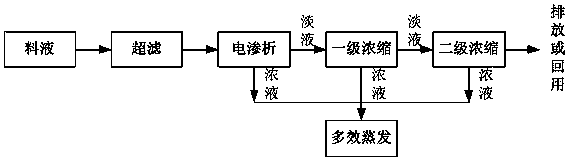

Method for treating low-concentration ammonia-containing wastewater by use of membrane separation technology

InactiveCN103663774AMeet the technical characteristics of the separationAvoid secondary pollutionChemical industryWater/sewage treatment bu osmosis/dialysisChemical industryUltrafiltration

The invention relates to a treatment method for low-concentration ammonia-containing wastewater, and particularly relates to a technical method taking a membrane separation technology as a core treatment unit. Low-concentration ammonia-containing wastewater often occurs in the production process of the chemical industry; although the concentration is relatively low, the low-concentration ammonia-containing wastewater is hard to treat and not easy to recycle. According to the characteristics, the invention provides a method for treating low-concentration ammonia-containing wastewater by use of a membrane separation technology, which specifically comprises the steps of neutralization with sulfuric acid, ultrafiltration separation, nanofiltration concentration and separation and reverse osmosis concentration and separation. The concentrated solution of nanofiltration can be recycled as a concentrated ammonium sulfate solution and is utilized in a production process; the yielding water of reverse osmosis can reach relatively high yielding water quality and can be discharged or recycled; the thick water of reverse osmosis flows back to the incoming water of nanofiltration so that the whole process basically realizes zero discharge and is environmentally friendly and energy-saving.

Owner:SUZHOU FAITH HOPE MEMBRANE TECH

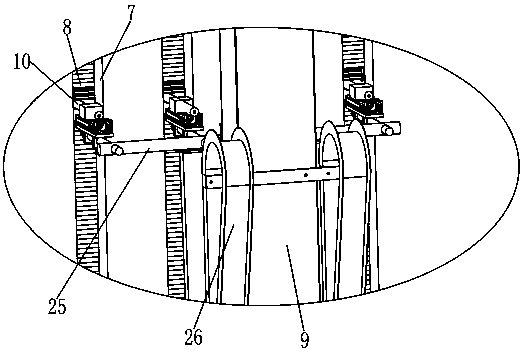

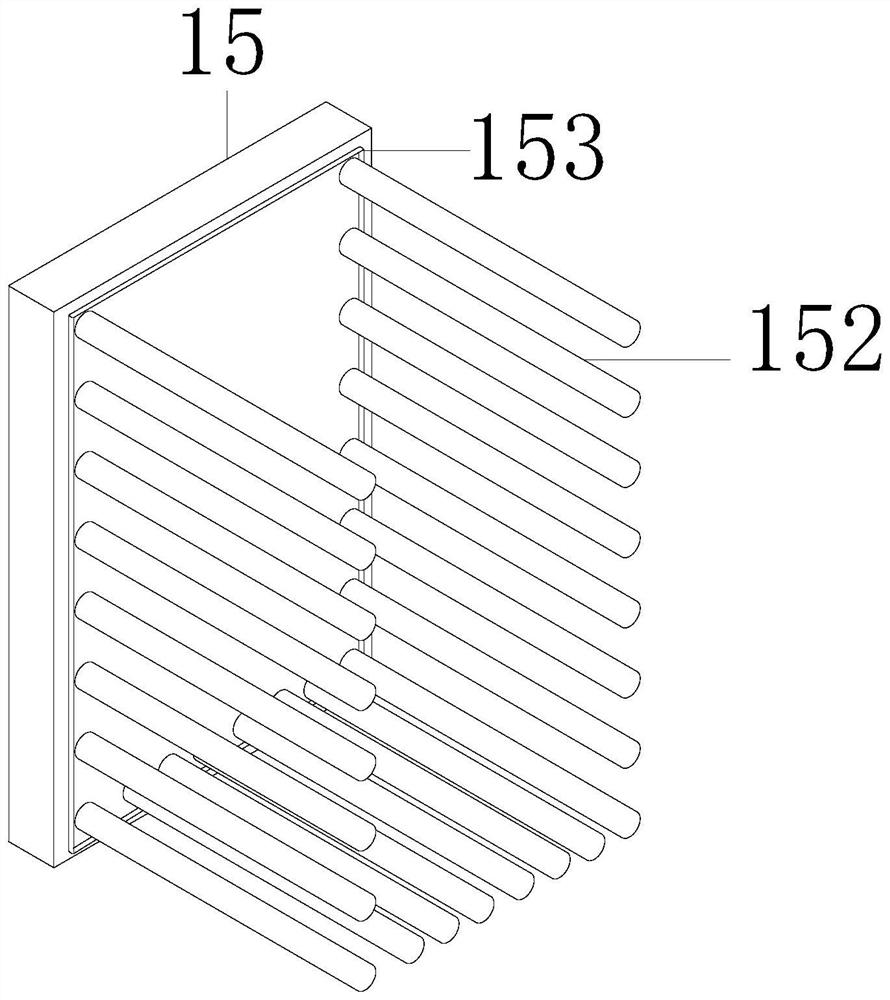

Spraying device with powder recycling function

PendingCN109332057AAvoid splashing out of the spray tankNot dirtySpraying apparatusEngineeringMechanical engineering

A spraying device with a powder recycling function comprises a spraying box; the left side wall and the right side wall of the spraying box are provided with openings communicate with the inner spaceof the spraying box; the side wall of the upper side of the spraying box is provided with a conveying channel communicating with the inner space of the spraying box; the left side and the right side of the spraying box are provided with a plurality of vertical frames; the vertical frames are provided with suspension conveying chains matched with the conveying channel; the vertical frame located onone side of the spraying box is provided with inductive probes; the outer walls of the front side and the rear side of the spraying box are provided with a plurality of uniformly-distributed longitudinal slide ways, and the longitudinal slide ways communicate with the interior of the spraying box; the front side and the rear side of the spraying box are provided with symmetrical positioning mechanisms; and the inner walls of the front side and the rear side of the spraying box are spread with organ telescopic plates, and the longitudinal slide ways are blocked and sealed through the organ telescopic plates. Through the spraying device with the powder recycling function, powder sprayed out from a spray gun can be stopped in the spraying device, and moreover, the powder can be recycled.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

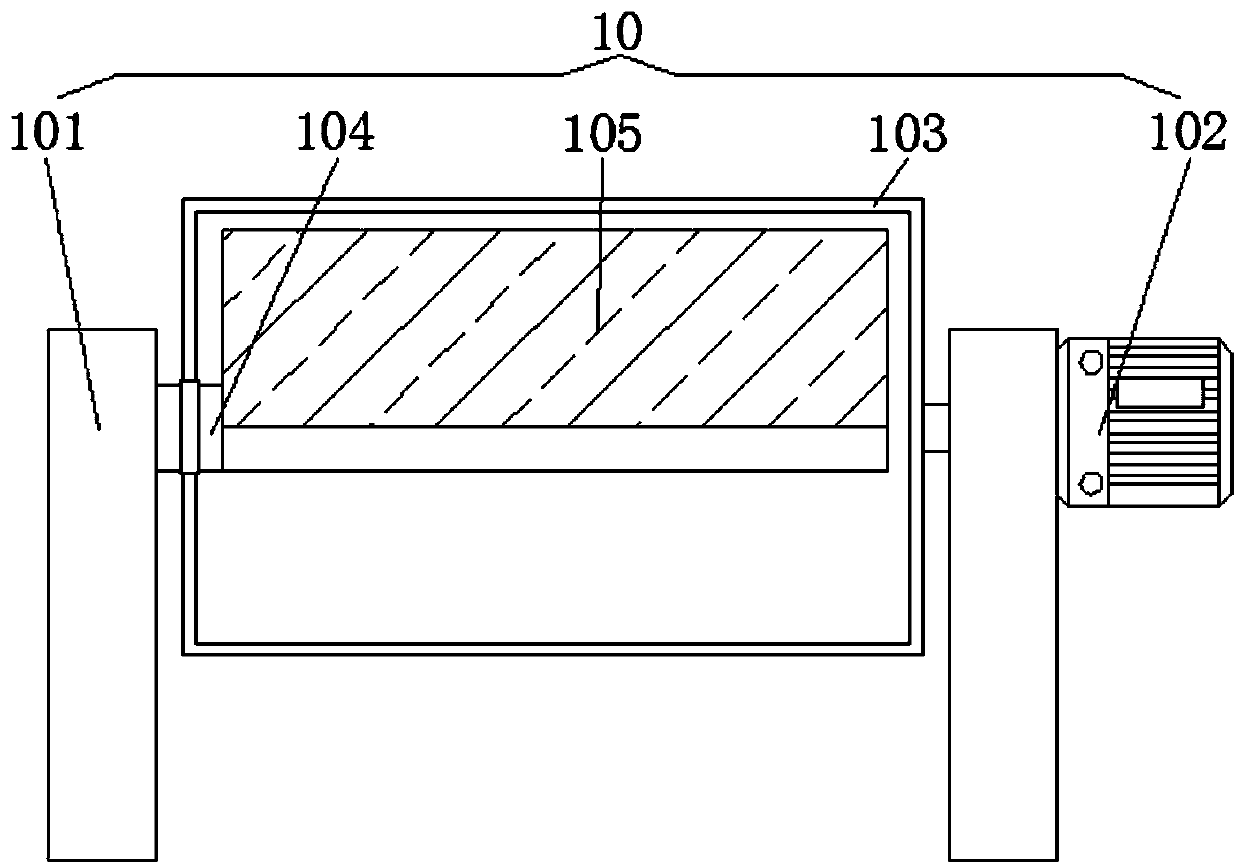

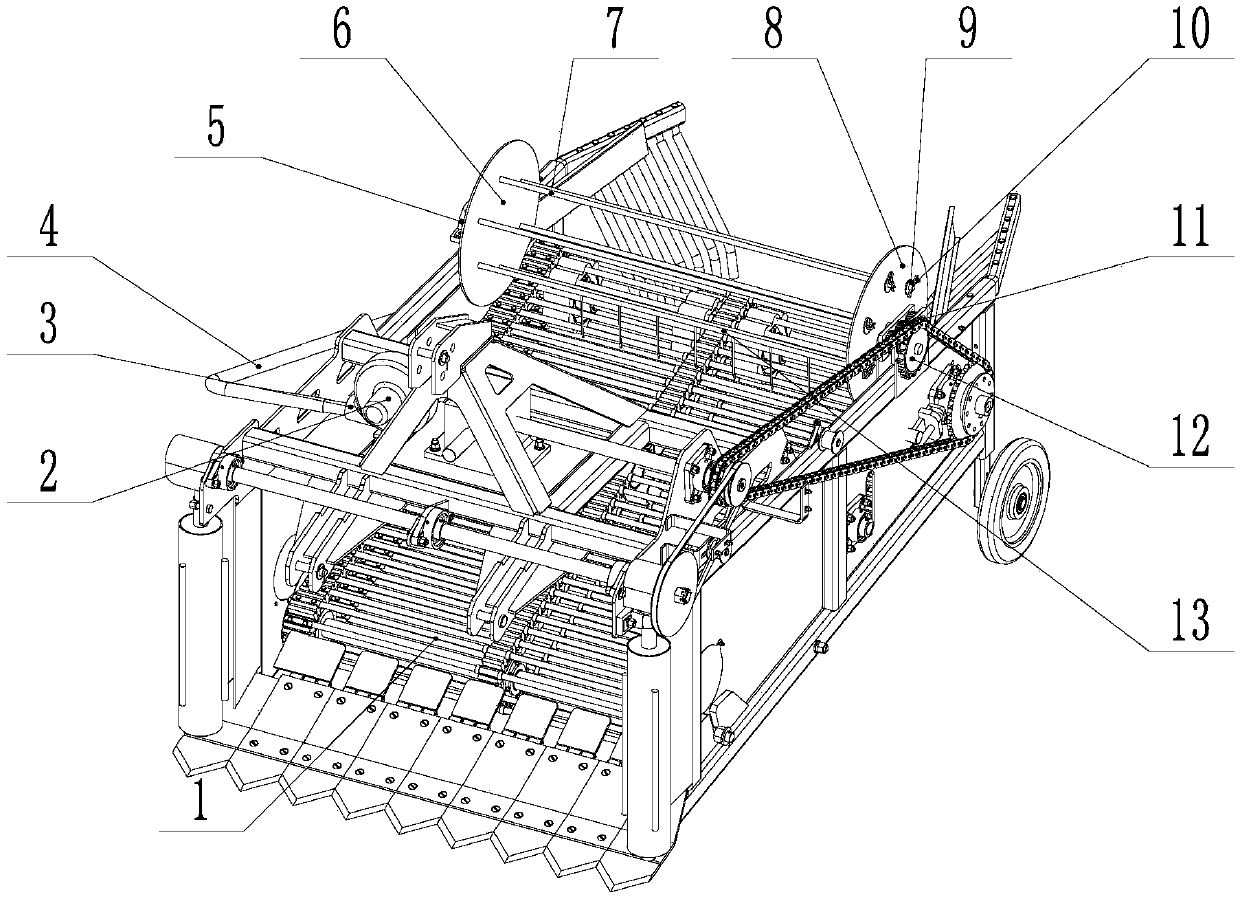

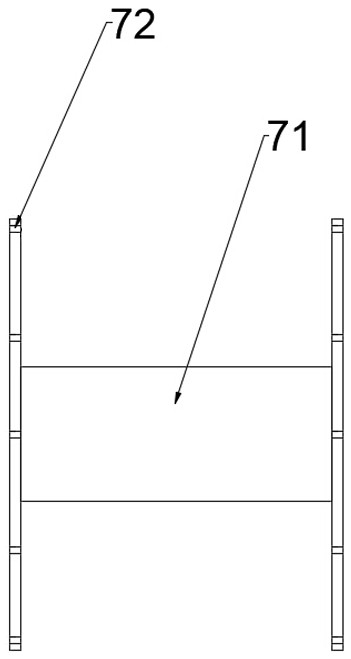

Automatic recovery system of scutching machines for hemp fibers

ActiveCN105239216AReduce manual labor intensityReduce manufacturing costContinuous processingFibre feedersHemp fiberProcess engineering

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

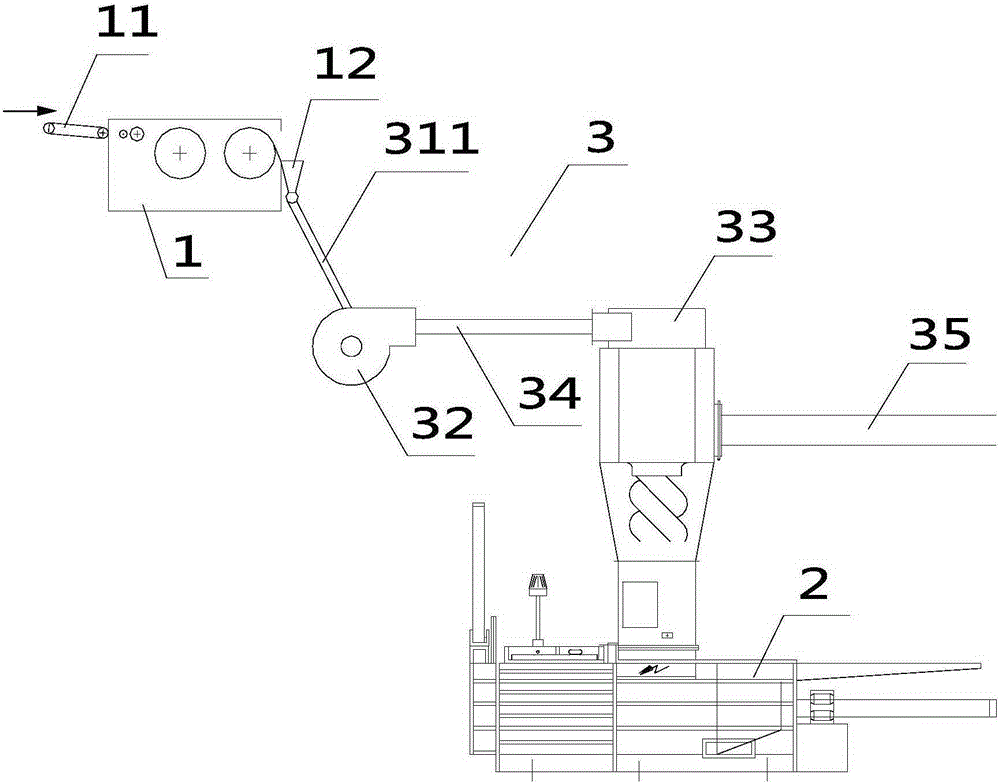

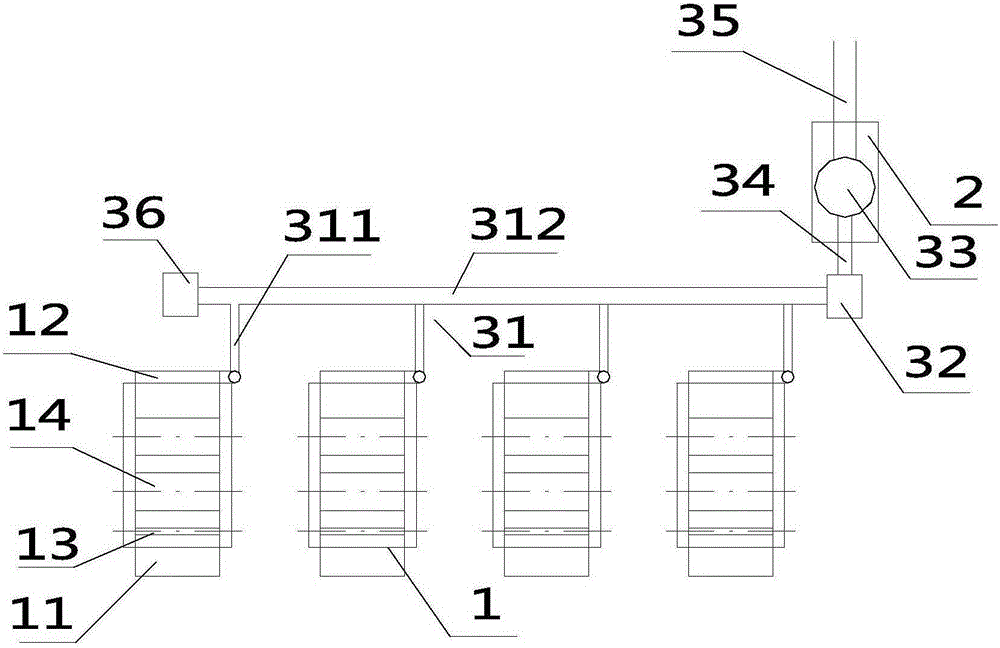

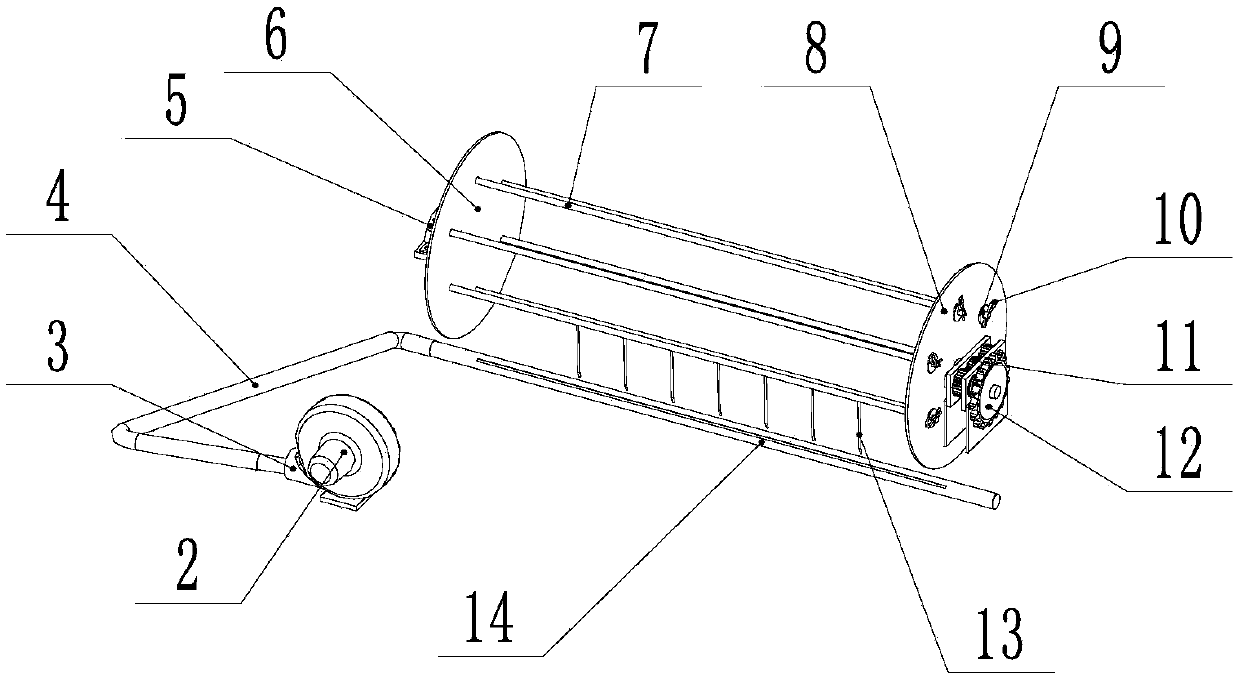

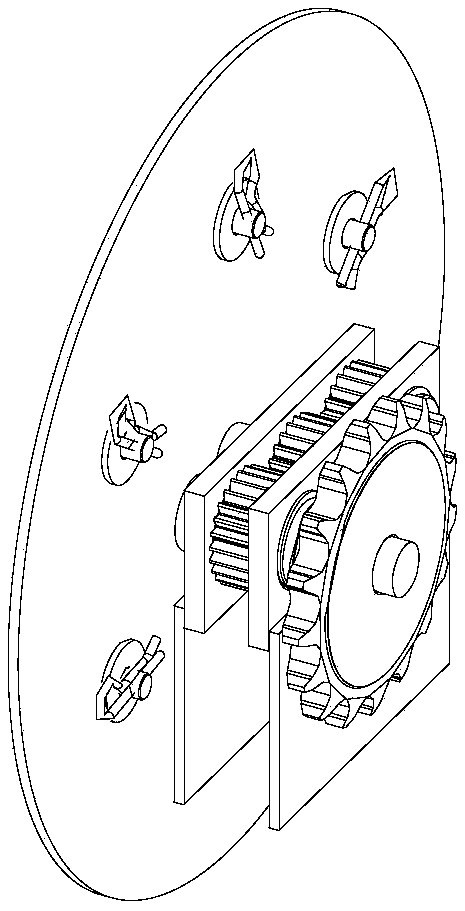

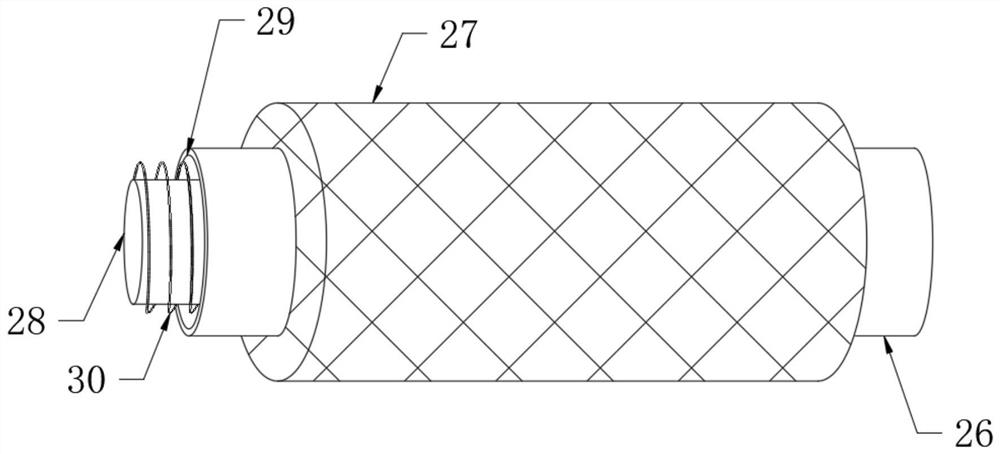

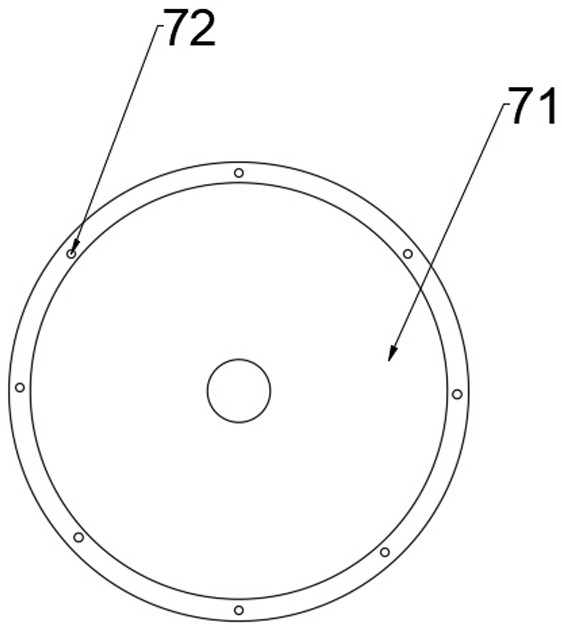

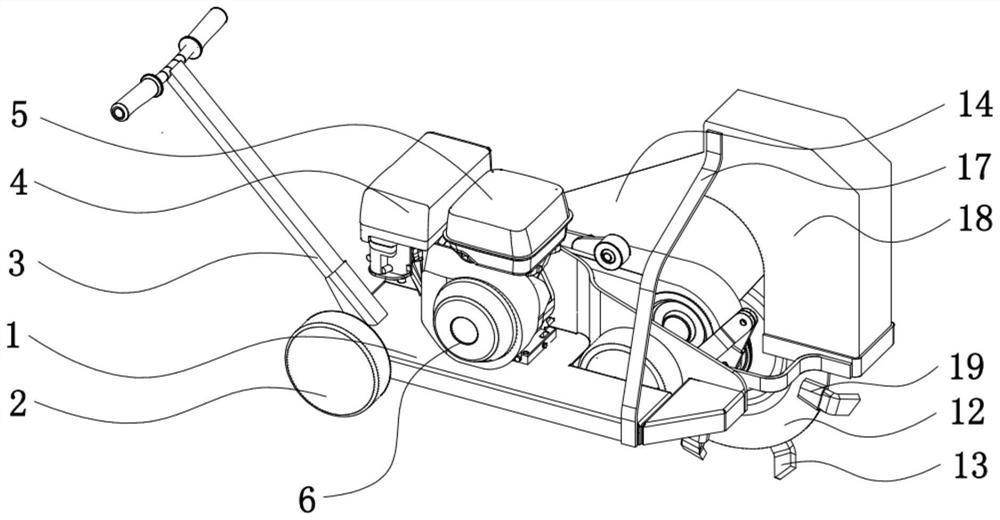

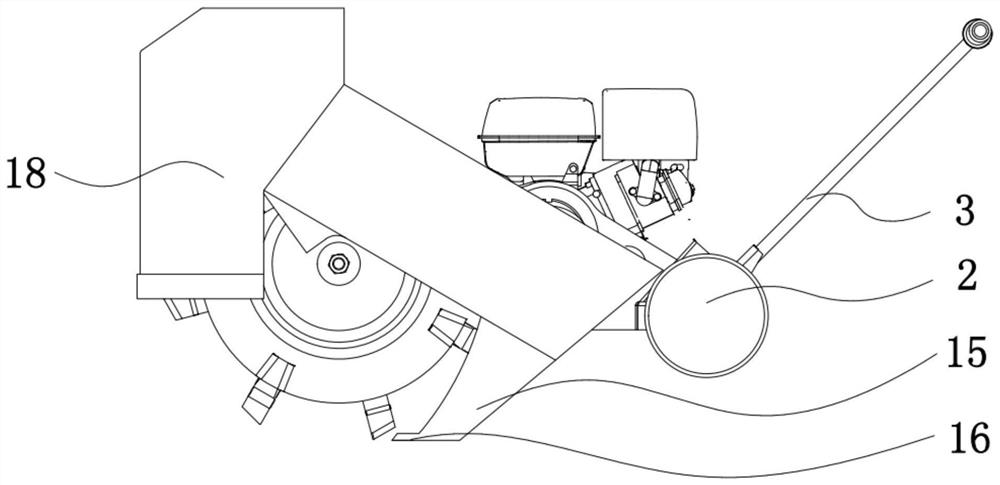

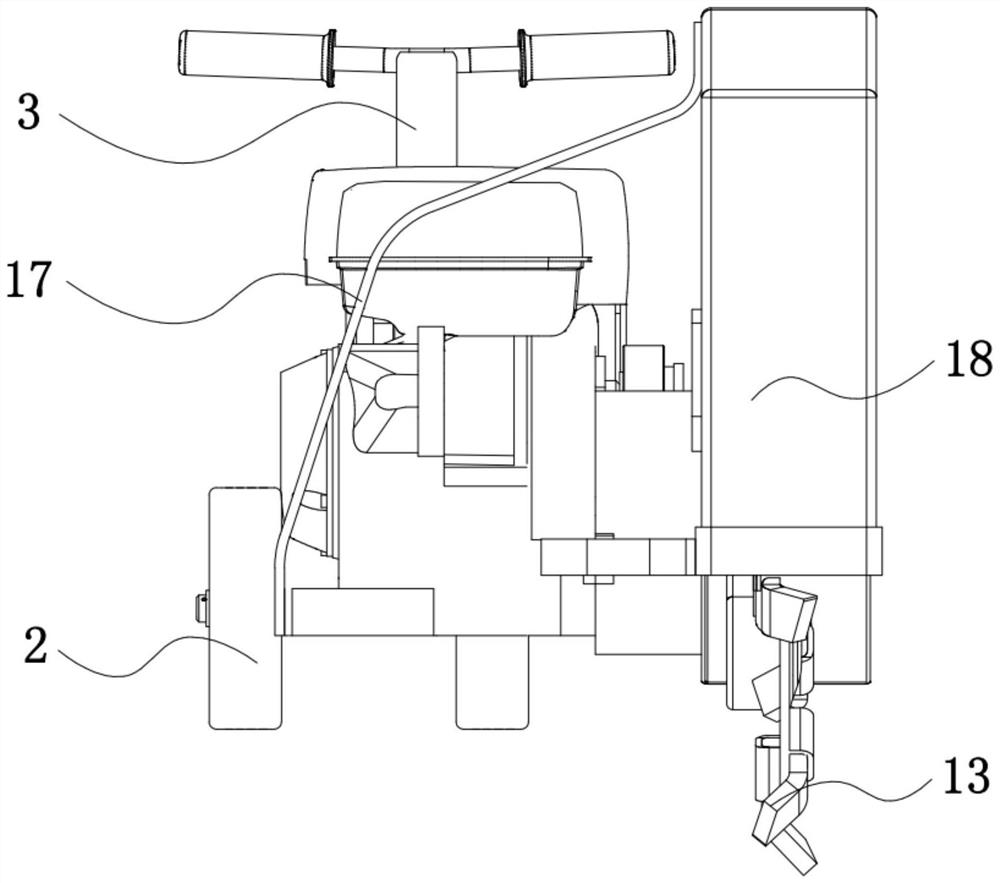

Pneumatic plastic film residue winding roller device, subsoil harvester and operation method thereof

PendingCN109565965AAchieve windingGuarantee the quality of recyclingDigger harvestersGatherer machinesEngineeringPlastic film

The invention discloses a pneumatic plastic film residue winding roller device, a subsoil harvester and an operation method thereof. The problems that in the prior art, an existing subsoil harvester has a single function, is narrow in application range and cannot achieve synchronization of subsoil harvesting and plastic film residue recycling are solved. The subsoil harvester has the effects thatplastic film residues can be automatically wound, the plastic film residue recycling efficiency is high, the rotating direction can be adjusted according to the types of plastic film residues, and theuniversality is high under the pneumatic effect; according to the technical scheme, the device comprises a film rolling device and a pneumatic device, the film rolling device comprises a driving halfshaft disc and a driven half shaft disc which are oppositely installed, the driving half shaft disc and the driven half shaft disc are connected through a plurality of annularly-distributed connecting rods, and one connecting rod is fixedly provided with a plurality of film lifting toothed bar; a reversing device for changing the rotating direction is installed at the side face of the driving half shaft disc; the pneumatic device comprises an air duct close to the film lifting toothed bar, and the angle of the air duct is adjustable.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

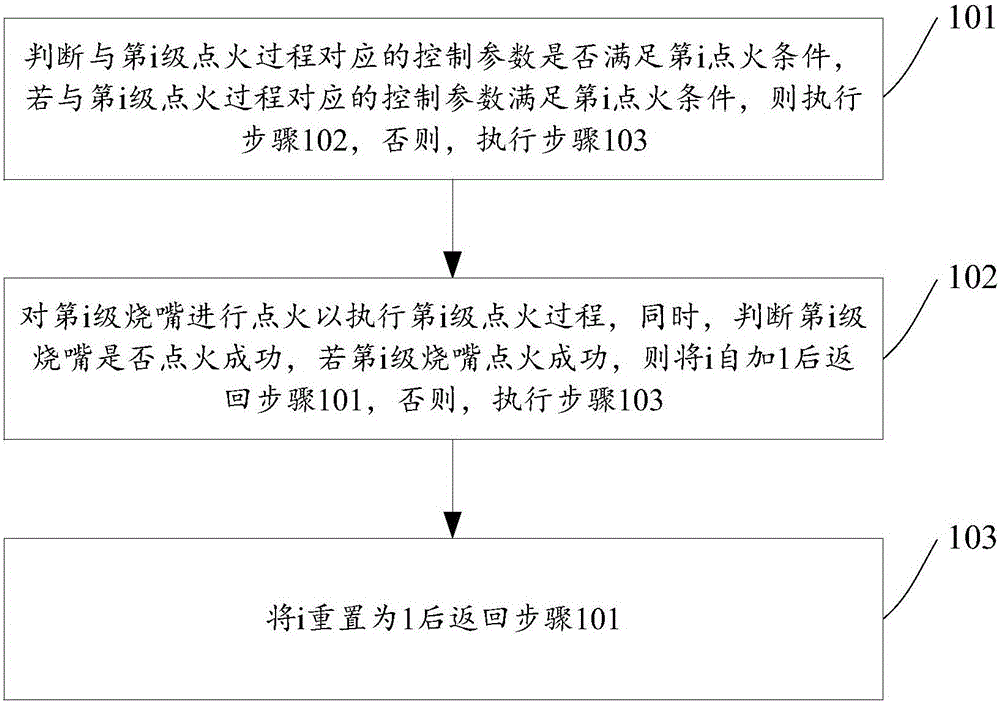

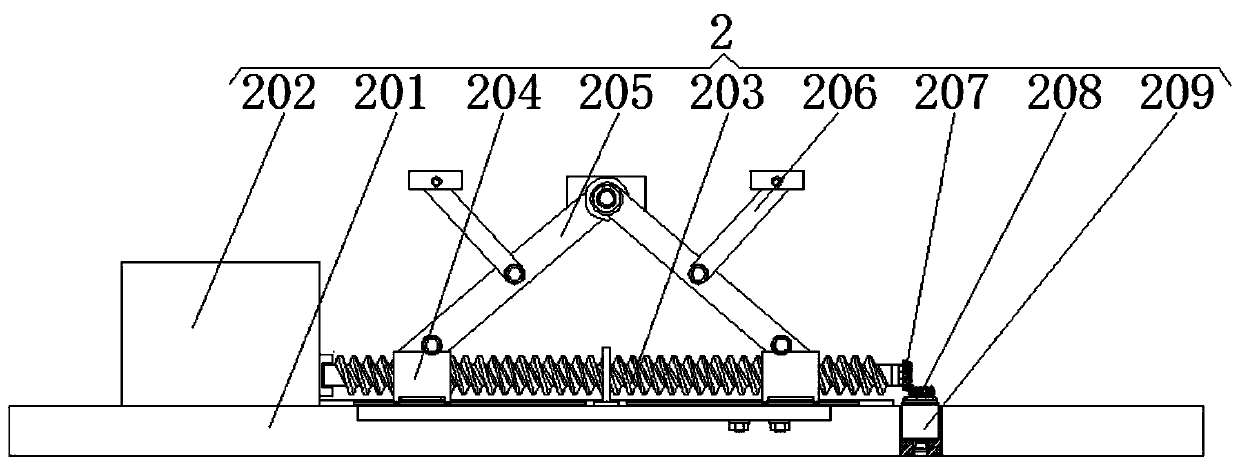

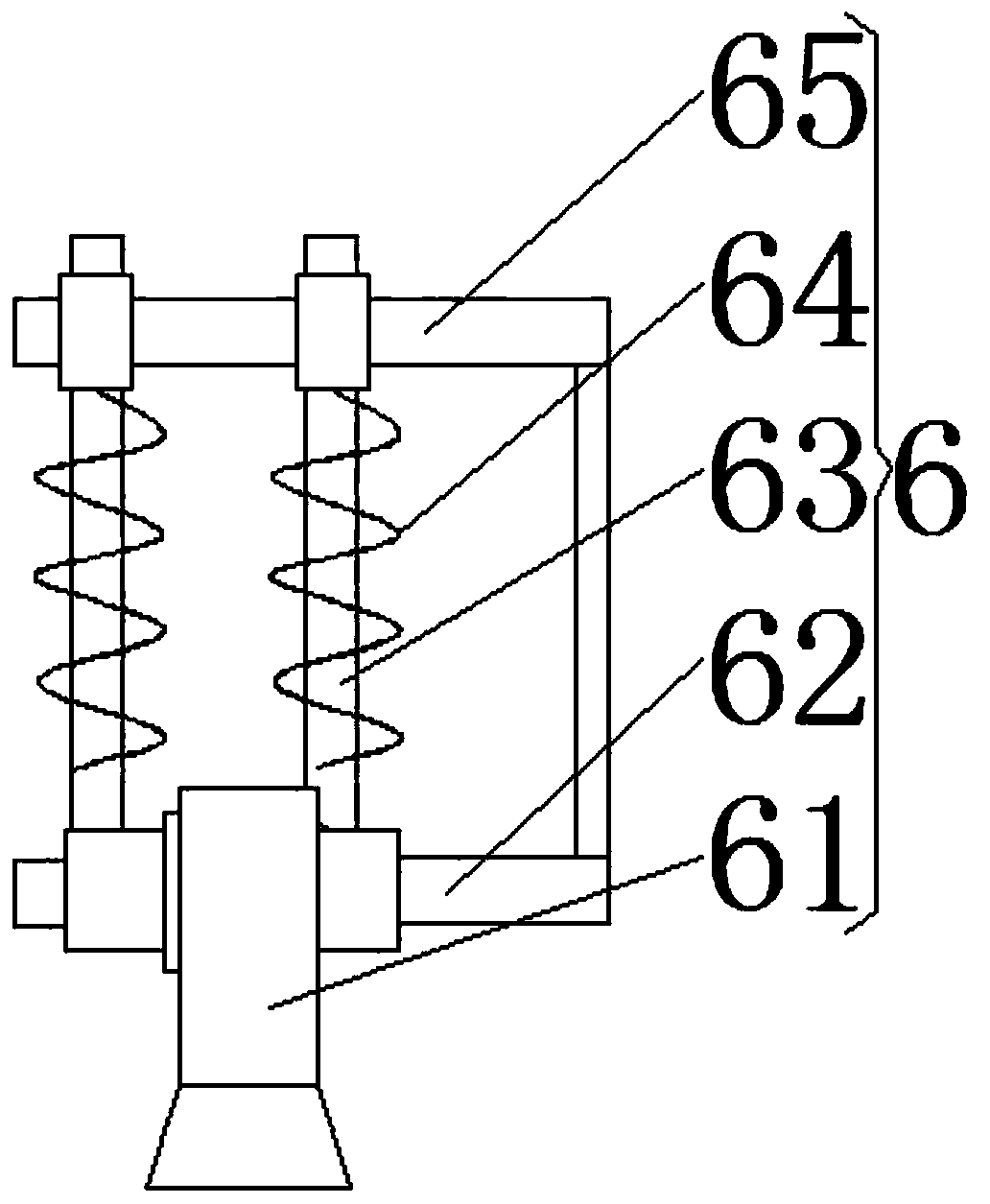

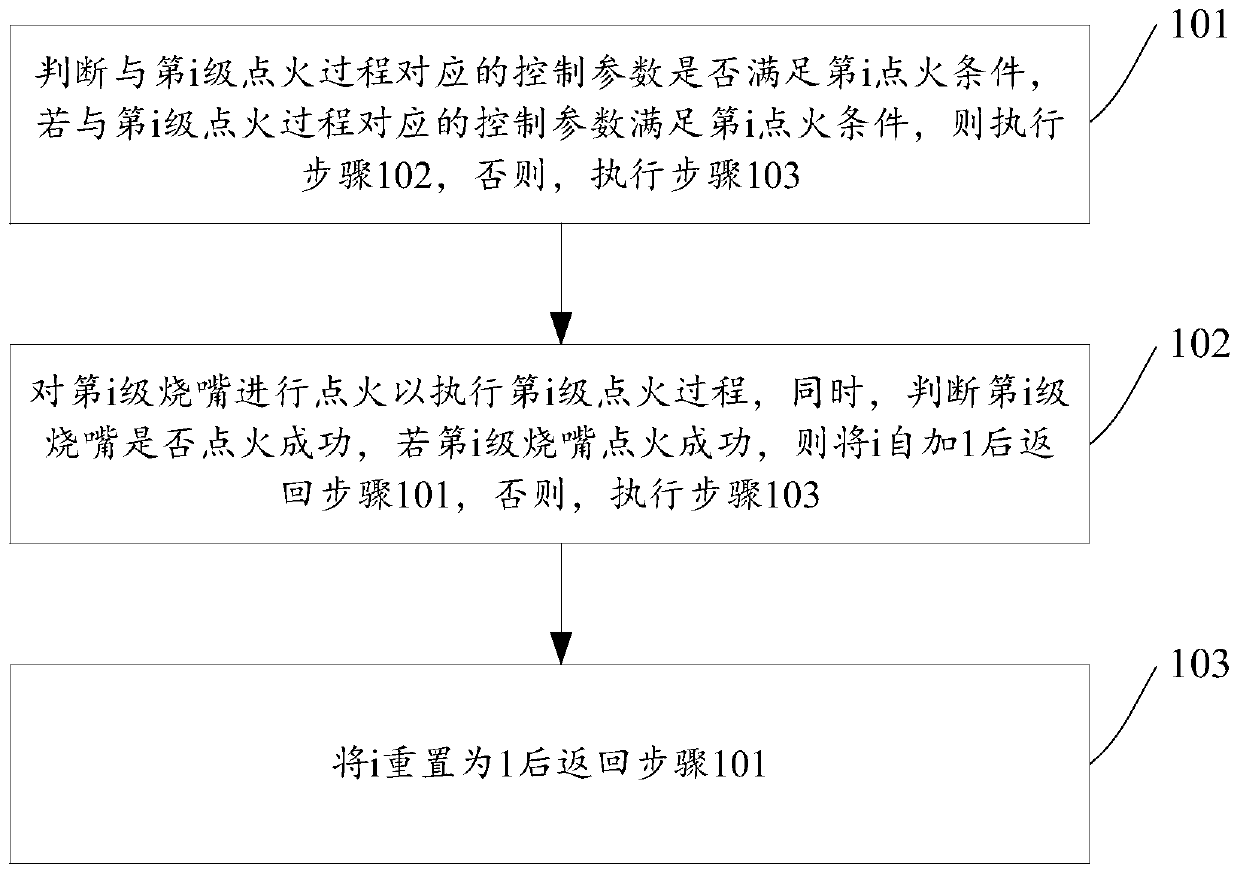

Coke oven ignition control method and device

ActiveCN106811213AGuarantee the quality of recyclingEvenly heatedCoke oven safety devicesProcess engineeringCoke oven

The invention relates to the technical field of coal chemical industry, and particularly relates to a coke oven ignition control method and a coke oven ignition control device; the method includes steps of i, orderly executing from 1 to N; step 101, judging if the control parameter corresponding to the i grade ignition process can meet the i ignition condition; if the control parameter corresponding to the i grade ignition process meets the i ignition condition, executing the step 102; or, executing step 103; step 102: igniting the i grade nozzle to execute the i grade ignition process; meanwhile, judging if the i grade nozzle is successfully ignited; if the i grade nozzle ignition is successful, adding 1 to i, and then returning to step 101; or, executing step 103; step 103: resetting i to 1, and then returning to step 101; when i is equal to N in step 102, completing the ignition i if the ignition of the N grade nozzle is successful, and not adding 1. The coke oven ignition control method and the device can guarantee the uniform temperature rise of the furnace body, and make the gas in the oven react safely, and improve the service life and the production safety of the cock furnace.

Owner:武汉钢铁有限公司

Dropped excess material recycling device for disposable glove production

ActiveCN112476909AGuaranteed filtering effectGuarantee the quality of recyclingCoatingsProcess engineeringMechanical engineering

The invention discloses a dropped excess material recycling device for disposable glove production. The device comprises a recycling box and an opening formed in the top of the recycling box, a flow guiding box is arranged at the bottom of the recycling box, a filtering box is arranged at the bottom of the flow guiding box, a collecting box is arranged at the bottom of the filtering box, a dripping net plate is arranged in the middle of the interior of the opening, and buffering assemblies are arranged on the two sides of the dripping net plate. According to the device, a filtering plate can be disassembled by unscrewing a connecting bolt and pulling a pulling ring so that a user can conveniently clean the filtering plate, and the filtering effect of the filtering plate on excess materialsand the recycling quality are guaranteed; a pump body is automatically controlled through an arranged pump body control assembly, so that energy is saved, and the environmental protection property ofdevice use is improved; and meanwhile, the stability of the dripping net plate in a using process is guaranteed through the arranged buffering assemblies, and the excess materials can stably enter the recycling box, so that the using effect of the device is guaranteed.

Owner:江西美宝利实业有限公司

Process for recovering glucosamine in activated carbon

InactiveCN102391321AReduce recycling efficiencyReduced recycling qualitySugar derivativesSugar derivatives preparationActivated carbonDistillation

The invention relates to a process for recovering glucosamine in activated carbon, which comprises the following steps of: 1) adding the activated carbon and water into a reaction kettle according to a ratio of parts by weight being 1: (2.5-3.5), agitating and heating to 75-85 DEG C to enable the glucosamine in the activated carbon to be dissolved in the water; 2) conducting solid-liquid separation to the materials subject to the treatment through a filter press to separate solid activated carbon from aqueous solution containing the glucosamine; and 3) conducting negative-pressure distillation to the aqueous solution containing the glucosamine in the reaction kettle to obtain the glucosamine. By using the characteristic that the glucosamine can be easily dissolved in the water and by mixing the activated carbon containing absorbed glucosamine with the water, the glucosamine can be removed. Therefore, not only can the glucosamine be recovered, but also the activated carbon can be recycled and the economic benefit is greatly improved.

Owner:GAOYOU MINGZENG BIOLOGICAL PROD CO LTD

A device for recycling residual material after dripping for the production of disposable gloves

ActiveCN112476909BGuaranteed filtering effectGuarantee the quality of recyclingCoatingsProcess engineeringIndustrial engineering

The invention discloses a device for recovering residual material after dripping for the production of disposable gloves, comprising a recovery box and an opening on the top of the recovery box. A filter box, a collection box is arranged at the bottom of the filter box, a drip screen plate is arranged in the middle position inside the opening, and buffer components are arranged on both sides of the drip screen plate. The invention can complete the disassembly of the filter plate by unscrewing the connecting bolt and pulling the pull ring, which facilitates the cleaning of the filter plate by the user, ensures the filtering effect of the filter plate on the residual material and the recovery quality, and is controlled by the set pump body. The component realizes the automatic control of the pump body, thereby saving energy and improving the environmental protection of the device. At the same time, the set buffer component ensures the stability of the dripping screen during use, and also enables the remaining material to enter more smoothly. Inside the recycling box, so as to ensure the use effect of the device.

Owner:江西美宝利实业有限公司

A recovery and treatment device for waste gas containing chlorosilane

The invention provides a recycling and processing device for chlorosilane waste gas, comprising: a chlorosilane recovery unit, a chlorosilane rinsing unit and a tail gas venting unit, the chlorosilane recovery unit is connected with the chlorosilane rinsing unit, and is used to recover Part of the chlorosilane gas in the silane waste gas is recovered, and the remaining waste gas is sent to the chlorosilane washing unit; the chlorosilane washing unit is also connected with the tail gas venting unit, for the remaining chlorosilane gas in the remaining waste gas and The hydrogen chloride gas is washed down to remove the chlorosilane gas and hydrogen chloride gas in the remaining waste gas, and the remaining waste gas removed from the chlorosilane gas and hydrogen chloride gas is transported to the tail gas venting unit; the tail gas venting unit is used to remove the The remaining off-gases, cleaned of chlorosilane gases and hydrogen chloride gases, are vented. The recycling and processing device of the invention can not only fully recover the chlorosilane resources in the exhaust gas, but also perform pollution-free treatment on the unrecoverable chlorosilane in the exhaust gas.

Owner:XINTE ENERGY

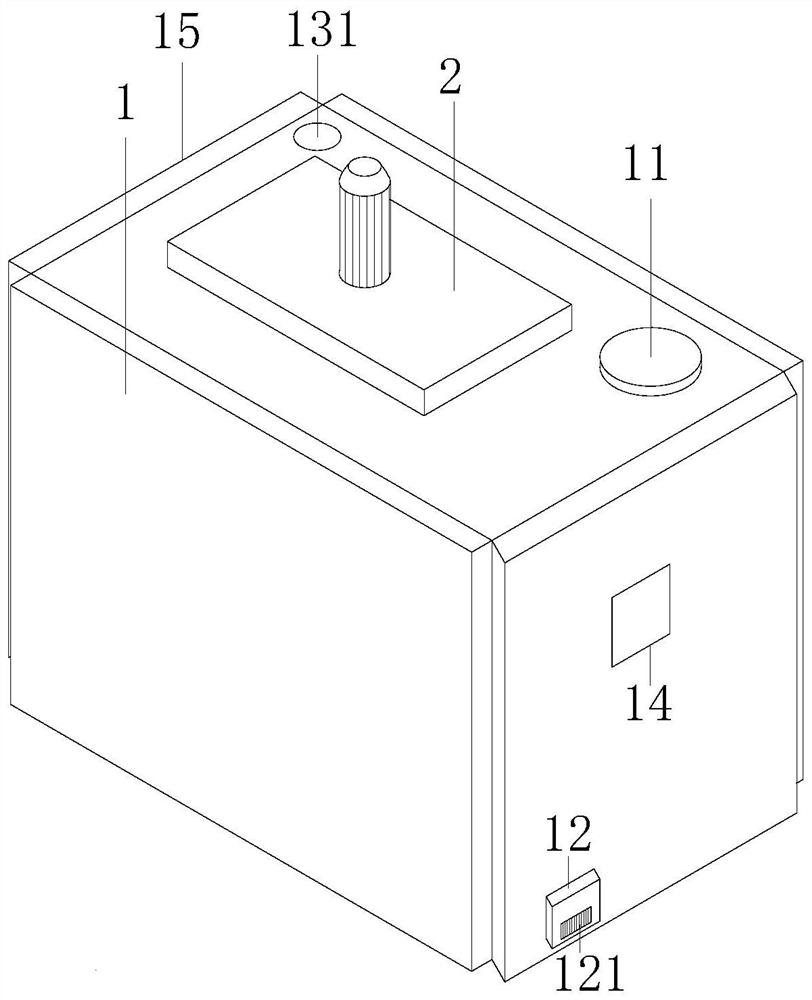

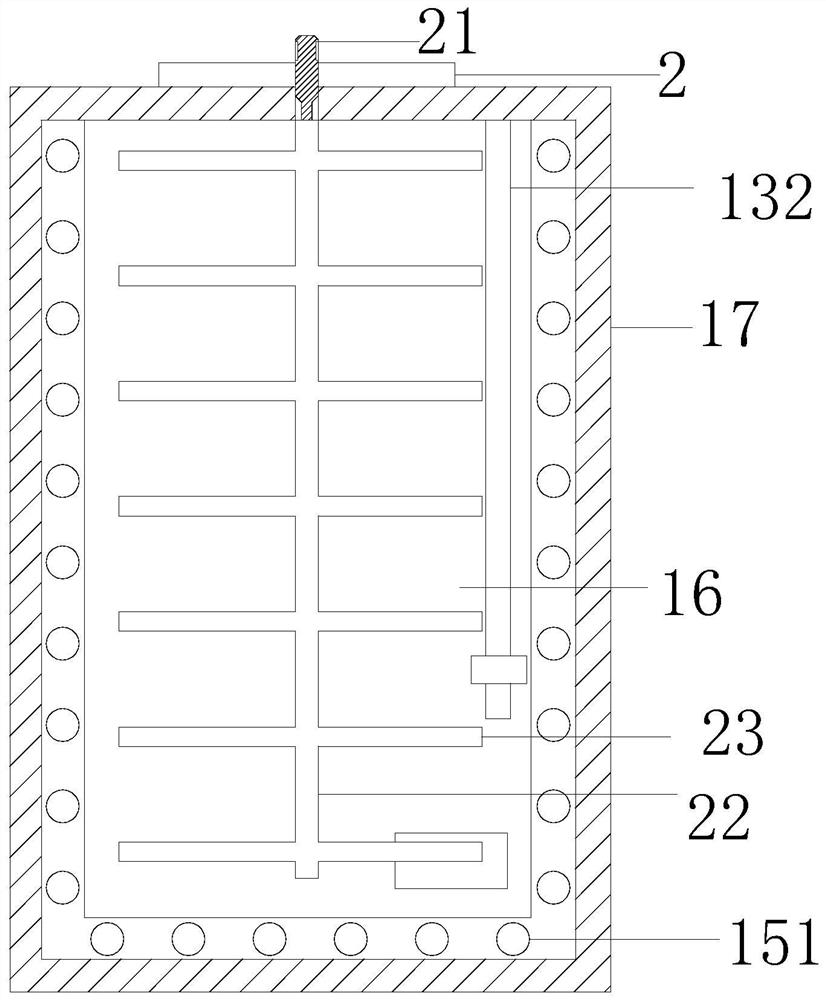

A recycling device for ternary lithium-ion power battery for vehicles

ActiveCN111490307BEasy dischargeEasy to separateWaste accumulators reclaimingStationary filtering element filtersPower batteryElectric machinery

The invention discloses a recycling production device for a ternary lithium-ion power battery for vehicles, which comprises a tank body, a feed inlet, a separator and a discharge outlet. The top of the tank body is sleeved with a feed inlet. The inside of the tank body is fixedly connected with a partition, the left bottom of the tank body is provided with a discharge port, and the inside of the tank body is equipped with a power mechanism. The vehicle ternary lithium-ion power battery recovery and reuse device, through the use of motors, couplings, screw rods, first bearings and first pulleys, is conducive to the solid-liquid separation of battery raw materials, through the rotating rod, The combined use of the second bearing, cam, second pulley and belt is beneficial to the discharge of solid residues on the surface of the second screen, through the joint use of the connecting seat, the first screen, pin rods, torsion springs and connecting rods , to increase the filtering effect of the liquid, through the combined use of the second net plate, baffle plate and bolts, the second net plate can be taken out of the tank for cleaning by opening the bolts.

Owner:哈工(芜湖)新材料科技有限公司

Classified treatment type waste engine oil recovery device

InactiveCN108048199AGuarantee the quality of recyclingReduce recycling costsLubricant compositionHydraulic cylinderDehydration

The invention discloses a classified treatment type waste engine oil recovery device. The device comprises a heavily-polluted waste engine oil storage chamber, a light-polluted waste engine oil storage chamber, an acidification chamber, a concentrated sulfuric acid delivery pipe, stirring rods, conveying belts, filter plates, brush heads, hydraulic cylinders, residue discharge ports, waste residuerecovery boxes, an alkalization chamber, a lime solution delivery pipe, an activated clay purification chamber and a dehydration chamber, wherein the heavily-polluted waste engine oil storage chamberis connected with the top end of the acidification chamber; the upper right end of the acidification chamber is connected with the concentrated sulfuric acid delivery pipe. Compared with the prior art, the classified treatment type waste engine oil recovery device has the beneficial effects as follows: waste engine oil can be divided into heavily-polluted waste engine oil and light-polluted wasteengine oil and is recovered in a classified manner, so that not only is the recovery quality of the waste engine oil guaranteed, but also the recovery cost of the waste engine oil is reduced, besides, the device is further equipped with a waste residue cleaning device, waste residues produced during recovering of the waste engine oil can be cleaned automatically, and the device is quite convenient.

Owner:CHENGDU YUYA TECH

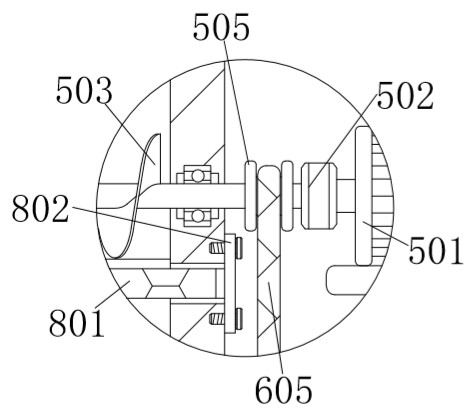

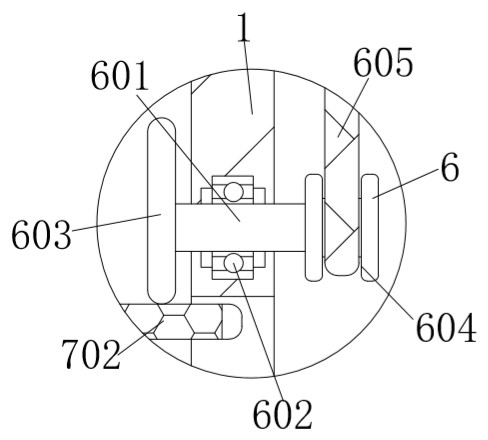

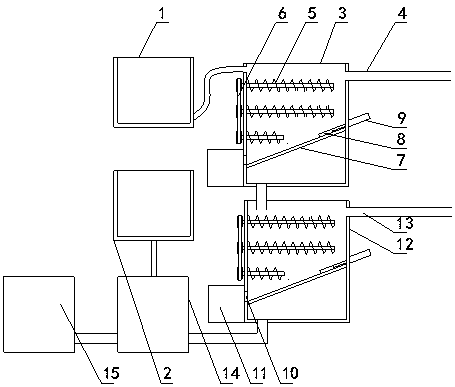

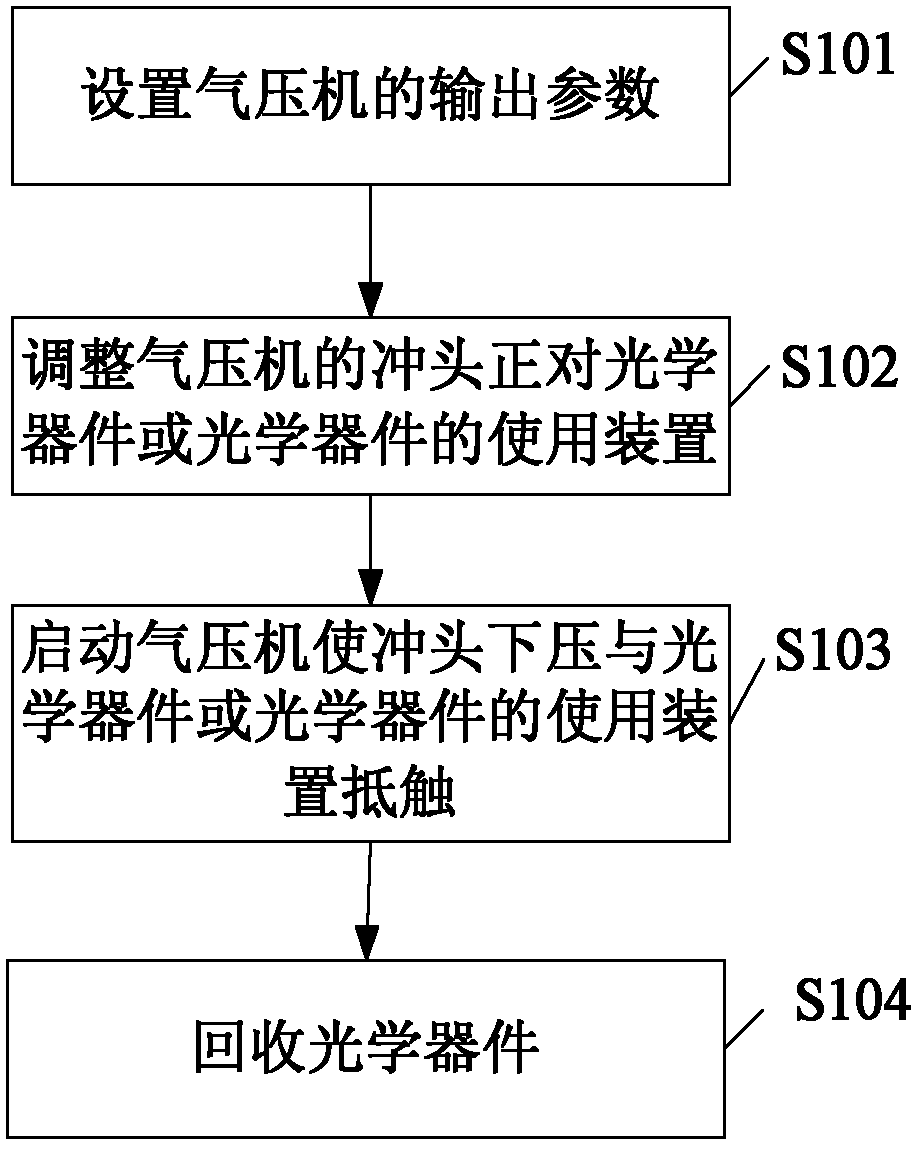

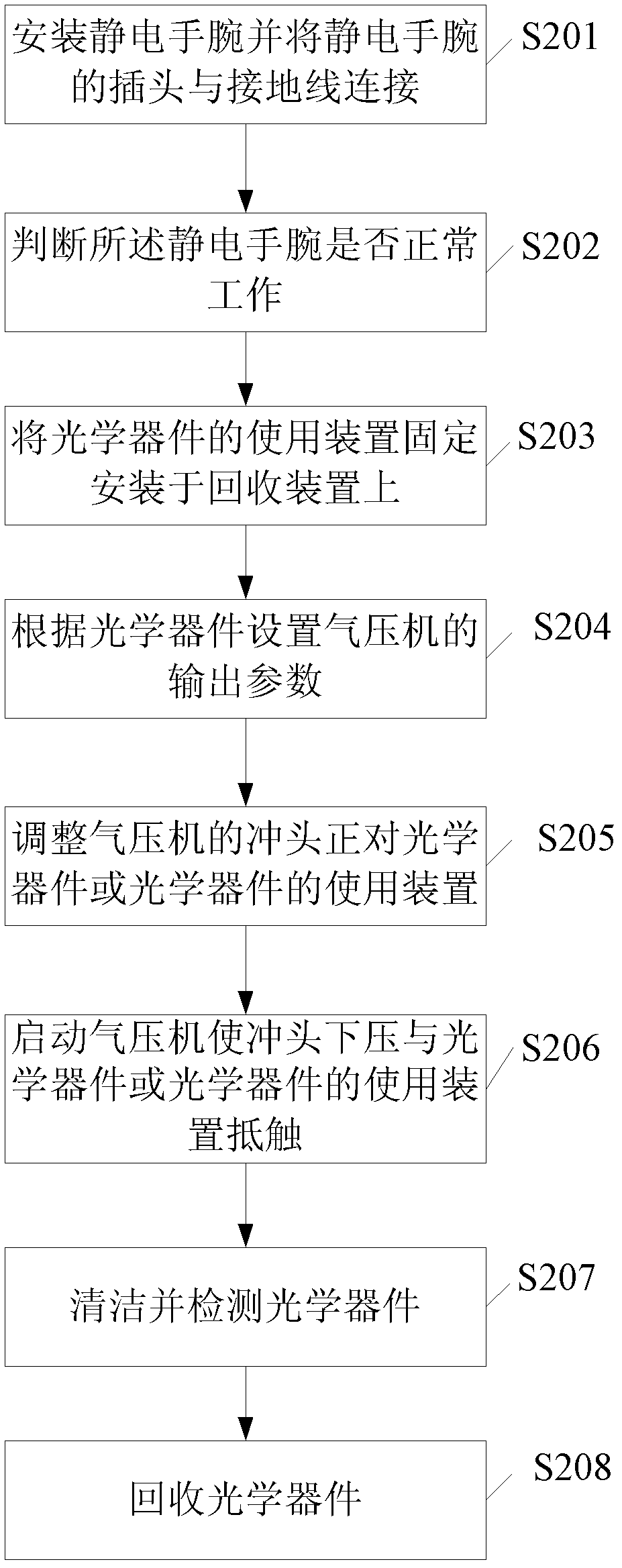

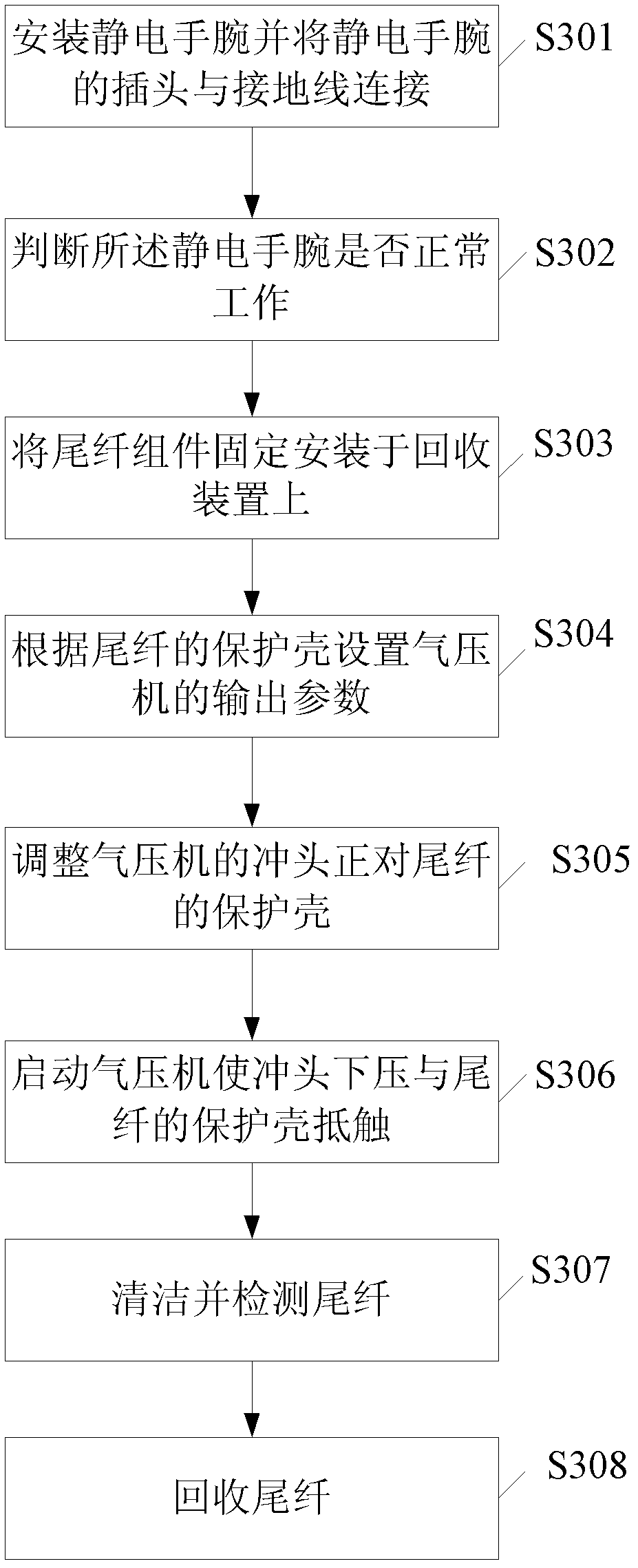

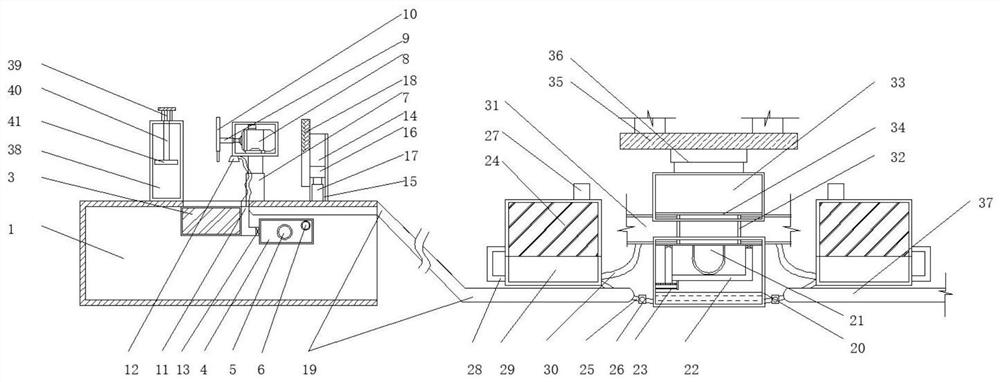

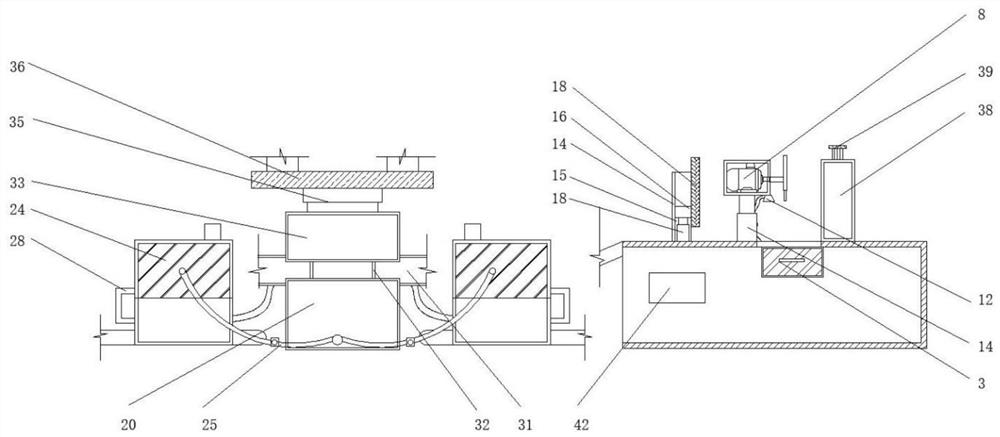

Method for recycling optical devices

InactiveCN102436039AExtended service lifeSo as not to damageCoupling light guidesFiberGas compressor

The invention discloses a method for recycling optical devices. The optical devices comprise tail fibers, inserted cores and isolators. The method comprises the following steps: setting the output parameters of a gas compressor; adjusting a punch of the gas compressor to be over against the optical devices or using devices of the optical devices; starting the gas compressor to press the punch downwards so as to ensure the punch to abut against the optical devices or the using devices of the optical devices; and recycling the optical devices. The method has the following beneficial effects: the optical devices can be effectively separated and recycled; the service lives of the optical devices are prolonged; the materials are saved and the expenditures are saved for the enterprises; and the recycling quality of the optical devices is ensured.

Owner:SOURCE PHOTONICS CHENGDU

A three-way elbow forming and processing integrated equipment

ActiveCN110732881BGood for cleaning and recyclingReduce entryOther manufacturing equipments/toolsMetal working apparatusScrew threadIndustrial engineering

The invention discloses three-way elbow forming and processing integration equipment which comprises a base, a second water delivery pipe, a third water delivery pipe and a fourth water delivery pipe,wherein a first slideway is arranged in the base; a bellows is arranged on the right side of a withdrawal box; a waste gas treatment tank cover is connected on the front side of a waste gas treatmenttank by screw threads; a first electric expansion link is fixed on the upper side of the base; a material suction port is formed at one end of the bellows in a penetrating manner; a fixing plate is arranged on the right side of the first electric expansion link; a second slideway is arranged in the fixing plate; a second electric expansion link is fixed on the lower side of a sliding block; a first conveying belt is inserted at the upper end of the base; a three-way elbow die groove is formed on the upper side in a lower die block; and a filter screen is arranged at the lower end of the leftside of a first water delivery pipe. The three-way elbow forming and processing integration equipment is provided with the withdrawal box, so that scraps generated during pipeline cutting fall into the withdrawal box by a hole in the base to be stored.

Owner:江苏新泰隆管件有限公司

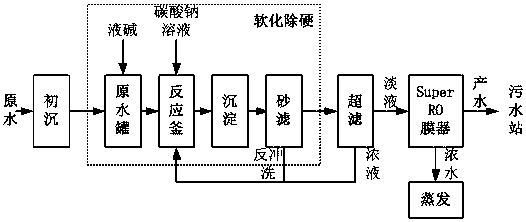

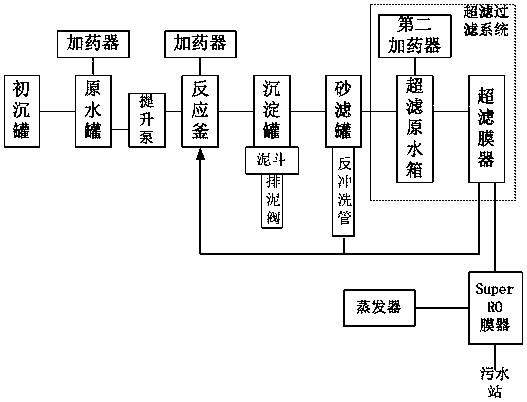

A mother liquor treatment process and system for separation and concentration of dichloropyralic acid materials

ActiveCN105439347BGuarantee the quality of recyclingReduce evaporation costsTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisUltrafiltrationSludge

The invention discloses a mother liquor treatment process and system applied to clopyralid material separation and concentration. The mother liquor treatment system comprises a primary sedimentation tank, a raw water tank, a reaction kettle, a sedimentation tank, a sand filter tank, an ultrafiltration system and a Super RO (reverse osmosis) membrane module which are connected sequentially as well as an evaporator connected with the Super RO membrane module, wherein raw clopyralid mother liquor enters the primary sedimentation tank, both the raw water tank and the reaction kettle are provided with chemical feeders, and the raw water tank and the reaction kettle are communicated through a lift pump; a sludge valve is arranged at the bottom of the sedimentation tank, the sand filter tank is provided with a backwash pipe, a backwash water outlet end of the backwash pipe is communicated with the reaction kettle, and the ultrafiltration system is communicated with the reaction kettle. According to the mother liquor treatment system, design is improved according to the characteristics of the clopyralid material, softening is performed firstly for hardness removal, then ultrafiltration and special RO membrane filtration are performed, and small amount of concentrated water is subjected to evaporative crystallization finally; the evaporation cost is reduced, the influence of a thermal oxidation action on the material is avoided in the whole process, the mother liquor recovery quality is guaranteed, the energy consumption can be reduced obviously, and accordingly, the operation cost is reduced greatly.

Owner:四川美峰环境治理有限责任公司

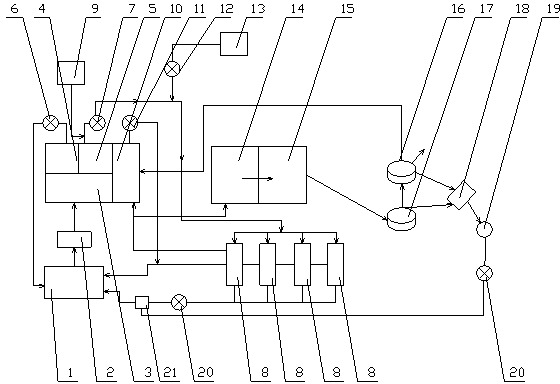

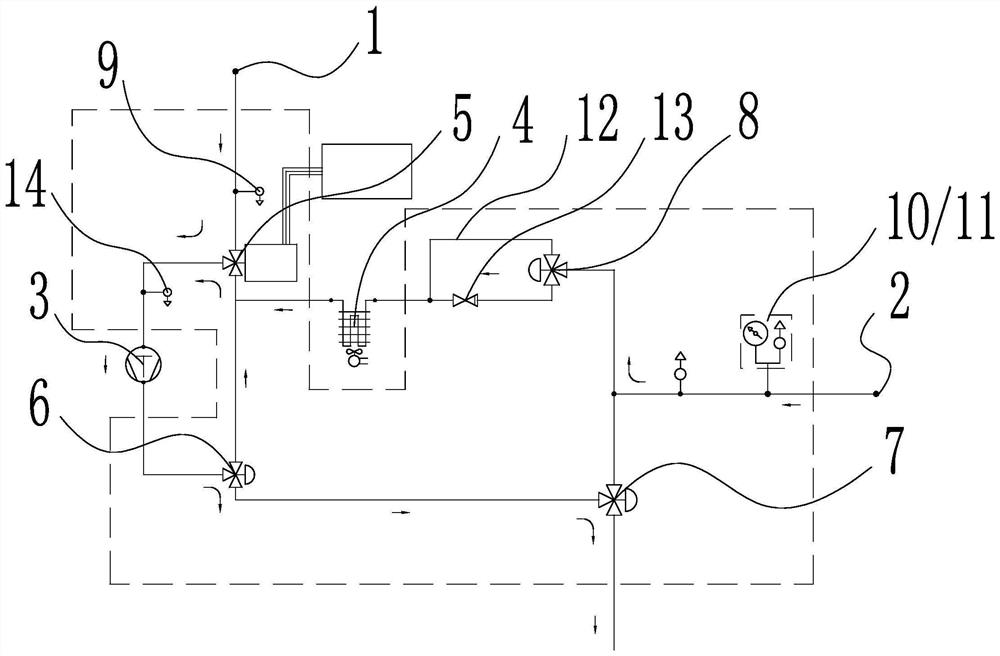

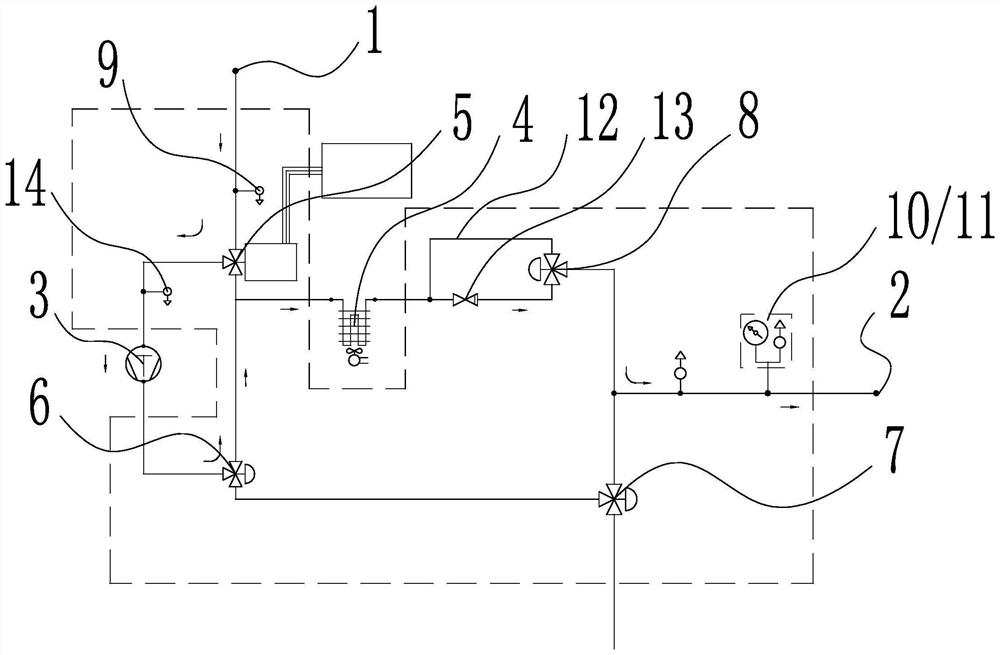

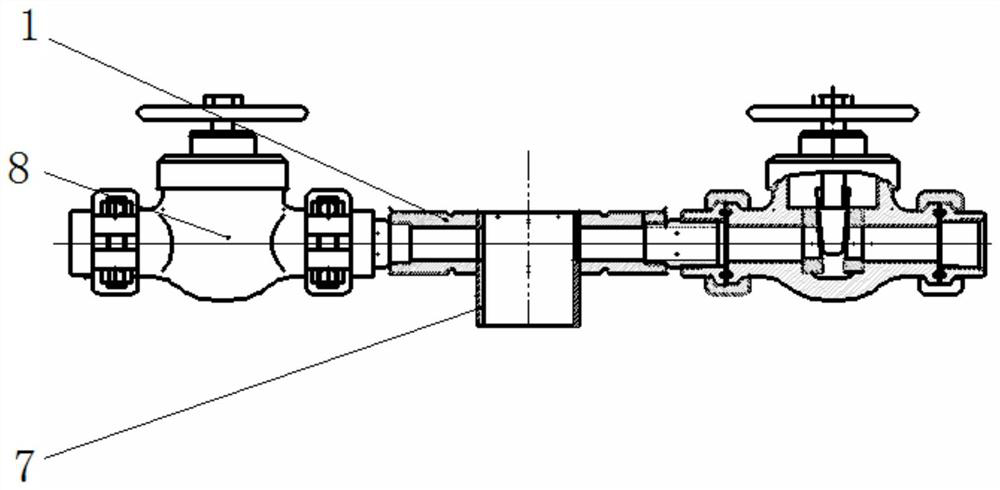

Refrigerant recovery machine intelligent control recovery method

ActiveCN113203229BGuarantee the quality of recyclingImprove recycling efficiencyRefrigerantsAutomatic controlControl system

The invention discloses a refrigerant recovery machine, which provides a simple structure, automatic identification and completion of recovery and self-cleaning operations during refrigerant recovery, automatic control of the whole process, time-saving and labor-saving, safe and reliable intelligent control recovery method of the refrigerant recovery machine, It solves the technical problems in the prior art that the refrigerant recovery process is greatly influenced by humans, the efficiency is low, and the recovery machine is easily damaged when it is misoperated, and even a safety accident is caused in serious cases. It includes parallel connection at the air inlet and exhaust port Between the compressor and the condenser, the compressor and the condenser are connected to the inlet port through the main valve, the compressor is connected to the exhaust port through the first synchronous valve and the bleed valve in turn, and the condenser is connected through the third synchronous valve On the exhaust port, the main valve is connected to the first synchronous valve through an intermediate pipeline, and the control system automatically controls the main valve, the first synchronous valve, the discharge valve and the third synchronous valve according to the pressure values of the air inlet and the exhaust port. The connection state of the valve.

Owner:ZHEJIANG VALUE MECHANICAL & ELECTRICAL PROD CO LTD

Photocatalytic material recovery device

InactiveCN110270275AGuaranteed recycling efficiency and qualityWill not reactFeed devicesChemical/physical/physico-chemical moving reactorsDrive motorBall valve

A photocatalytic material recovery device includes a case, a median position of that bottom of the inner cavity of the case is fixedly connected with an adjusting device, a raw material pump is fixedly connected to that right side of the top of the adjusting device, a ball valve is fixedly connected to one side of the adjusting device away from the case, a driven gear is fixedly connected to the middle position of the outer surface of the reaction kettle, a drive gear is fixedly connected to the right side of the outer surface of the driven gear, a drive motor is fixedly connected to the inner surface of the driving gear through a coupling, a three-way pressure valve is fixedly connected to the top of the outer surface of the reaction kettle, and pressure pumps are fixedly connected to the top of the inner cavity of the case at symmetrical positions on both sides of an induction switch. The invention relates to the technical field of photocatalytic materials. By applying pressure, the reaction can be carried out quickly and effectively, and the catalytic material is discharged by the pressure, so that the discharge is clean and thorough, thereby ensuring that the reaction is not affected and the recovery efficiency and quality are ensured.

Owner:HUANGSHAN UNIV

A coke oven ignition control method and device

ActiveCN106811213BGuarantee the quality of recyclingEvenly heatedCoke oven safety devicesProcess engineeringCoke oven

Owner:武汉钢铁有限公司

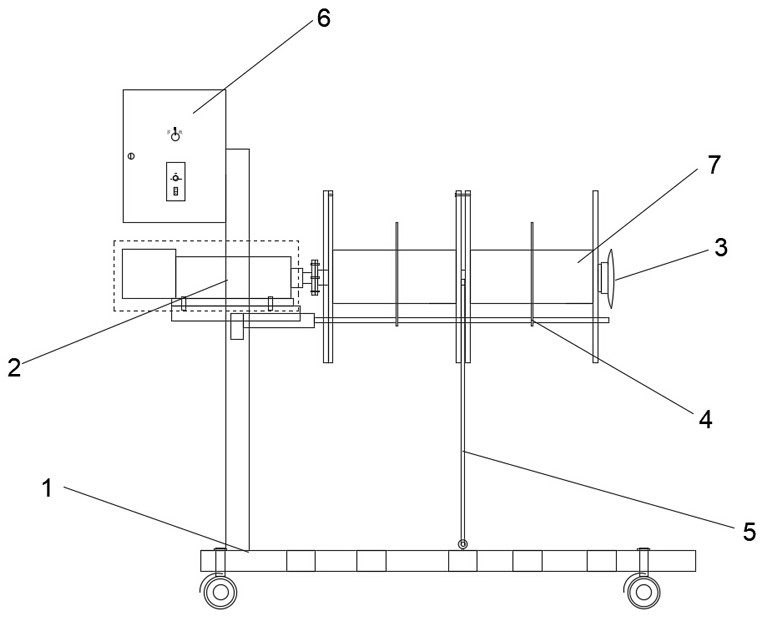

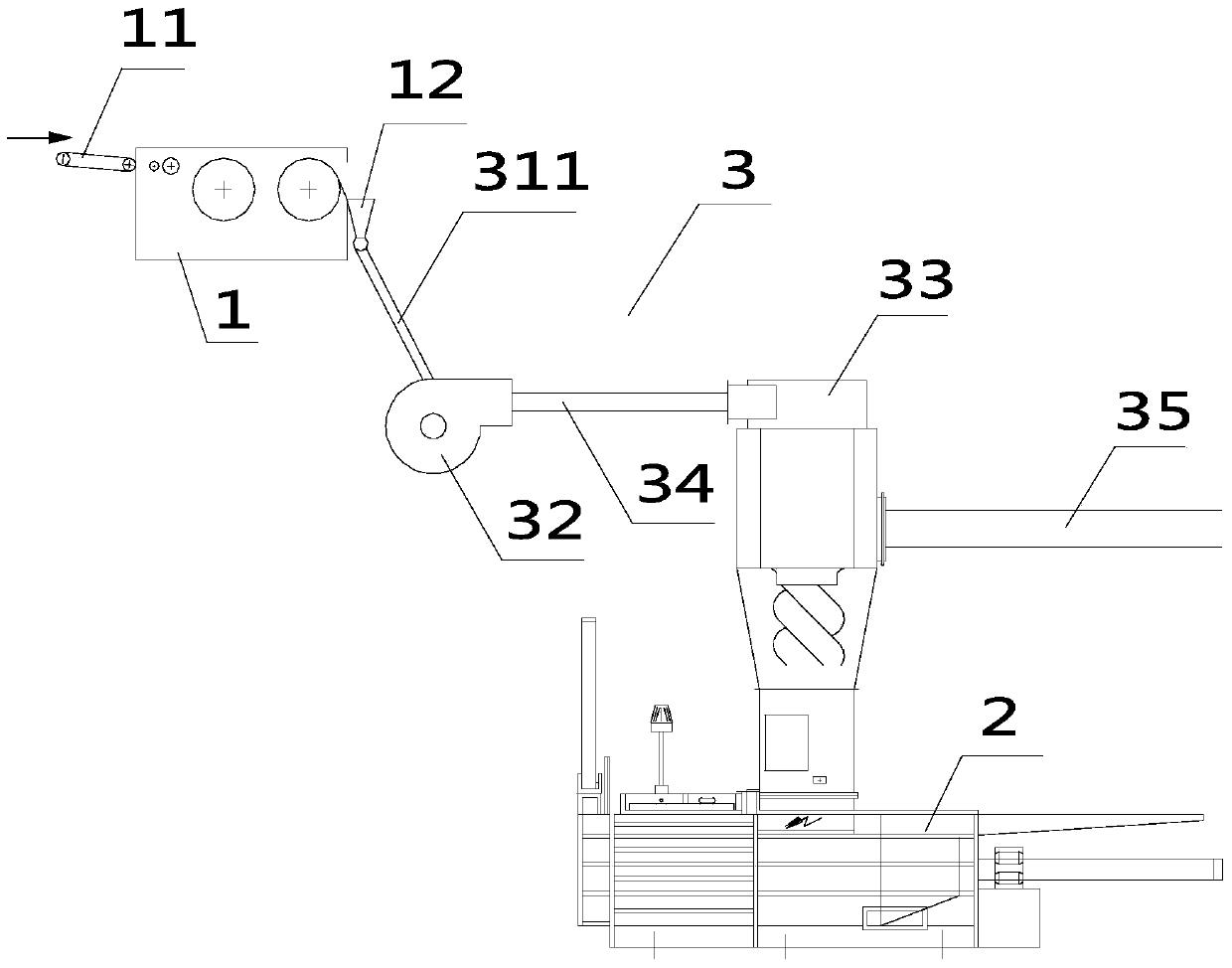

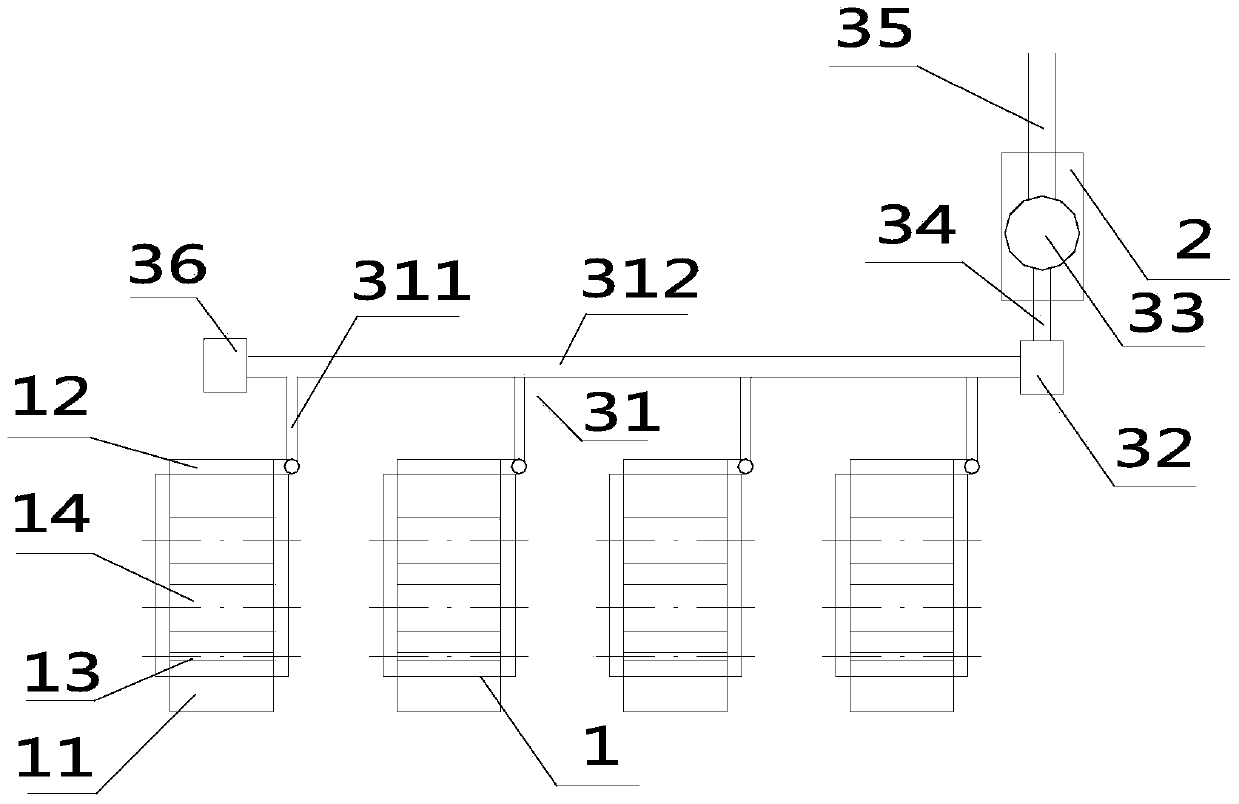

An electric movable ice-making exhaust pipe recovery workbench and its construction method

The invention discloses an electric movable ice-making exhaust pipe recovery workbench and a construction method thereof. The recovery workbench includes a workbench frame, a speed-regulating motor component connected to the workbench frame, and a power distribution device connected to the speed-regulating motor component. The control box component, the axle assembly connected to one side of the speed regulating motor component, the ice making pipe adjustment assembly located on one side of the axle assembly, the rotating shaft support assembly connected directly below the axle assembly; the recovery wheel assembly is installed on the axle assembly. The present invention provides an installation space through the setting of the workbench frame, and is convenient for moving and fixing; through the combined setting of the speed-regulating motor component and the power distribution control box component, it is beneficial to the recovery of the ice-making exhaust pipe, and can carry out forward and reverse rotation and Recycling at different speeds; through the setting of the wheel shaft assembly, it is convenient for batch recycling, and the bayonet on the recovery wheel shaft can effectively fix the recovery wheel; through the setting of the rotating shaft support component, it is beneficial to provide vertical support to ensure the load bearing when recycling the ice making pipe.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

A kind of automatic recovery system of hemp fiber bomb cleaning machine

The invention relates to an automatic recovery system for a hemp fiber bomb cleaning machine, comprising at least one bomb cleaning machine and a baler, a collection bucket is provided at the discharge end of the bomb cleaning machine, and a recovery device, which includes a first cotton delivery pipeline , the first cotton conveying fan, the cyclone separator and the second carding pipeline, one end of the first cotton conveying pipeline communicates with the outlet at the lower end of the collecting hopper, and the other end communicates with the air inlet of the first cotton conveying fan, and the first conveying The air outlet of the cotton fan is connected to one end of the second carding pipe, the other end of the second carding pipe is connected to the inlet of the cyclone separator, and the outlet of the cyclone separator is connected to the inlet of the baler. The air port discharges the separated air to the outside. The opened hemp fiber is transported to the cyclone separator through the recovery device, and the cyclone separator transports the opened hemp fiber to the baler for packaging and recycling, which reduces the labor intensity and production cost, improves the production efficiency, and avoids the waste of hemp fiber Scatter, pollute the air, and damage human health.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

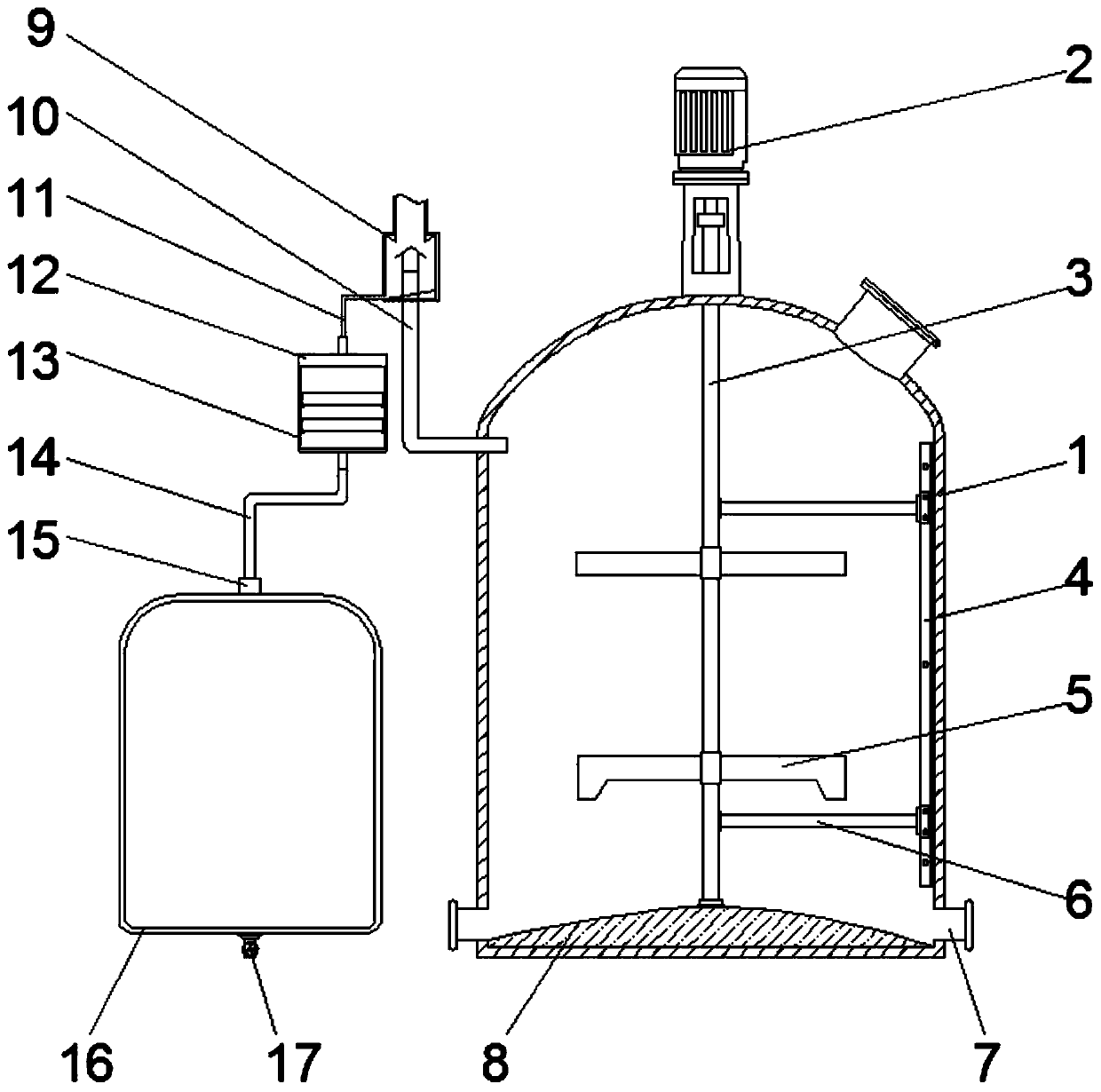

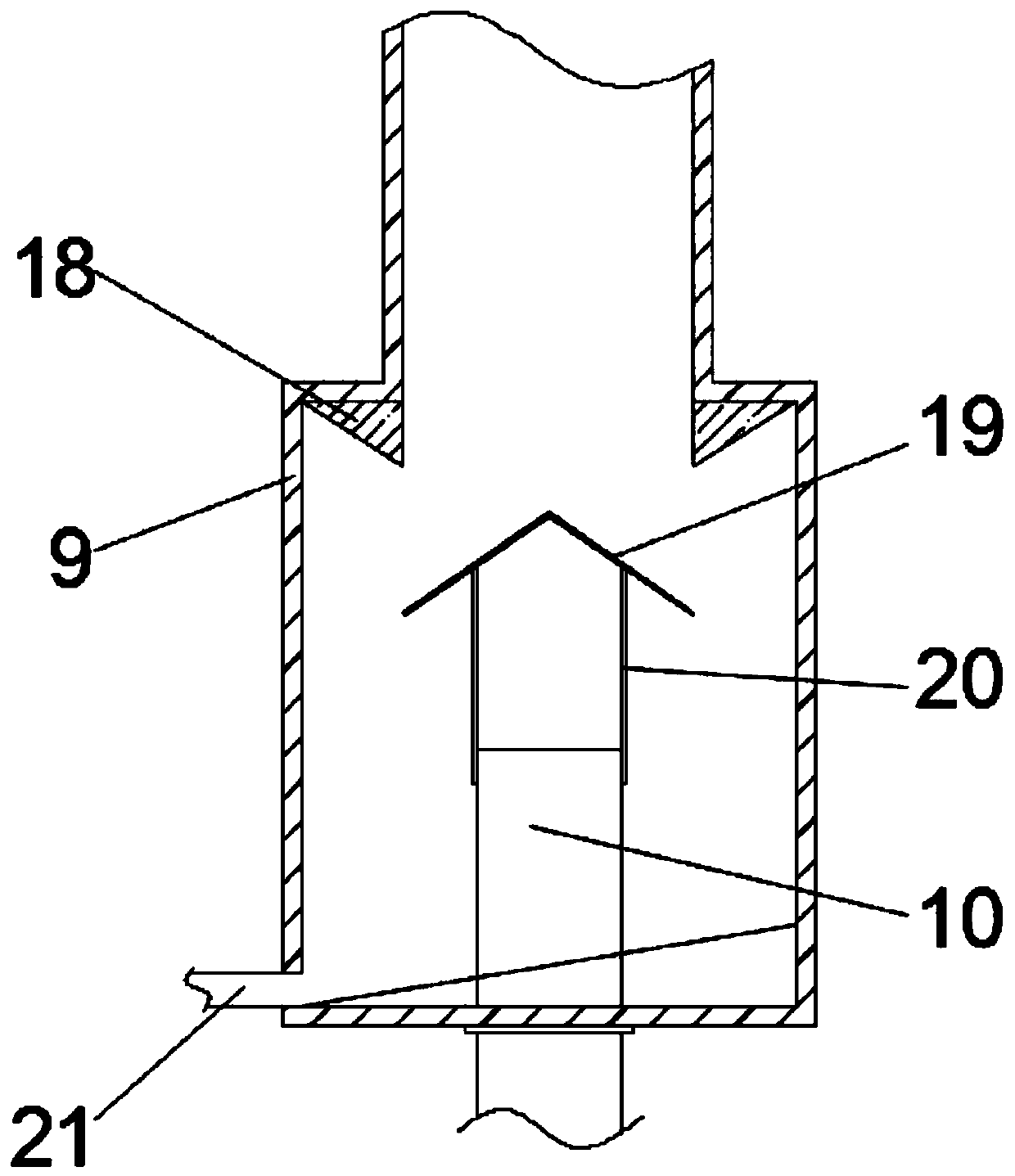

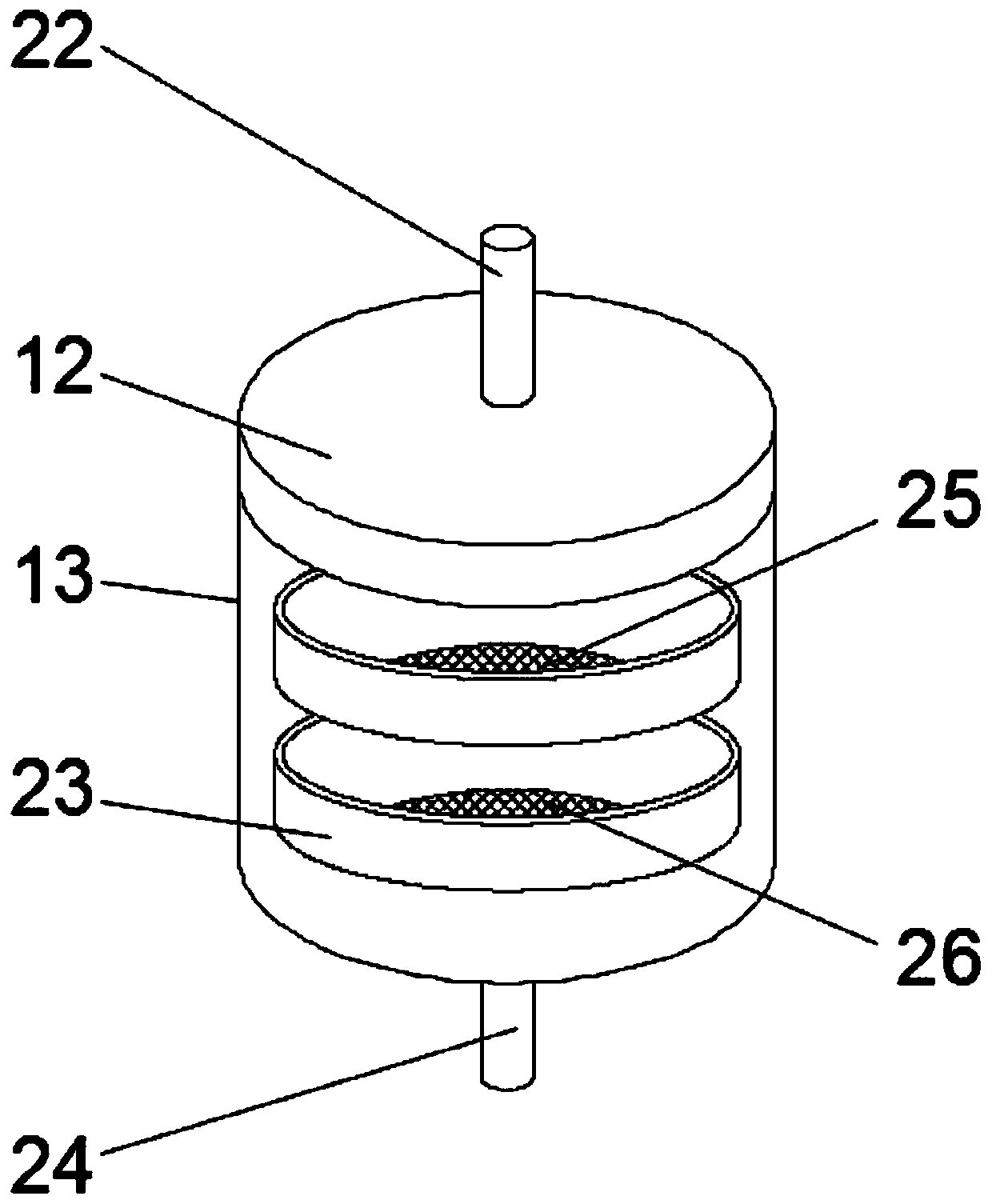

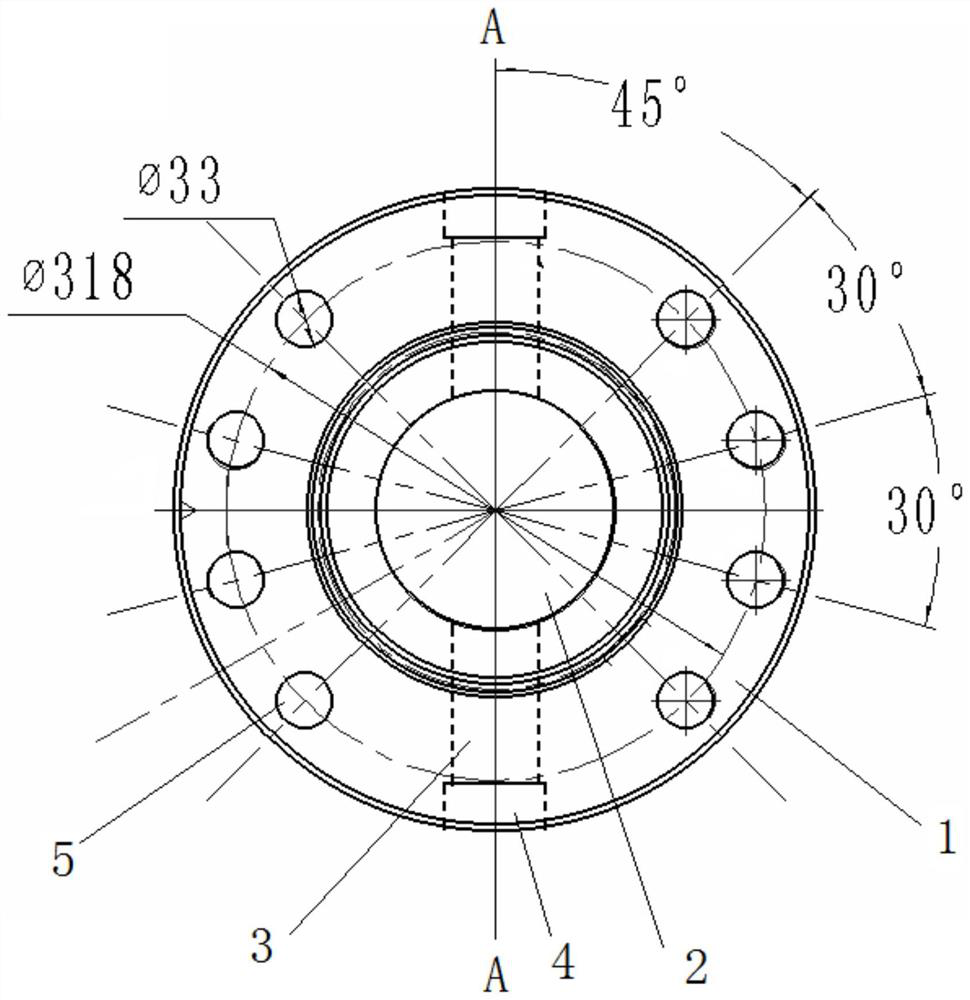

Yeast fermenter and recovery method having function of recovering feed liquid

PendingCN110184169AGuaranteed recycling efficiencyGuarantee the quality of recyclingBioreactor/fermenter combinationsBiological substance pretreatmentsRecovery methodEngineering

The invention discloses a yeast fermenter and recovery method having function of recovering feed liquid, and relates to yeast fermentation equipment, in particular to a fermenter. One end of an exhaust pipe is arranged on one side of the top of the inner cavity of the fermenter, the other end of the exhaust pipe penetrates out the fermenter and extends to the inner cavity of a liquid collecting tank from a penetrating hole in the bottom of the liquid collecting tank, a slope plate is fixedly connected to the bottom of the inner cavity of the liquid collecting tank, a liquid dripping pipe fixedly communicates with the outer wall of the liquid collecting tank from the bottom end of the slope plate, a filter tank communicates with the liquid dripping pipe through a liquid outlet pipe, a feedliquid filtering mechanism is arranged in the filtering tank, the other end of a liquid draining pipe extends into a liquid inlet hole formed in the top of the liquid collecting tank, and besides, a liquid outlet pipe is fixedly connected to the bottom of the liquid collecting tank. Two-time liquid collecting processes are designed, feed liquid carried by air current is gathered to form large feeddrips after being in contact with a liquid collecting hood B, and finally, the drips drop into the lower inner part of the liquid collecting tank through self gravity, so that the purpose of recoveryis achieved.

Owner:湖北中农华威生物工程有限公司

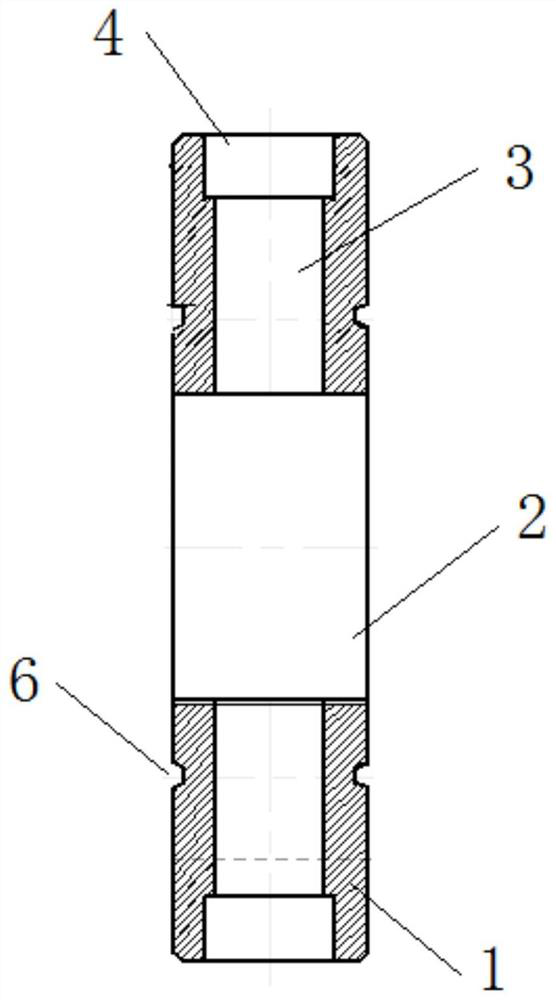

Spiral-flow type underground liquid-gas separation device

PendingCN111849576AGuarantee the quality of recyclingGuaranteed blending effectGaseous fuelsResidual oilPour point

The invention relates to a mechanical device, in particular to a spiral-flow type underground liquid-gas separation device. The device comprises an oil mixing middle flange, a pup joint, an oil mixingouter pipe and a cyclone separator, the oil mixing middle flange is connected with a big king eight cover and a big four-way joint of a Christmas tree, the pup joint is fixedly connected with the oilmixing middle flange, the oil mixing outer pipe is connected with the pup joint, the oil mixing outer pipe is arranged between an oil pipe and a casing pipe, and the cyclone separator is arranged onthe oil mixing outer pipe and is used for separating out residual oil in the associated natural gas. The spiral-flow type underground liquid-gas separation device provided by the invention can form three layers of overflowing channels after being matched and mounted with a Christmas tree, and an exhaust port is separated from a pour point depressant injection port and a thickening agent injectionport, so that the pour point depressing and thickening effects are guaranteed.

Owner:鞍山宏景石油机械有限公司 +1

Printing dye raw material recycling device

InactiveCN113069966AAvoid uneven mixingGuarantee the quality of recyclingTransportation and packagingRotary stirring mixersElectric machineStructural engineering

The invention provides a printing dye raw material recycling device which comprises a dye recycling box, a dye containing cavity is formed in the dye recycling box, a cover plate is arranged at the upper end of the dye containing cavity, a motor is arranged on the upper surface of the cover plate and fixed to the cover plate, and the output end of the motor is connected with a stirring rod. The end, away from the motor, of the stirring rod penetrates through the cover plate and extends to the bottom in the dye containing cavity, a plurality of stirring blades are arranged on the stirring rod, a fixing base is connected to one side of the dye recycling box, a plurality of heating pipes are arranged on the fixing base, and a control valve is arranged at the bottom of the dye recycling box. The device is simple in structure, and can guarantee that dye cannot be solidified due to low temperature, and the recycling efficiency of the dye is improved.

Owner:JIANGSU UNIV

Surface rock sampling device for geological exploration

PendingCN114593978AGuaranteed timelinessGuarantee the quality of recyclingSievingScreeningRock sampleGeological exploration

The invention belongs to the technical field of rock sampling, and particularly relates to a geological prospecting surface rock sampling device which comprises a base, a controller is arranged on one side of the base, a transmission mechanism is arranged at the top of the base, and an excavating mechanism is arranged at the output end of the transmission mechanism; the excavating mechanism comprises a rotating disc, the middle shaft of the rotating disc is fixedly connected with the output end of the transmission mechanism, multiple sets of tooth grooves are evenly formed in the outer surface of the rotating disc in an array mode, and displacement sensors are arranged at the ends, located on the outer surface of the rotating disc, of the tooth grooves; according to the device, long groove type sampling of rock samples is achieved, the versatility of rock sampling is improved, meanwhile, the problems that errors occur in a sampling area, the device stability and trafficability are poor, and the operation difficulty is large in the rock sampling process are solved, meanwhile, the length of digging teeth can be adaptively adjusted according to different grounds, the rock samples are screened, and the rock sampling efficiency is improved. The digging teeth can be cleaned and protected, and the sampling efficiency and the sampling effect of the device are improved.

Owner:河南省有色金属地质矿产局第七地质大队

Dry battery disassembling and recycling device

InactiveCN112331876AImprove recycling ratesGuarantee the quality of recyclingReclaiming serviceable partsDry cellsProcess engineeringEnvironmental engineering

The invention relates to the related field of waste battery treatment, and discloses a dry battery disassembling and recycling device. The device comprises a main box, a disassembling cavity with a downward opening is formed in the main box, an electrolyte recycling cavity is formed in the left side of the disassembling cavity, a diameter limiting hole is formed between the electrolyte recycling cavity and the disassembling cavity in a communicating mode, and a storage box cavity is formed in the right side of the disassembling cavity in a communicating mode. According to the device, waste drybatteries are subjected to fine treatment and recovery, positive and negative electrode metal sheets of the dry batteries are cut and recovered firstly, then electrolyte in the dry batteries is pushed out of dry battery shells and collected, finally, the device can eject the final dry battery shells out of the device, the whole process is continuous and repeated, large-batch dry batteries can becontinuously machined, the recycling rate of the dry batteries is high under fine disassembly of the device, the recycling quality is guaranteed, and all collected parts can be machined again in the follow-up process.

Owner:广州艺鸣电容器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com