An electric movable ice-making exhaust pipe recovery workbench and its construction method

A technology of workbench and ice row, which is applied in the direction of thin material handling, delivery of filamentous materials, transportation and packaging, etc., to achieve the effects of easy installation and adjustment, simple and easy construction method, and convenient batch recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

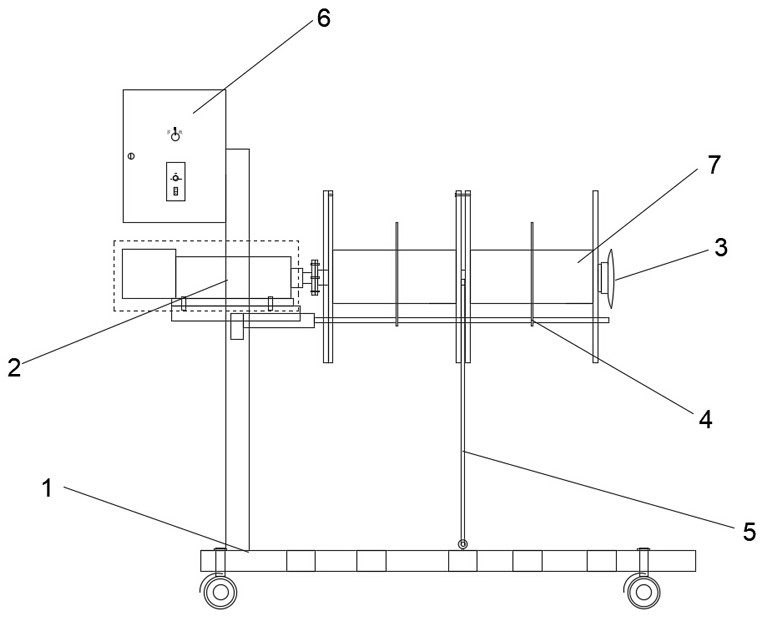

[0040] Such as figure 1 As shown, an electric movable ice-making exhaust pipe recovery workbench includes a workbench frame 1, a speed-regulating motor component 2 connected to the workbench frame 1, connected to the top of the speed-regulating motor component 2 and located on the workbench frame 1 The power distribution control box component 6, the axle assembly 3 connected to the side of the speed regulating motor component 2, the ice-making pipe adjustment assembly 4 connected to the workbench frame 1 and located on the side of the axle assembly 3, and the axle assembly 3 connected to the front The rotating shaft support assembly 5 below; the wheel shaft assembly 3 is equipped with a set of recovery wheel assembly 7 for recovering the ice-making exhaust pipe.

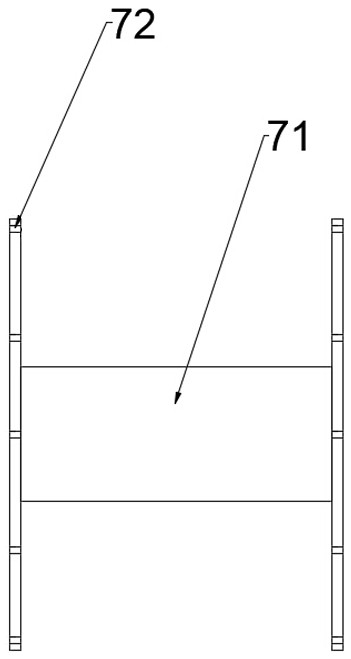

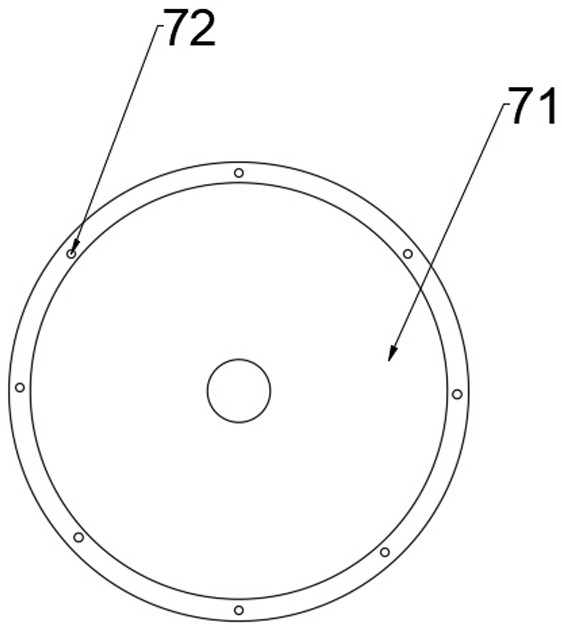

[0041] Such as figure 2 and image 3 As shown, the recovery wheel assembly 7 is made of steel or plastic, and two are a group. The recovery wheel assembly 7 includes a recovery wheel and a recovery wheel connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com