Method for treating low-concentration ammonia-containing wastewater by use of membrane separation technology

A technical treatment and low-concentration technology, which is applied in the field of low-concentration ammonia-containing wastewater treatment with membrane separation technology as the core treatment unit, can solve the problems of high energy consumption, huge energy consumption, poor economy and other problems, and can prevent the composition of feed and liquid. The effect of interference, prevention of secondary pollution, and prolongation of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

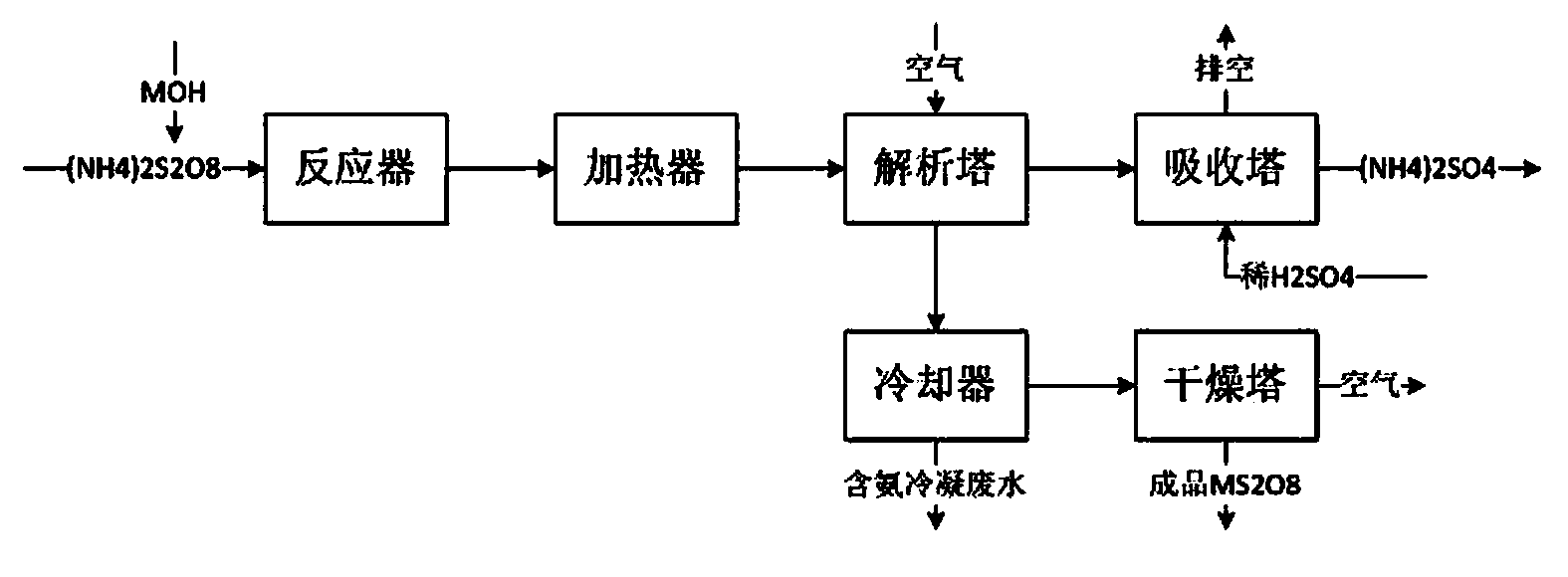

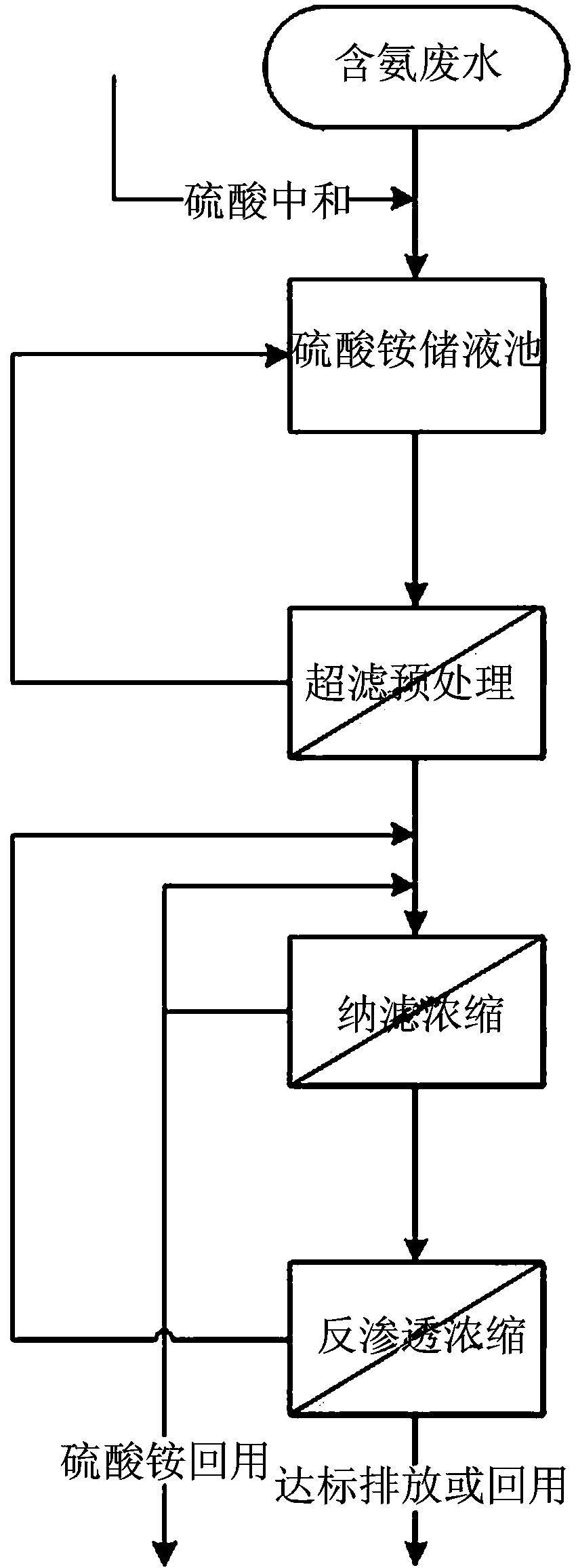

[0044] The ammonia-containing condensate wastewater discharged from the condenser in the production process of sodium persulfate has an ammonia content of 1250ppm. After being neutralized by dilute sulfuric acid with a mass concentration of 5% in a closed pipeline mixer, the pH value is adjusted to 6.7. After the reaction, ammonium sulfate The concentration of the solution is 4780ppm, and it is discharged into the ammonium sulfate storage tank to be treated.

[0045] The ammonium sulfate wastewater after the neutralization reaction enters the hollow fiber ultrafiltration membrane system with a molecular weight cut-off of 300K from the lift pump through the security filter for pretreatment. 200 roll-type nanofiltration membrane. The concentration ratio of the nanofiltration membrane unit is 5, the mass concentration of the recycled ammonium sulfate concentrate is 2.39%, and the product water (permeate) enters the roll-type reverse osmosis system with a desalination rate of 99.2...

Embodiment approach 2

[0047] The ammonia-containing condensate wastewater discharged from the condenser in the production process of sodium persulfate has an ammonia content of 1800ppm. In a closed pipeline mixer, after being neutralized by 7% dilute sulfuric acid, the pH value is 6.6, and the concentration of ammonium sulfate is 6900ppm. into the liquid storage tank to be processed.

[0048] The ammonium sulfate wastewater after the neutralization reaction enters the roll-type ultrafiltration membrane treatment unit with a molecular weight cut-off of 100K from the lift pump through the security filter. 300 roll-type nanofiltration membrane unit, the concentration ratio of the roll-type nanofiltration membrane is 4, the mass concentration of recycled ammonium sulfate is 2.76%, and the produced water enters the roll-type reverse osmosis system with a desalination rate of 99.5%. The reverse osmosis system is concentrated 8 times, and the concentrated water is returned to the nanofiltration inlet and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com