Patents

Literature

33results about How to "Reduce evaporation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

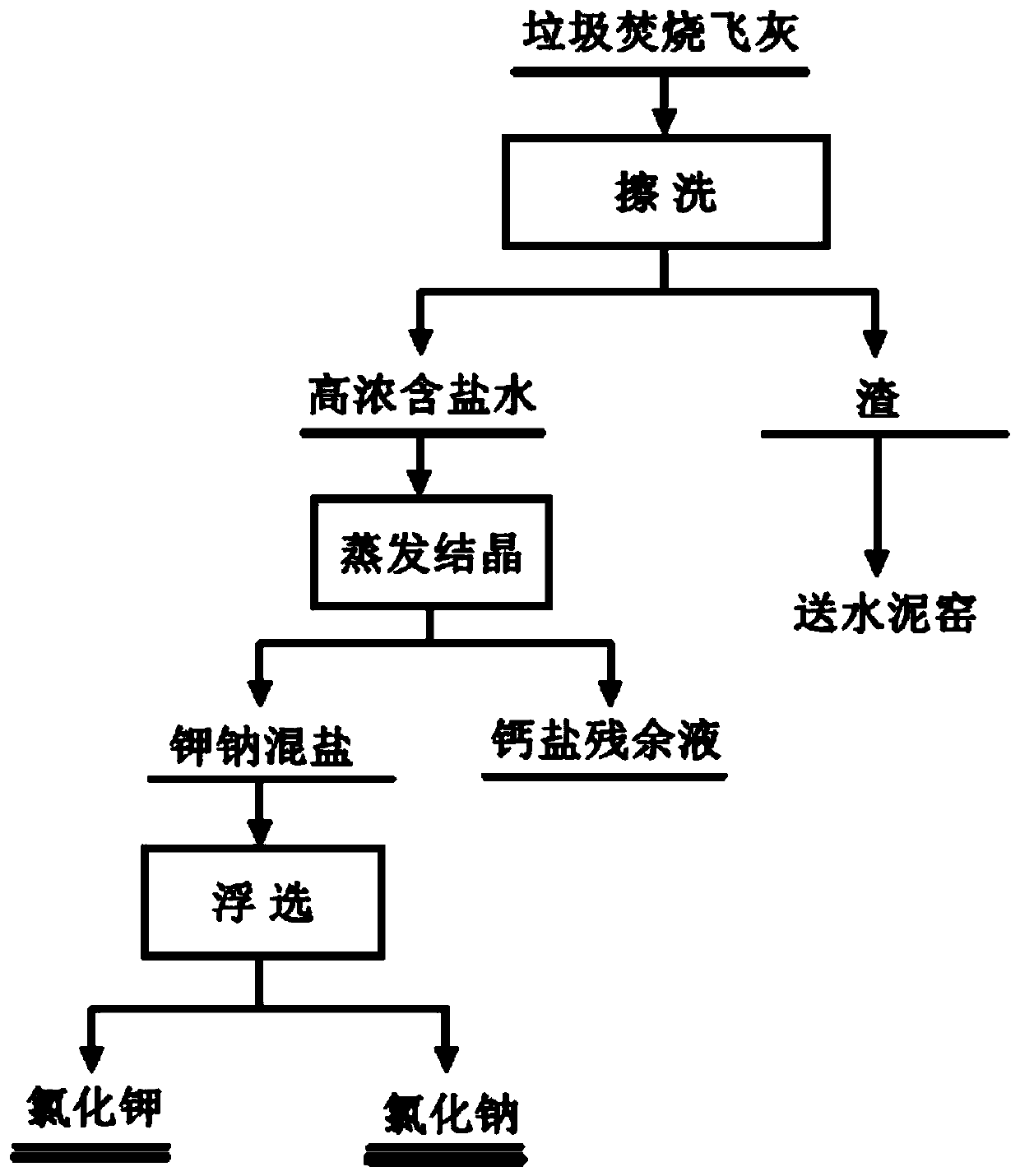

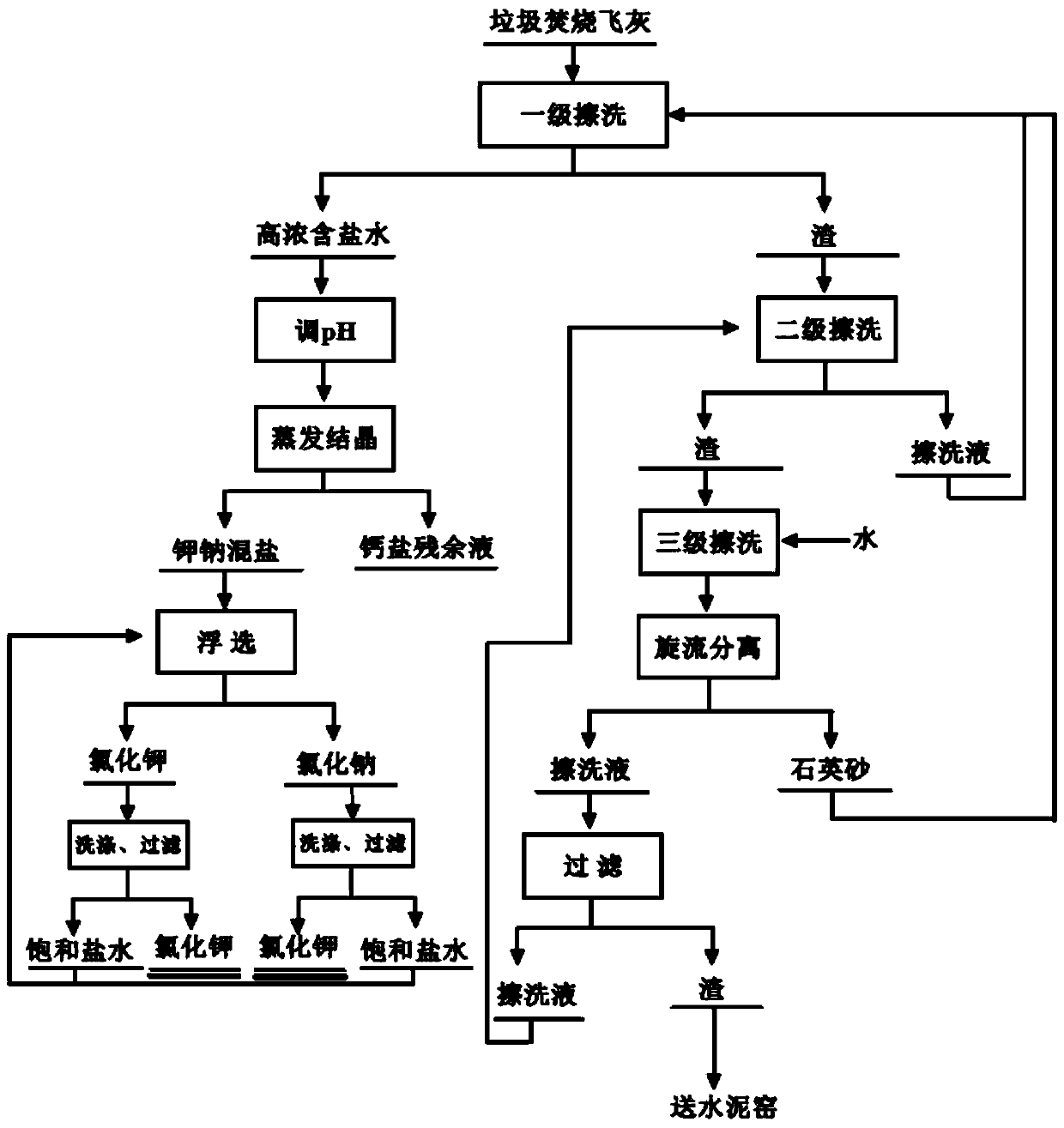

Method for recovering and separating potassium salt and sodium salt from waste incineration fly ash

InactiveCN110589856AImprove the dissolution rate of soluble saltsReduce consumptionCalcium/strontium/barium chloridesAlkali metal chloridesHigh concentrationFiltration

The invention relates to a method for recovering and separating a potassium salt and a sodium salt from waste incineration fly ash, which comprises the following steps of: extracting the potassium salt, the sodium salt and a calcium salt from the waste incineration fly ash by quartz sand and water to obtain high-concentration salt-containing water, separating the quartz sand from the fly ash, returning the quartz sand for continue use; adjusting the pH value of the high-concentration salt-containing water to 5-7 with an acid, and conducting evaporating and concentrating to obtain potassium andsodium mixed salts and a residual calcium chloride saturated solution; conducting flotation separation on the potassium and sodium mixed salts in saturated potassium chloride and sodium chloride solutions, and conducting filtration, so as to obtain a foam product, namely potassium chloride, and tailings slurry, namely sodium chloride; respectively conducting stirring washing on the potassium chloride and sodium chloride obtained by flotation through corresponding saturated salt water, and conducting filtering to obtain industrial grade potassium chloride and sodium chloride products, whereina washing solution is a saturated potassium chloride and sodium chloride mixed solution and is returned to the flotation procedure as a supplement solution of a flotation medium. The method effectively separates soluble salts in the fly ash: potassium chloride, sodium chloride and calcium chloride without decalcification to obtain high purity or industrial grade potassium chloride and sodium chloride products; and the efficiency-cost ratio of the treatment process is greatly improved.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

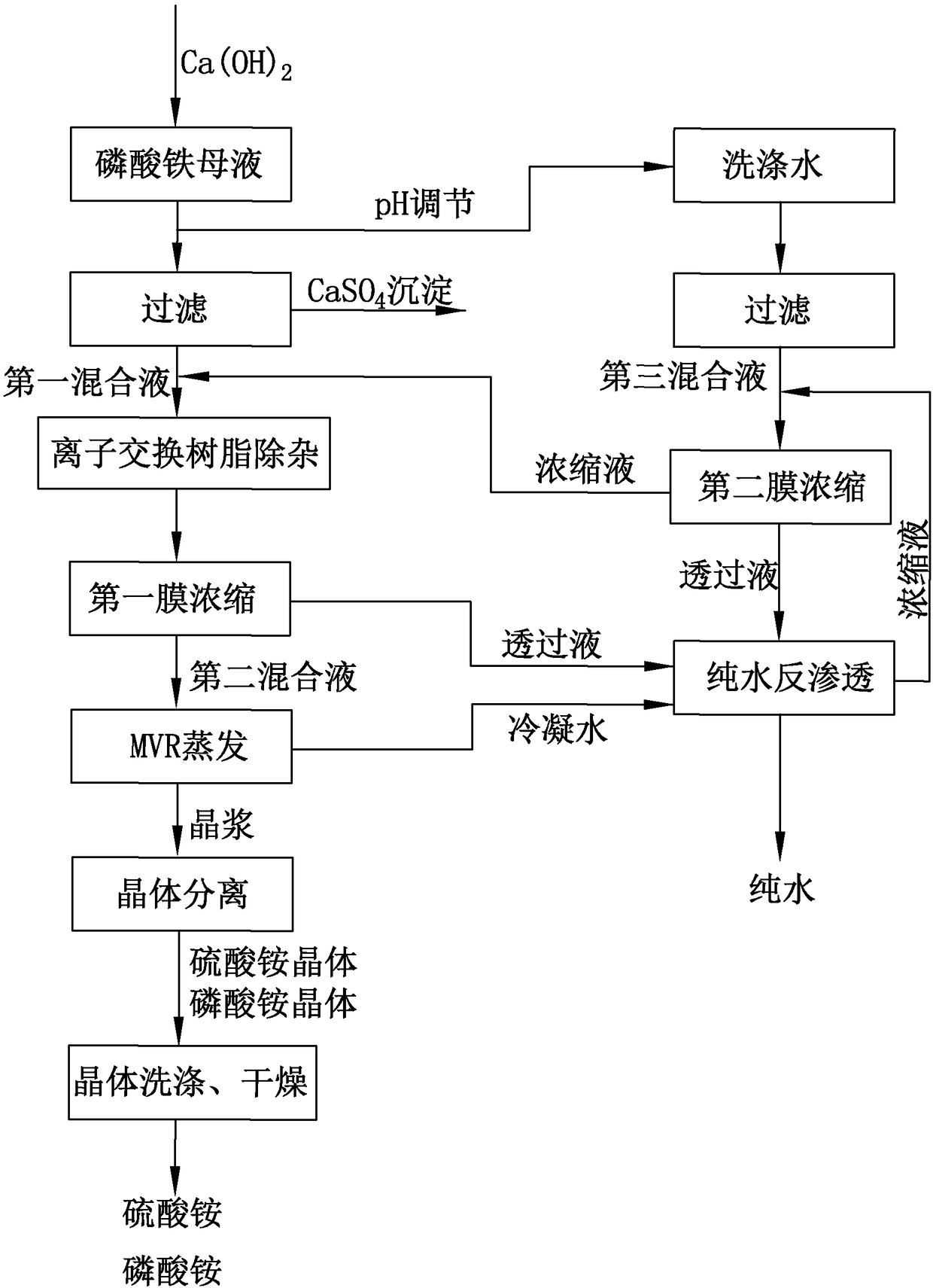

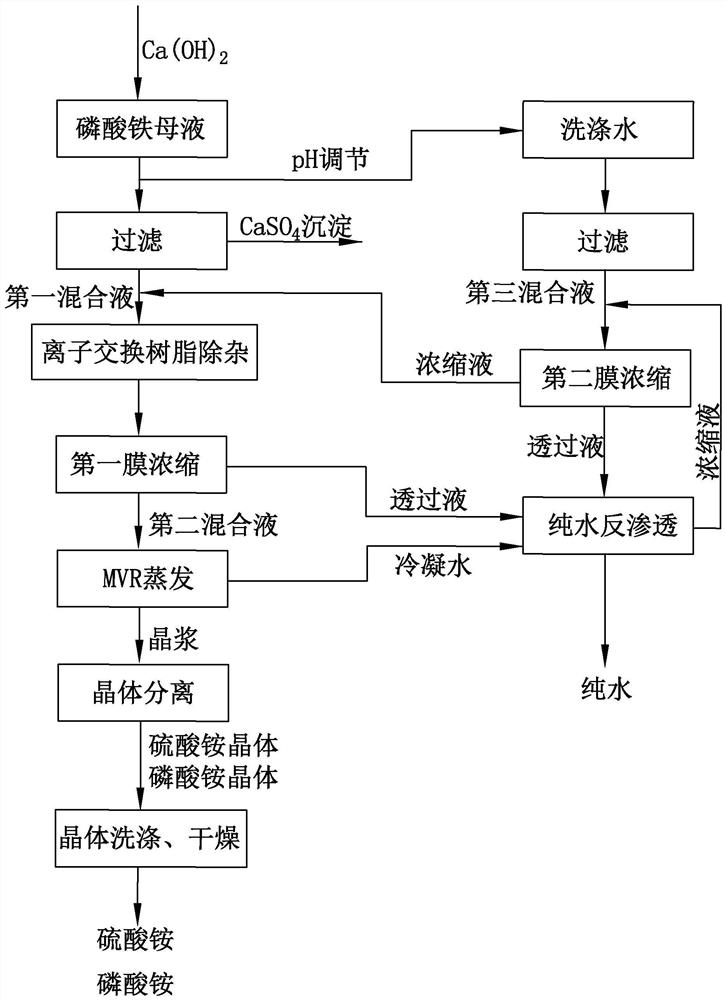

Low-cost iron phosphate ammonia-nitrogen-containing wastewater treatment method

ActiveCN109250857AAchieve recyclingSimple processWater/sewage treatment by centrifugal separationPhosphatesEvaporationPhosphoric acid

The invention discloses a low-cost iron phosphate ammonia-nitrogen-containing wastewater treatment method, which comprises: adding an appropriate amount of Ca(OH)2 to an iron phosphate mother liquor,adjusting the pH value to 6-8 to form a calcium sulfate precipitate, and filtering the precipitate to obtain a first mixed liquid, wherein the first mixed liquid mainly contains NH4<+>, SO4<2-> and PO4<3->; carrying out first membrane concentration on the first mixed liquid to obtain a second mixed liquid; carrying out MVR evaporation on the second mixed liquid, and separating to obtain an ammonium sulfate crystal and an ammonium phosphate crystal; and washing the crystals, and drying to obtain the ammonium sulfate finished product and the ammonium phosphate finished product. According to thepresent invention, the process of the method is simple, and the used raw material is Ca(OH)2, and Ca(OH)2 can reduce the salt concentration in the system, such that the amount of the water entering the MVR evaporation can be reduced so as to correspondingly reduce the evaporation cost; and Ca(OH)2 is a solid, and cannot increase the amount of the water in the system so as to reduce the treatment capacity of the first membrane concentration system and the treatment cost.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

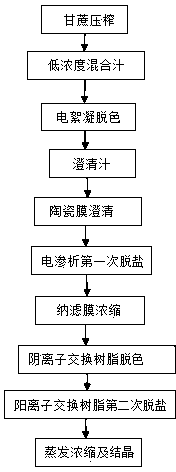

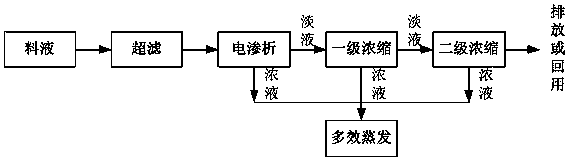

White granulated sugar production technology

InactiveCN103937913AReduce in quantityReduce evaporation costsPurification by electrical meansPurification using ion-exchange materialsChemistryNanofiltration

The invention discloses a white granulated sugar production technology. The white granulated sugar production technology comprises the following steps: 1, adding sodium hydroxide to mixed juice obtained by pressing sugarcane till the pH value of the mixed juice is 5.5-6.5, heating the mixed juice to 60-65 DEG C, and decolorizing the mixed juice through electric flocculation so as to obtain clear liquor; 2, clarifying the clear liquor by adopting a ceramic membrane separation system; 3, desalinating ceramic membrane dialysate for the first time in an electrodialysis system; 4, concentrating electrodialysis desalted liquid by adopting a nanofiltration membrane concentration system; 5, decolorizing a nanofiltration concentrated solution by using macroreticular strong alkaline anion exchange resin; 6, desalting sugar liquor (which is decolorized by macroreticular strong alkaline anion exchange resin) by using macroreticular weak-acid cation-exchange resin for the second time; and 7, evaporating, concentrating and crystallizing the sugar liquor which is desalinated for the second time so as to obtain white granulated sugar. The white granulated sugar production technology disclosed by the invention has the beneficial effects that the produced white granulated sugar is sulfur-free white granulated sugar, and the discharge of wastewater is reduced.

Owner:XIAMEN STARMEM TECH

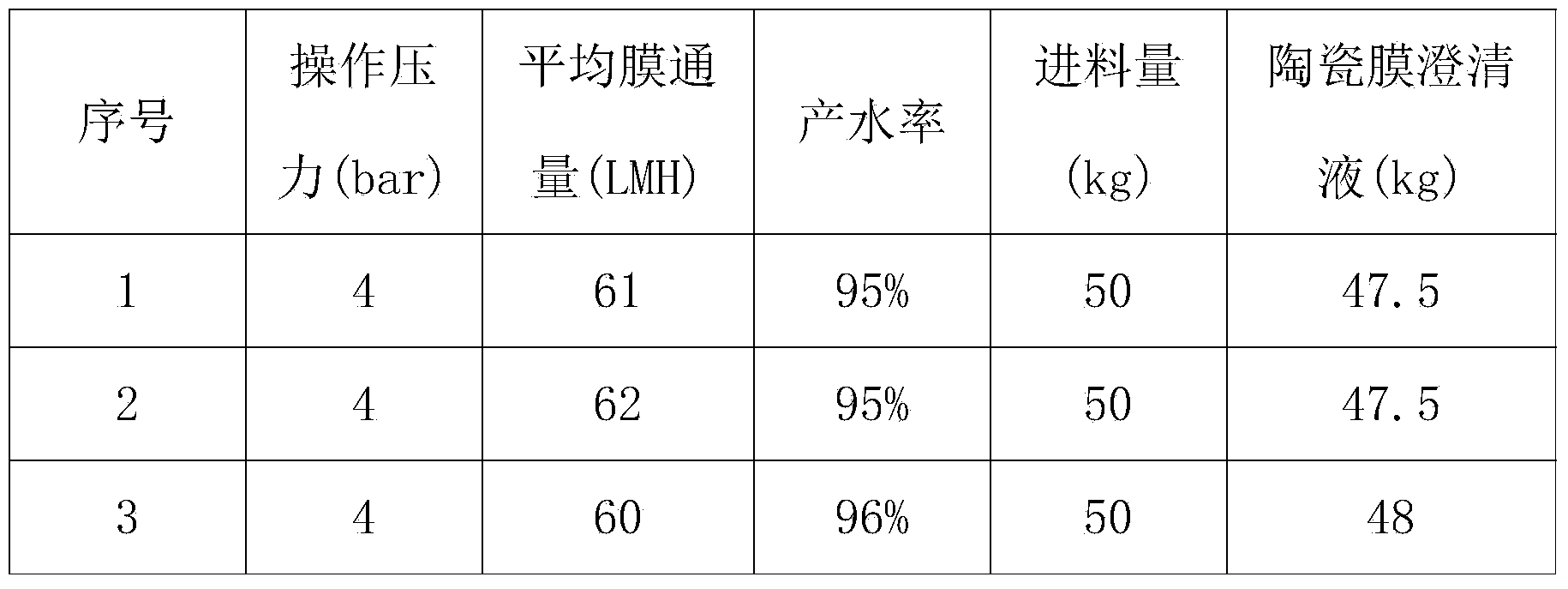

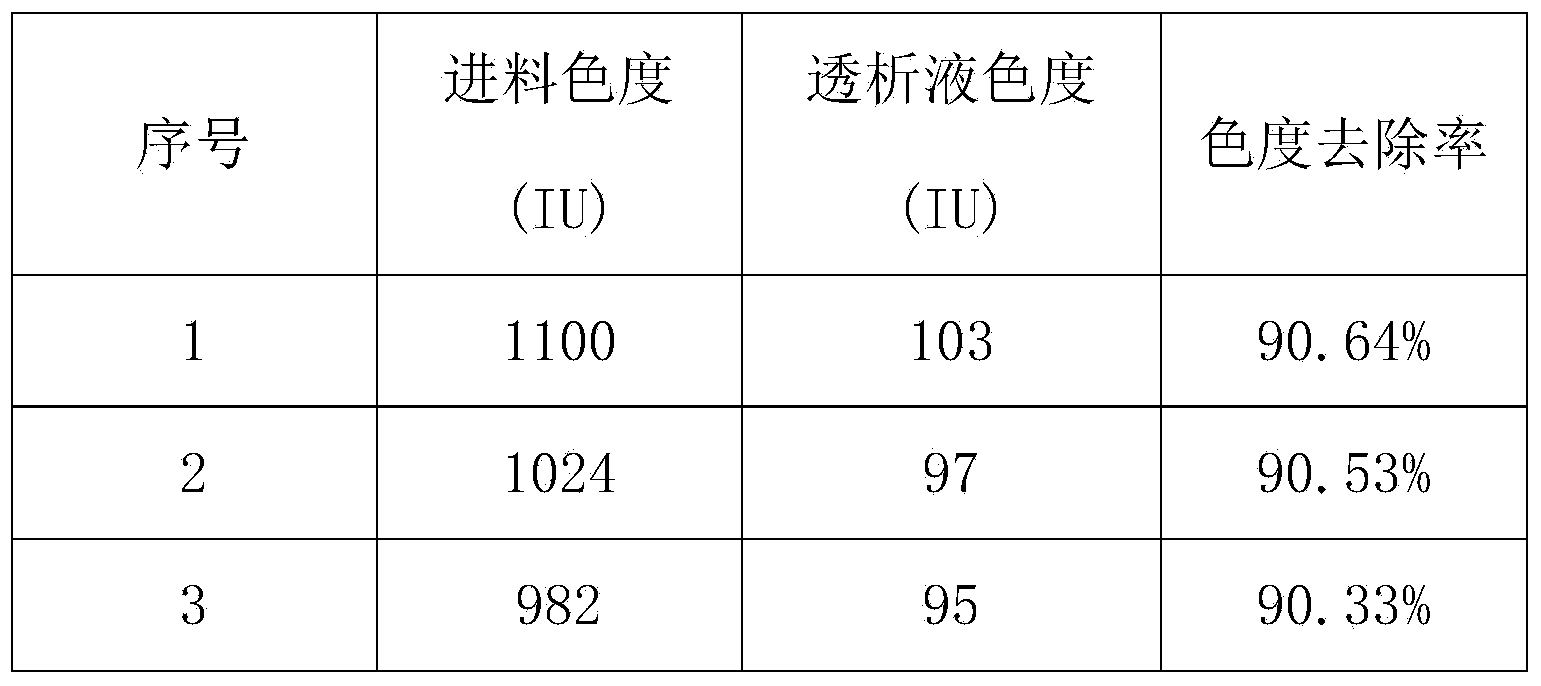

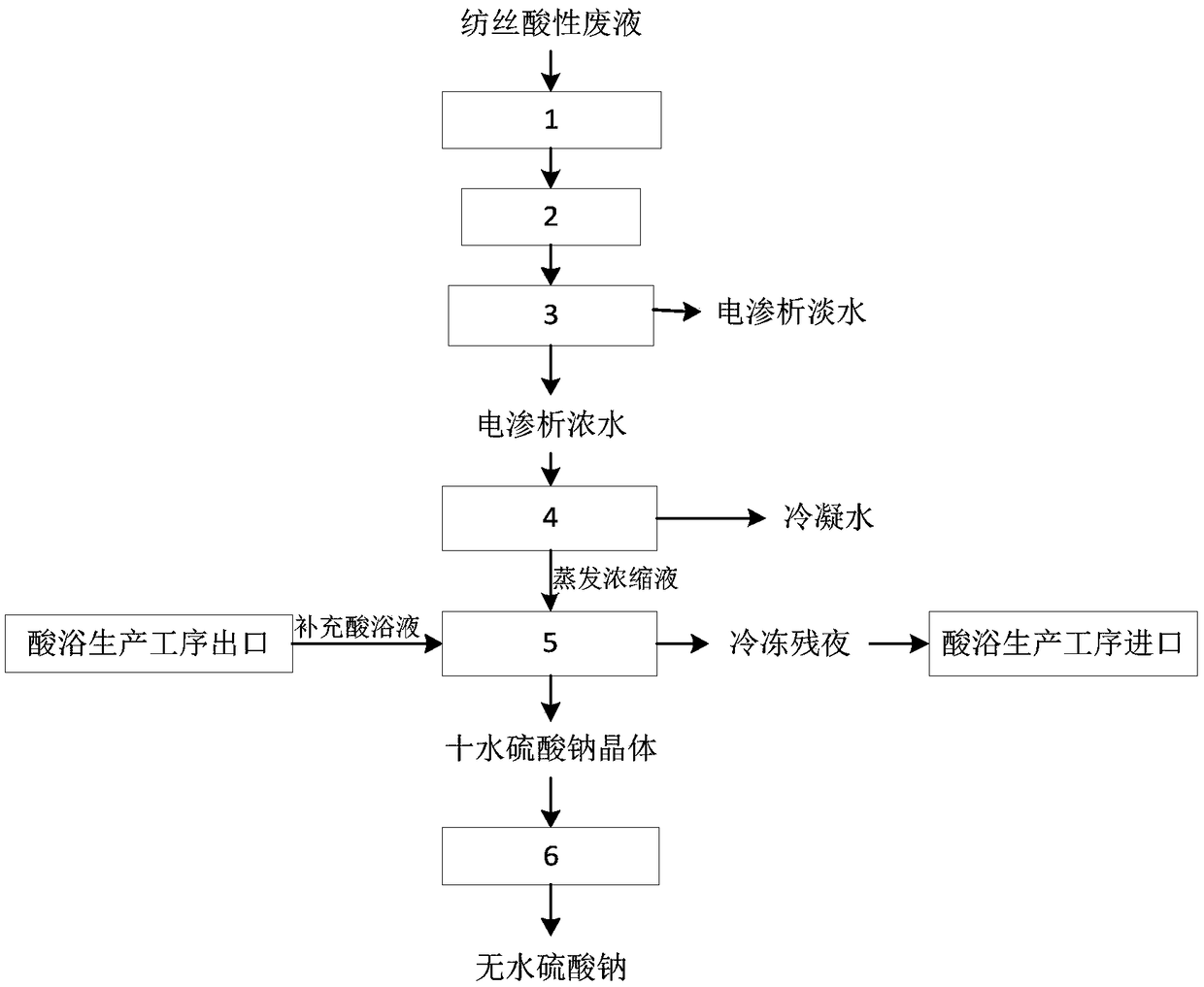

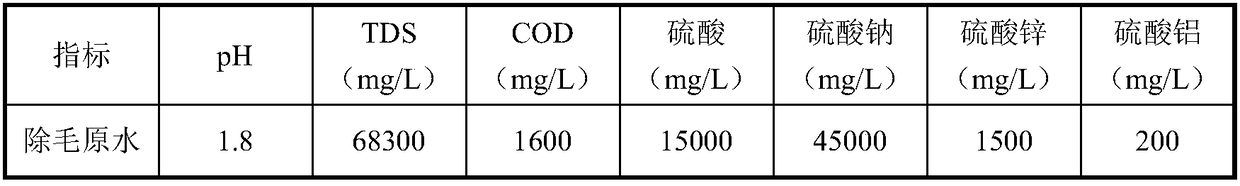

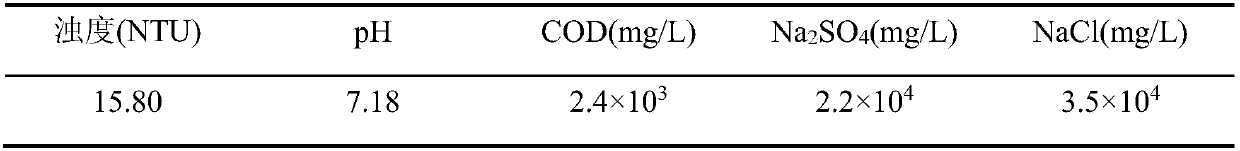

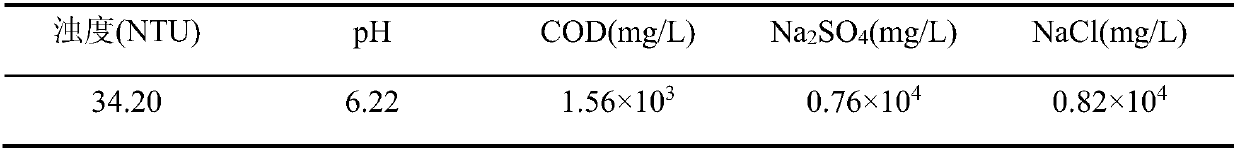

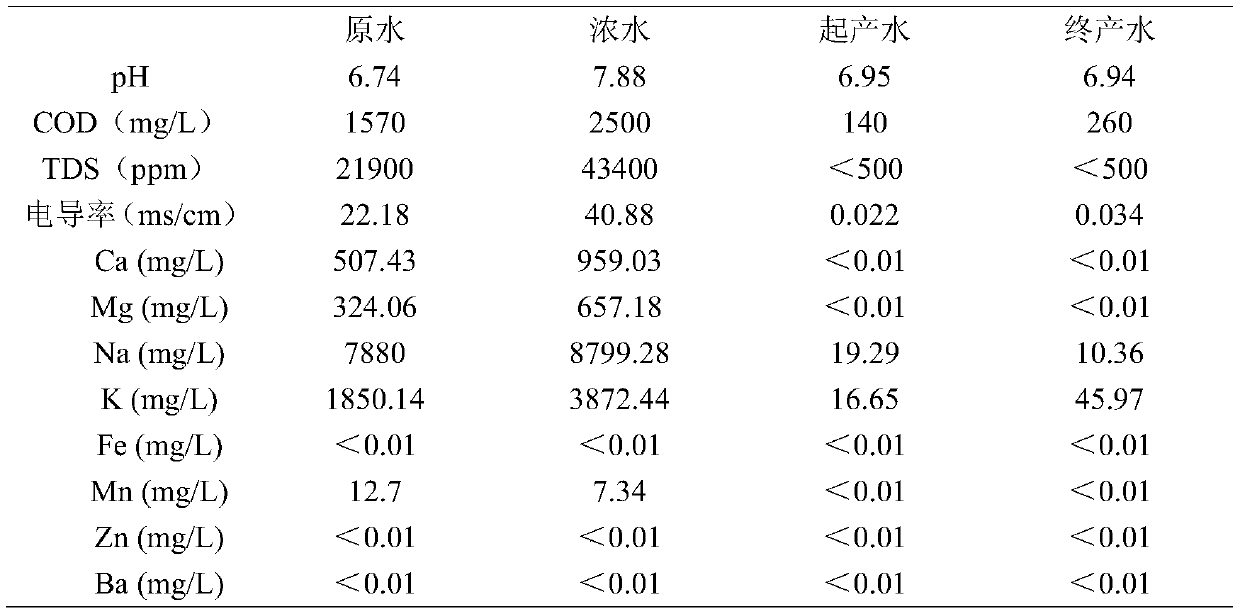

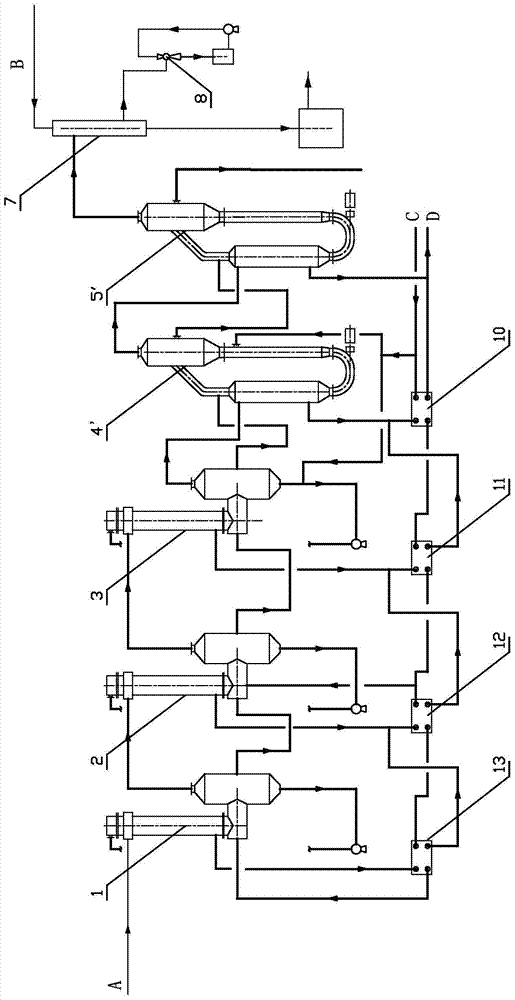

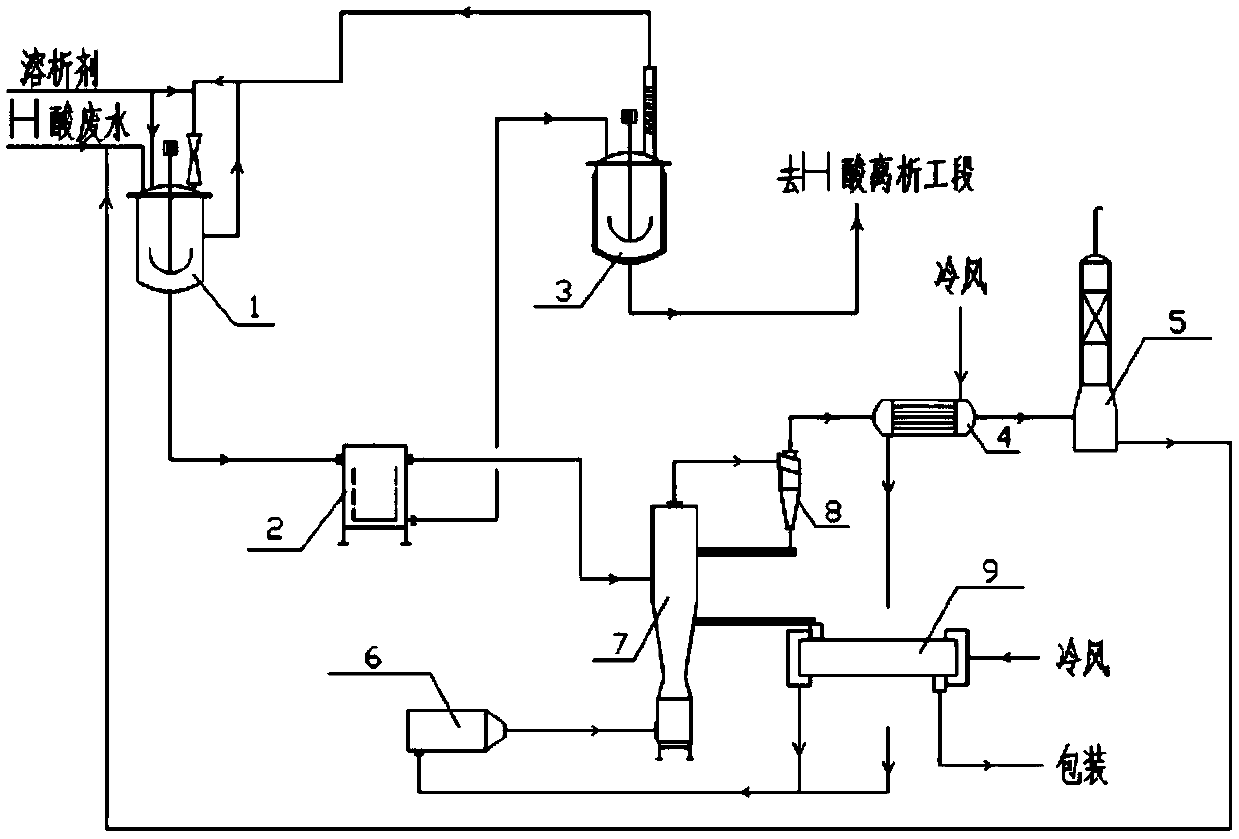

Method and device for progressively recovering and circularly applying viscose fiber spinning acid waste liquid

InactiveCN109457325AAchieve balanceSolve the reuse problemArtificial filament recoveryArtificial filaments from viscoseLiquid wasteResource utilization

The invention discloses a method and a device for progressively recovering and circularly applying viscose fiber spinning acid waste liquid. The method comprises the following steps of (1), carrying out cooling and heat interchange on spinning acid waste liquid from a viscose fiber industry, and then removing a solid insoluble substance in the waste liquid by adopting a precision filter; (2), carrying out electrodialysis on the waste liquid treated in step (1), removing an organic substance in waste water, and carrying out evaporation concentration treatment on thick water subjected to the electrodialysis, so that a concentrated solution with a saline mass concentration of 30% to 50% is obtained; (3), recycling a sodium sulfate decahydrate crystal in the concentrated solution obtained in the step (2) by adopting a freezing crystallization way, and recycling freezing residual liquid in an acid bath device in a spinning production process; and (4), refining the sodium sulfate decahydratecrystal recycled in the step (3) to obtain anhydrous sodium sulfate. By using the method, the balancing of sodium sulfate in a system is realized; the resource utilization and the near zero emissionof viscose fiber spinning waste water are realized; and an organic substance is prevented from being enriched in the system.

Owner:JIANGSU NJU ENVIRONMENTAL TECH

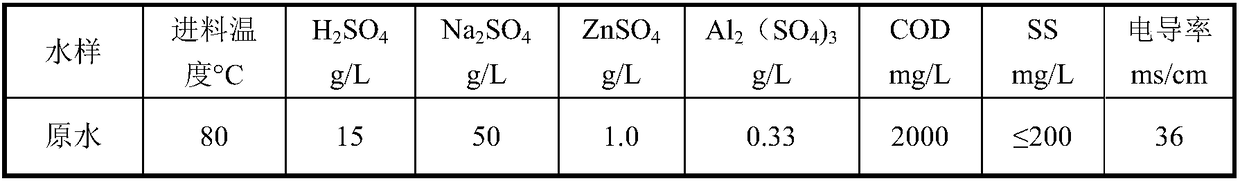

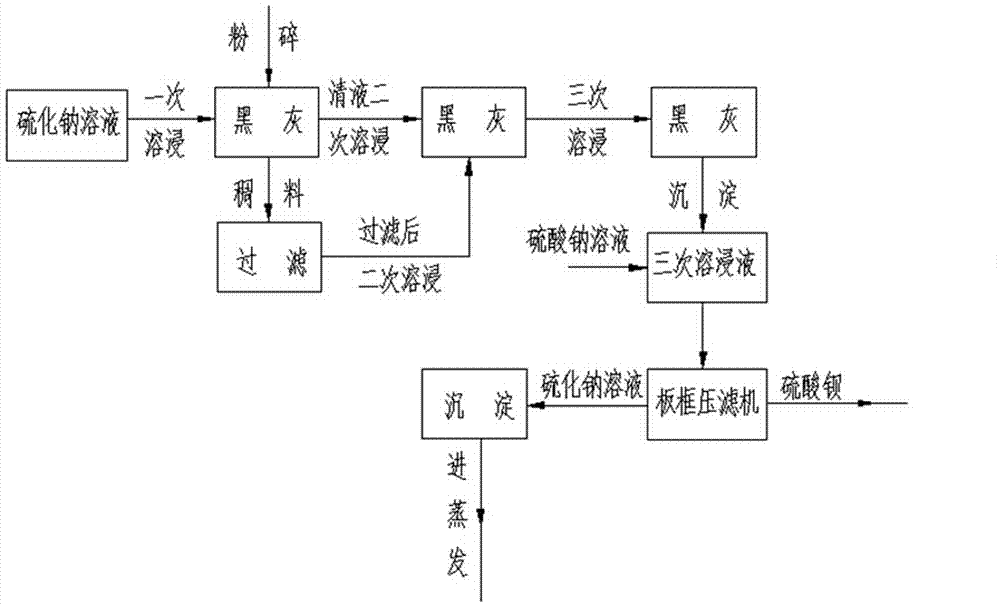

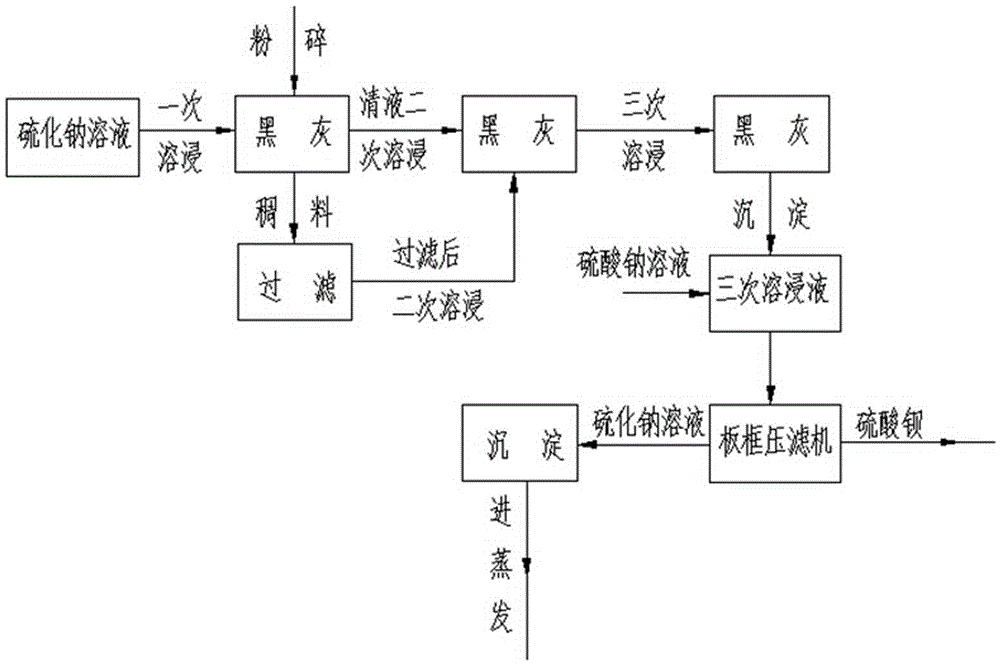

Method for improving sodium sulfide solution concentration by leaching black ash for three times

ActiveCN104326499AIncrease concentrationReasonable designCalcium/strontium/barium sulfatesAlkali metal sulfides/polysulfidesBarium sulphideEnvironmental engineering

The invention discloses industrialized application of a sodium-sulfide solution three-time black-ash (a product which is obtained by calcining barite and has the main composition barium sulfide) leaching technology to barium sulfate production industry, and concretely discloses a method for improving sodium sulfide solution concentration by leaching black ash for three times. The method comprises: using a sodium sulfide solution with the concentration of 4-5% to perform leaching on crushed black ash for three times, namely, performing precipitate separation on a solution subjected to first leaching to obtain a mother liquid I, using the mother liquid I to continue to perform secondary leaching on black ash, and performing secondary precipitate separation on the leached solution to obtain a mother liquid II, using the mother liquid II to performing third leaching, and performing precipitate separation on a solution subjected to third leaching to obtain a mother liquid III, using the mother liquid III to react with a sodium sulfate solution to generate barium sulfate and a sodium sulfide solution which has the concentration of 8-10% after three times of leaching, performing solid-liquid separation on the sodium sulfide solution, and then performing precipitation and clarification, so as to enable the sodium sulfide solution to enter a next process of evaporation. The method is reasonable in design, helps to improve the concentration of the sodium sulfide solution and reducing the evaporation amount by performing leaching on black ash for three times, and realizes the purpose of reducing production cost of 60 alkali (an alkali sulfide with the sodium sulfide content of 60%).

Owner:南风化工(运城)集团有限公司

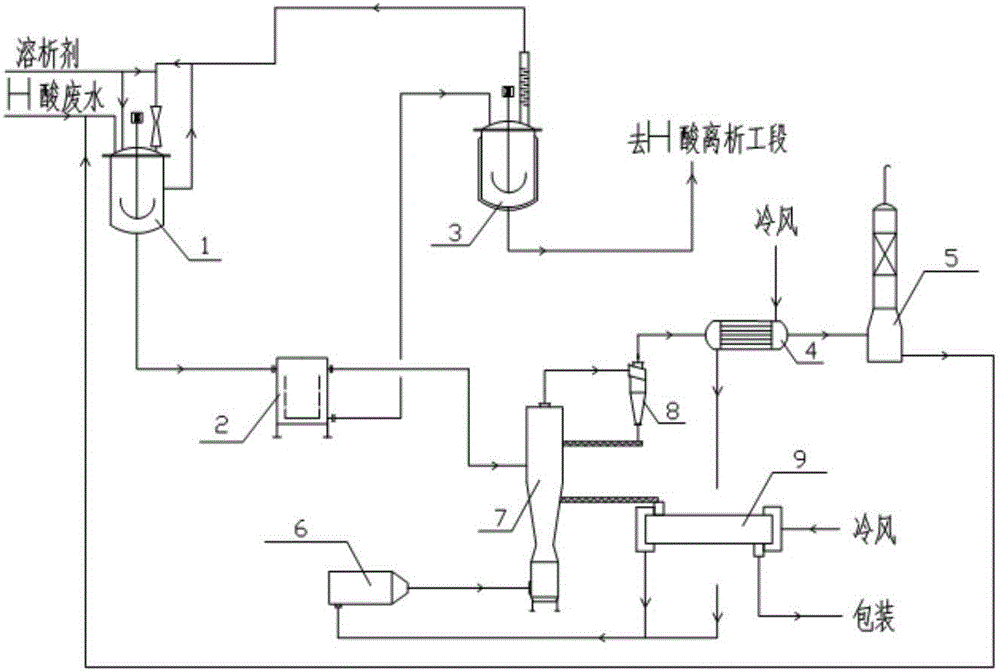

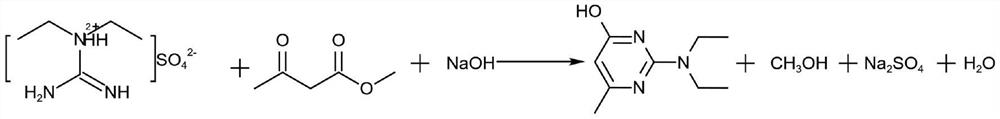

Recycling process and system for high-salt and high-concentration non-biodegradable organic matter-containing H acid wastewater

ActiveCN105948350AReduce usageReduce processing costsChemical industryAlkali metal sulfite/sulfate purificationHigh concentrationSocial benefits

The invention discloses a recycling process and system for cyclic utilization of high-salt and high-concentration non-biodegradable organic matter-containing H acid wastewater and production of anhydrous sodium sulfate; the process for production of anhydrous sodium sulfate through solvent-out crystallization, waste acid cyclic utilization and high-temperature boiling granulation and oxidation is designed for the high-salt high-organic-matter H acid wastewater, so all components of the H acid wastewater are recycled with low cost, the production costs of H acid is reduced, zero emission of pollutants is achieved, and the method is the best way for H acid wastewater low-cost recycling, has demonstration significance for treatment of high-salt and high-concentration non-biodegradable organic matter wastewater, and has huge economic and social benefits.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +2

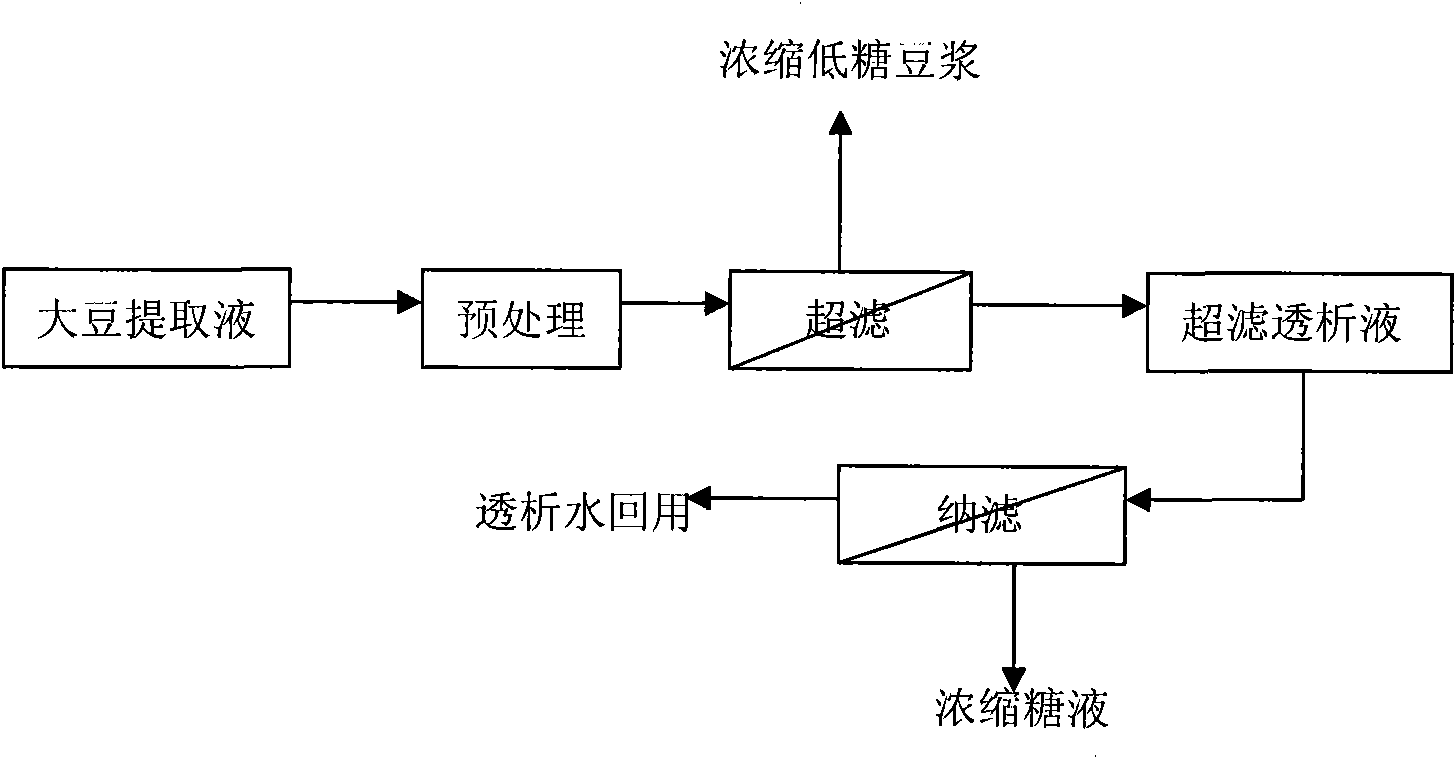

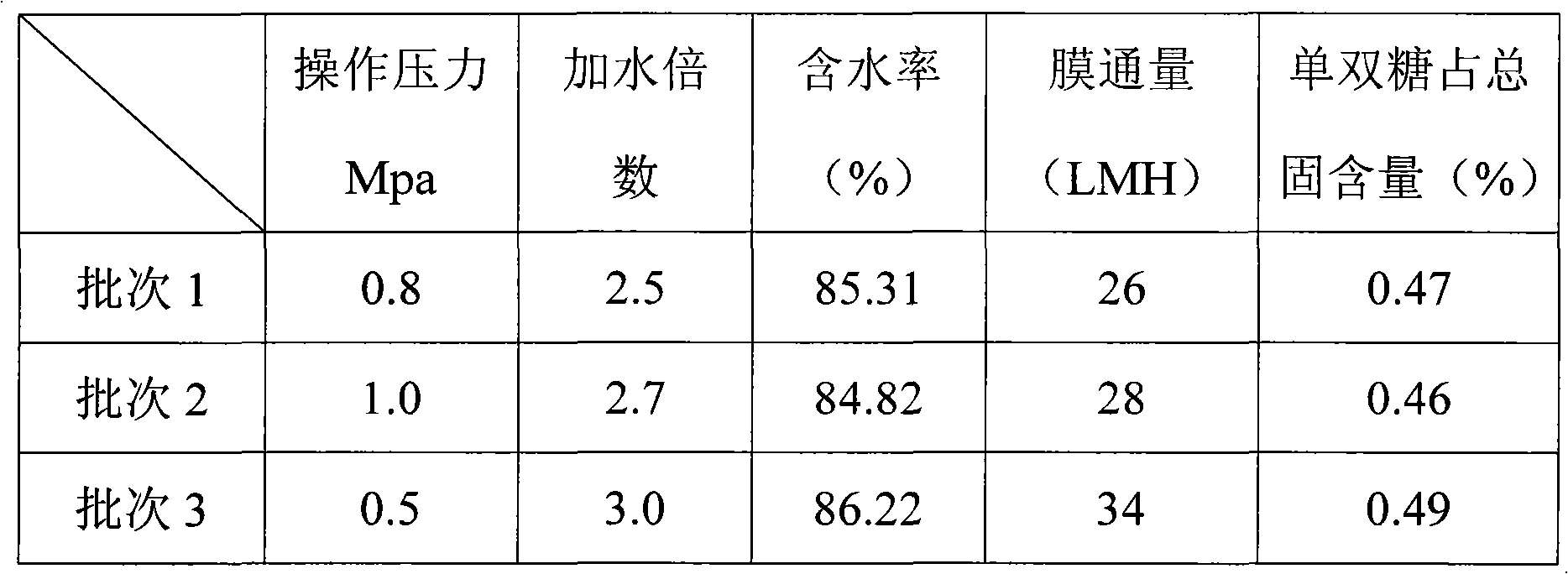

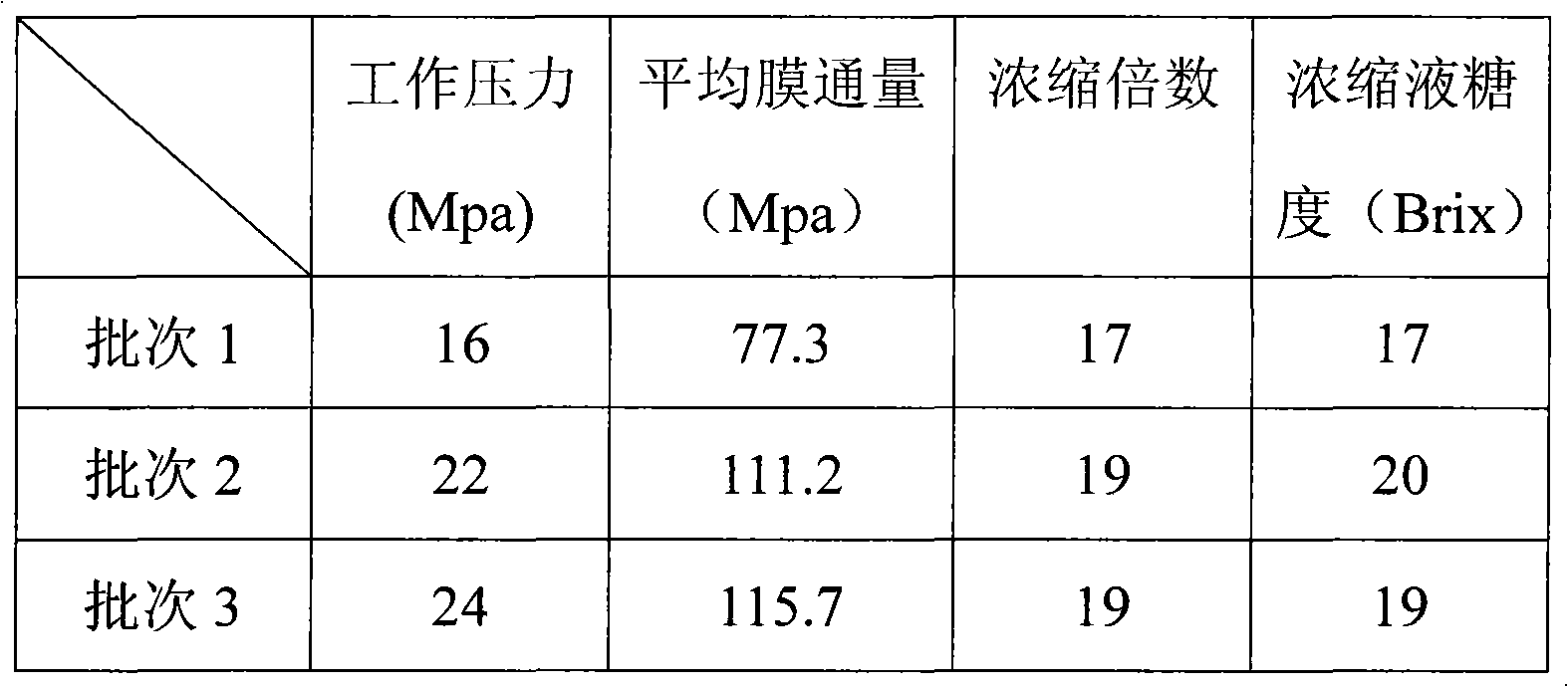

Production method of low-sugar soya-bean milk

InactiveCN101669551AAvoid pollutionReduce evaporation costsMilk substitutesFood scienceUltrafiltrationChemistry

The invention discloses a production method of low-sugar soya-bean milk, which mainly comprises the following steps: (1) pretreatment: soybean extracting solution is filtered by a filtering bag, suspended matters such as bean dregs in the soybean extracting solution can be removed, so as to ensure the safety of a membrane system and obtain clear solution of the soybean extracting solution; (2) sugar removal by hyperfiltration: the clear solution of the soybean extracting solution, which is pretreated, enters into a hyperfiltration membrane system, hyperfiltration concentration is carried out,and the solution is concentrated by two times, water is added in the concentrated solution for washing, so as to wash sugar ingredient in the concentrated solution in a circulating way and measure thesugar degree in the concentrated solution and dialysate at regular time, until the sugar ingredient in the concentrated solution is reduced to be stable, the treatment of sugar removal by hyperfiltration is stopped; (3) nanofiltration and contraction: the hyperfiltration dialysate is placed in a nanofiltration membrane system, the sugar ingredient in the dialysate is concentrated and extracted, and the nanofiltration dialysate water returns back to the production to be used as pulping water. In the whole treating process, other substances are not added, the treatment is carried out at normaltemperature, and the method has the advantages of energy saving, environmental protection and good separating effect.

Owner:XIAMEN STARMEM TECH

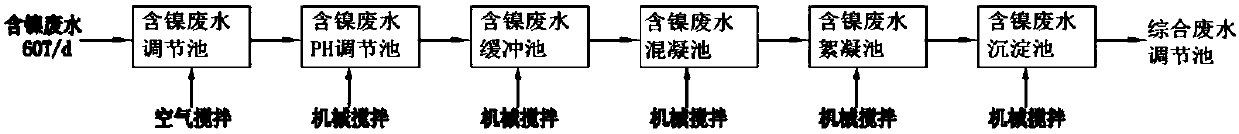

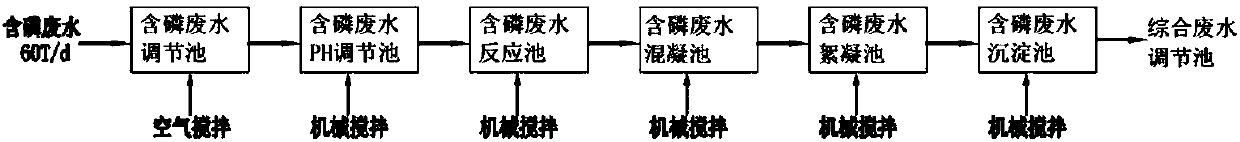

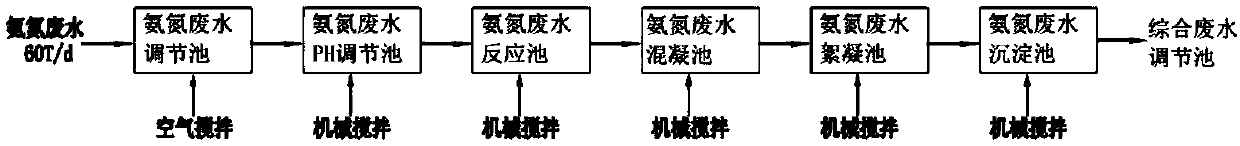

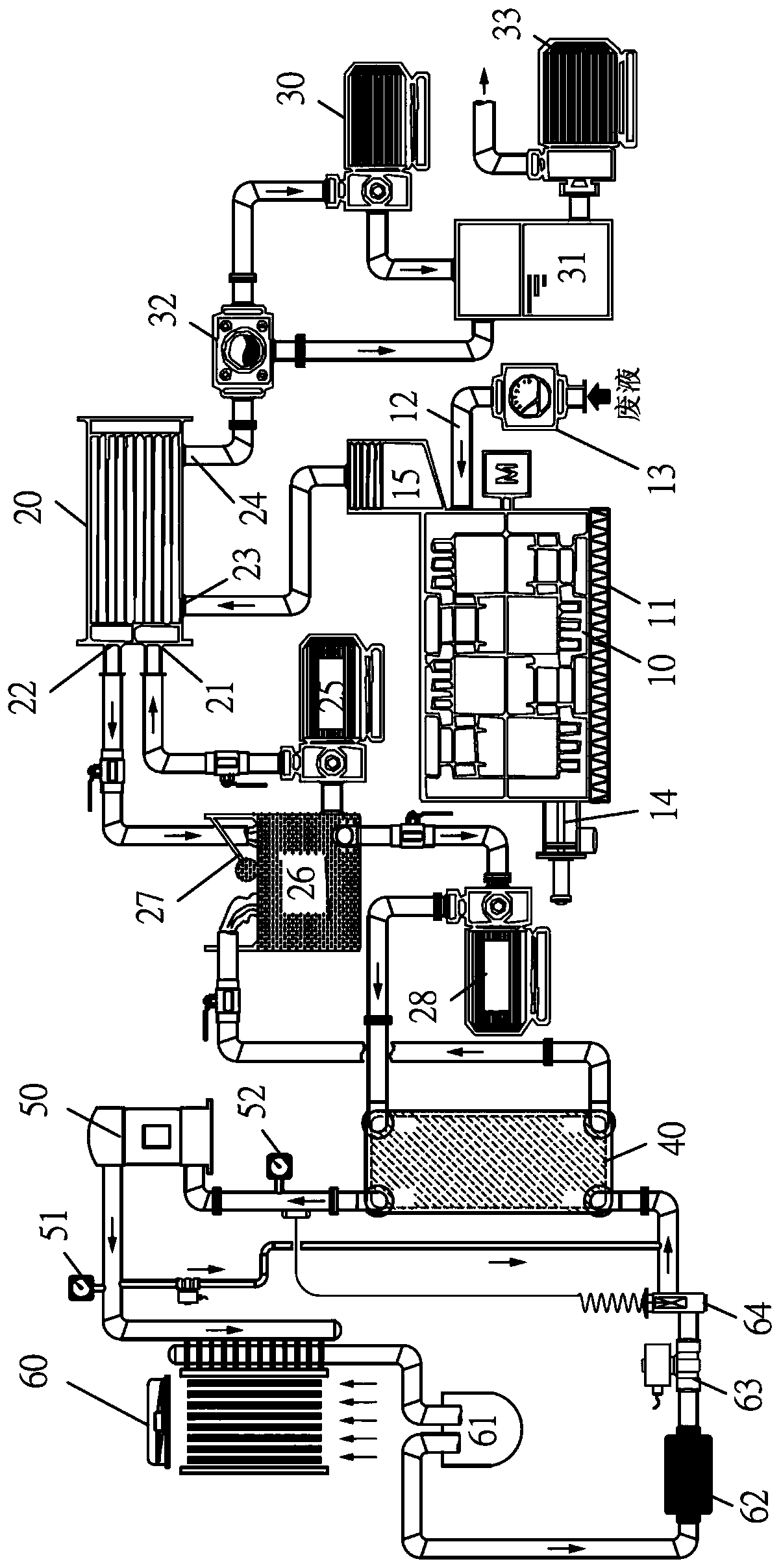

Electroplating waste water zero discharge system

PendingCN108033651AImprove removal efficiencyGuaranteed uptimeGeneral water supply conservationTreatment involving filtrationSludgeMembrane technology

The invention provides an electroplating waste water zero discharge system and relates to the technical field of sewage treatment. The bottoms of a nickel-containing waste water regulating pool, a nickel-containing waste water PH regulating pool, a nickel-containing waste water buffer pool, a nickel-containing waste water coagulating pool, a nickel-containing waste water flocculating pool and a nickel-containing waste water settling pool are connected with a nickel-containing sludge concentration pool through pipelines; the nickel-containing sludge concentration pool is connected with a nickel-containing sludge compressor; concentrated liquid in the nickel-containing sludge compressor is connected with the nickel-containing waste water regulating pool through a pipeline; a phosphorus-containing waste water regulating pool, a phosphorus-containing waste water PH regulating pool, a phosphorus-containing waste water reaction pool, a phosphorus-containing waste water coagulating pool, a phosphorus-containing waste water flocculating pool and a phosphorus-containing waste water settling pool are connected through pipelines. The electroplating waste water zero discharge system is high inremoval rate of pollutants and stable to operate, reasonably utilizes an advanced membrane technology, reduces membrane blockage, guarantees the service life of the membrane, increases the water production rate of the membrane, can reduce evaporation cost and has higher practicability.

Owner:SHENZHEN RUIWEISHENG ENVIRONMENTAL PROTECTION TECH

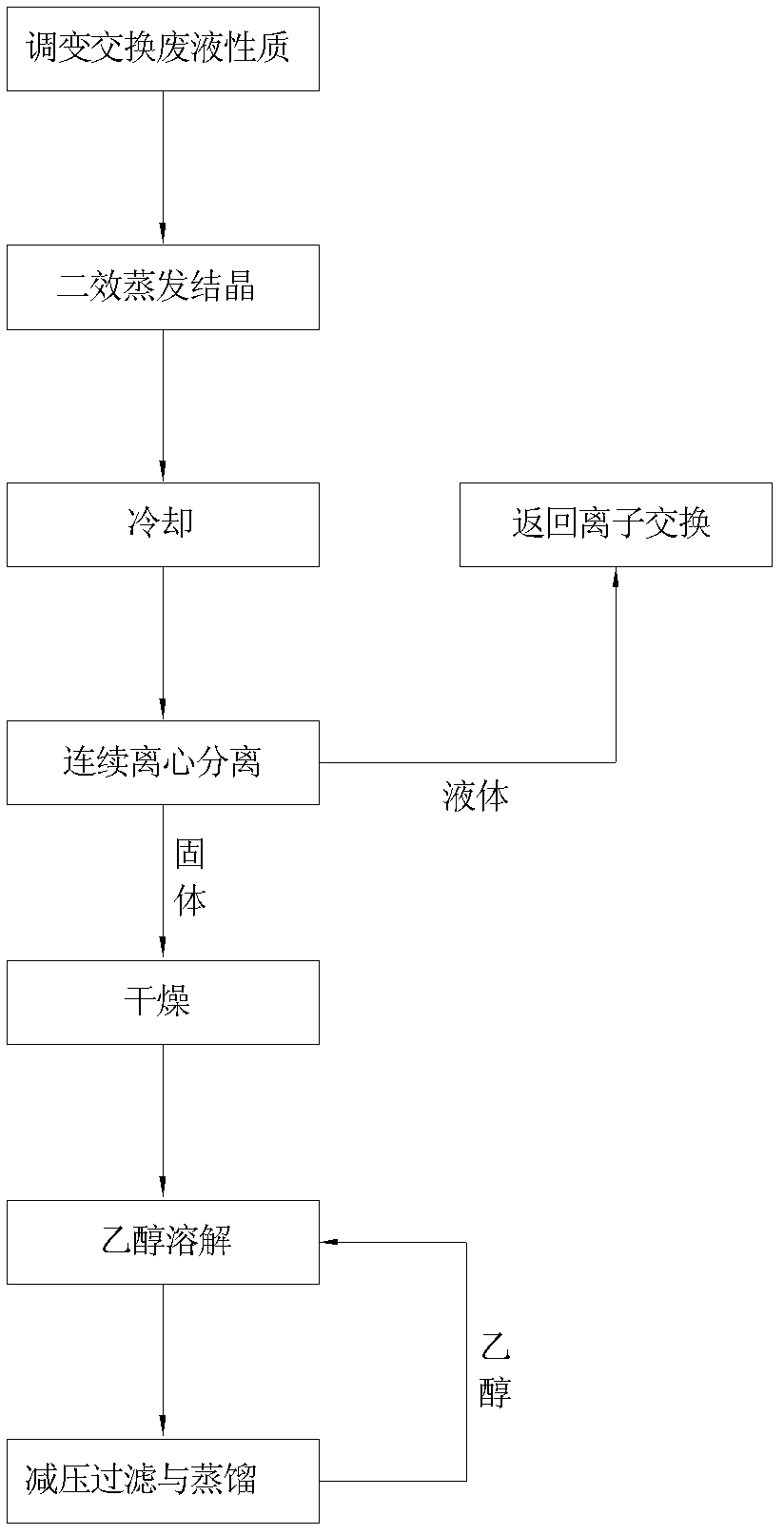

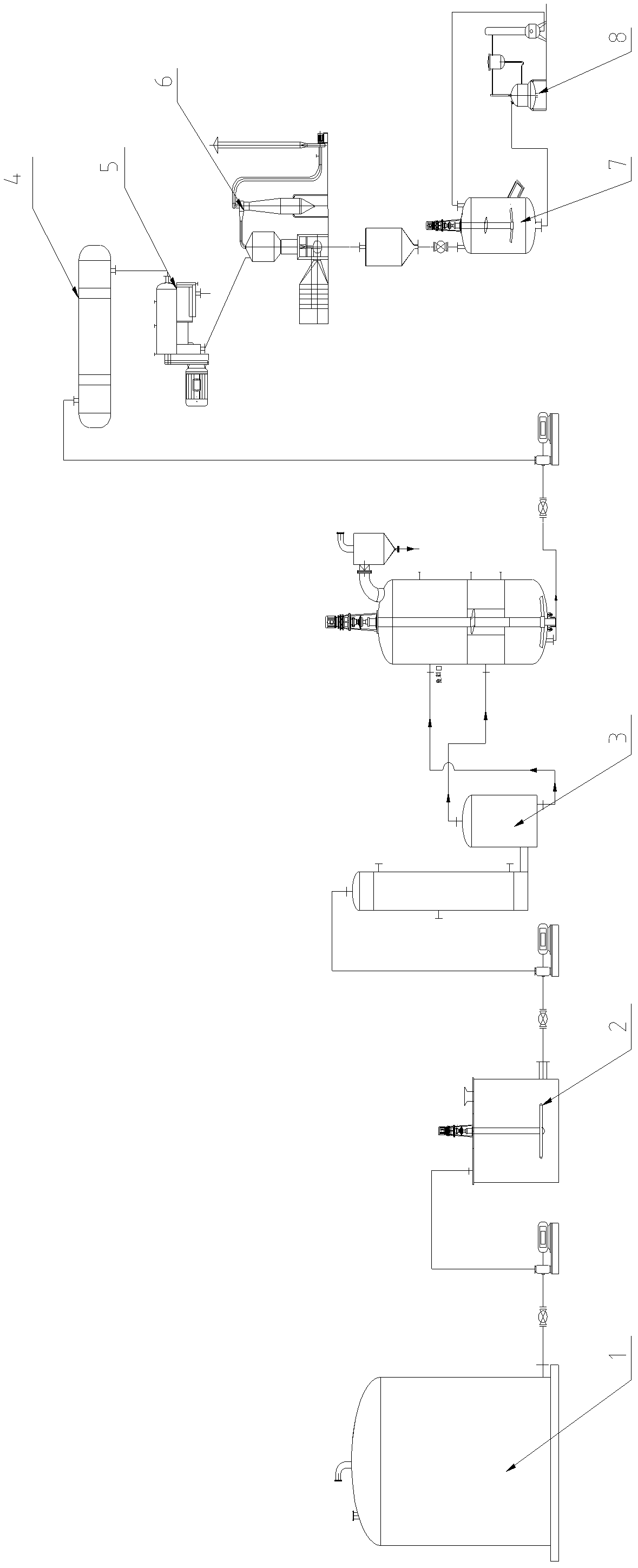

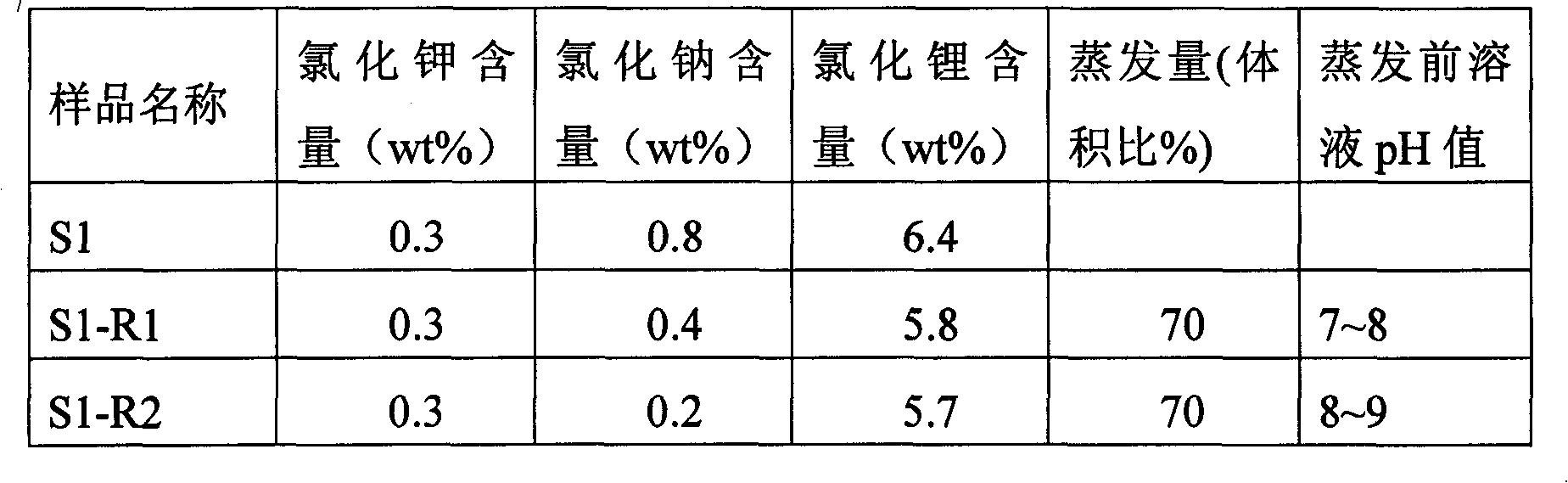

Method and device for recycling lithium from exchange waste fluid containing lithium

ActiveCN102491364AHigh recovery rateSimple operation and control parametersCrystalline aluminosilicate zeolitesLithium chlorideHydrogen

The invention relates to a method and device for recycling lithium from exchange waste fluid containing lithium. The method comprises the steps of modulating potential of hydrogen (pH) value and concentration of the exchange waste fluid, evaporating and recrystallizing, cooling crystal mush, continuously subsiding and performing centrifugal separation, performing fluidized drying, dissolving withethanol and performing vacuum filtration distillation. Compared with the prior art, the method and device for recycling the lithium from the exchange waste fluid containing the lithium are suitable for recycling the lithium in the exchange waste fluid containing the lithium which is produced in the production of efficient adsorbent containing the lithium, and the method is high in recycling rate of lithium chloride, simple in process control, friendly to environment and free of pollution of waste gas, waste water and waste residues.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

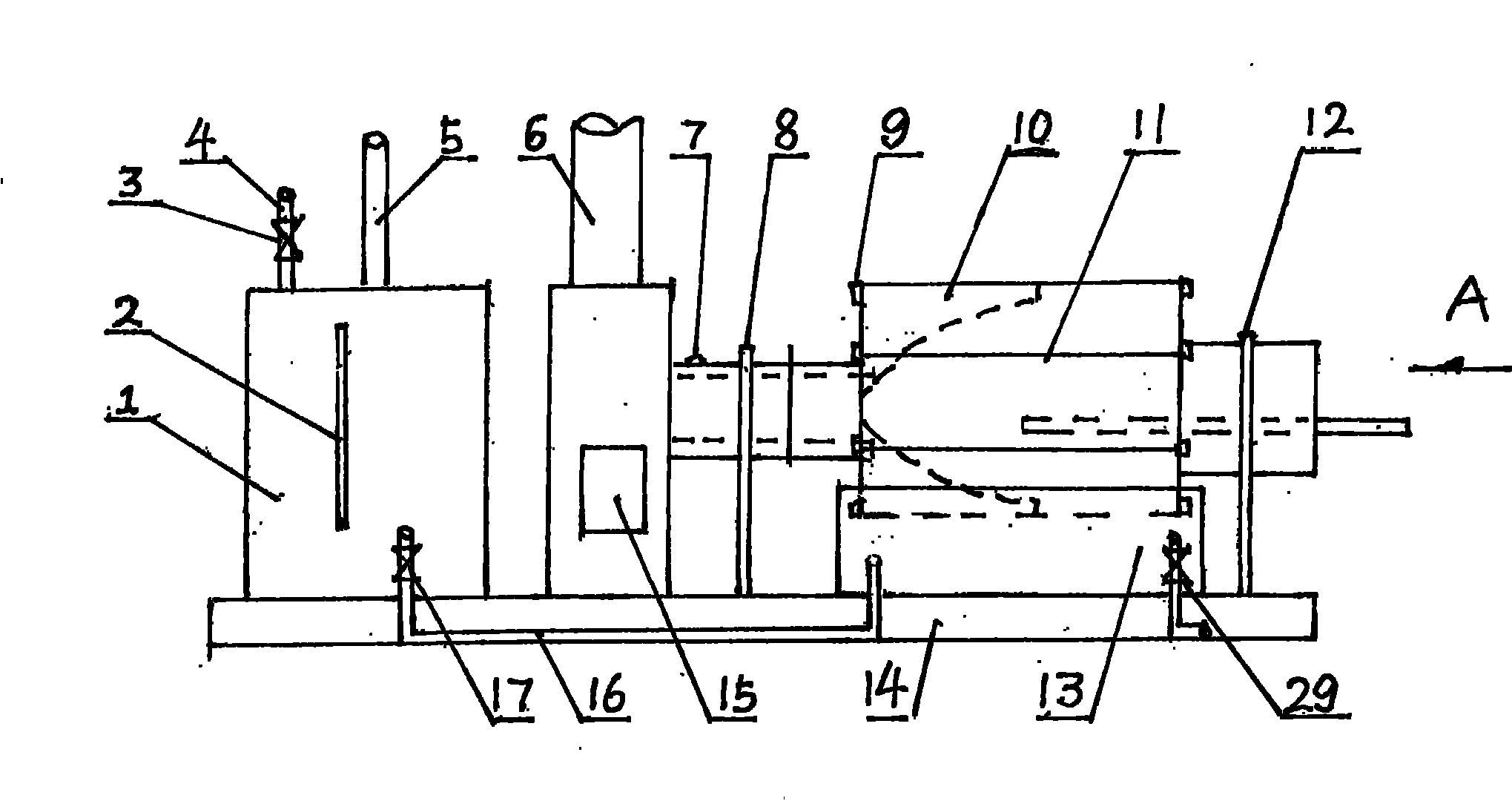

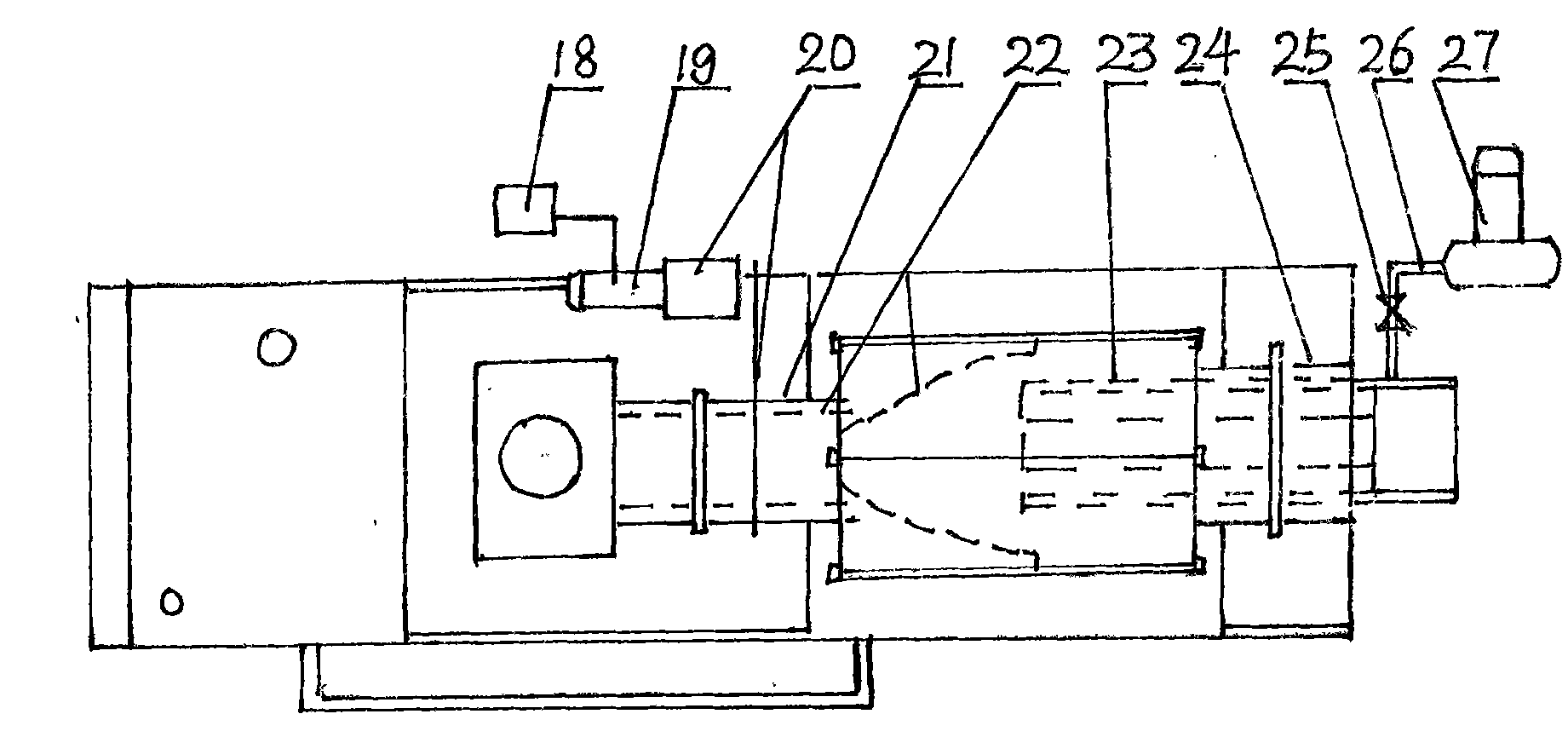

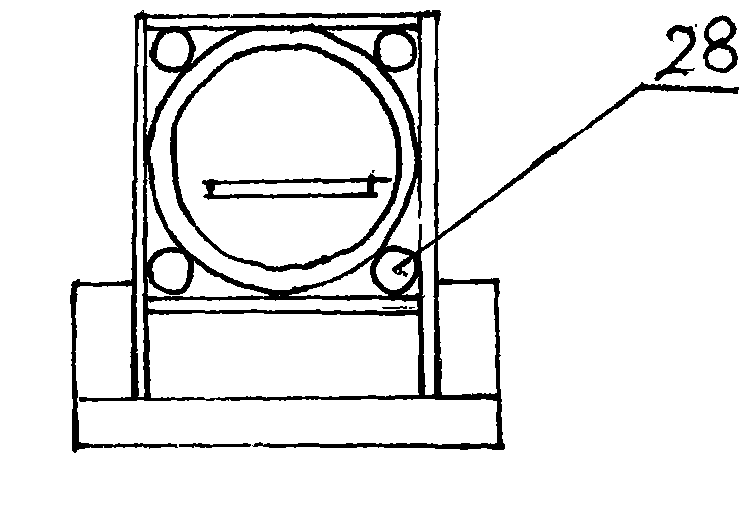

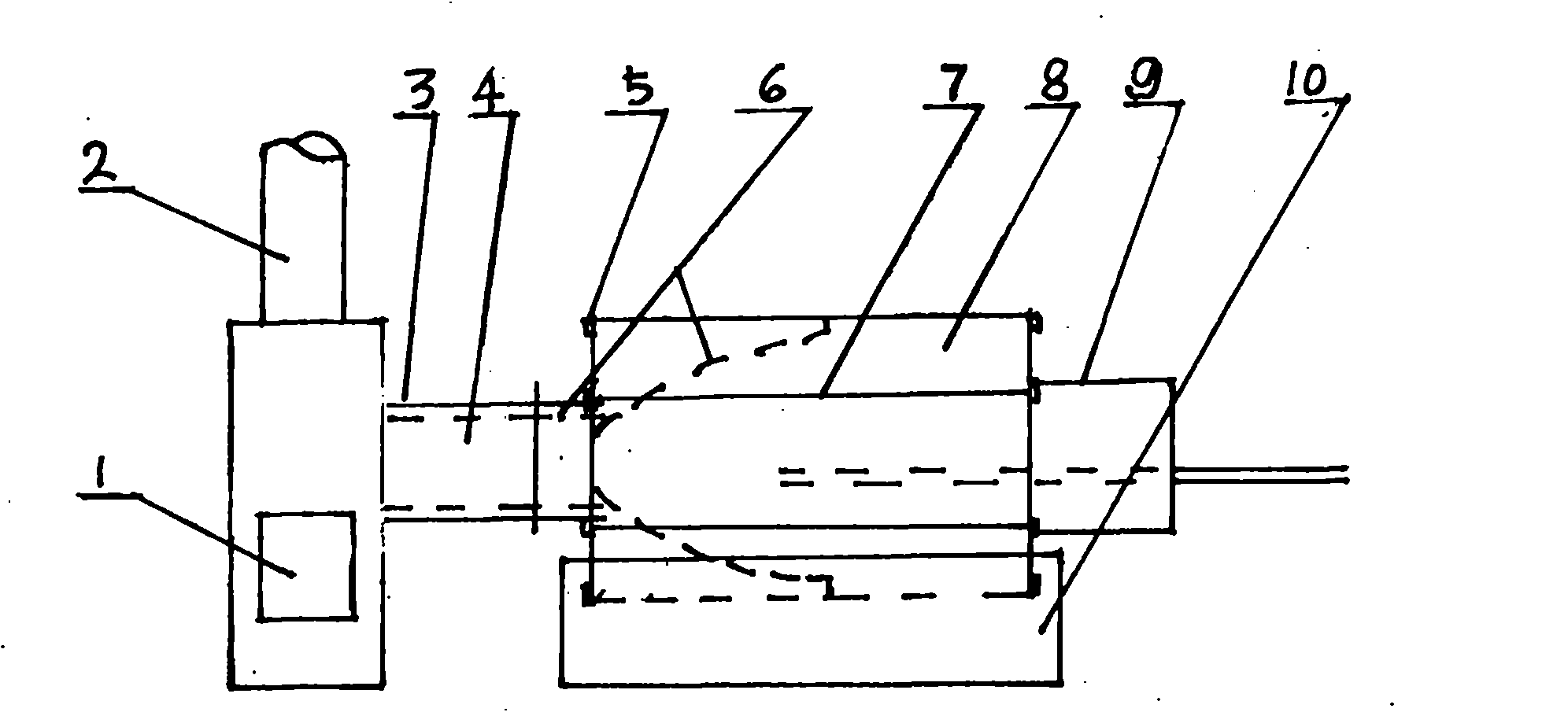

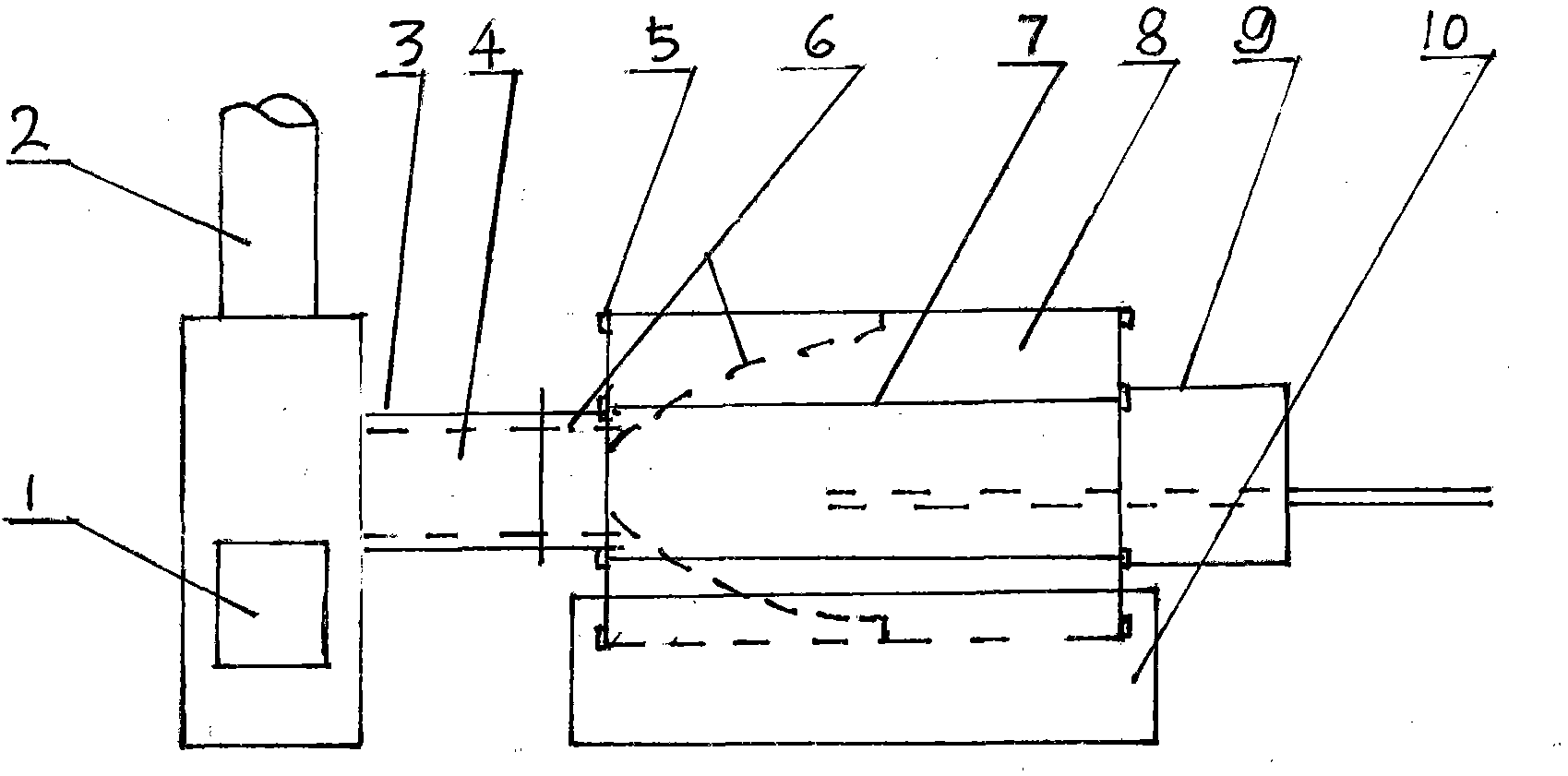

Internal-combustion waste water treatment device

InactiveCN102060343AReduce heat lossImprove evaporation efficiencyWater/sewage treatment by heatingCombustionEvaporation

The invention discloses an internal-combustion waste water treatment device which comprises a motor, a transmission device, an evaporation cylinder, an evaporation tank, a chimney, an ash discharge port, an air blower, an air valve, an air supply pipe, a fuel inlet pipeline, an ash discharge pipeline, a frame, a waste water raw material pool and a liquid transmission pipe, wherein one side of the transmission device is connected with the motor, and the other side is connected with the evaporation cylinder; the evaporation cylinder is installed inside the evaporation tank; both ends of the evaporation cylinder are respectively provided with an opening, one opening is connected with the fuel inlet pipeline, and the other opening is connected with the ash discharge pipeline; the waste water raw material pool is positioned on the upper end of the back side of the frame; the upper end of the front side of the frame is provided with a front support and a back support; the evaporation tank is positioned between the front support and the back support; the fuel inlet pipeline is installed on the upper end of the front support; the ash discharge pipeline is installed on the upper end of the back support; the tail end of the ash discharge pipeline is provided with the chimney and the ash discharge port; the side of the fuel inlet pipeline is provided with the air blower; and the waste water raw material pool is connected with the evaporation tank through the liquid transmission pipe. The invention has the advantages of low heat loss, manpower saving and low cost for waste water treatment.

Owner:兴宁市洪才电镀废水处理设备有限公司

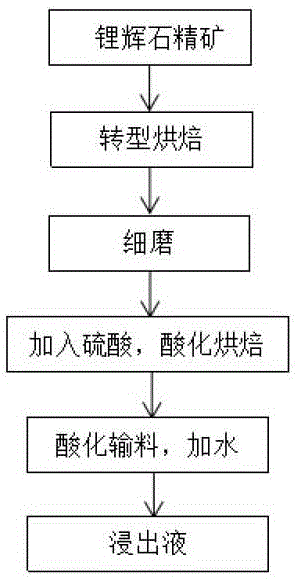

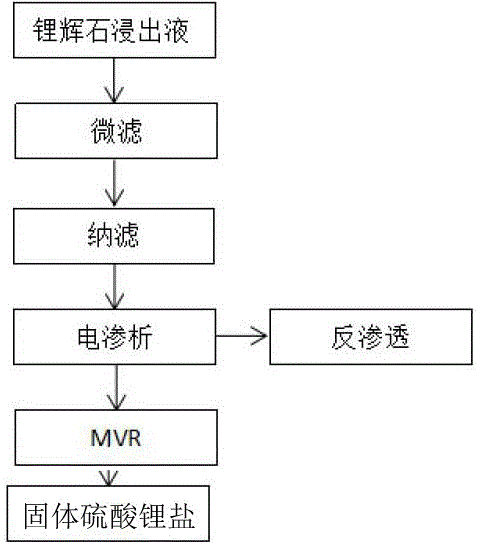

Lithium sulfate leaching agent separation and purification technology

InactiveCN106086473AReduce addTo achieve the purpose of separation and purificationProcess efficiency improvementWater useEvaporation

The invention discloses a new lithium sulfate leaching agent separation and purification technology. The technology is characterized by comprising following steps: firstly, a microfiltration system is used for pretreating a lithium sulfate leaching agent, impurities and suspended matter in feed liquid are removed, and microfiltration dialyzate is obtained; secondly, the microfiltration dialyzate enters a nanofiltration system to obtain nanofiltration dialyzate and a nanofiltration concentrated solution; thirdly, the nanofiltration concentrated solution enters an electrodialysis system to be concentrated, electrodialysis concentrated water and electrodialysis contributing water are obtained, the electrodialysis concentrated water is used for MVR evaporation, and solid sulfuric acid lithium is obtained; and fourthly, the electrodialysis contributing water uses reverse osmosis for deep treatment, reverse osmosis concentrated water returns to the third step to be continuously concentrated, and reverse osmosis contributing water returns to the production technology. According to the lithium sulfate leaching agent separation and purification technology, through microfiltration, nanofiltration and electrodialysis concentration, the separation and purification aim of lithium sulfate is achieved; meanwhile, due to adding of chemical reagents, the evaporation cost is reduced, the recycling water amount is improved, and the outward zero emission of the whole system is achieved.

Owner:XIAMEN STARMEM TECH

Circulating process for producing propylene oxide by using chlorohydrination method

InactiveCN104130218ARealize closed loopReduce evaporation costsOrganic chemistryElectrolysisEvaporation

The invention belongs to the field of organic chemical processes, and in particular relates to a circulating process for producing propylene oxide by using a chlorohydrination method. The circulating process comprises the following steps: adding hydrochloric acid into salt-containing wastewater generated in a chlorohydrination reactor, and then removing organic matters in the salt-containing wastewater; then performing evaporation and concentration in an MVR evaporator, filtering concentrated wastewater by virtue of a ceramic membrane and then entering the filtered concentrated wastewater into a diaphragm electrolytic tank for electrolysis to generate chlorine and liquid caustic soda, reacting chlorine with water to generate hydrochloric acid and hypochlorous acid, and then entering hydrochloric acid and hypochlorous acid into the chlorohydrination reactor to perform chlorohydrination reaction with propylene; entering a chloropropanol solution obtained in the chlorohydrination reactor into an extraction tower for extracting chloropropanol in the chloropropanol solution, and entering chloropropanol obtained by extraction into a saponification reactor; reacting chloropropanol in the saponification reactor with liquid caustic soda generated by the diaphragm electrolytic tank by virtue of electrolysis to generate crude propylene oxide, and rectifying to obtain pure propylene oxide. The process disclosed by the invention is reasonable, can achieve the recycling of wastewater and waste residues, and can achieve the closed circulation of salt.

Owner:SHANDONG BLUSR DONGDA CHEM

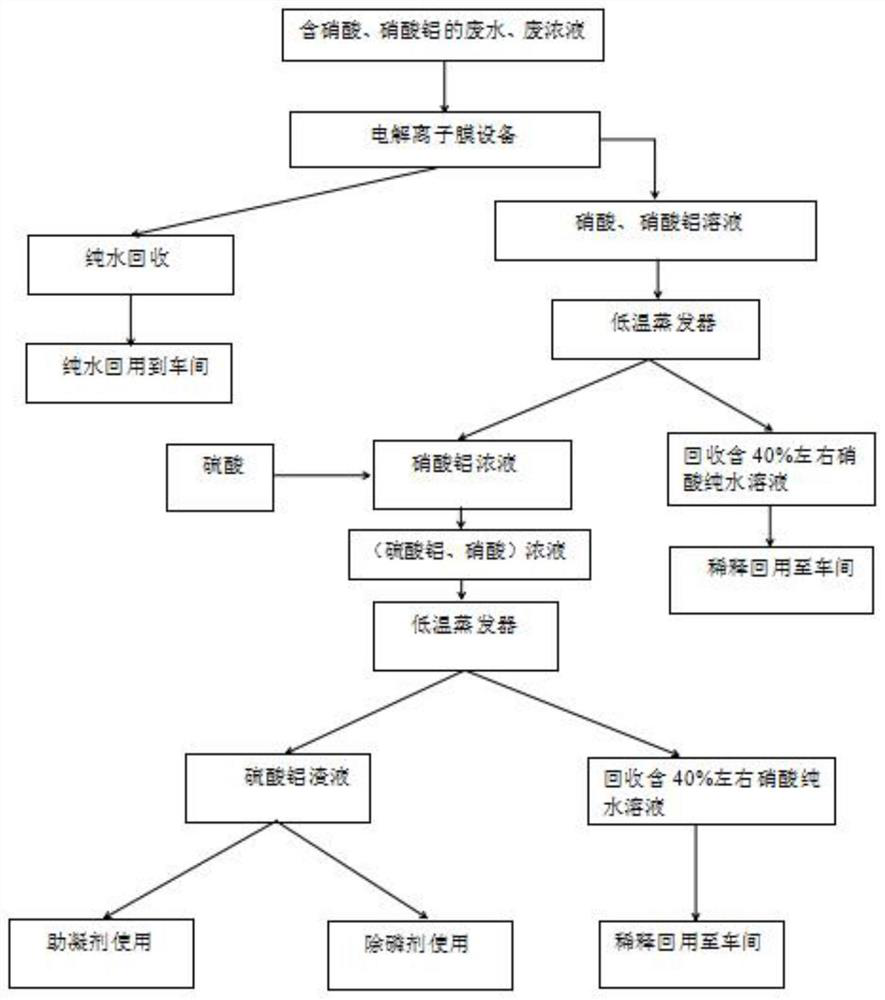

Anodic oxidation nitrate nitrogen-containing wastewater treatment process

InactiveCN112047546AAchieve recyclingLess dopeMultistage water/sewage treatmentWater/sewage treatment by heatingElectrolysisTotal nitrogen

The invention provides an anodic oxidation nitrate nitrogen-containing wastewater treatment process, belongs to the technical field of anodic oxidation wastewater treatment, and particularly relates to an anodic oxidation nitrate nitrogen-containing wastewater treatment process. The process comprises the following steps: electrolytic ionic film treatment, pure water recycling, low-temperature evaporation, nitric acid recycling, aluminum nitrate slag liquid treatment, secondary low-temperature evaporation, secondary nitric acid recycling and aluminum sulfate slag liquid treatment. Compared withthe prior art, the process has the following advantages and effects: firstly, the process can realize zero discharge of wastewater, recycling of nitric acid and utilization of waste residues, can thoroughly solve the problem that the it is difficult for total nitrogen discharged by the wastewater to reach the standard, and has considerable economic benefits; secondly, the purity of the produced water separated by the electrolytic ionic film is high, the conductivity is below 10us / cm, and the cyclic utilization of the wastewater can be realized; thirdly, the recovered nitric acid is high in purity and can be used as a raw material to be blended and recycled, and waste residue utilization can be achieved; and finally, the process is simple, low in cost and convenient to popularize and use.

Owner:何学文

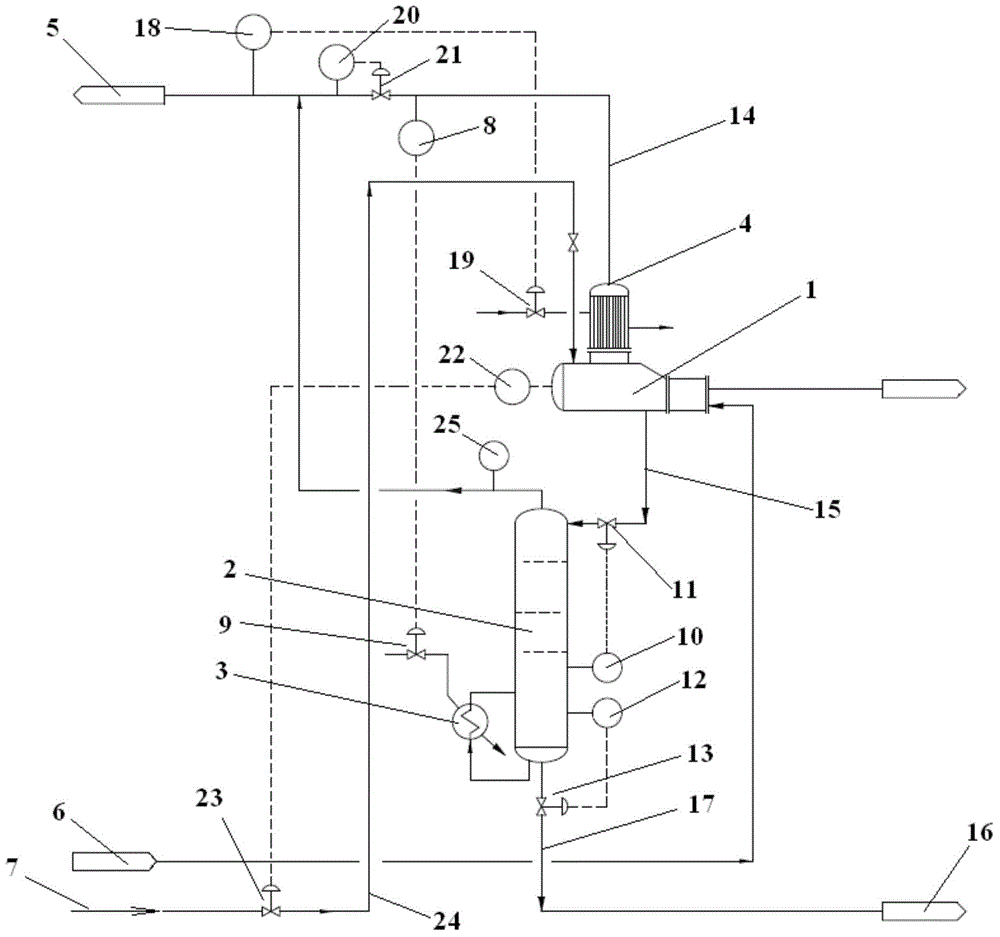

Evaporation cooling integrated equipment

PendingCN110665245ATemperature controlSolve processing problemsDistillation in boilers/stillsWater vaporEngineering

The invention relates to evaporation cooling integrated equipment. The equipment comprises a distillation still, a condenser, a heat exchanger, a compressor and an air cooling unit. The distillation still is connected to a water vapor inlet of the condenser through a pipeline, an evaporation condensed water outlet of the condenser is connected to a second water tank through a pipeline, the condenser is connected to a vacuum pump, a cooling water inlet and a cooling water outlet of the condenser are both connected to a first water tank, the distillation still is equipped with a waste liquid pipe and a slagging pipe, the compressor, the air cooling unit, an expansion valve and the heat exchanger are connected through pipelines to form a refrigerant circulation loop, and water from the firstwater tank enters the heat exchanger through a pipeline and is cooled by a refrigerant to form low-temperature water, which then returns to the first water tank again.

Owner:江苏惟亨环保科技有限公司

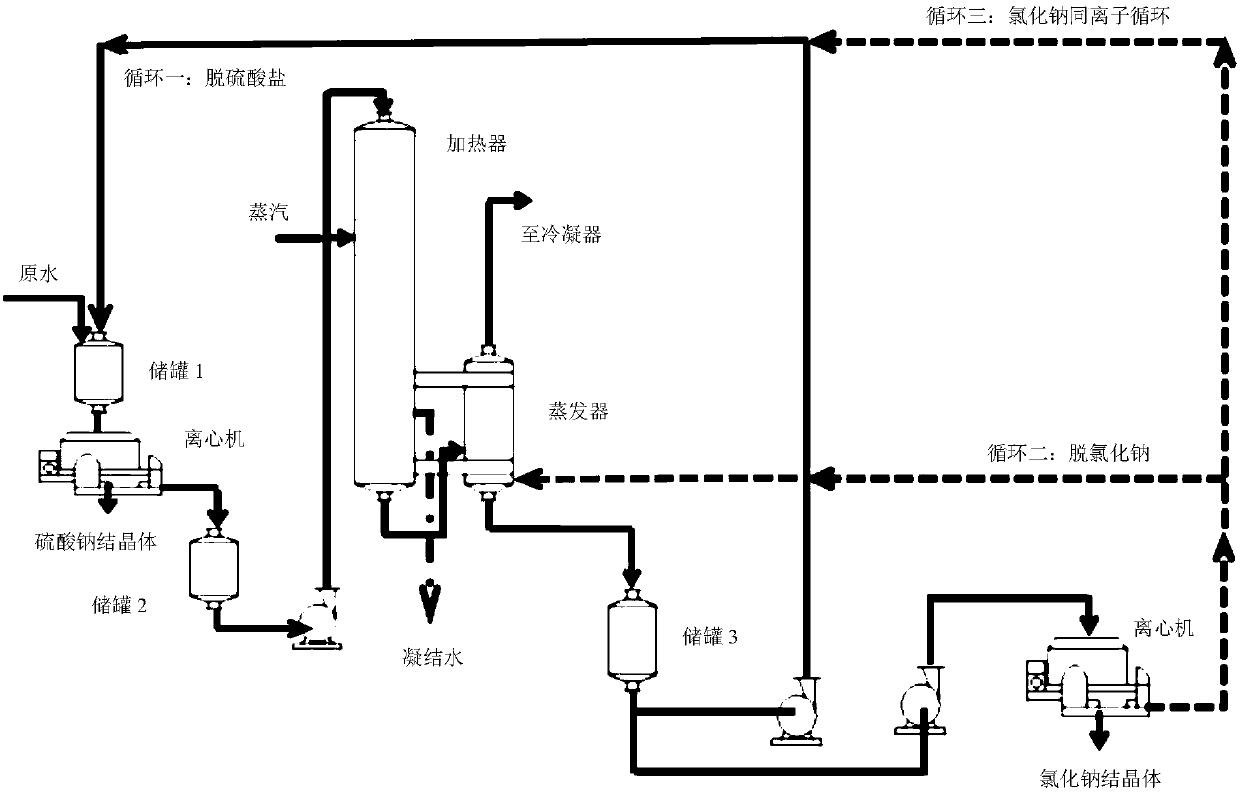

Method for synchronously removing sodium sulfate and sodium chloride in wastewater through three cycles

InactiveCN111377572AEfficient separationMeet quality requirementsWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentPhysical chemistryProcess engineering

The invention discloses a method for synchronously removing sodium sulfate and sodium chloride in wastewater through three cycles. The method has the advantages of simple process flow, strong stability, high product purity, low energy consumption and the like. The method provided by the invention comprises the following steps: first cycle: sodium sulfate crystallization cycle; second cycle: sodiumchloride crystallization cycle; third cycle: sodium chloride similar ion cycle.

Owner:江苏江中纪元科技有限公司 +1

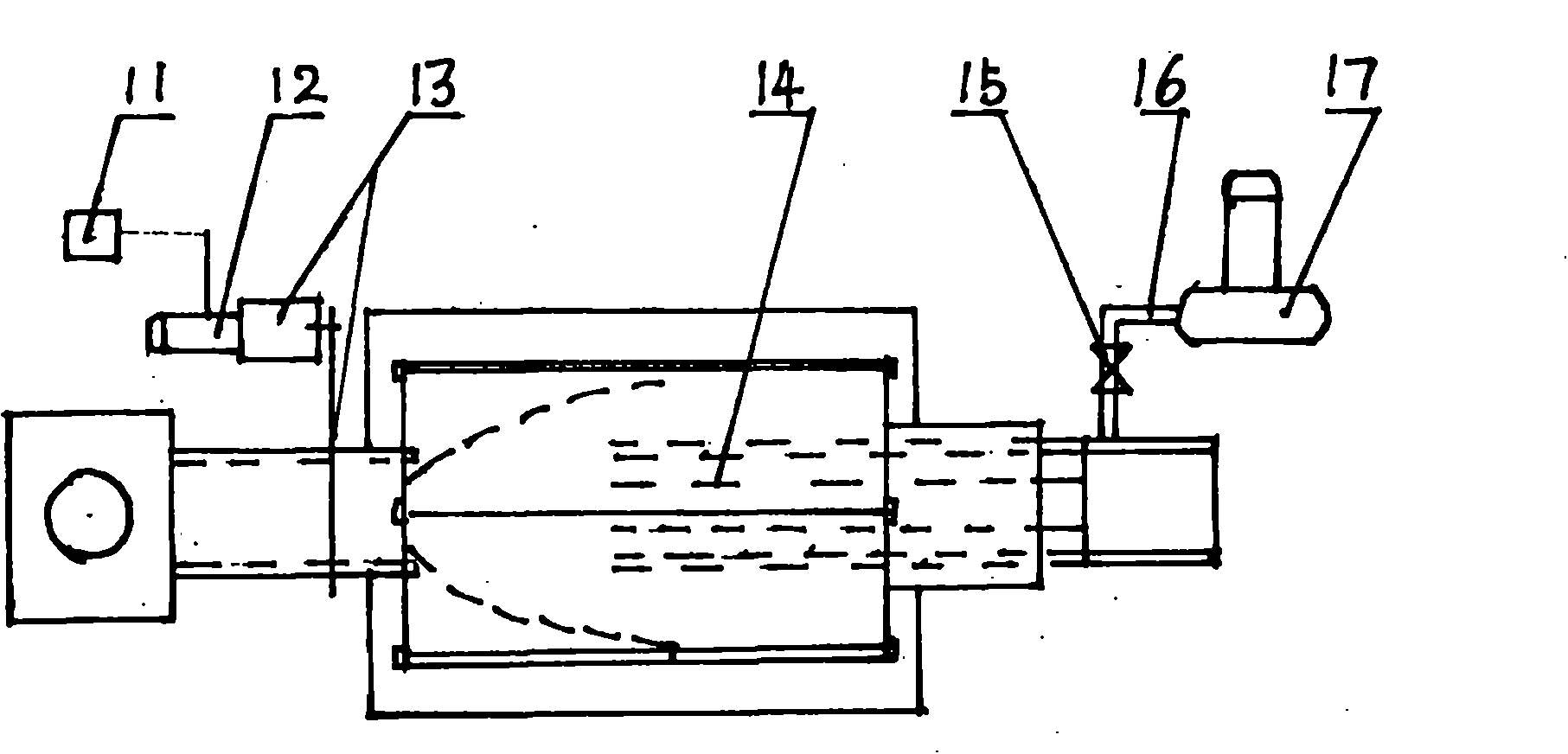

Internal combustion type wastewater treatment device with automatic temperature control rotating speed device

InactiveCN102092806AReduce heat lossImprove evaporation efficiencyGeneral water supply conservationWater/sewage treatment by heatingTemperature controlAutomatic Generation Control

The invention discloses an internal combustion type wastewater treatment device with an automatic temperature control rotating speed device, which comprises a motor, a driving device, the automatic temperature control rotating speed device, an evaporation cylinder, an evaporation groove, a chimney, an ash discharging port, a blower, an air valve, an air supply pipe, a fuel feeding pipeline and an ash discharging pipeline; one end of the automatic temperature control rotating speed device is connected with a power supply, and the other end is connected with the motor; one side of the driving device is connected with the motor, and the other side is connected with the evaporation cylinder; the evaporation cylinder is arranged inside the evaporation groove; the inside of the evaporation cylinder is hollow; a hearth is arranged inside the evaporation cylinder; two openings are respectively reserved at two ends of the evaporation cylinder; one opening is connected with the fuel feeding pipeline; the other opening is connected with the ash discharging pipeline; the chimney and the ash discharging port are arranged at the tail end of the ash discharging pipeline; the chimney is arranged at the upper part of the tail end of the ash discharging pipeline; the ash discharging port is arranged at the lower part of the tail end of the ash discharging pipeline; the blower is arranged on the side of the fuel feeding pipeline; the air supply pipe is arranged outside the blower and is connected to the hearth; and the air valve is arranged on the air supply pipe. The invention has the advantages of less heat loss, high evaporation efficiency and low wastewater treatment cost.

Owner:兴宁市洪才电镀废水处理设备有限公司

Concentration reduction method and concentration reduction device for reverse osmosis concentrated water

InactiveCN110526474AImprove interception effectImprove anti-pollution performanceMultistage water/sewage treatmentWater/sewage treatment by heatingPervaporationChemistry

The invention discloses a reverse osmosis concentrated water concentration reduction method. The method comprises the following steps: detecting the inlet water quality of reverse osmosis concentratedwater, directly entering a next step when the water quality of the reverse osmosis concentrated water meets the standard, otherwise, pretreating the reverse osmosis concentrated water, and then entering the next step; carrying out multiple times of circulating concentration on the reverse osmosis concentrated water, and heating the reverse osmosis concentrated water and then carrying out pervaporation during each time of concentration; concentrating the reverse osmosis concentrated water for multiple times to obtain a secondary concentrated solution, and entering the next step; and carrying out MVR multi-effect evaporation on the secondary concentrated solution to obtain fresh water and inorganic salt crystals. The method has the characteristics of large application range, low treatment cost and good treatment effect.

Owner:上一环保科技(杭州)有限公司

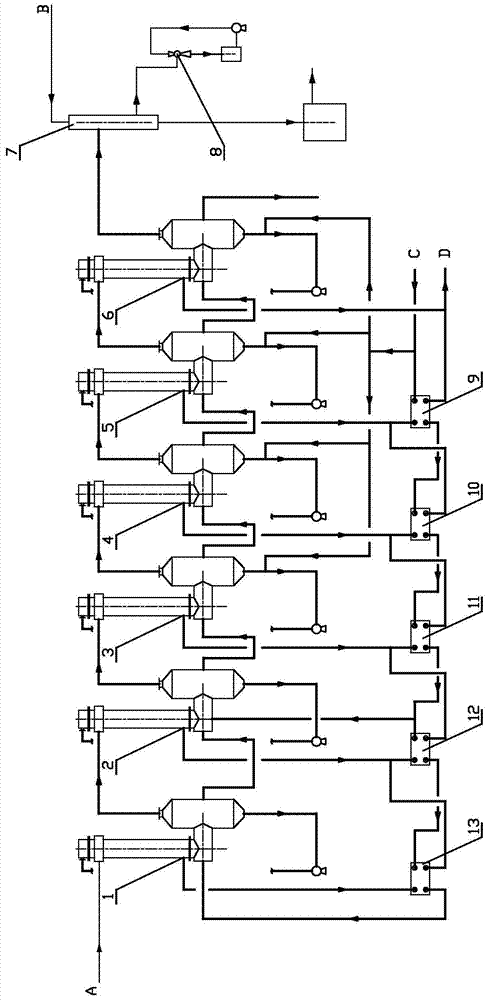

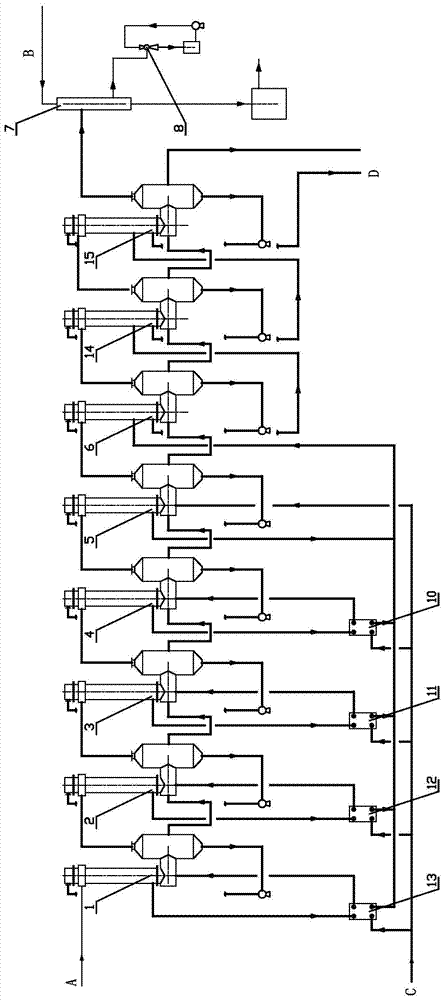

Multi-effect evaporation concentration device and process for sulfuric acid and its salt solution

ActiveCN105399168BHeating heat reductionReduce concentrationWater treatment parameter controlWater/sewage treatment by heatingSulphate IonEvaporation

The invention discloses a multi-effect evaporation and concentration device and a technology thereof for solution containing sulfuric acid and salts thereof, and specifically provides a apparatus and a method for the processes of horizontal flow acid inlet, focusing preheating, cocurrent flow acid discharge and final effect crystallization (optional), which are designed for acid bath, two-bath and acidic water. The apparatus and method are used for evaporation concentration of acid bath, two-bath and acidic water or evaporation crystallization of sodium sulfate. The method controls the horizontal flow acid inlet amount of the previous effect evaporators, and is combined with the utilization of condensate water waste for focusing preheating, so as to reach the purposes of reducing temperature rise heat of the previous effect acid inlets, increase the vaporization heat, and dramatically reduces evaporation vapor and water ratio. The invention has the advantages of significantly reducing energy consumption and costs of evaporation, resolving discharge of solution containing sulfuric acid and salts thereof, directly evaporating and crystallizing anhydrous sodium sulphate, and solving emission of sodium sulfate. The invention improves the economic efficiency of enterprises, and far exceeds the most advanced level in the industry.

Owner:许戈红

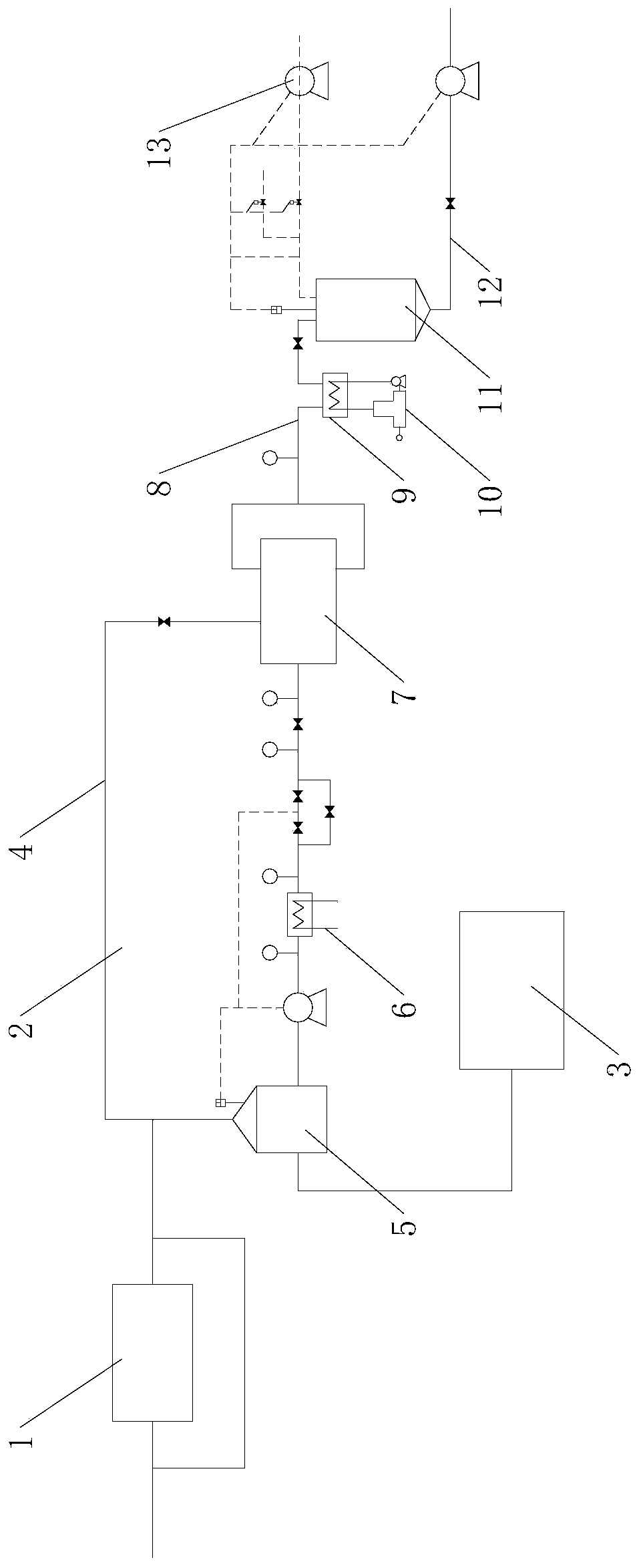

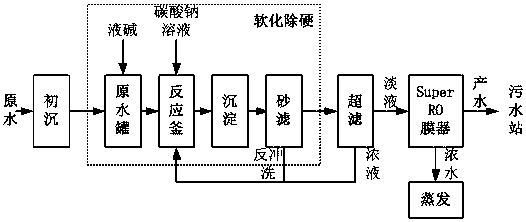

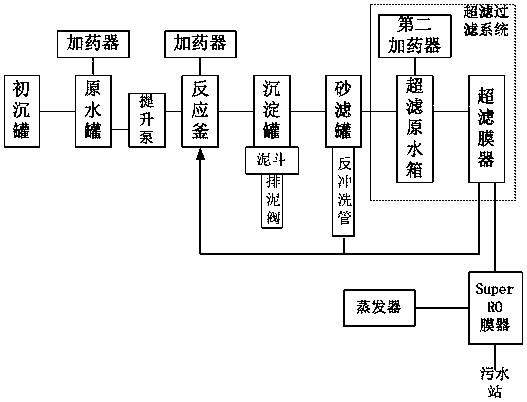

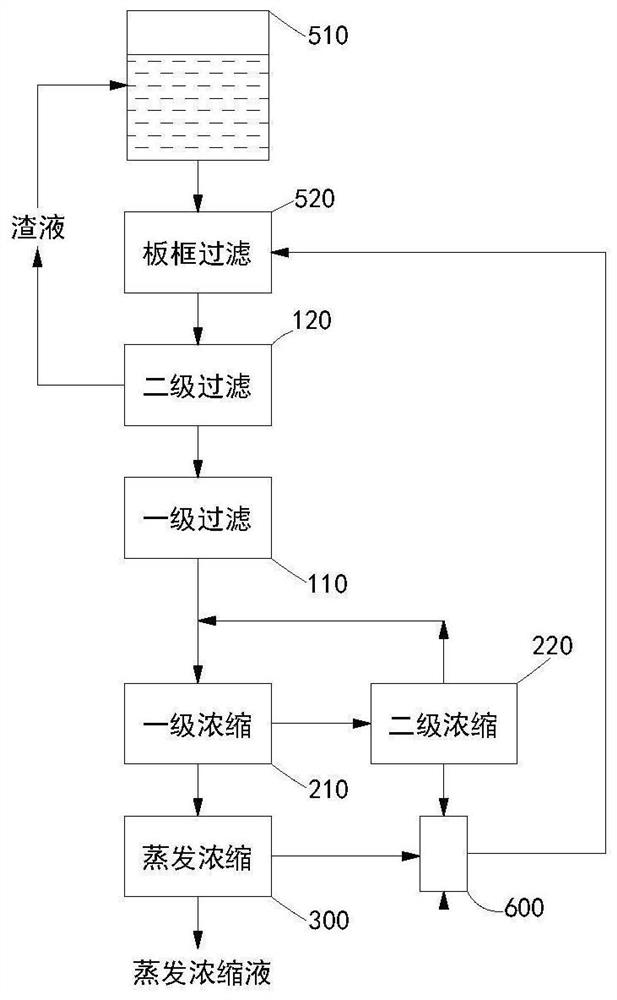

A mother liquor treatment process and system for separation and concentration of dichloropyralic acid materials

ActiveCN105439347BGuarantee the quality of recyclingReduce evaporation costsTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisUltrafiltrationSludge

The invention discloses a mother liquor treatment process and system applied to clopyralid material separation and concentration. The mother liquor treatment system comprises a primary sedimentation tank, a raw water tank, a reaction kettle, a sedimentation tank, a sand filter tank, an ultrafiltration system and a Super RO (reverse osmosis) membrane module which are connected sequentially as well as an evaporator connected with the Super RO membrane module, wherein raw clopyralid mother liquor enters the primary sedimentation tank, both the raw water tank and the reaction kettle are provided with chemical feeders, and the raw water tank and the reaction kettle are communicated through a lift pump; a sludge valve is arranged at the bottom of the sedimentation tank, the sand filter tank is provided with a backwash pipe, a backwash water outlet end of the backwash pipe is communicated with the reaction kettle, and the ultrafiltration system is communicated with the reaction kettle. According to the mother liquor treatment system, design is improved according to the characteristics of the clopyralid material, softening is performed firstly for hardness removal, then ultrafiltration and special RO membrane filtration are performed, and small amount of concentrated water is subjected to evaporative crystallization finally; the evaporation cost is reduced, the influence of a thermal oxidation action on the material is avoided in the whole process, the mother liquor recovery quality is guaranteed, the energy consumption can be reduced obviously, and accordingly, the operation cost is reduced greatly.

Owner:四川美峰环境治理有限责任公司

Ammonia dehydrating technology in production process of acrylonitrile

ActiveCN103819361AImprove evaporation efficiencyReduce ammonia lossPreparation by hydrocarbon ammoxidationAmmonia preparation/separationReboilerChemistry

The invention relates to an ammonia dehydrating technology which can be used in the production process of acrylonitrile. The technology comprises the following steps: raw material liquid ammonia is led in an ammonia evaporator for vaporization, ammonia gas which is formed after the vaporization is discharged out via an ammonia gas outlet, and surplus liquid-phase products after the vaporization are partially discharged into a rectifying tower; the liquid-phase products which are discharged into the rectifying tower absorb the heat provided by a reboiler and fractionate the ammonia gas, and the liquid-phase products after fractionating the ammonia gas are partially discharged out of a tower kettle; the heat which the reboiler provides for the rectifying tower is increased or reduced according to the pressure drop or the pressure rise of the ammonia gas at the ammonia gas outlet; the flow of the liquid-phase products discharged from the ammonia evaporator into the rectifying tower is enlarged or decreased according to the decline or the rise of liquid level in the rectifying tower; the flow of the liquid-phase products discharged out of the tower kettle is enlarged or decreased according to the fact whether the temperature of the tower kettle of the rectifying tower is higher or lower than a first set temperature. In the evaporation process of the ammonia, through technology, the liquid discharging opportunity and the liquid discharging amount of the ammonia evaporator are accurately controlled, the evaporation efficiency of the ammonia gas is increased, and the loss of the ammonia is reduced.

Owner:中石油吉林化工工程有限公司

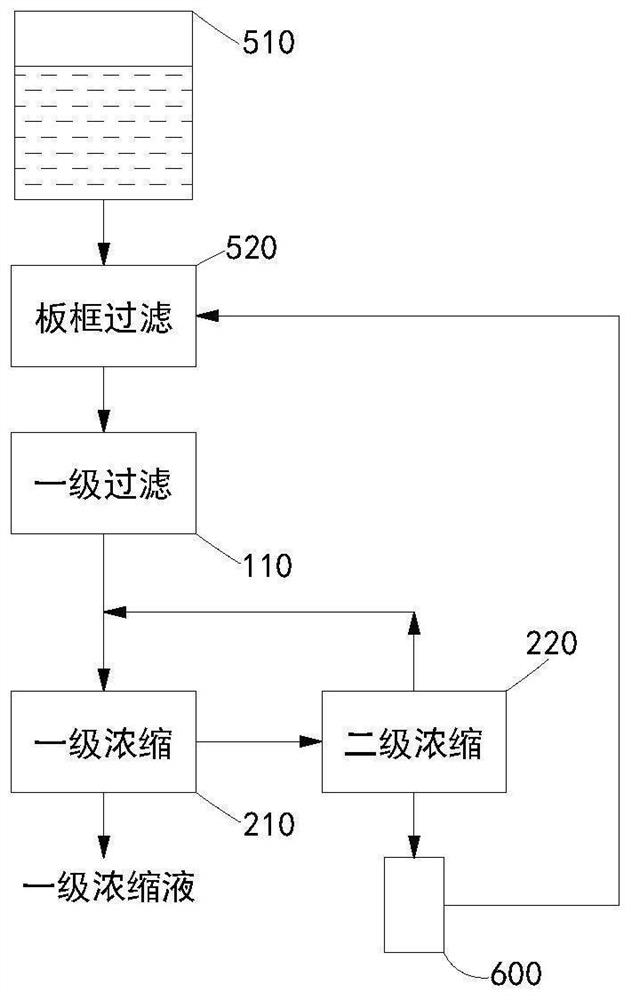

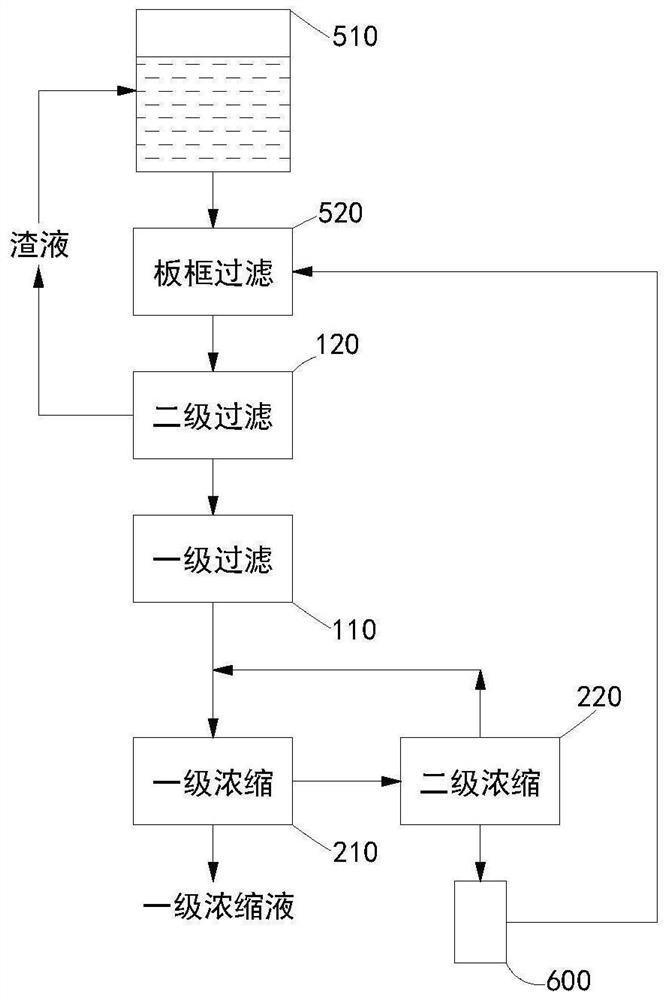

Method for recovering sodium sulfate from white carbon black feed liquid

ActiveCN113044859ASolve the costReduce lossesAlkali metal sulfite/sulfate purificationSilicon dioxideSodium sulfate

The invention discloses a method for recovering sodium sulfate from white carbon black feed liquid. The method comprises the following steps: (1) filtering a white carbon black feed liquid to obtain filtrate with SDI less than or equal to 5; (2) performing membrane concentration on the filtrate to obtain a membrane concentrated solution with the sodium sulfate content being greater than or equal to 180 g / L; (3) evaporating and concentrating the membrane concentrated solution to obtain an evaporated concentrated solution with the content of sodium sulfate being greater than or equal to 280 g / L; and (4) separating out sodium sulfate in the evaporation concentrated solution to obtain sodium sulfate. According to the method disclosed by the invention, residual silicon dioxide in the white carbon black feed liquid is effectively recovered in a filtering manner, the loss and pollution of granular silicon dioxide are reduced, the pretreatment investment is reduced, and the stability and economic benefits of the process are improved; through verification, compared with the mode of pure evaporation and concentration, the mode of combining membrane concentration and evaporation and concentration can reduce the evaporation capacity by 75-85%, so that the evaporation cost is reduced by more than 50%; and the sodium sulfate finally obtained by the method is high in purity and can be sold, and salt benefits are remarkably improved.

Owner:SICHUAN SIDANENG ENVIRONMENTAL PROTECTION TECH CO LTD

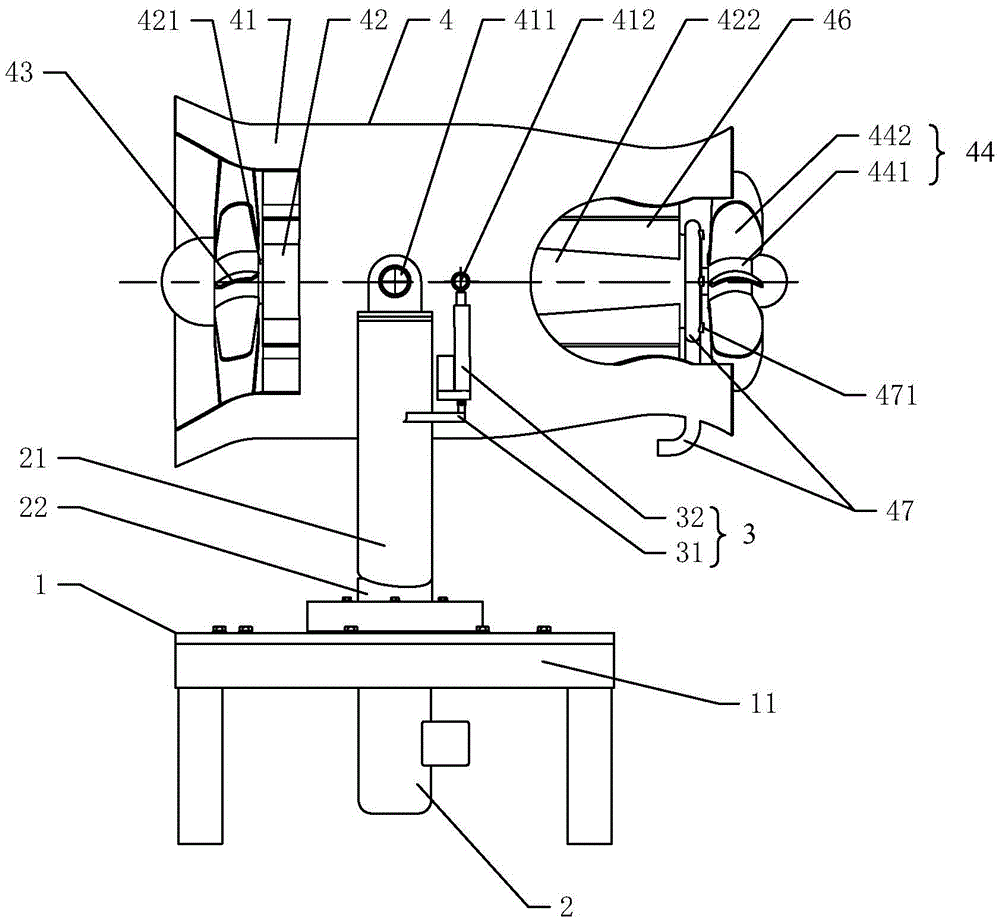

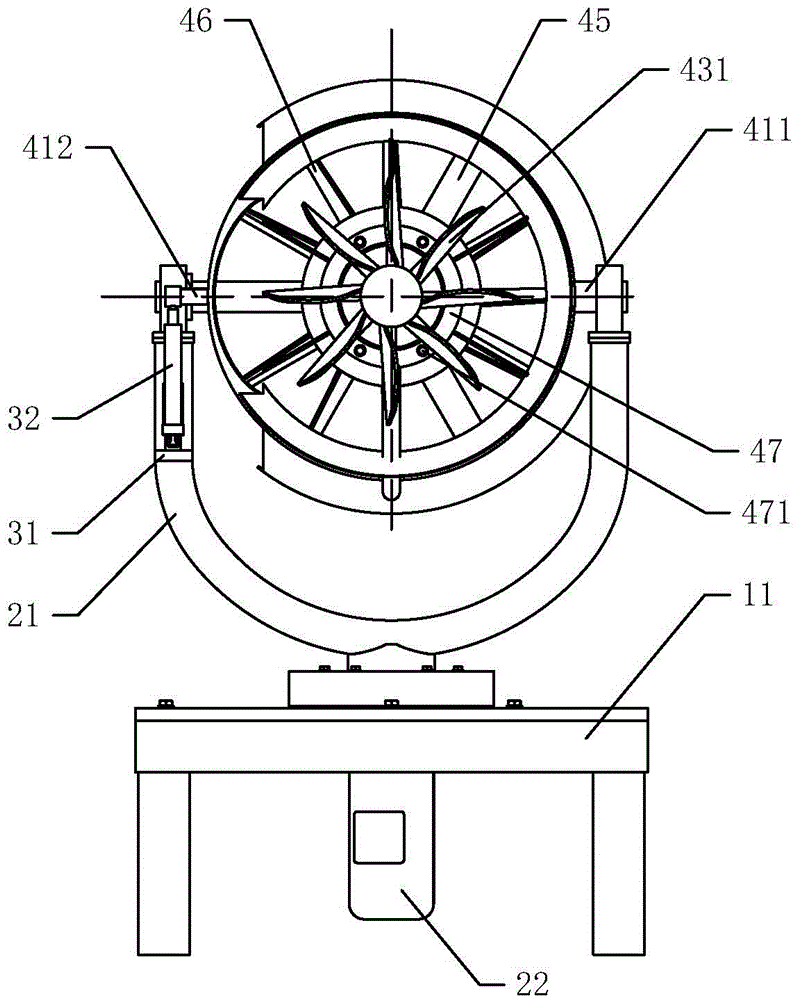

High concentration sewage accelerated evaporation equipment

The invention relates to high-concentration sewage accelerated-evaporation equipment which comprises a support frame and a water distributing device, wherein the water distributing device comprises a housing, a dual-output-shaft motor is arranged in the housing along a longitudinal axial line of the housing, a fan is arranged on a first output shaft of the dual-output-shaft motor, and a crushing impeller is arranged on a second output shaft of the dual-output-shaft motor. According to the high-concentration sewage accelerated-evaporation equipment provided by the invention, over-saturated high-concentration sewage is crushed into super fine particles by virtue of the high-speed rotating crushing impeller, and the super fine particles are sent into air by virtue of the fan for evaporating. By adopting a crushing and atomizing manner in the invention, a mechanical crushing and atomizing manner is used for replacing a high-pressure pump nozzle spray-atomizing manner, so that the evaporation cost is lowered, and the defects such as sewage blockage, scaling formation and corrosion of a nozzle are prevented.

Owner:JIANGSU WATER BUSINESS DOCTOR ENVIRONMENTAL PROTECTION TECH

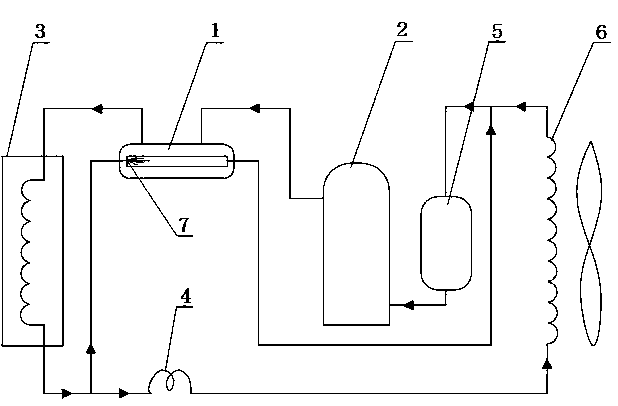

A spray evaporation system for low-temperature heating of air source heat pumps and air conditioners

InactiveCN102748901BReduce evaporation costsFacilitate or accelerate gasificationHeat pumpsEvaporators/condensersElectricityEvaporation

The invention relates to an atomizing evaporating system for low-temperature heating of an air source heat pump and an air conditioner, comprising a compressor, a heat exchanger, a liquid storage tank, an expansion valve, an atomizing evaporator and an evaporator. The heat energy dissipated normally by the exhaust pip of the compressor is utilized, the liquid drops are atomized and evaporated by the sandwich layer of the evaporator, no electric heating and other auxiliary energy is used, and the evaporation cost is reduced. In addition, the one-time atomizing evaporating is adopted on the basis of the one-time evaporating by the evaporator of the existing system, so that two-time evaporating is realized. Due to the adoption of the two-time evaporating, the low-temperature gas-liquid refrigerant medium is fully evaporated, the evaporating efficiency is improved, and sufficient refrigerant gas is supplied to the compressor of an air conditioner for low-temperature heating, so that the compressor can heat normally and stably at the low temperature of lower than 5 DEG C below zero, and the efficiency of heating by the heat pump of the air conditioner at the low temperature of lower than 5 DEG C below zero is guaranteed.

Owner:辛钟杰

Method for recycling waste mushroom sticks

PendingCN111423263AImprove degradation rateEfficient killingSuperphosphatesBio-organic fraction processingMicrobial agentNutrition

The invention relates to a method for recycling waste mushroom sticks, which comprises the following steps: (1) exposing the shiitake mushroom waste mushroom sticks to the sun, crushing, sieving, andcarrying out constant-temperature treatment in hydrochloric acid, so as to obtain shiitake mushroom waste mushroom stick powder; 2) soaking the shiitake mushroom waste mushroom stick powder in the fresh tobacco leaf boiling liquid at a high temperature, and performing ultrasonic treatment to obtain a mixed liquid; 3) preparing a sodium hydroxide solution from the mixed solution and carrying out constant-temperature treatment; 4) preparing an ammonium nitrate solution from the mixed solution and carrying out constant-temperature treatment; 5) adjusting the pH value of the mixed solution by using vinegar residues, and then evaporating and concentrating to obtain a mushroom waste stick recycled material; (6) mixing and fermenting the shiitake mushroom waste mushroom stick recycled material with potato residues, corncob powder, beet pulp and an EM microbial agent to obtain a fermented material; 7, adding urea, monopotassium phosphate, calcium superphosphate and lime into the fermented material, then performing constant-temperature treatment and bagging, and obtaining the composite organic material. The composite organic material prepared through the method is used for the shiitake mushroom and oyster mushroom cultivation material, so nutritional requirements in the hypha germination and growth process can be met, and the effect of preventing diseases and insect pests is achieved.

Owner:徽县智禾农业科技有限公司

Recycling process and system of h-acid wastewater containing high salt and high concentration of refractory organic matter

ActiveCN105948350BReduce evaporation costsLow costChemical industryAlkali metal sulfite/sulfate purificationHigh concentrationSocial benefits

The invention discloses a recycling process and system for cyclic utilization of high-salt and high-concentration non-biodegradable organic matter-containing H acid wastewater and production of anhydrous sodium sulfate; the process for production of anhydrous sodium sulfate through solvent-out crystallization, waste acid cyclic utilization and high-temperature boiling granulation and oxidation is designed for the high-salt high-organic-matter H acid wastewater, so all components of the H acid wastewater are recycled with low cost, the production costs of H acid is reduced, zero emission of pollutants is achieved, and the method is the best way for H acid wastewater low-cost recycling, has demonstration significance for treatment of high-salt and high-concentration non-biodegradable organic matter wastewater, and has huge economic and social benefits.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY +2

A kind of treatment method of waste gas waste water in the production process of trichloroisocyanuric acid

ActiveCN103980214BRealize cleaner production processSolve pollutionOrganic chemistryCalcium/strontium/barium chloridesWater productionSlurry

The invention discloses a method for treating a waste gas and wastewater in the trichloroisocyanuric acid production process. The method comprises the following steps of carrying out dechlorination reaction by using hydrochloric acid to generate cyanuric acid and chlorine, wherein cyanuric acid is fed back to production; thoroughly absorbing chlorine gas by using a calcium cyanurate solution, and absorbing residual carbon dioxide gas with an alkali solution to generate baking soda; and adding lime slurry in the excessive hydrochloric acid solution in the reaction to generate calcium chloride which is mixed with calcium chloride in the original wastewater so as to produce anhydrous calcium chloride. The method has the advantages that treatment on the waste gas and the wastewater of trichloroisocyanuric acid is achieved, not only is the environment pollution caused by the waste gas and the wastewater prevented, but also production benefits are made, the treatment process is simple, the reaction is easy to control and achieve, no secondary pollution is caused, the problem of discharging the wastewater and the waste gas in the process of producing trichloroisocyanuric acid from a cyanuric acid calcium solution which is prepared by introducing chlorine into cyanuric acid, calcium carbonate and water is solved, and an environmental-friendly production process of the trichloroisocyanuric acid without wastewater or waste gas is achieved.

Owner:山东大明消毒科技有限公司

A low-cost ferric phosphate wastewater treatment method containing ammonia nitrogen

ActiveCN109250857BAchieve recyclingSimple processWater/sewage treatment by centrifugal separationPhosphatesO-Phosphoric AcidPhosphate

The invention discloses a low-cost iron phosphate wastewater treatment method containing ammonia nitrogen. This includes the steps of: adding an appropriate amount of Ca(OH) to the ferric phosphate mother liquor 2 , adjust the pH value to 6-8, generate calcium sulfate precipitate, filter the precipitate to obtain the first mixed solution, the first mixed solution mainly contains NH 4 + , SO 4 2‑ and PO 4 3‑ Concentrating the first mixed solution with the first membrane to obtain the second mixed solution; performing MVR evaporation on the second mixed solution to separate and obtain ammonium sulfate crystals and ammonium phosphate crystals; washing and drying the crystals to obtain ammonium sulfate and ammonium phosphate finished products. The low-cost ferric phosphate ammonia nitrogen-containing wastewater treatment method provided by the invention has a simple process and the raw material used is Ca(OH) 2 , can reduce the salt concentration in the system, thereby reducing the amount of water entering the MVR for evaporation, and correspondingly reducing the evaporation cost. At the same time, Ca(OH) 2 As a solid, it will not increase the water volume of the system, thereby reducing the treatment capacity and treatment cost of the first membrane concentration system.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

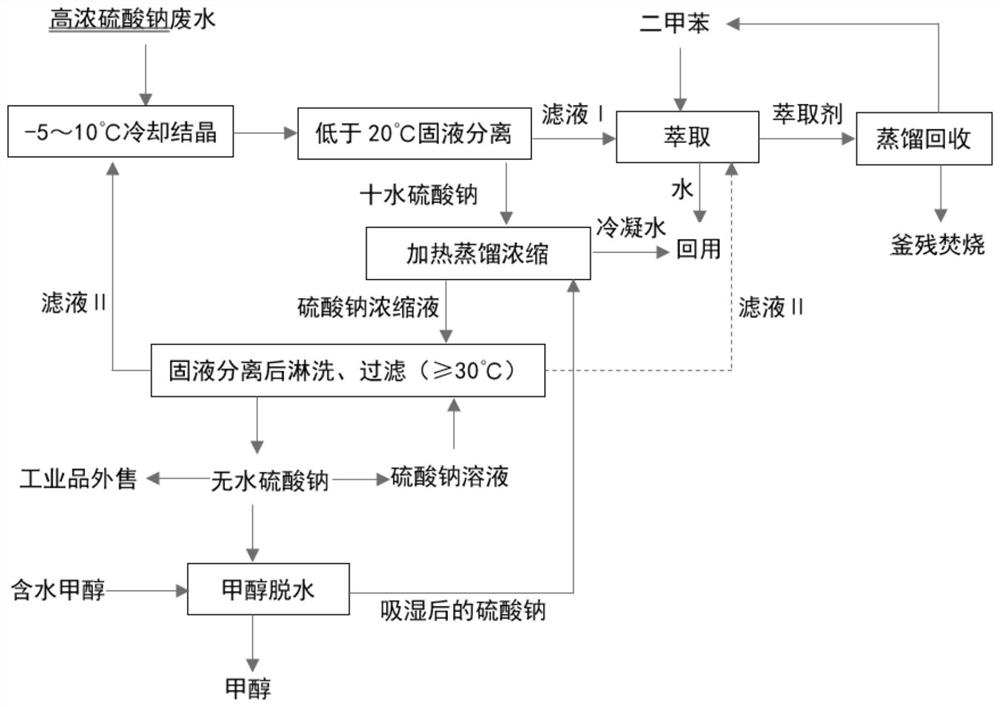

Integrated synergistic recovery method for sodium sulfate and methanol in pirimiphos-methyl production wastewater

PendingCN114262110AHigh purityBoost Salt BenefitsMultistage water/sewage treatmentHydroxy compound separation/purificationXylyleneWater methanol

The invention discloses an integrated synergistic recovery method of sodium sulfate and methanol in pirimiphos-methyl production wastewater, which comprises the following steps: cooling sodium sulfate wastewater to-5-10 DEG C for crystallization, carrying out solid-liquid separation at the temperature of less than or equal to 20 DEG C, and carrying out heating, distillation concentration and centrifugal treatment on obtained sodium sulfate decahydrate to obtain sodium sulfate decahydrate; and leaching the obtained anhydrous sodium sulfate crude product with a sodium sulfate solution, carrying out centrifugal treatment, drying to obtain a sodium sulfate solid, and purifying water-containing methanol by using the sodium sulfate solid to obtain anhydrous methanol. According to the integrated synergetic recovery method for sodium sulfate and methanol in pirimiphos-methyl production wastewater, through combined treatment of cooling crystallization, low-temperature filtration, distillation concentration and leaching filtration, zero discharge of wastewater can be realized, the environment can be improved, energy can be saved, consumption can be reduced, byproducts (sodium sulfate, methanol, xylene and water) can be synergistically recovered, and the method is suitable for industrial production. And the economic benefits of enterprises are improved.

Owner:HUNAN CHEM RES INST

Method for increasing the concentration of sodium sulfide solution by leaching black ash three times

ActiveCN104326499BIncrease concentrationReasonable designCalcium/strontium/barium sulfatesAlkali metal sulfides/polysulfidesEnvironmental engineeringSodium sulfate

The invention discloses the industrial application of the technique of leaching black ash three times with sodium sulfide solution in the barium sulfate production industry. Specifically, it is a method for increasing the concentration of sodium sulfide solution by leaching black ash three times. The black ash is leached three times, that is, the solution that has been leached for the first time is precipitated and separated to obtain the mother liquor I, and the mother liquor I is used to continue to leaching the black ash for the second time, and the leached solution is subjected to the second precipitation and separation to obtain the mother liquor II. Carry out three leaching with mother liquor II again, after the solution after three leachings is precipitated and separated, mother liquor III is obtained, and mother liquor III is reacted with sodium sulfate solution to form barium sulfate and sodium sulfide solution, and the concentration of sodium sulfide solution after three leaching can be Reaching 8~10%, the solid-liquid separation sodium sulfide solution is precipitated, clarified and then enters the next process to evaporate. The invention has a reasonable design, increases the concentration of the sodium sulfide solution by leaching the black ash three times, reduces the evaporation amount, and achieves the purpose of reducing the evaporation cost of producing 60 alkali.

Owner:南风化工(运城)集团有限公司

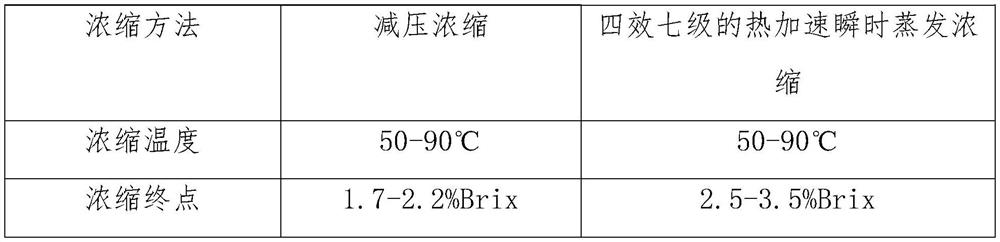

Preparation method of edible mushroom high-viscosity concentrated solution

PendingCN114376209APrevent extractionSimple production processFood ingredientsUltra high pressure food processesProcess engineeringEdible mushroom

The invention relates to a concentrated solution, in particular to a preparation method of an edible mushroom high-viscosity concentrated solution, which comprises the following steps of: cleaning edible mushrooms by using water, and treating by using the methods of ultrasonic countercurrent extraction, filtration by using a vibrating screen and a disc centrifuge, UHT sterilization, concentration by using a four-effect seven-stage heat acceleration instantaneous evaporation concentrator, sterile filling and the like. The difficulty in extracting and concentrating the edible mushroom concentrated solution can be obviously reduced. According to the method, the filtering difficulty caused by high viscosity in the traditional extraction method is avoided; according to the preparation method of the edible mushroom high-viscosity concentrated solution, the concentration efficiency can be improved by utilizing a four-effect seven-stage thermal acceleration instantaneous evaporation concentrator, and the product quality is remarkably improved.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com