A mother liquor treatment process and system for separation and concentration of dichloropyralic acid materials

A clopyralid acid material and treatment process technology, applied in filtration treatment, natural water treatment, water/sewage treatment, etc., can solve the problems of low water recovery rate, shorten the use of instruments, affect the quality of effluent, etc., and reduce system energy. The effect of reducing energy consumption, avoiding high energy consumption, and ensuring the quality of influent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

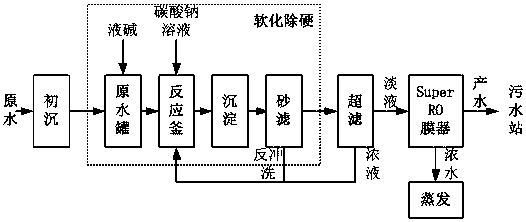

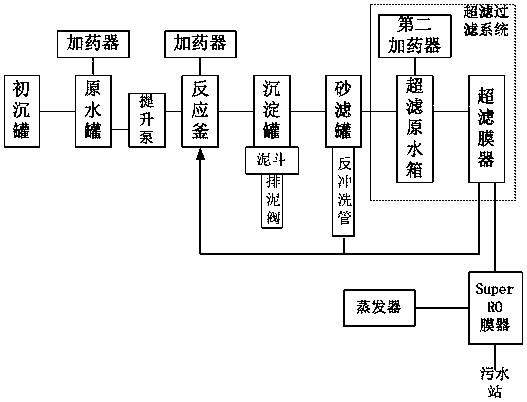

[0037] Such as Figure 1 to Figure 4 As shown, the mother liquor treatment system for the separation and concentration of clopyralid materials includes primary sedimentation tanks, raw water tanks, reaction kettles, sedimentation tanks, sand filter tanks, ultrafiltration filtration systems and SuperRO membrane devices connected in sequence, and SuperRO The evaporator connected to the membrane device, wherein the raw water of the mother liquid of clopyralid enters the primary settling tank, the raw water tank and the reaction kettle are equipped with dosing devices, and the raw water tank and the reaction kettle are connected through a lift pump; the bottom of the sedimentation tank is equipped with a drain A mud valve, the sand filter tank is provided with a backwash pipe, and its backwash water outlet is connected to the reactor, and the ultrafiltration filtration system is connected to the reactor. Further, a stirrer is provided in the reaction kettle.

[0038] In order to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com