Surface rock sampling device for geological exploration

A technology for rock sampling and geological exploration, applied in the field of rock sampling, can solve the problems of inability to carry out long trough sampling, lack of screening function, sampling area error, etc., to improve the passing performance and durability, improve the crushing effect, improve the The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

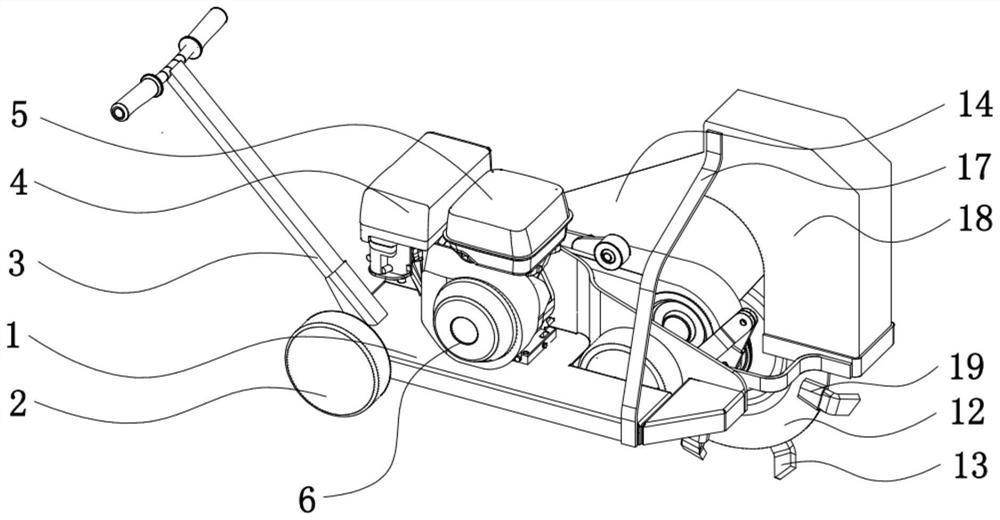

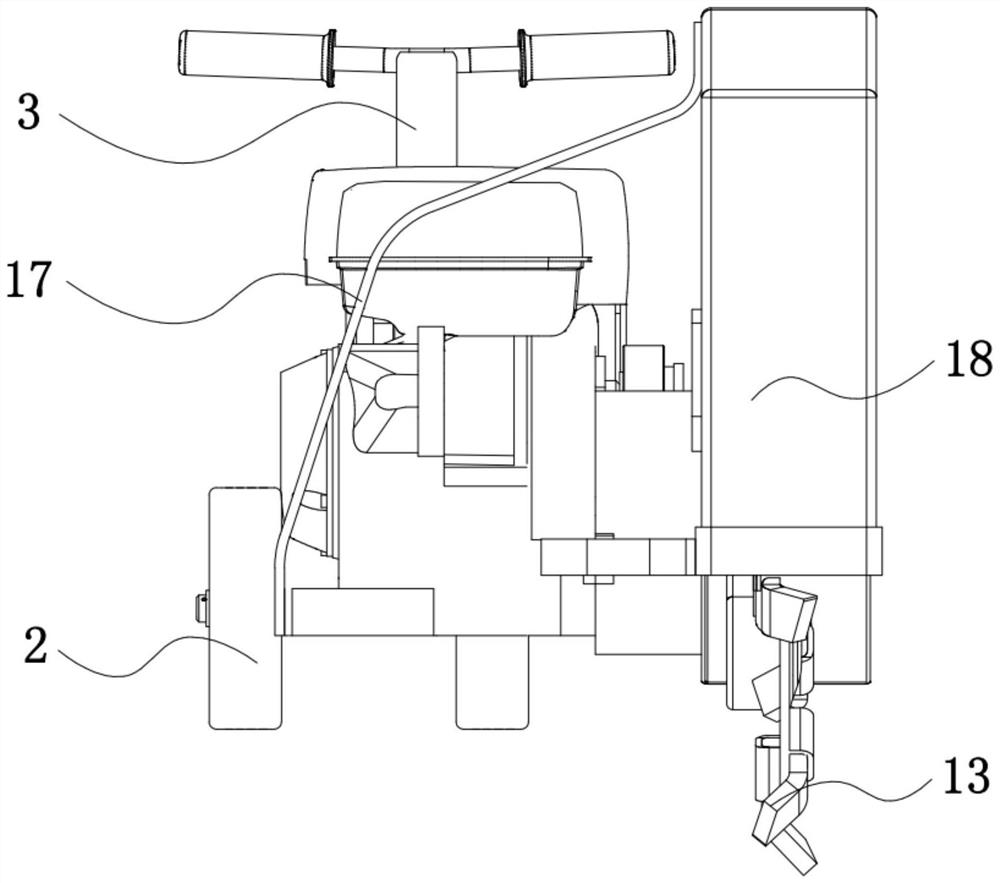

[0030] like Figure 1-6As shown, a surface rock sampling device for geological exploration includes a base 1, the bottom of the base 1 is provided with a plurality of groups of moving wheels 2 in a uniform array through a shock-absorbing device, and the outer surface of the moving wheels 2 is provided with puncture-resistant tires. 2. It is convenient for the sampling device to move in the field, so as to meet the complex driving adjustment in the field, in which the stability of the base 1 can be well ensured with the help of the shock absorption device, so as to avoid damage to the top device in the uneven field environment. Tires can effectively improve the passability in the field environment, so it is more adaptable. The top of the base 1 is provided with a transmission mechanism 21, which provides power for rock excavation and sampling with the help of the transmission mechanism 21. The output end of the transmission mechanism 21 is provided with There is an excavation m...

no. 2 example

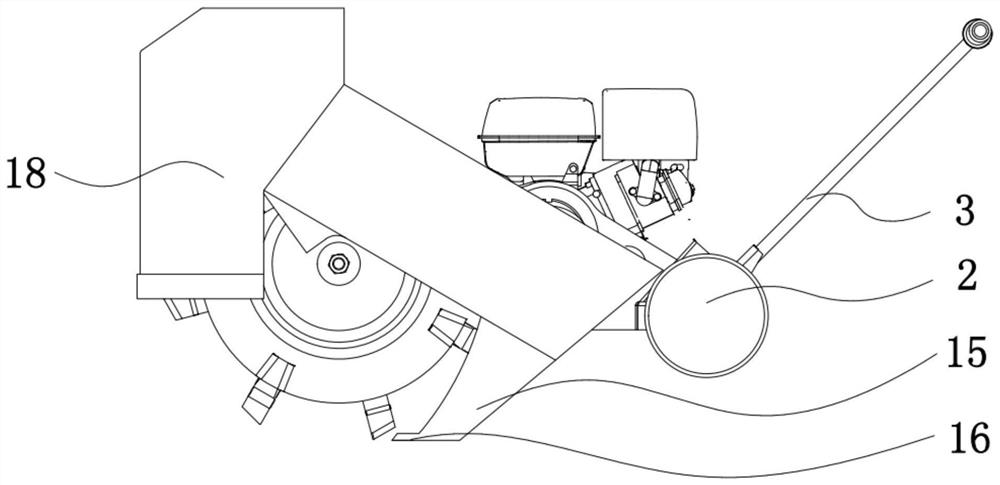

[0044] like Figure 7 and Figure 8 As shown in the figure, in actual use, due to the ground with different unevenness, the base 1 of the rotating disk 12 responds slowly to the change of the ground, so that the rock sampling depth cannot be guaranteed to be kept at the same depth. The length of 13 is longer than the bottom of the moving wheel 2, which will hinder the normal movement of the device. At the same time, with the change of the digging depth of the digging teeth 13, the shoveling depth of the rock in the long groove by the blade 16 also changes. During rock sampling and collection, as the amount of rock continues to increase, the efficiency of collecting the gravel in the long groove by only the blade 16 is relatively slow, and subsequent manual sorting of the rock is still required, which is difficult to sample, and the After tooth 13 excavates the rock sample, its surface will carry some gravel. If this part of gravel cannot be cleaned in time, it will not only r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com