Spiral-flow type underground liquid-gas separation device

A technology of liquid-gas separation and cyclone separator, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., and can solve the problems of reducing pour point depressing, thickening efficiency, affecting oil well production, increasing pour point depressing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

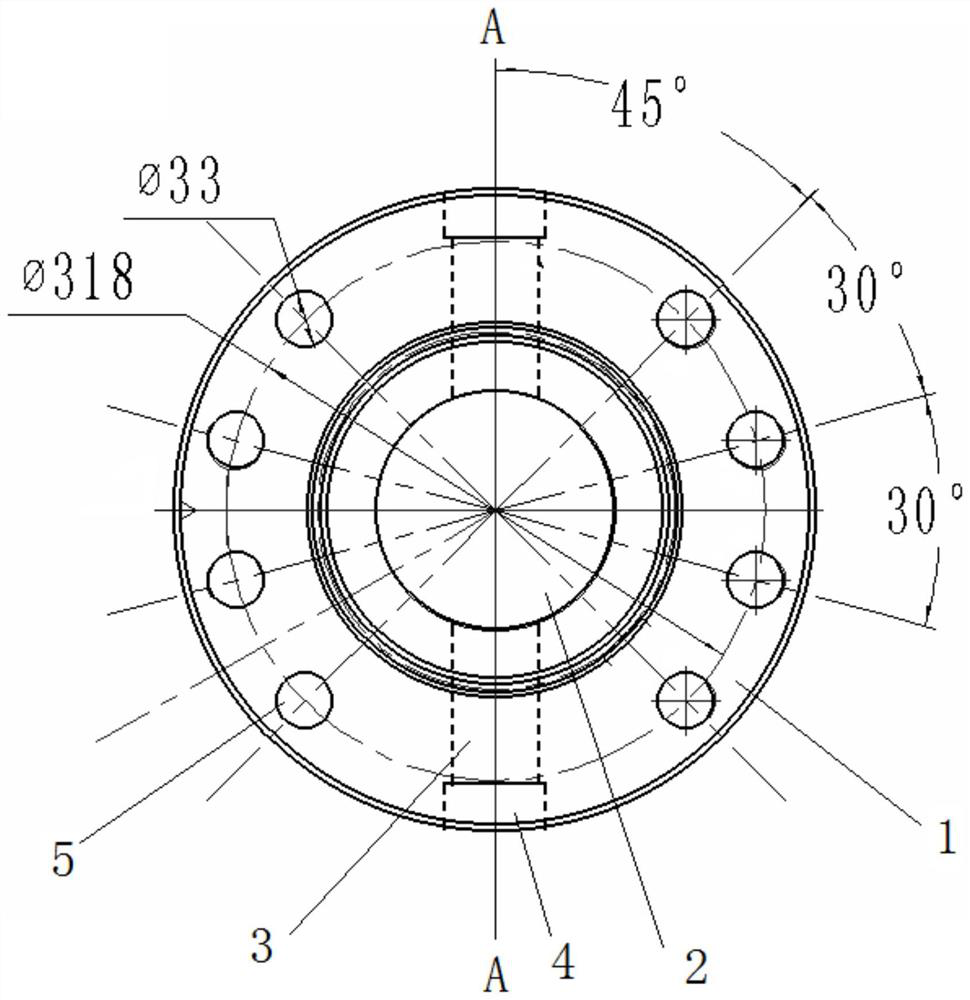

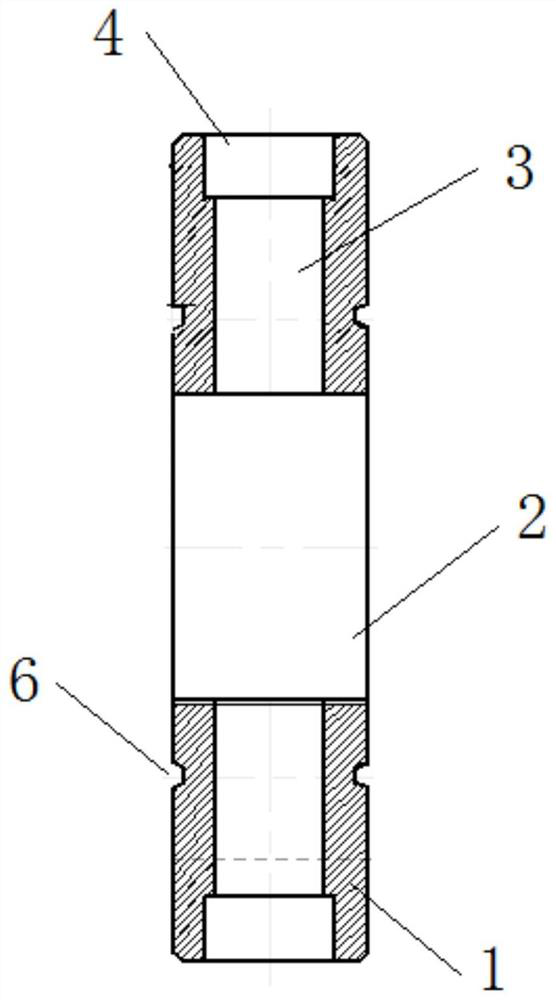

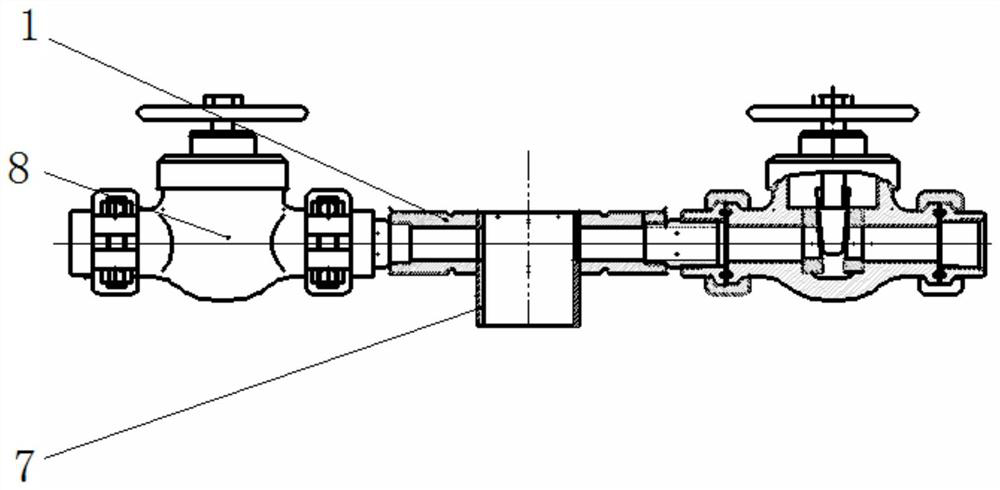

[0020] like Figure 1-7 As shown, a swirl-type downhole liquid-gas separation device includes an oil-infused intermediate flange, a short connection 7, an oil-infused outer pipe 12 and a cyclone separator 15, and the oil-infused intermediate flange is respectively connected to the large The bastard cover 9 and the big cross 10 are connected, the short joint 7 is fixedly connected with the oil-filled intermediate flange, and the oil-filled outer pipe 12 is connected with the short joint 7; the method of the oil-filled intermediate flange The flange main body 1 is disc-shaped, and the center of the flange main body 1 is provided with an oil-filled pipeline 2, and both sides of the oil-filled pipeline 2 are symmetrically provided with oil-filled through holes 3, and the oil-filled pipeline 2 communicates with the oil-filled through hole 3; The outer end of the through hole 3 is provided with a gate clamping hole 4, and an oil-mixed gate 8 is installed at the gate clamping hole 4;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com