Method and device for progressively recovering and circularly applying viscose fiber spinning acid waste liquid

A technology of acid waste liquid and viscose fiber, which is applied in the fields of rayon recycling, fiber chemical characteristics, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

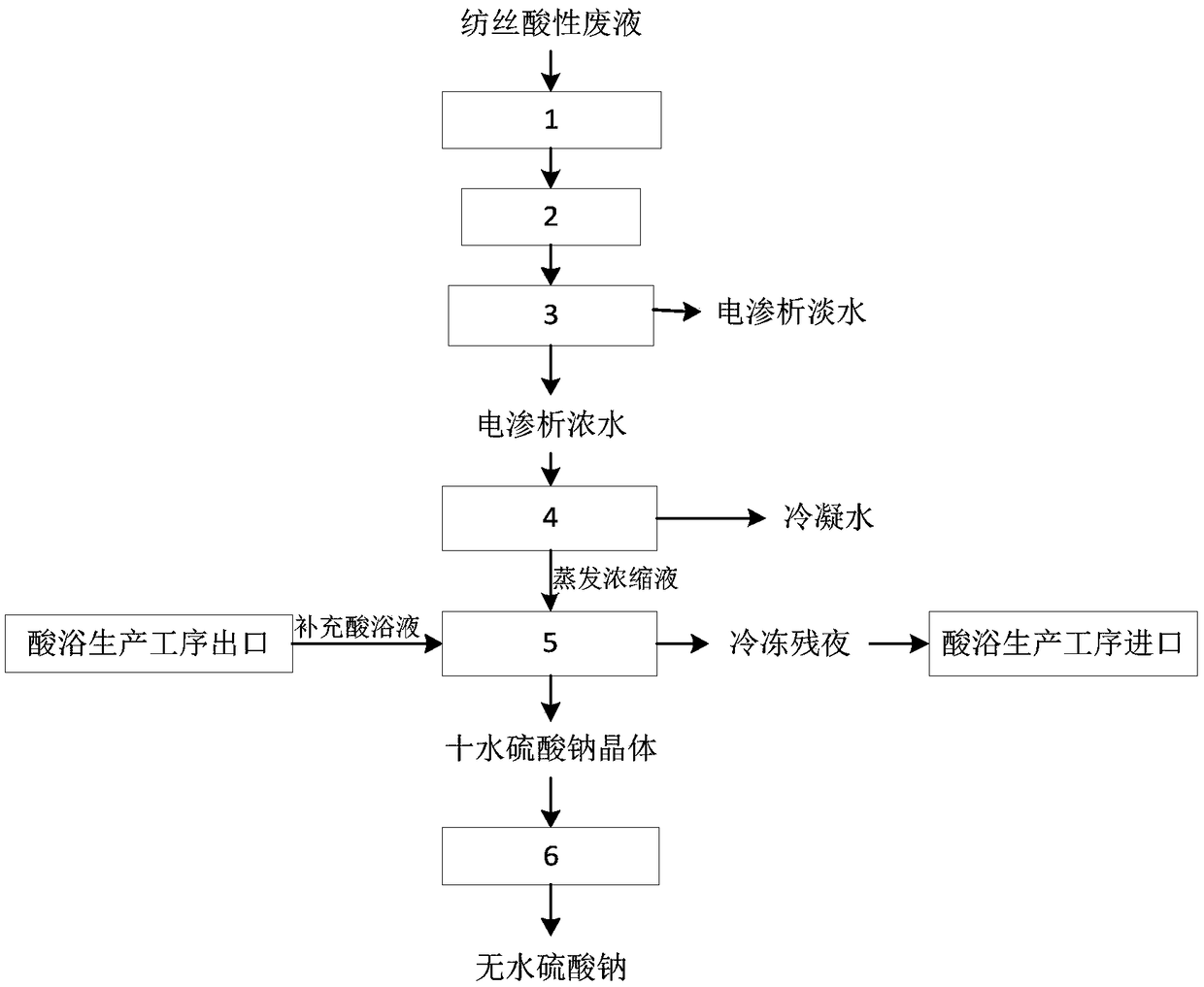

Method used

Image

Examples

Embodiment 1

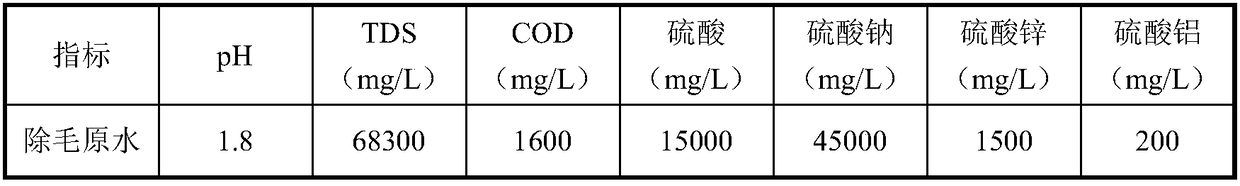

[0059] (1) Take 2000ml of spinning acid waste liquid from a viscose fiber company at a temperature of 80 degrees Celsius. After heat exchange with a heat exchanger, the temperature of the acidic waste liquid is reduced to 40 degrees Celsius, and the effluent after heat exchange is finely filtered device to remove solid insoluble matter in wastewater. The raw water index of spinning acid waste liquid is shown in Table 1-1.

[0060] Table 1-1 Raw water index data

[0061]

[0062] (2) 2000ml of effluent water passing through the precision filter enters the electrodialysis device, and 1000ml of pure water is used as the receiving solution in the electrodialysis device (the volume ratio of the electrodialysis water inlet volume to the receiving solution is 1:0.5), when the electrodialysis device The electrodialysis process is completed when the ratio of the salt content of the dialysis feedwater to the concentrated water is 1:1. In the electrodialysis process, 1200ml of fresh...

Embodiment 2

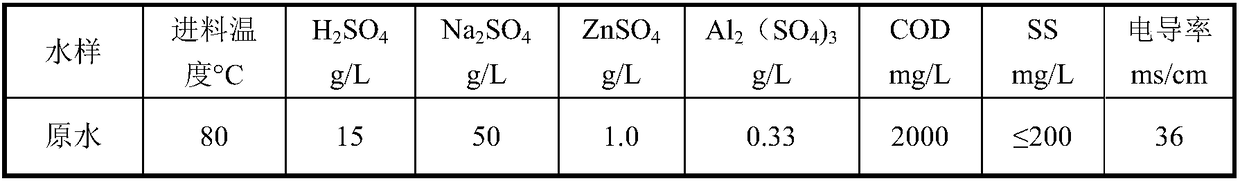

[0082] (1) Take 2000ml of spinning acid waste liquid from a viscose fiber company at a temperature of 85 degrees Celsius. After heat exchange with a heat exchanger, the temperature of the acidic waste liquid is reduced to 20 degrees Celsius, and the effluent after heat exchange is finely filtered device to remove solid insoluble matter in wastewater. Raw water index of spinning acid waste liquid is shown in Table 2-1.

[0083] Table 2-1 Raw water index data

[0084]

[0085] (2) 2000ml of effluent water through the precision filter enters the electrodialysis device, and 2000ml of pure water is used as the receiving solution in the electrodialysis device (the volume ratio of the electrodialysis water inlet volume to the receiving solution is 1:1), when the electrodialysis device The electrodialysis process is completed when the ratio of the salt content of the dialysis feedwater to the concentrated water is 1:2. In the electrodialysis process, 3000ml of fresh water and 100...

Embodiment 3

[0105] (1) Take 2000ml of spinning acid waste liquid from a viscose fiber company at a temperature of 90 degrees Celsius, heat exchange through a heat exchanger, reduce the temperature of the acid waste liquid to 10 degrees Celsius, and filter the effluent after heat exchange device to remove solid insoluble matter in wastewater. Raw water index of spinning acid waste liquid is shown in Table 3-1.

[0106] Table 3-1 Raw water index data

[0107]

[0108] (2) Enter 2000ml of the effluent water through the precision filter into the electrodialysis device, and use 4000ml of pure water as the receiving solution in the electrodialysis device (the volume ratio of the electrodialysis water inlet volume to the receiving solution is 1:2), when the electrodialysis device The electrodialysis process is completed when the ratio of the salt content of the dialysis feedwater to the concentrated water is 1:3. In the electrodialysis process, 5450ml of fresh water and 550ml of concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com