Recycling process and system for high-salt and high-concentration non-biodegradable organic matter-containing H acid wastewater

A technology of refractory organic matter and high concentration, applied in the field of environmental resources, can solve the problems of high treatment cost and large organic waste residue, and achieve the effect of zero discharge, reduction of treatment cost, and reduction of sulfuric acid usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

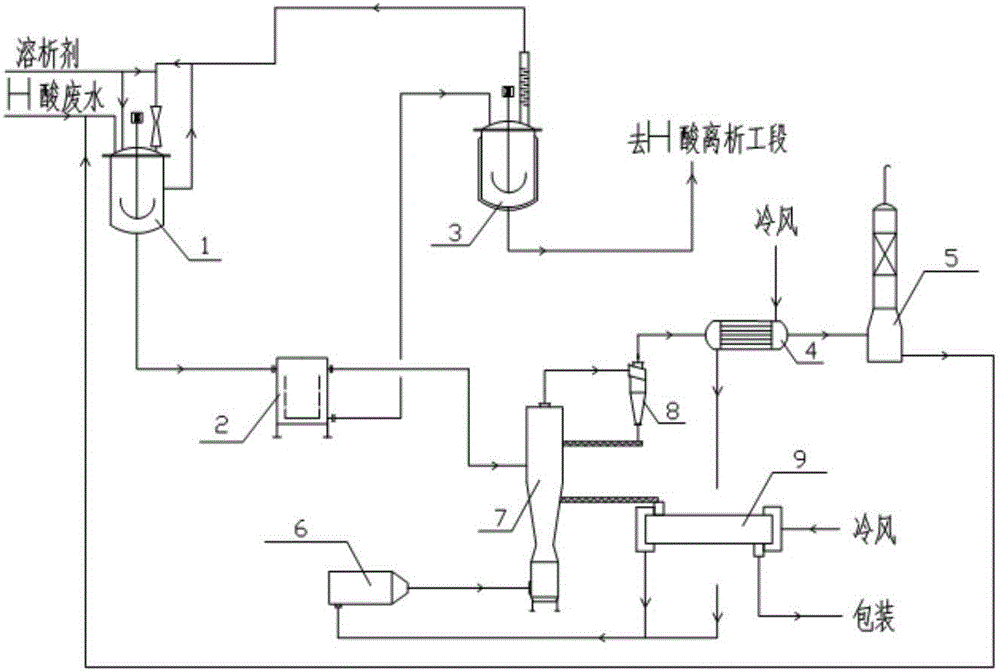

[0028] A process for resource utilization of H-acid waste water containing high-salt and high-concentration refractory organic matter, the steps are as follows:

[0029] 1) Solvent crystallization

[0030] Add the H-acid wastewater into the dissolution and crystallization kettle, at a temperature of 35°C, use a Venturi circulation feeding system, add 40% of the quality of the H-acid wastewater to dissolve the crystallization solvent ethanol, leave it for 20 minutes, the sodium sulfate crystals are precipitated, and the sulfuric acid is separated The sodium crystal is sent to 3) the high temperature boiling granulation oxidation furnace system, and the waste acid solution is sent to step 2) the waste acid recycling section.

[0031] 2) Recycling of waste acid

[0032] The waste acid solution containing a large amount of dissolved solvent and sulfuric acid, a small amount of sodium sulfate, a small amount of H acid and other organic components from step 1) enters the evaporatio...

Embodiment 2

[0036] A process for resource utilization of H-acid waste water containing high-salt and high-concentration refractory organic matter, the steps are as follows:

[0037] 1) Solvent crystallization

[0038] Add the H-acid wastewater into the dissolution and crystallization kettle, and at a temperature of 45°C, use a Venturi circulation feeding system, add 30% of the quality of the H-acid wastewater to dissolve the crystallization solvent methanol, and leave it for 60 minutes, the sodium sulfate crystals are precipitated, and the sulfuric acid is separated The sodium crystal is sent to 3) the high temperature boiling granulation oxidation furnace system, and the waste acid solution is sent to step 2) the waste acid recycling section.

[0039] 2) Recycling of waste acid

[0040] The waste acid solution containing a large amount of dissolved solvent and sulfuric acid, a small amount of sodium sulfate, a small amount of H acid and other organic components from step 1) enters the e...

Embodiment 3

[0044] A process for resource utilization of H-acid waste water containing high-salt and high-concentration refractory organic matter, the steps are as follows:

[0045] 1) Solvent crystallization

[0046] Add the H-acid wastewater into the dissolution and crystallization kettle, and at a temperature of 50°C, use a Venturi circulation feeding system, add 15% of the H-acid wastewater quality to dissolve the crystallization solvent ethanol, leave it for 100 minutes, the sodium sulfate crystals are precipitated, and the sulfuric acid is separated The sodium crystal is sent to 3) the high temperature boiling granulation oxidation furnace system, and the waste acid solution is sent to step 2) the waste acid recycling section.

[0047] 2) Recycling of waste acid

[0048] The waste acid solution containing a large amount of dissolved solvent and sulfuric acid, a small amount of sodium sulfate, a small amount of H acid and other organic components from step 1) enters the evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com