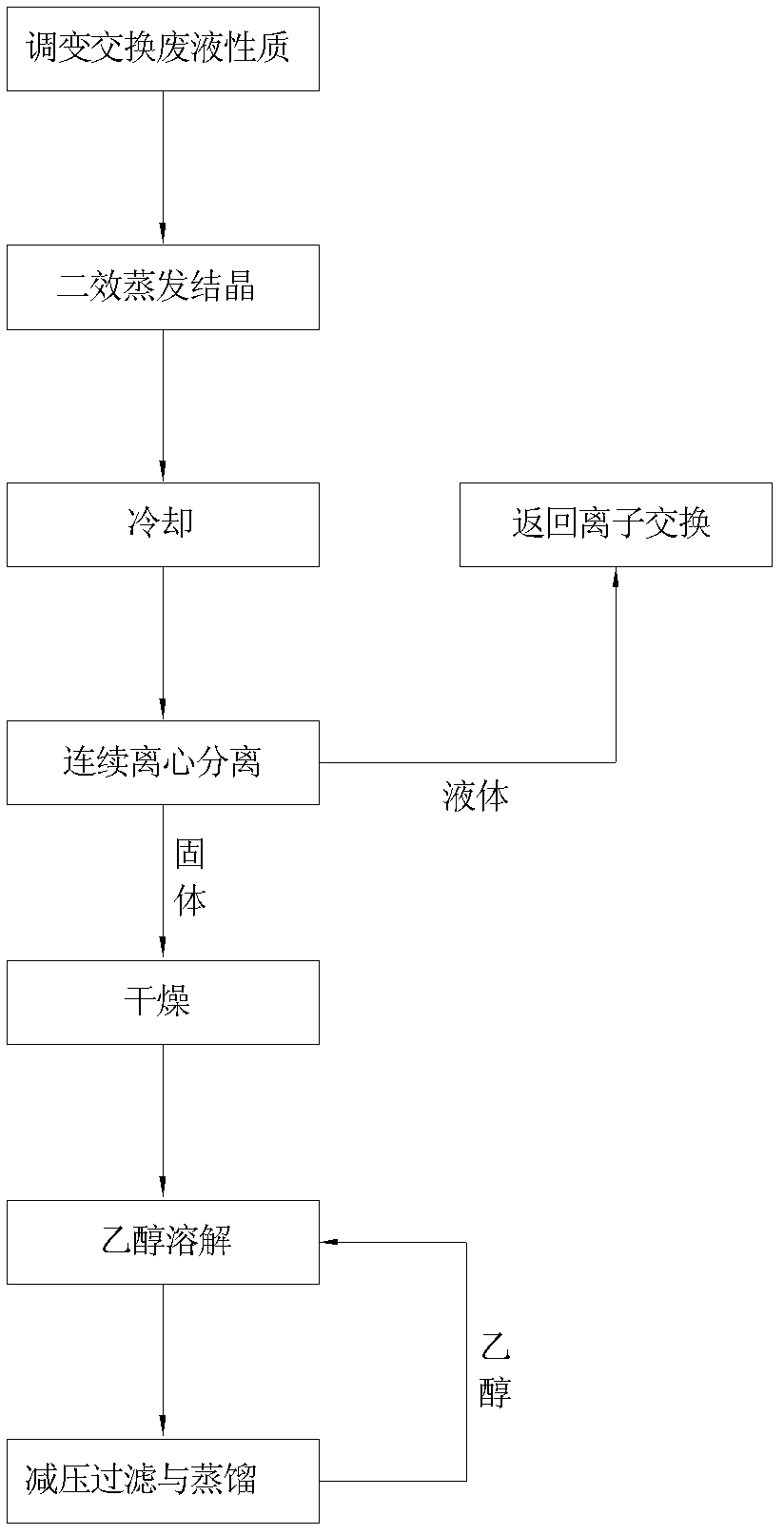

Method and device for recycling lithium from exchange waste fluid containing lithium

A lithium exchange and waste liquid technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of lithium ion loss, no further involvement in treatment process and equipment, and difficult control of soft water washing and crystallization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

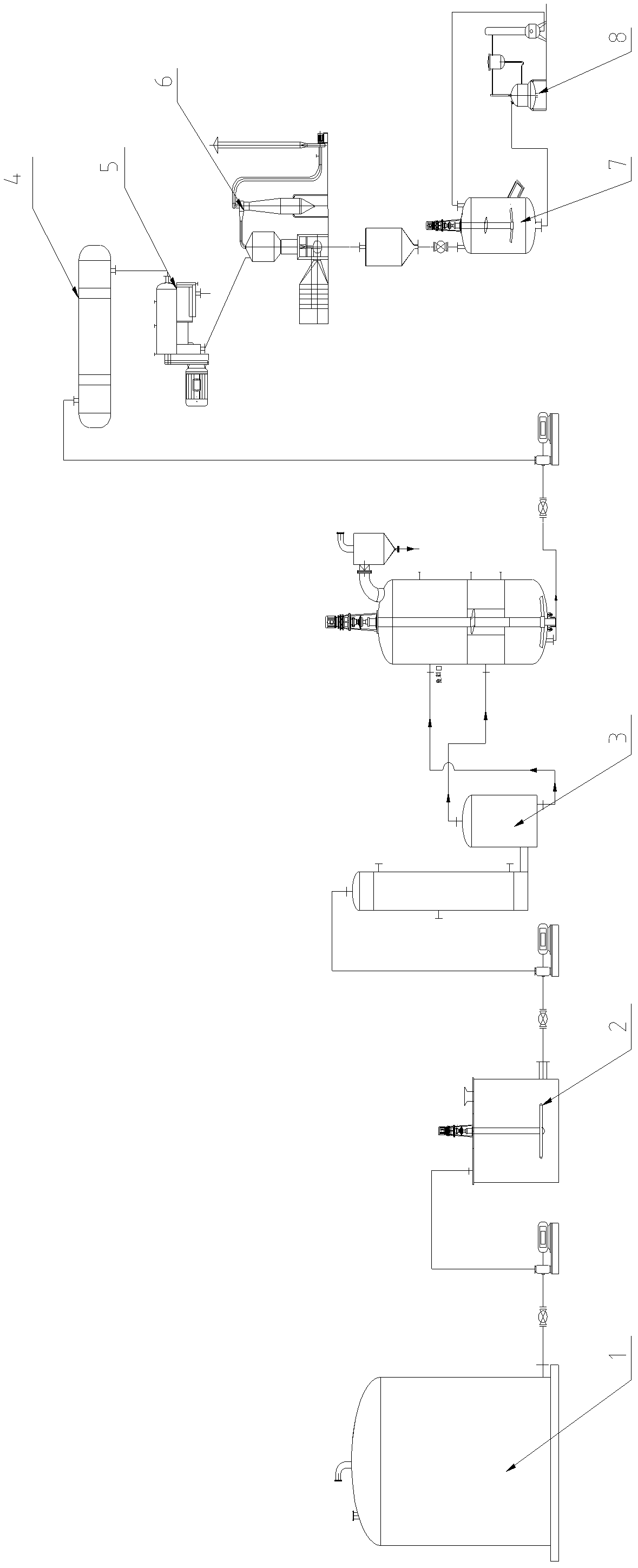

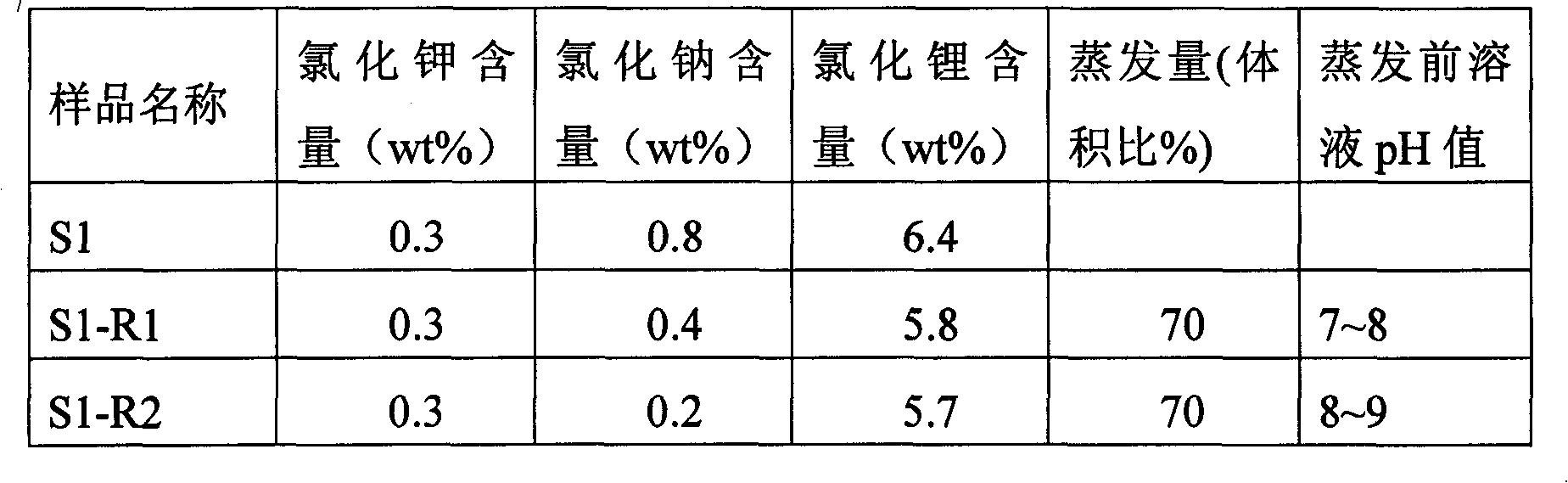

Embodiment 1

[0046]The exchange waste liquid in the small amount of liquid storage tank 1 is extracted, the pH value is 8, and the mass contents of KCl, NaCl, and LiCl are 2.3%, 5.4%, and 6.1%, respectively. Pump into the stirring tank 2 at a rate of 720 L / h, add 1 mol / L LiOH solution, control its flow rate to 1.5 L / h, mix and stir, and adjust the pH value of the solution to 10.5. Pump from the stirring tank 2 into the second-effect evaporation crystallizer with a flow rate of 720L / h through a plunger flow pump, evaporate at a temperature of 160°C, and evaporate the solution until the mass content of lithium chloride in the solution is 19%, and the second-effect The evaporation efficiency of the evaporative crystallizer is 540L / h, and the material discharged from the second-effect evaporative crystallizer is a solid-liquid mixture, that is, crystal slurry. The solid content of a part of the material is about 30% for testing. The magma is pumped into the shell and tube cooler 4 at a flow ra...

Embodiment 2

[0049] Extract the exchange waste liquid in the small amount of liquid storage tank 1, wherein the mass contents of KCl, NaCl, and LiCl are 3.7%, 7.6%, and 3.0%, respectively, and the pH value is 8.5. Pump into the stirring tank 2 at a rate of 790L / h, add 1mol / L LiOH solution, control its flow to 1.7L / h, add lithium chloride solid at a rate of 31kg / h, mix and stir, and dissolve the lithium chloride The content was adjusted to 7.0%, and the pH value of the solution was adjusted to 10.5. From the stirring tank 2, pump it into the second-effect evaporation crystallizer with a flow rate of 790L / h through the plunger flow pump, evaporate at 160°C, and evaporate the solution until the lithium chloride mass content in the solution is 18%, and the second-effect evaporation crystallizer The evaporation efficiency is 540L / h, and the material discharged from the second-effect evaporation crystallizer is a solid-liquid mixture, and the solid content of some materials is about 30% for test...

Embodiment 3

[0052] Extract the exchange waste liquid in a small amount of liquid storage tank 1, wherein the mass contents of KCl, NaCl, and LiCl are 3.7%, 7.6%, and 4.2%, respectively, and the pH value is 8.5. Pump into the stirring tank 2 at a rate of 790L / h, add 1mol / L LiOH solution, control its flow rate to 1.8L / h, add lithium chloride solid at a rate of 31kg / h, mix and stir, and dissolve the lithium chloride The content was adjusted to 7.0%, and the pH value of the solution was adjusted to 11. From the stirring tank 2, the flow rate of 790L / h is pumped into the falling film evaporator of the second-effect evaporation crystallizer through the plunger flow pump, and evaporated at a temperature of 150°C. The circulating evaporator uses the secondary steam generated in the falling film evaporator to evaporate again, and the solution is evaporated until the mass content of lithium chloride in the solution is 16%. The evaporation efficiency of the second-effect evaporation crystallizer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com