Lithium sulfate leaching agent separation and purification technology

A technology for separation and purification of leaching solution, which is applied in the field of separation and purification of lithium sulfate leaching solution, which can solve the problems of high cost, large water volume, land occupation, and high labor costs, and achieve the effects of reducing evaporation costs, increasing reuse water consumption, and reducing additions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

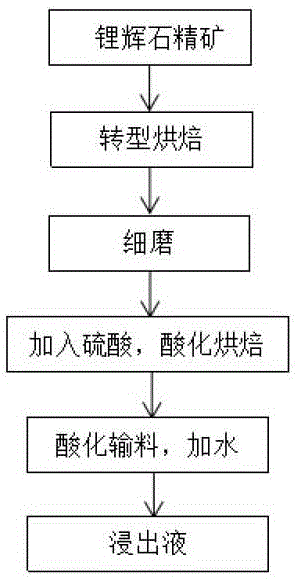

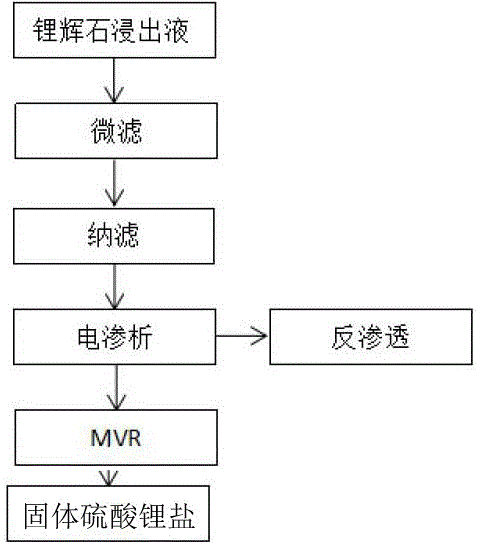

[0019] Step 1: Use a microfiltration system to pretreat the lithium sulfate leaching solution to remove impurities and suspended solids in the feed solution to obtain a microfiltration dialysate; the lithium sulfate leaching solution is converted to roasted, finely ground, and acidified for spodumene concentrate Roasting, the obtained lithium sulfate leaching solution;

[0020] Step 2: The microfiltration dialysate enters the nanofiltration system to obtain nanofiltration dialysate and nanofiltration concentrate; the nanofiltration membrane is made of organic material, the operating pressure is 2-3 MPa, and the operating temperature is below 40°C.

[0021] Step 3: The nanofiltration concentrated solution enters the electrodialysis system for concentration, and the concentrated electrodialysis adopts electrode reversal electrodialysis. The electrode reversal time of the electrode reversal electrodialysis is 20 minutes to reverse the electrode once, and the electrodialysis concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com