Method for synchronously removing sodium sulfate and sodium chloride in wastewater through three cycles

A technology of sodium chloride and sodium sulfate, applied in chemical instruments and methods, alkali metal chlorides, alkali metal sulfites/sulfites, etc., can solve the problems of poor stability, complicated process flow, low product purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

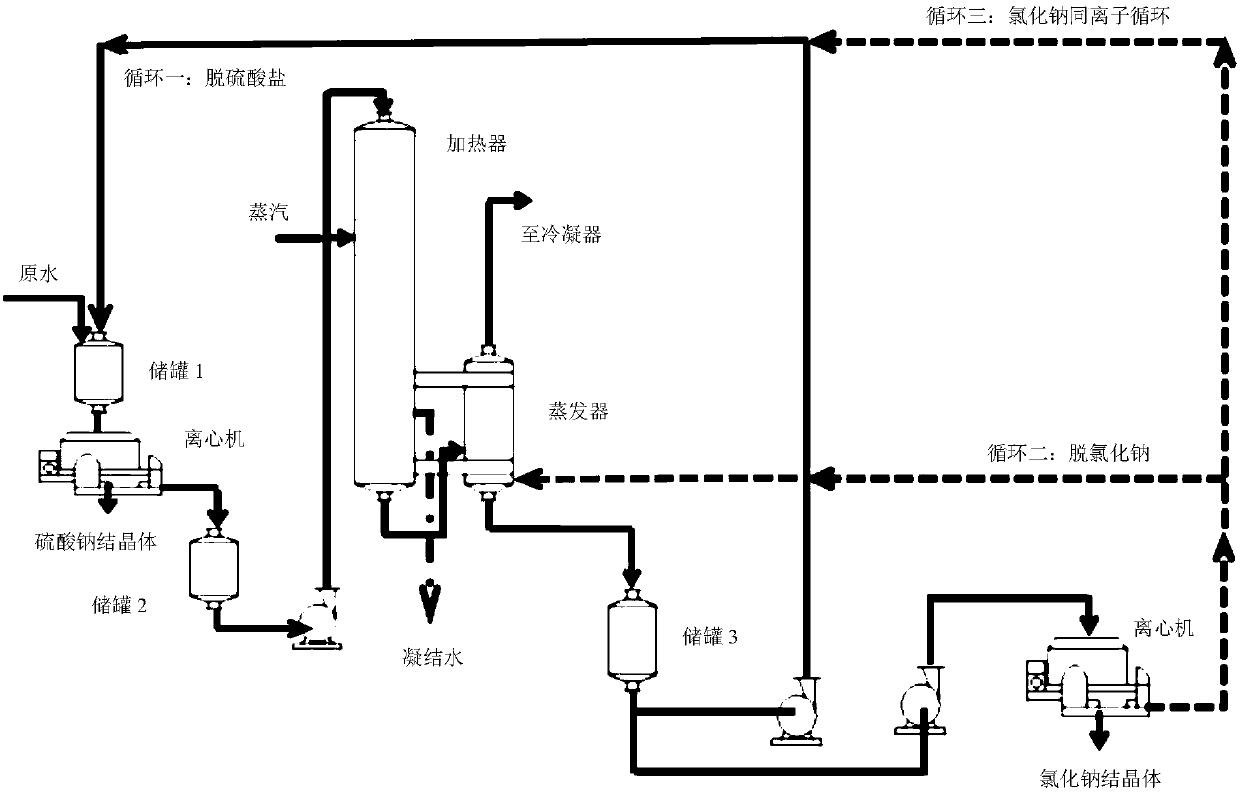

Image

Examples

Embodiment 1

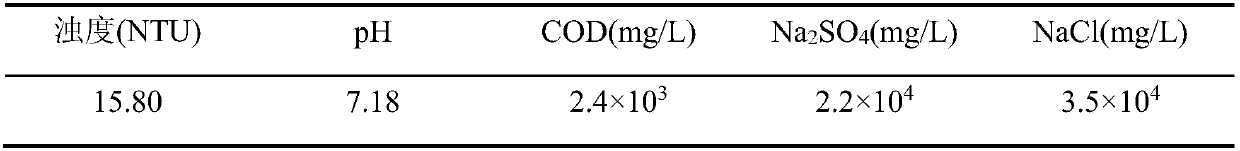

[0043] The water quality index of an industrial high-salt wastewater (No. 1) is shown in the table below:

[0044] Table 1 Water quality index of an industrial high-salt wastewater (No. 1)

[0045]

[0046] Using a method and device for synchronously removing sodium sulfate and sodium chloride in water with three cycles to treat industrial high-salt wastewater, the experimental results: 12m 3 After 24 hours of mixed wastewater operation, the zero discharge rate of wastewater was 99.9%, the average removal rate of COD was 87.2%, the removal rate of sodium sulfate was as high as 97.0%, and the removal rate of sodium chloride was as high as 98.1%. A total of 0.256×10 3 kg sodium sulfate crystals, 0.412×10 3 kg of sodium chloride crystals, the equipment operates stably.

Embodiment 2

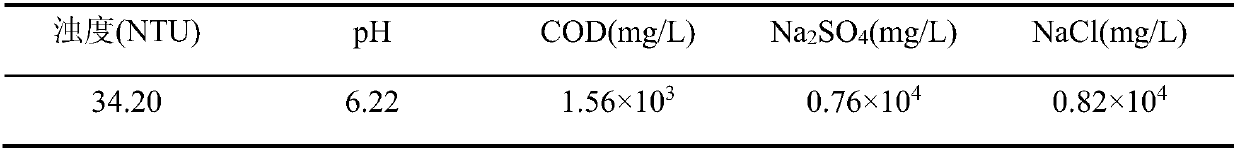

[0048] The water quality index of an industrial high-salt wastewater (No. 2) is shown in the table below:

[0049] Table 1 Water quality index of an industrial high-salt wastewater (No. 2)

[0050]

[0051] Using a method and device for synchronously removing sodium sulfate and sodium chloride in water with three cycles to treat industrial high-salt wastewater, the experimental results: 12m 3 After 24 hours of mixed wastewater operation, the zero discharge rate of wastewater was 99.9%, the average removal rate of COD was 92.3%, the removal rate of sodium sulfate was as high as 94.2%, and the removal rate of sodium chloride was as high as 92.0%. A total of 0.086×10 3 kg sodium sulfate crystals, 0.091×10 3 kg of sodium chloride crystals, the equipment operates stably.

Embodiment 3

[0053] The water quality index of an industrial high-salt wastewater (No. 3) is shown in the table below:

[0054] Table 1 Water quality index of an industrial high-salt wastewater (No. 3)

[0055]

[0056] Using a method and device for synchronously removing sodium sulfate and sodium chloride in water with three cycles to treat industrial high-salt wastewater, the experimental results: 12m 3 After 24 hours of mixed wastewater operation, the zero discharge rate of wastewater was 99.9%, the average removal rate of COD was 77.4%, the removal rate of sodium sulfate was as high as 94.3%, and the removal rate of sodium chloride was as high as 96.1%. A total of 0.204×10 3 kg sodium sulfate crystals, 0.242×10 3 kg of sodium chloride crystals, the equipment operates stably.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com